Understanding Kubota Snowblower Parts Diagram

Understanding the intricate layout of various elements is essential for efficient operation and maintenance of complex machines. Knowing how these individual components work together helps to ensure optimal performance and longevity. The correct identification and placement of mechanical parts play a crucial role in smooth functionality and system efficiency.

In this guide, we will explore the detailed structure of these vital elements, their interactions, and how to maintain them effectively. Special attention will be given

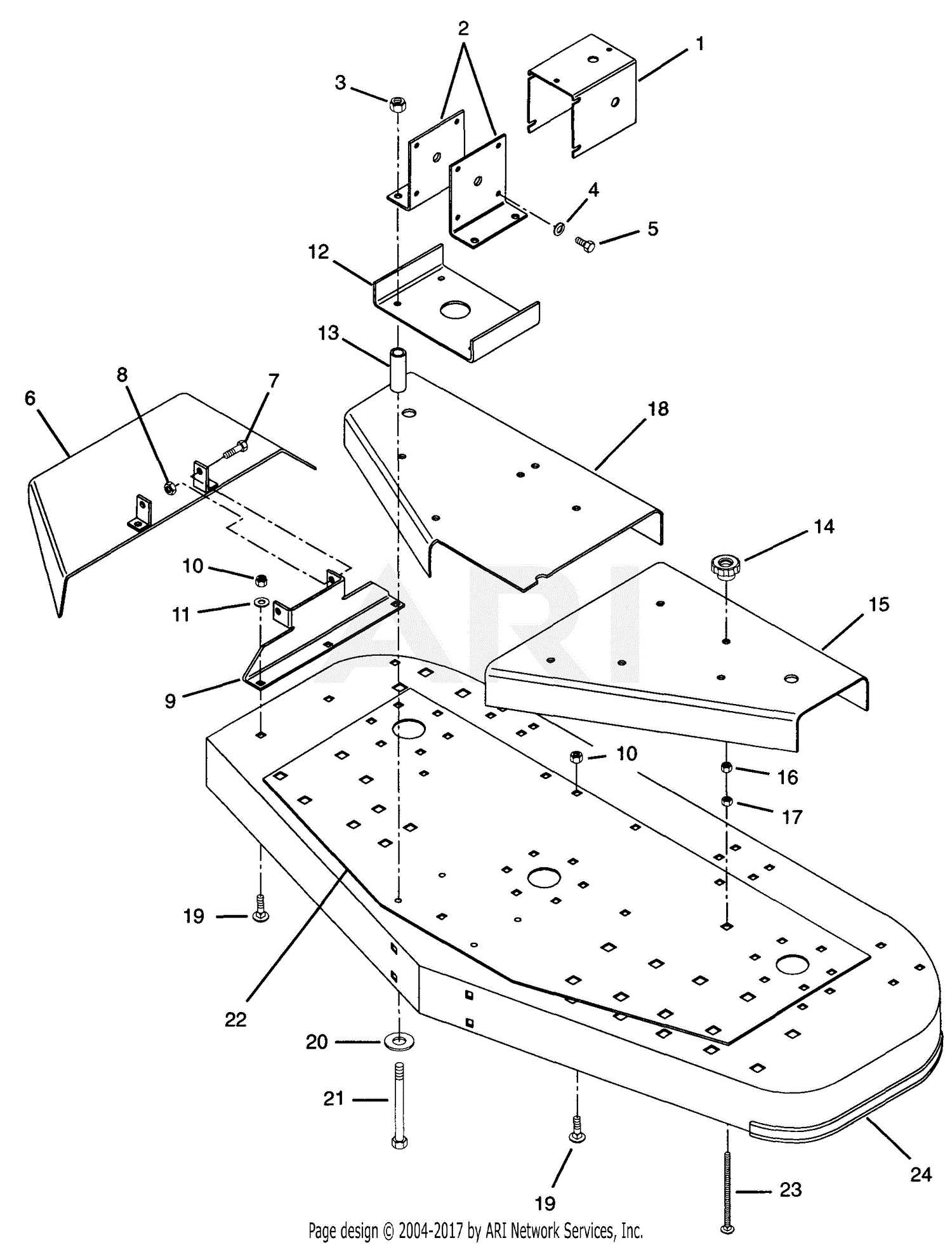

Kubota Snowblower Parts Overview

When maintaining winter equipment, understanding the essential components is crucial for ensuring smooth operation during harsh conditions. Each machine is built with various mechanical elements that work together to deliver reliable performance. Familiarity with these core features allows for timely upkeep and efficient troubleshooting.

