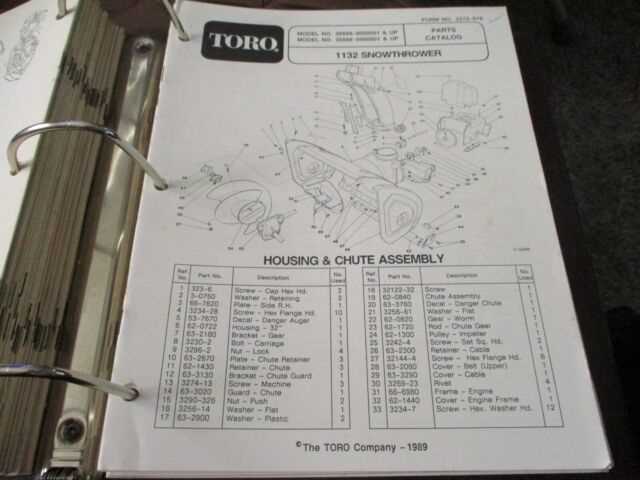

Toro 1132 Snowblower Parts Diagram Overview

When winter strikes, having reliable machinery at your disposal is essential for efficient snow removal. Proper maintenance and understanding of your device’s structure can significantly enhance its performance and longevity. This section delves into the essential components that make up these powerful machines, highlighting their functions and interconnections.

Each model has its unique arrangement, and familiarizing yourself with the individual elements is crucial. By knowing how the various sections fit together, you can better troubleshoot issues, perform repairs, and conduct routine maintenance. Comprehensive visual guides serve as invaluable resources, allowing you to pinpoint each part and understand its role in the overall operation.

Whether you’re a seasoned user or a newcomer, grasping the layout of your equipment can lead to more efficient use and fewer unexpected challenges. This knowledge empowers you to tackle the winter season with confidence, ensuring your machinery operates smoothly when you need it most.

Understanding Toro 1132 Snowblower Components

When it comes to winter equipment, comprehending the individual elements that contribute to its functionality is essential. Each component plays a vital role in ensuring efficient operation and optimal performance during challenging weather conditions. This section delves into the key features that make up this particular machine, providing insight into their functions and importance.

Main Mechanisms

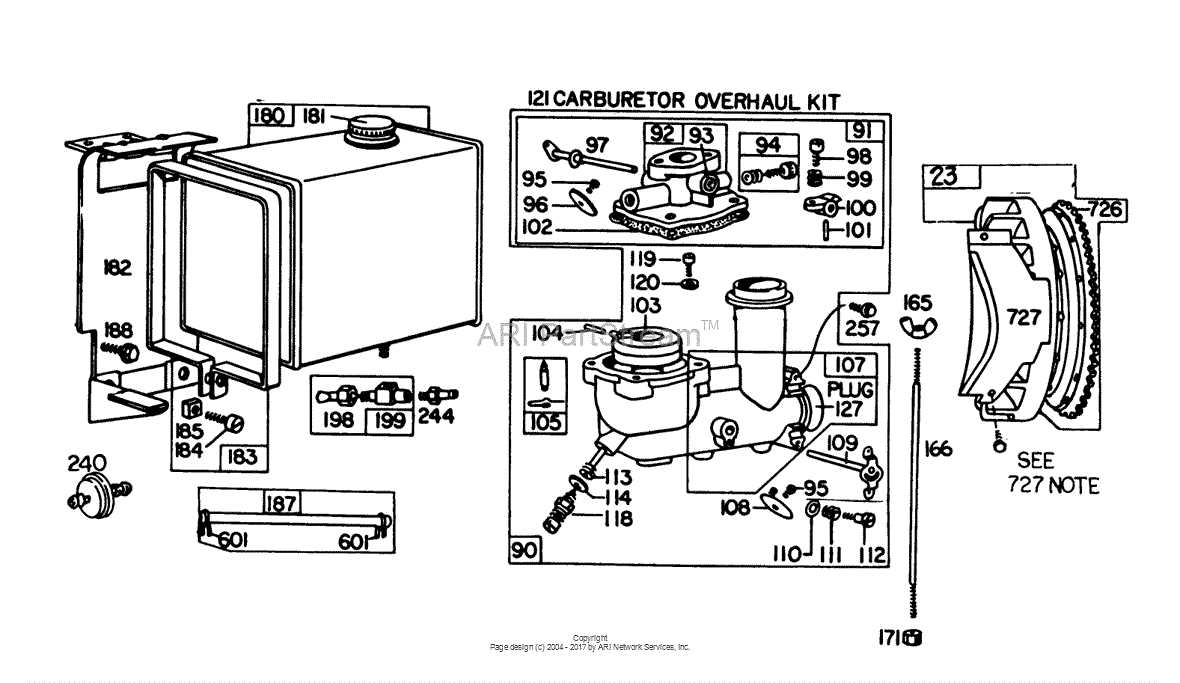

At the heart of this machine are the primary mechanisms that facilitate movement and snow removal. The engine serves as the powerhouse, providing the necessary energy to drive all functions. Coupled with the auger, which gathers and lifts snow, these components work in tandem to clear pathways effectively. Understanding how these mechanisms interact is crucial for maintenance and troubleshooting.

