Understanding the Canadiana Snowblower Parts Diagram

As winter approaches, the importance of reliable equipment for managing heavy snowfall becomes increasingly evident. Ensuring that your machinery is in optimal condition is crucial for maintaining efficiency and performance during the colder months. A thorough examination of the various components involved can help in diagnosing issues and performing necessary maintenance.

In this guide, we will delve into the intricate layout of the essential elements that make up your winter clearing device. By familiarizing yourself with these components, you can gain insights into their functions and identify any potential areas requiring attention. Understanding the relationship between each segment not only aids in troubleshooting but also enhances your overall operational knowledge.

Moreover, possessing a clear visualization of the assembly will empower you to tackle repairs with confidence. Whether you’re a seasoned user or a newcomer to winter maintenance, having a comprehensive grasp of how everything fits together is vital for ensuring your equipment runs smoothly and efficiently.

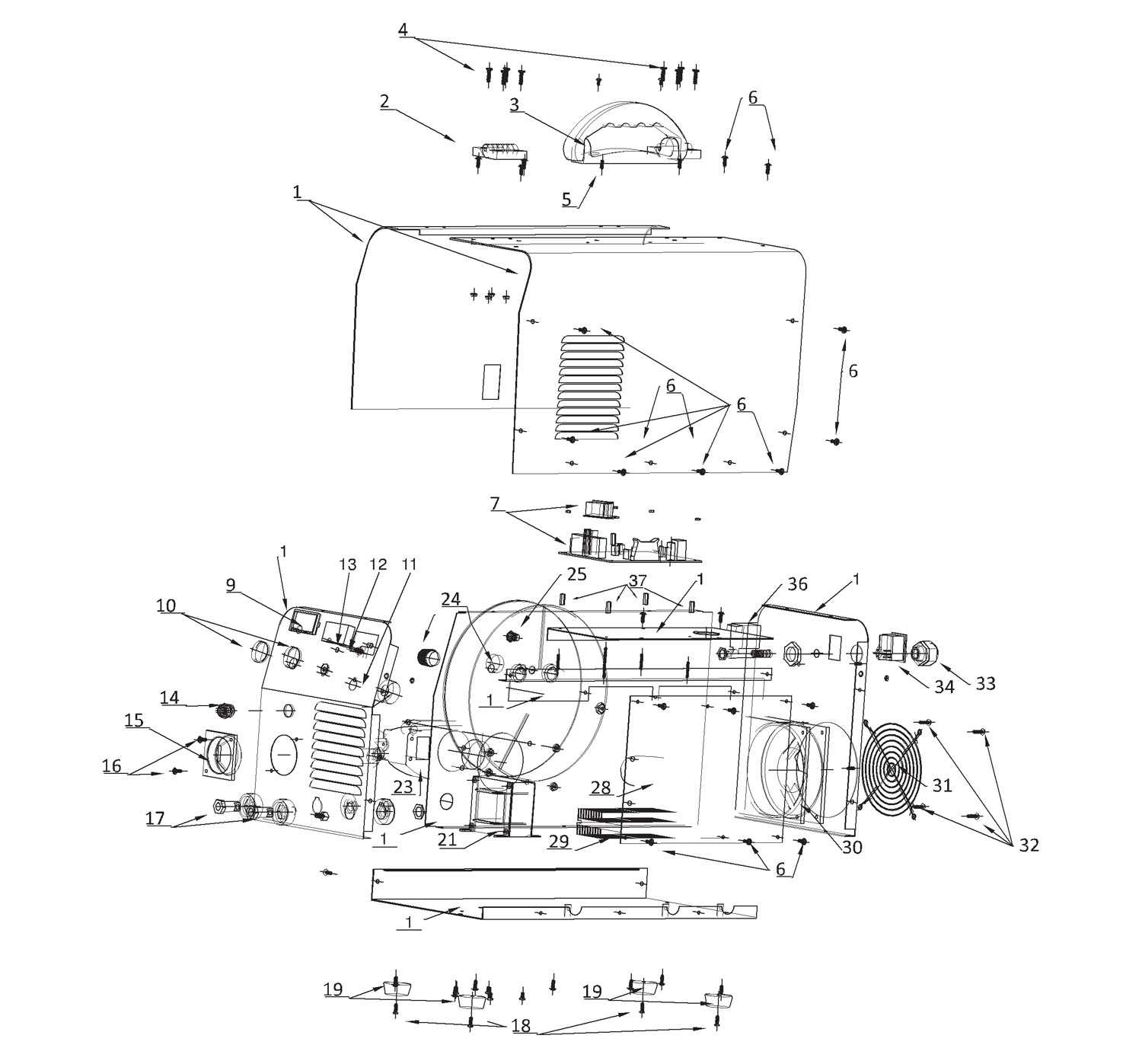

Understanding Snowblower Components

Maintaining a winter clearing machine requires a solid grasp of its various elements and how they work together. Each component plays a crucial role in ensuring effective operation during harsh weather conditions. Familiarity with these mechanisms can greatly enhance efficiency and prolong the life of the equipment.