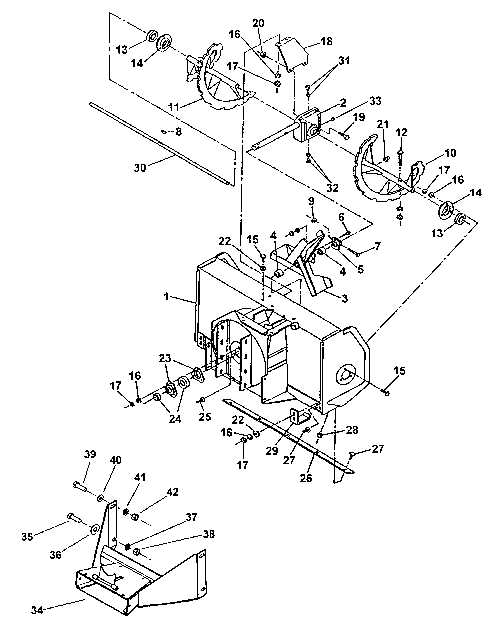

Key structural elements include the mechanisms responsible for propulsion and the assembly that directs the removal of snow. These components are crafted to withstand heavy use, often requiring regular inspection to prevent wear and tear. Regular maintenance of these vital systems ensures the machinery operates at peak efficiency throughout the winter months.

Equally important are the drive and control systems, which ensure precise handling and maneuverability. These functions are essential for user control and the safe execution of tasks in challenging environments. Keeping these mechanisms in optimal condition enhances both performance and safety during operation.

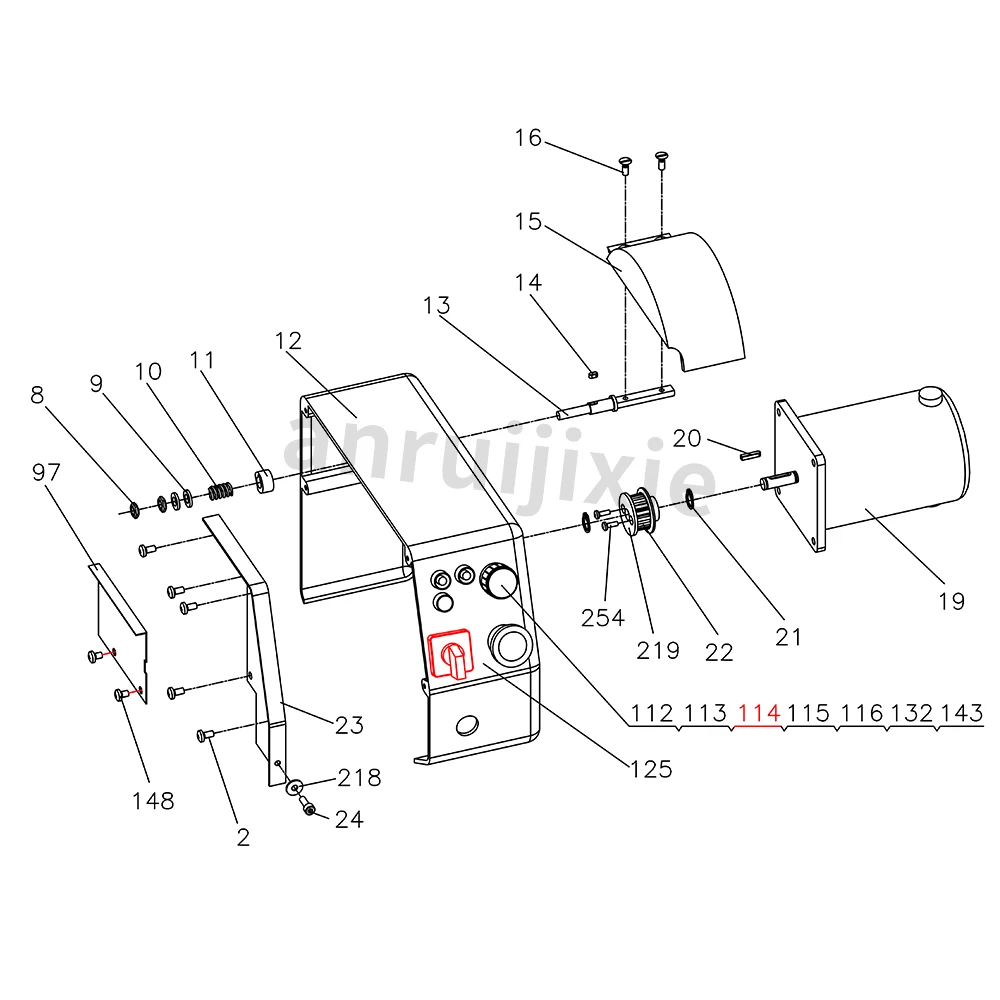

Understanding Key Components of the Snowblower

The efficient operation of a machine designed for clearing snow relies on the functionality of various crucial elements. By familiarizing yourself with these key parts, you can ensure proper maintenance and enhance performance, which is essential for handling harsh winter conditions.