Additional Features

In addition to the main mechanisms, several supplementary elements enhance usability. The chassis provides stability and support, ensuring the equipment can withstand harsh conditions. Furthermore, controls allow operators to adjust settings easily, contributing to a more user-friendly experience. Familiarity with these features can significantly improve efficiency and extend the lifespan of the machine.

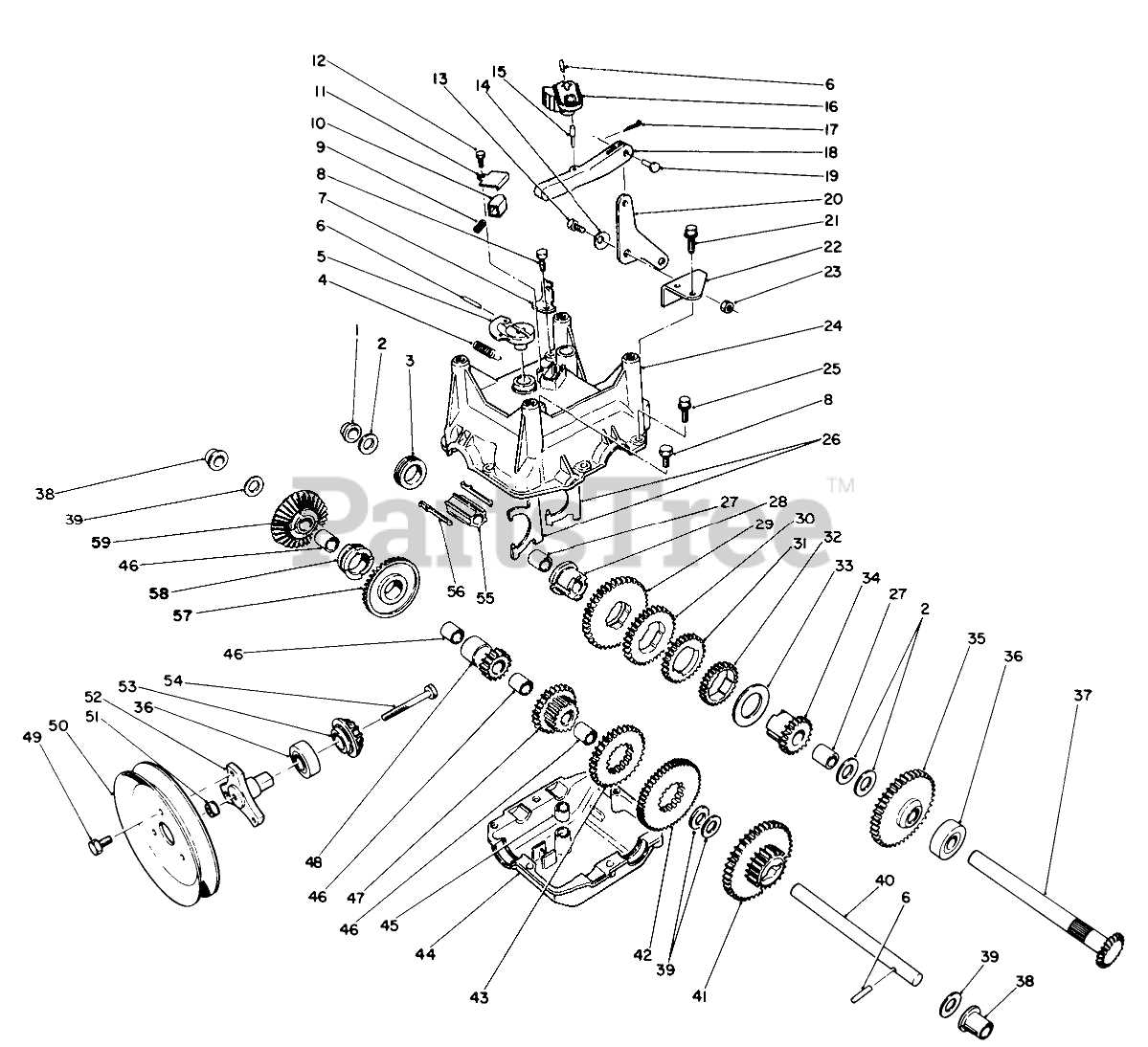

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repairs. These illustrations serve as guides that detail the various elements and their relationships within a mechanical system. By familiarizing yourself with how to interpret these visuals, you can streamline your repair process and ensure proper functionality.