The core of any clearing device typically consists of a powerful engine that drives the entire system. This engine converts fuel into mechanical energy, enabling movement and the effective clearing of snow. Connected to the engine are transmission systems that facilitate speed adjustment and power distribution to other elements.

The housing of the machine serves to protect its internal parts while also directing the flow of snow. Within this casing, you will find augers and impellers, essential for gathering and expelling the snow. Understanding their placement and functionality is vital for optimal performance during usage.

Additionally, control mechanisms allow the operator to manage speed and direction with ease. Familiarizing yourself with the levers and switches will ensure a smoother operation. Regular inspection and maintenance of these controls can prevent malfunctions and enhance user experience.

Lastly, wheels or tracks provide mobility over varying terrains, making it important to know their maintenance requirements. Proper care of these components not only ensures safety but also improves overall performance during winter tasks.

Importance of Quality Parts

Ensuring optimal performance and longevity in any machinery relies heavily on the standard of its components. High-quality elements not only enhance efficiency but also significantly reduce the likelihood of malfunctions. Investing in superior materials can lead to smoother operation and better overall results, making it a crucial aspect for users who seek reliability and durability.

Performance and Reliability

Using top-notch components directly impacts the functionality of the equipment. Quality materials are designed to withstand wear and tear, allowing for consistent performance over time. When individuals choose reliable options, they are more likely to avoid unexpected breakdowns and costly repairs.

Cost-Effectiveness

While opting for cheaper alternatives might seem economical initially, it often leads to greater expenses in the long run. Investing in high-grade materials ensures fewer replacements and repairs, ultimately saving time and money. Quality components provide peace of mind, knowing that the equipment will function efficiently without frequent interruptions.

Identifying Your Snowblower Model

Understanding the specific model of your winter equipment is essential for effective maintenance and repairs. Accurate identification allows you to access the correct resources and support tailored to your machine’s requirements. This process can seem daunting, but with the right approach, it becomes straightforward.

To begin, check the manufacturer’s label, usually located on the frame or engine. This label typically includes the model number, serial number, and other critical information. Take note of any markings or labels that could assist in recognizing your equipment.

Additionally, consulting the user manual is a valuable step. It often provides detailed insights into various models and their specifications. If the manual is unavailable, online resources can serve as an excellent alternative for finding model information based on visual characteristics.

Lastly, comparing the design and features of your machine with those available on manufacturer websites or forums can be immensely helpful. Identifying key attributes like the type of controls, size, and engine specifications can further narrow down your search and ensure you find the exact match.

Common Issues with Snowblower Parts

When operating outdoor equipment designed for clearing snow, users often encounter a range of challenges that can hinder performance. Understanding these frequent problems can help ensure a smoother experience during winter months. This section highlights some typical concerns associated with the components of these machines.

One of the most prevalent issues is wear and tear on essential elements, which can lead to decreased efficiency. Components such as belts and paddles may become frayed or damaged over time, resulting in reduced power transfer or ineffective snow removal. Regular inspections can help identify these wear patterns before they become serious setbacks.

Another common difficulty arises from improper maintenance. Neglecting to clean or lubricate moving parts can lead to rust buildup or mechanical binding, causing the machinery to operate sluggishly. Routine care is crucial for ensuring longevity and optimal functionality.

Additionally, fuel-related issues may manifest, particularly during colder months. Old or contaminated fuel can result in starting problems or erratic engine performance. Keeping fuel systems clean and utilizing fresh fuel can mitigate these concerns significantly.

Finally, operator error is often a contributing factor to malfunctions. Misunderstanding the correct settings or usage can lead to improper handling, causing strain on various components. Familiarity with the equipment’s manual and features is essential for effective operation and minimizing potential issues.