Engine and Drive System

The power source is the heart of the machine, converting fuel into the energy needed to drive the other components. The transmission connects the engine to the wheels, allowing for smooth movement and control during operation. Ensuring both are in optimal condition guarantees that the equipment functions effectively.

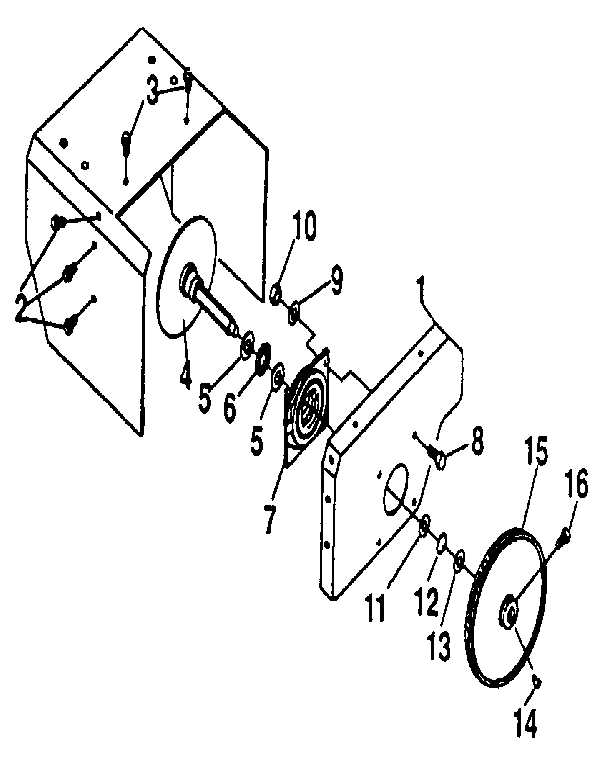

Auger and Impeller

The auger is responsible for gathering and breaking up snow, while the impeller propels it through the discharge chute. These components work in tandem to ensure efficient snow removal, making them vital to the overall performance. Regular inspection and cleaning help maintain their longevity.

Maintenance Tips for Long-Lasting Performance

Regular upkeep is essential to ensure the optimal functioning of any equipment, allowing it to remain efficient over time. Consistent care minimizes wear and tear, extending its service life while ensuring smooth operation even in demanding conditions.

Follow these guidelines to maintain top performance:

- Lubrication: Keep all moving components well-lubricated to reduce friction and prevent damage. Regular oiling ensures smoother operation and helps avoid mechanical failures.

- Inspect belts and cables: Regularly check belts for any signs of wear or cracks. Replace them when needed to avoid unexpected breakdowns. Also, ensure cables are free from fraying or

Identifying Wear and Tear in Parts

Over time, mechanical components inevitably show signs of degradation due to constant use. Recognizing early indications of damage is essential to ensure optimal functionality and avoid costly repairs. The key to maintaining longevity is understanding which areas are most susceptible to fatigue and how to spot subtle changes in their condition.

Common signs of deterioration include abnormal vibrations, unusual sounds during operation, and visible wear on critical surfaces. Pay attention to any loosening of bolts or connections, as this can often signal underlying issues. Regular inspections help identify potential failures before they escalate into larger problems.

In addition to visual and auditory cues, changes in the efficiency or performance of the machine can also indicate that components are wearing out. Consistent maintenance and timely replacements play a crucial role in extending the lifespan of the equipment.