Key Elements to Identify

When analyzing a visual representation, focus on the following critical aspects:

| Element | Description |

|---|---|

| Labels | Indicate specific parts, often accompanied by reference numbers. |

| Connections | Show how different components interact or fit together. |

| Annotations | Provide additional information such as specifications or warnings. |

Steps for Effective Interpretation

To effectively interpret these visuals, follow these steps:

- Start by familiarizing yourself with the overall layout and structure.

- Identify and note the labeled components and their corresponding reference numbers.

- Examine the connections to understand how parts relate to one another.

- Review any annotations for crucial insights that may affect your task.

Essential Tools for Snowblower Repair

Having the right equipment is crucial for effective maintenance and repair of outdoor machinery. A well-stocked toolbox not only enhances efficiency but also ensures that tasks are completed safely and accurately. Understanding the necessary tools can help extend the lifespan of your equipment and improve its performance.

Must-Have Tools

- Screwdrivers: A set of both flathead and Phillips screwdrivers is essential for loosening or tightening various components.

- Wrenches: Adjustable and socket wrenches are vital for dealing with different sizes of nuts and bolts.

- Pliers: Needle-nose and standard pliers can assist in gripping and bending wires or small parts.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications, preventing damage.

- Spark Plug Wrench: Specifically designed for easy removal and installation of spark plugs.

Additional Useful Equipment

- Multimeter: Helpful for diagnosing electrical issues and checking voltage levels.

- Oil Filter Wrench: Simplifies the removal of oil filters during routine maintenance.

- Shop Manual: A comprehensive guide that offers detailed instructions and troubleshooting tips.

- Safety Gear: Includes gloves and goggles to protect yourself while working on machinery.

- Cleaning Supplies: Brushes and solvents are important for keeping components free from debris and buildup.

By equipping yourself with these essential tools, you can tackle repairs confidently and ensure that your equipment operates smoothly throughout the winter season.

Common Issues with Toro 1132 Models

When operating outdoor equipment designed for clearing snow, users may encounter several recurring challenges. Understanding these common problems can help in maintaining the machinery efficiently and prolonging its lifespan. Proper troubleshooting can ensure smooth operation during the winter months.

Frequent Mechanical Failures

Mechanical components may experience wear and tear, leading to operational issues. The most frequently reported failures involve the drive system and auger assembly, which can hinder performance if not addressed promptly.

| Issue | Symptoms | Solutions |

|---|---|---|

| Drive System Slippage | Machine fails to move forward or backward | Check belts for wear; replace if necessary |

| Auger Not Engaging | Snow is not being collected effectively | Inspect cables and controls; adjust or replace |

Fuel and Engine Problems

Engine performance is critical for effective operation. Issues related to fuel quality or engine wear can cause significant interruptions. Regular maintenance and proper fuel storage can mitigate these problems.

| Issue | Symptoms | Solutions |

|---|---|---|

| Hard Starting | Engine struggles to start | Check spark plug condition; clean or replace |

| Stalling During Use | Engine stops unexpectedly | Inspect fuel lines; clear any blockages |

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your outdoor equipment. Regular attention to detail can prevent costly repairs and ensure efficient performance throughout its use. Here are some key strategies to keep in mind for maintaining your machine.

| Tip | Description |

|---|---|

| Regular Cleaning | Remove debris and buildup after each use to prevent rust and corrosion. |

| Check Fluids | Monitor oil levels and change fluids according to the manufacturer’s recommendations. |

| Inspect Components | Regularly examine belts, blades, and other key parts for wear and tear. |

| Sharpen Blades | Keep cutting edges sharp for optimal performance and efficiency. |

| Store Properly | When not in use, store the equipment in a dry place to avoid moisture damage. |

| Follow Manual Guidelines | Adhere to the specific maintenance schedule outlined in the user manual. |

By implementing these practices, you can significantly enhance the reliability and durability of your equipment, ensuring it serves you well for many seasons to come.