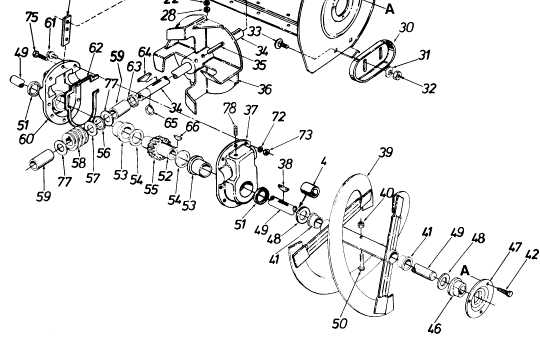

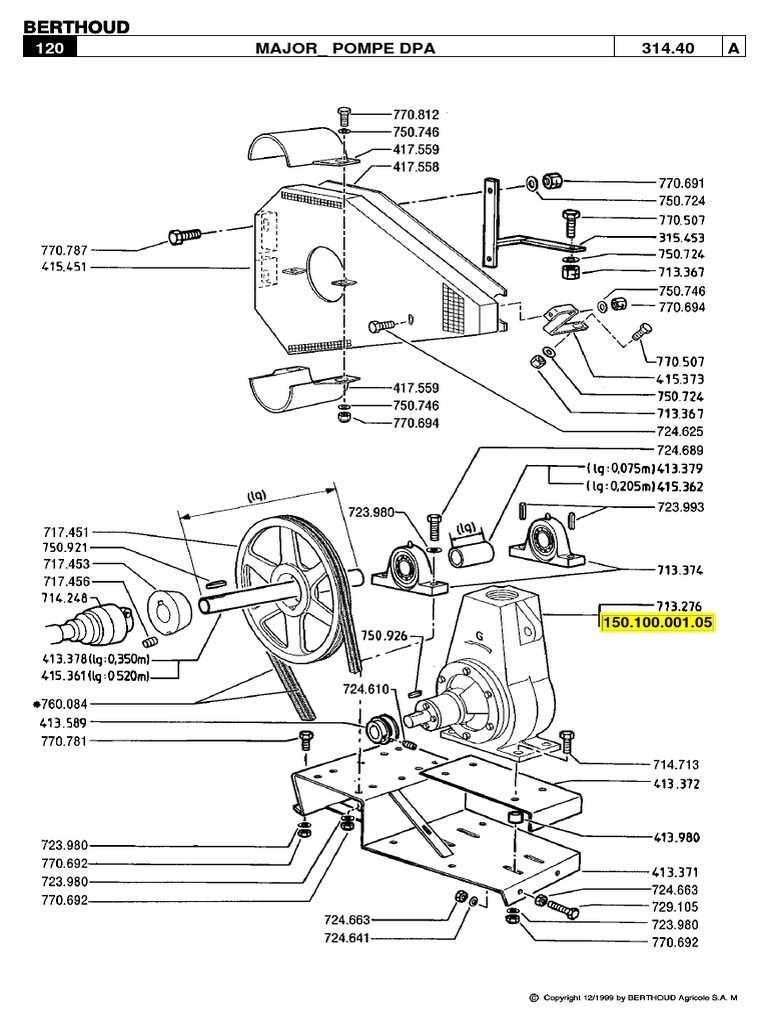

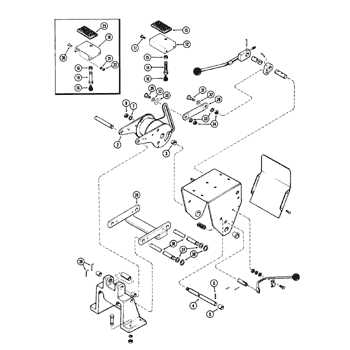

Parts Diagram Overview

This section aims to provide a comprehensive understanding of the various components involved in the machinery’s functionality. By exploring the intricate relationships and arrangements of these elements, users can gain insights into maintenance and repair processes.

Key elements to consider include:

- Functionality: Each component plays a vital role in the overall operation.

- Interaction: Understanding how parts work together can simplify troubleshooting.

- Maintenance: Familiarity with each piece aids in effective care and longevity of the machine.

To better grasp the structure, one can refer to organized illustrations that depict the arrangement of these vital elements. Such visual guides not only clarify the layout but also enhance the learning experience.

- Overview of key components

- Understanding connections and functions

- Tips for maintenance and troubleshooting

Ultimately, gaining knowledge about these individual pieces equips users with the tools needed to ensure their equipment remains in optimal condition.

How to Read a Parts Diagram

Understanding a schematic representation of components can significantly enhance your ability to identify and procure necessary items for maintenance or repairs. This guide provides essential insights into interpreting these visual aids effectively, ensuring you can navigate through various elements with ease.

Key Elements of a Schematic

- Labels: Each component is usually marked with a specific identifier or number, which corresponds to a list of items.

- Legend: A legend often accompanies the illustration, explaining the symbols used for different parts.

- Connection Lines: These indicate how various elements interact or connect with one another, providing clarity on assembly.

Steps to Interpret the Visual Aid

- Examine the overall layout to familiarize yourself with the arrangement of components.

- Refer to the labels and the legend to understand what each symbol or number signifies.

- Cross-reference with a parts list to identify and locate any items you may need.

- Pay attention to the connection lines to ensure you understand how components fit together.

By following these guidelines, you will be better equipped to analyze and utilize a schematic effectively, facilitating smoother repairs and maintenance tasks.