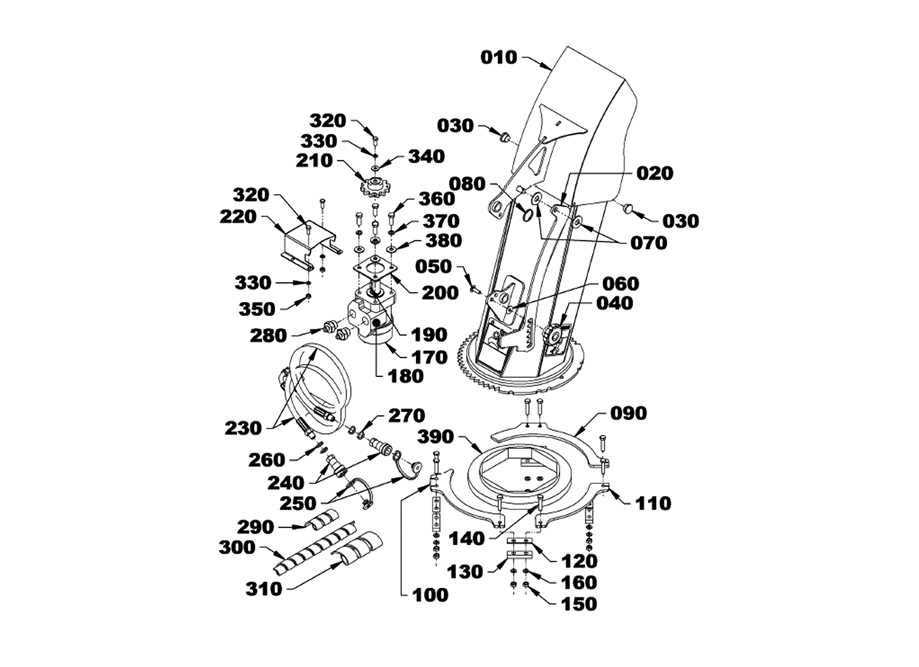

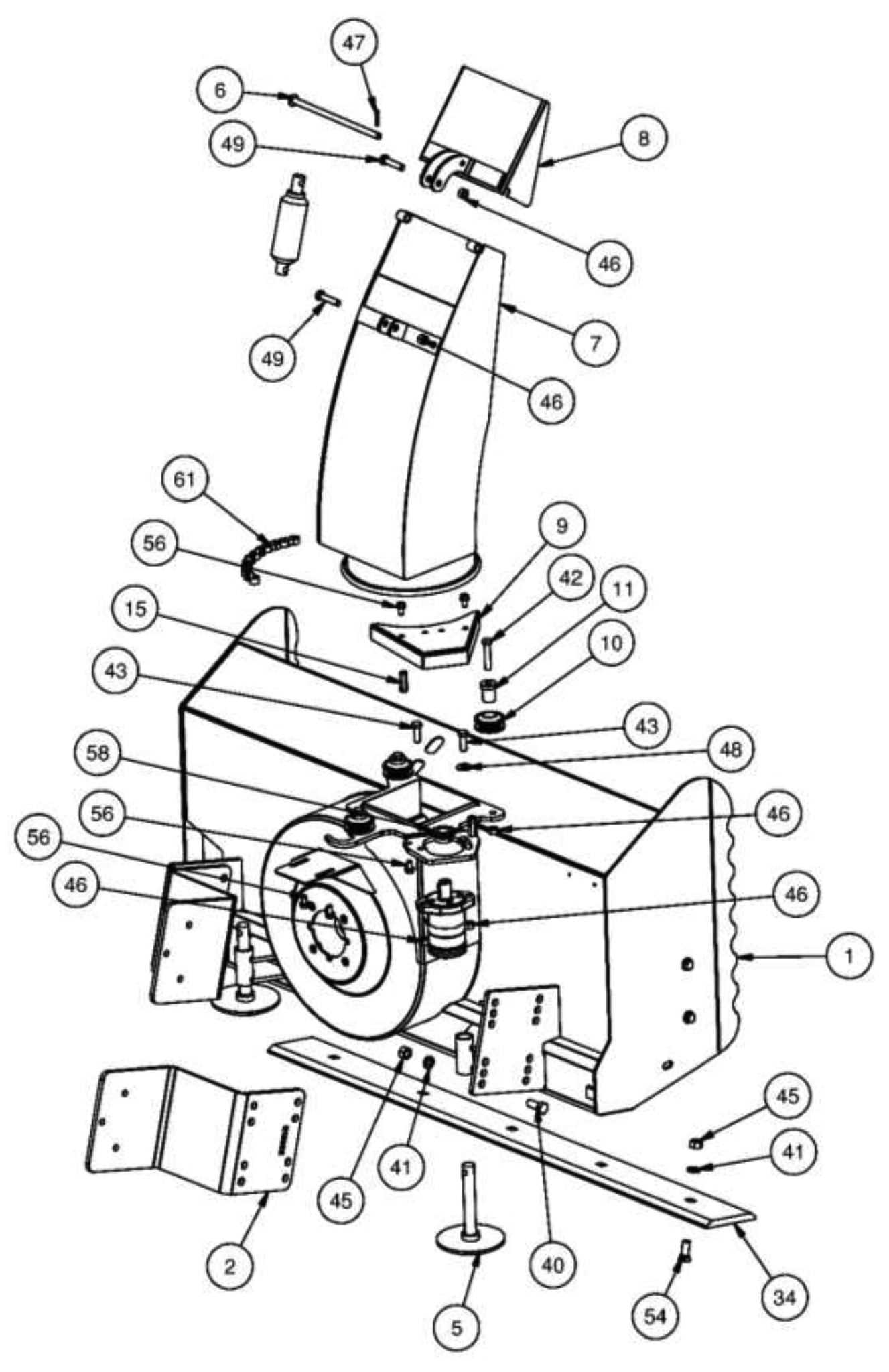

Replacing the Auger Mechanism Efficiently

Maintaining optimal performance of your equipment involves ensuring that key components, such as the auger mechanism, are replaced when necessary. Proper handling and understanding of the replacement process will not only extend the life of your machine but also ensure smooth and reliable operation.

To replace the auger mechanism effectively, follow these steps:

- First, disconnect the machine from any power source to ensure safety during the process.

- Next, carefully remove any guards or panels covering the auger area, using the appropriate tools for your equipment.

- Once the mechanism is exposed, inspect the assembly for wear or damage, and take note of any parts that need replacement.

- Detach the auger from its housing by loosening the bolts or fasteners that hold it in place.

- Replace the worn-out auger with a new one, ensuring that it is securely fastened in the same position as the previous mechanism.

- Finally, reas

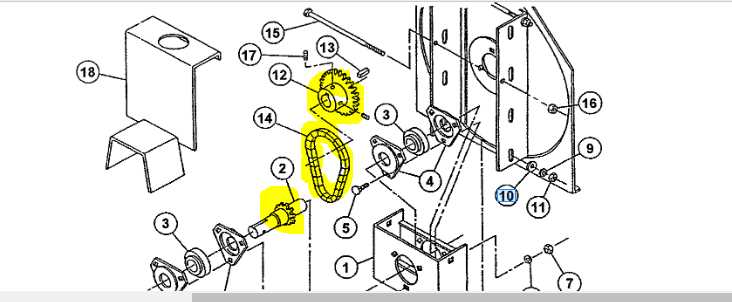

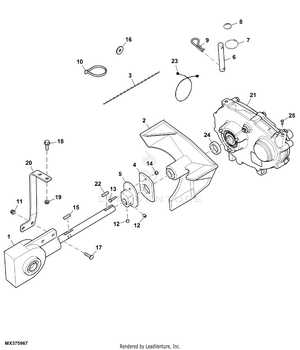

Choosing the Right Belts and Pulleys

Selecting appropriate drive components is essential for ensuring optimal performance and longevity of your equipment. The right combination of belts and pulleys not only affects power transmission efficiency but also impacts the overall operational reliability. Understanding the specifications and functions of these components will guide you in making informed decisions.