Finding Replacement Parts Online

Locating components for your outdoor equipment can seem daunting, but with the right approach, it can be a straightforward process. The internet provides a plethora of resources to assist in identifying and acquiring the necessary items for maintenance and repairs. Understanding how to navigate these options is key to ensuring your machinery operates efficiently.

Start with Trusted Retailers: Look for reputable online suppliers that specialize in outdoor machinery. Many of these websites offer extensive catalogs, allowing you to search for specific components based on model numbers or descriptions. Reading reviews can help you gauge the reliability of the seller.

Utilize Manufacturer Resources: Often, the official websites of equipment manufacturers provide detailed listings of available components. These resources may include schematics and guides that can assist you in identifying what you need. This is particularly helpful if you’re unsure about the exact item to purchase.

Join Online Communities: Engaging with forums or social media groups focused on outdoor machinery can be beneficial. Members often share their experiences, recommend vendors, and may even have tips on where to find hard-to-locate items. Networking with other enthusiasts can provide insights that enhance your search.

Consider Local Options: While online shopping is convenient, don’t overlook local retailers. Many brick-and-mortar stores have websites and offer the option to order components for in-store pickup. This can save time and shipping costs while supporting local businesses.

By following these strategies, you can simplify the process of sourcing replacement components, ensuring your equipment remains in optimal condition for years to come.

Assembly Instructions for Key Parts

Understanding the assembly of essential components is crucial for ensuring optimal performance and longevity of your equipment. This section provides detailed guidance on how to effectively piece together the main elements, enabling smooth operation and maintenance.

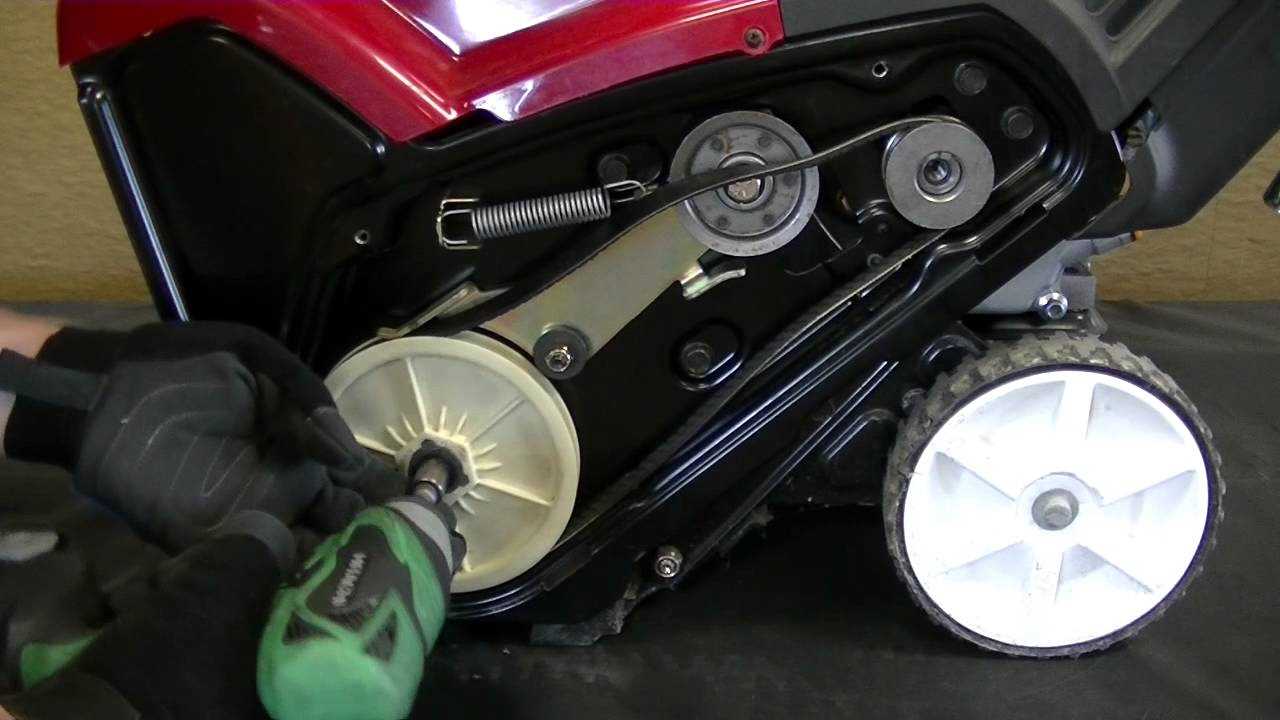

Connecting the Drive Mechanism

To begin, ensure all necessary tools are at hand. First, align the drive shaft with the transmission housing. Insert the securing bolts, making sure to tighten them evenly. It’s important to check that the connection is firm to avoid any slippage during use. After securing the bolts, apply a light lubricant to enhance performance and reduce wear over time.