Replacement Parts Sources

Finding reliable sources for essential components is crucial for maintaining the efficiency of your outdoor equipment. Various options are available for acquiring these necessary items, ensuring that you can keep your machinery running smoothly. From authorized dealers to online retailers, understanding where to look can save time and money.

Authorized Dealers

One of the most dependable avenues for obtaining specific components is through authorized distributors. These outlets typically carry a comprehensive selection of genuine items, ensuring compatibility and quality. Additionally, purchasing from these vendors often comes with warranty benefits, providing peace of mind for your investment.

Online Retailers

In the digital age, numerous online platforms offer a wide variety of components. Websites dedicated to equipment and tool sales frequently feature user-friendly search functions, allowing you to easily locate the exact items needed. Customer reviews and ratings can help gauge the reliability of sellers, ensuring you make informed decisions.

Maintenance Tips for Snowblowers

Regular upkeep is essential for ensuring optimal performance during the winter months. By following a few straightforward guidelines, you can enhance the lifespan of your machine and minimize the risk of unexpected breakdowns.

1. Check the Oil Level: Regularly inspect the oil level and quality. Change the oil as recommended by the manufacturer to keep the engine running smoothly.

2. Inspect the Spark Plug: A clean and functioning spark plug is crucial for easy starting. Remove it periodically to check for wear and replace it if necessary.

3. Clear the Auger and Chassis: After each use, remove any accumulated snow and debris from the auger and chassis. This prevents rust and maintains efficient operation.

4. Examine the Belts: Inspect the belts for signs of wear or damage. Replace any frayed or cracked belts to ensure reliable functionality.

5. Lubricate Moving Parts: Regularly lubricate all moving components according to the manufacturer’s recommendations. This reduces friction and prolongs the life of the machine.

6. Store Properly: When the season ends, clean the unit thoroughly and store it in a dry place. Consider using a protective cover to prevent dust and moisture accumulation.

By following these simple maintenance practices, you can ensure your equipment remains efficient and reliable throughout the winter season.

Tools Needed for Repairs

When undertaking maintenance and repair tasks, having the right instruments at hand is crucial for efficiency and effectiveness. The appropriate tools not only facilitate the work but also ensure safety and accuracy during the process. Below is a list of essential instruments you may need to have ready before starting any repair activities.

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening nuts and bolts. |

| Screwdriver Set | For fastening and removing screws. |

| Socket Set | For accessing hard-to-reach fasteners efficiently. |

| Pliers | For gripping and bending materials as needed. |

| Torque Wrench | To ensure that fasteners are tightened to the correct specifications. |

| Safety Goggles | To protect your eyes from debris during repairs. |

| Gloves | To protect your hands and improve grip while handling parts. |

| Multimeter | For diagnosing electrical issues and checking voltages. |

Safety Precautions During Repairs

When undertaking maintenance tasks, prioritizing safety is essential to prevent accidents and injuries. Adhering to specific guidelines can significantly reduce risks while ensuring a smooth repair process.

- Wear Appropriate Gear: Always don protective clothing, including gloves, goggles, and sturdy footwear.

- Work in a Well-Lit Area: Ensure your workspace is adequately illuminated to avoid missteps and enhance visibility.

- Disconnect Power Sources: Before beginning any repair, unplug the equipment to eliminate the risk of accidental activation.

- Use the Right Tools: Select appropriate tools for the job to avoid mishaps and damage to the machinery.

- Follow Manufacturer Instructions: Always refer to the manual for guidelines on disassembly and reassembly.

In addition to these basic precautions, staying focused and organized can further enhance safety. A clutter-free workspace minimizes hazards, while a clear understanding of the repair process reduces the likelihood of errors. Always keep a first aid kit nearby in case of emergencies.

Upgrading Snowblower Performance

Enhancing the efficiency of your winter equipment can significantly improve its effectiveness in handling snow and ice. By implementing a few strategic upgrades, you can elevate the overall functionality, ensuring a smoother and more powerful operation during the harshest conditions. This section explores several ways to boost performance and extend the lifespan of your machinery.

Improving Engine Power

One of the most impactful modifications involves upgrading the engine. Opting for a more powerful unit can enhance torque and speed, allowing for quicker and more efficient clearing. Additionally, regular maintenance, such as changing the oil and replacing air filters, can optimize engine performance and ensure it runs at peak efficiency.

Enhancing Cutting Mechanisms

Improving the cutting mechanisms can also yield remarkable results. Consider investing in high-quality blades designed for better snow penetration and durability. Sharpening existing blades regularly will maintain their effectiveness, while adding features like adjustable skids can provide improved handling on varying terrains, resulting in a more thorough snow removal process.