When considering belts, it is crucial to evaluate factors such as material, width, and length. Different types of belts are designed to handle varying loads and speeds. Pulleys, on the other hand, should be selected based on their diameter, groove design, and compatibility with the belt type. A mismatch can lead to premature wear and inefficiency.

Component Type Key Considerations Common Materials Belts Load capacity, length, width Rubber, Polyurethane, Nylon Pulleys Diameter, groove shape, material Aluminum, Steel, Plastic Regular inspections and maintenance of these components are also vital. By ensuring that belts are not frayed and pulleys are not damaged, you can prevent costly repairs and downtime. Proper installation and alignment will further enhance performance and extend the lifespan of your machinery.

Snowblower Blades and Their Function

Blades play a crucial role in the efficient operation of any snow-clearing machine. Their primary function is to effectively cut and remove accumulated ice and snow from various surfaces. Understanding their design and mechanics can significantly enhance performance and longevity.

Types of Blades

- Steel Blades: Known for their durability, these blades can withstand harsh conditions and heavy use.

- Plastic Blades: Lightweight and resistant to corrosion, these are ideal for less aggressive applications.

- Composite Blades: A blend of materials providing a balance between strength and weight, suitable for a variety of tasks.

Functions of Blades

- Cutting through compacted snow and ice layers.

- Propelling snow away from the surface, facilitating quick and efficient removal.

- Ensuring smooth operation by minimizing friction with the ground.