Attaching the Auger Assembly

Next, focus on the auger assembly. Begin by positioning it correctly onto the main frame. Insert the designated pins through the pre-drilled holes to secure the auger in place. Ensure that the auger rotates freely without obstruction. Finally, adjust the height settings as necessary to match the specific requirements of your operating conditions, ensuring efficient material handling.

Safety Precautions During Repairs

When undertaking maintenance tasks on outdoor machinery, ensuring personal safety should be the top priority. Proper precautions not only protect the individual performing the repairs but also enhance the longevity and functionality of the equipment. Understanding the potential hazards and preparing accordingly can prevent accidents and injuries.

Wear Appropriate Protective Gear

Utilizing suitable protective equipment is essential. This includes safety goggles to shield the eyes from debris, gloves to protect the hands from sharp edges, and sturdy footwear to prevent slips and falls. Additionally, ear protection may be necessary when working with loud machinery to guard against hearing damage.

Maintain a Clean Workspace

A tidy work environment minimizes the risk of accidents. Ensure that the area is free of clutter and spills. Keeping tools organized and within reach can help prevent unnecessary movements that may lead to injuries. Furthermore, ensuring adequate lighting can enhance visibility and reduce the likelihood of mishaps.

Upgrades for Improved Performance

Enhancing the efficiency and effectiveness of your outdoor equipment can significantly elevate its functionality. By investing in specific modifications, users can experience improved power, reliability, and ease of use. This section explores various enhancements that can transform performance, ensuring optimal operation during challenging weather conditions.

Key Enhancements to Consider

- High-Performance Engine Oil: Upgrading to synthetic oil can improve engine efficiency and longevity.

- Adjustable Skid Shoes: These allow for better clearance adjustments on varying surfaces, preventing damage to driveways or pathways.

- Auger Blade Replacement: Installing sharper, reinforced blades can enhance cutting capability and reduce effort during operation.

- Fuel Stabilizers: Using additives helps maintain fuel quality, ensuring optimal performance during use.

- LED Work Lights: Adding brighter lights improves visibility, making nighttime operation safer and more effective.

Maintenance Practices for Optimal Functionality

- Regularly check and tighten all bolts and screws to prevent wear and tear.

- Keep the equipment clean to prevent debris buildup, which can hinder performance.

- Inspect and replace air filters as needed to ensure proper airflow.

- Sharpen or replace blades periodically for maximum efficiency.

- Store the machine properly during off-seasons to prolong its lifespan.

Warranty Information for Toro Products

Understanding the warranty details for your equipment is essential for ensuring a smooth ownership experience. Warranties provide valuable protection against manufacturing defects and offer peace of mind, knowing that your investment is safeguarded for a certain period. Familiarizing yourself with the terms and conditions can help you maximize the benefits of your purchase.

Coverage and Duration

The coverage generally includes repairs or replacements for faulty components under normal usage conditions. The duration varies depending on the product type and model, typically ranging from one to three years. It is advisable to review the specific warranty documentation provided at the time of purchase to understand the precise terms applicable to your equipment.

Claim Process

In the event of a defect, initiating a claim involves several straightforward steps. First, gather the necessary documentation, including proof of purchase and warranty details. Next, contact customer service for guidance on the process and any required forms. Prompt reporting of issues ensures that you receive the necessary assistance swiftly.

Remember, keeping your equipment well-maintained not only enhances its performance but also helps in preserving warranty eligibility. Regular servicing and adherence to the usage guidelines are crucial for enjoying the full benefits of your warranty coverage.

Customer Support Resources for Toro

Finding assistance for your equipment can greatly enhance your experience and ensure optimal performance. Accessing reliable support resources is essential for addressing any concerns or questions you may have regarding your machinery. This section highlights the various avenues available for effective customer assistance, making it easier for you to maintain and troubleshoot your devices.

Online Support Portal

An extensive online support portal is available, offering a wealth of information including manuals, FAQs, and troubleshooting guides. This resource allows users to quickly find solutions to common issues and access detailed documentation related to their specific model. By utilizing this portal, customers can efficiently resolve problems without the need for direct contact.

Customer Service Hotline

If you require personalized assistance, a dedicated customer service hotline is at your disposal. Trained representatives are ready to help you navigate any challenges you may encounter. Whether you need advice on maintenance or have questions about features, calling the hotline connects you with knowledgeable staff who can provide immediate support.