Toro Snowblower Parts Diagram Explained

When it comes to maintaining efficiency during the winter months, having a comprehensive grasp of your snow removal equipment is essential. Familiarity with its various components ensures optimal performance, allowing you to tackle even the harshest of weather conditions with ease. A clear understanding of the intricate layout of your device can make all the difference in its operation and longevity.

By exploring the arrangement and function of each segment, users can effectively troubleshoot issues, perform timely repairs, and enhance their machinery’s functionality. Knowledge of these crucial elements not only empowers you to handle challenges with confidence but also promotes safer usage. Embracing this information can significantly impact your overall experience during the snowy season.

Whether you’re a seasoned operator or a newcomer, delving into the specifics of your clearing apparatus will undoubtedly lead to improved proficiency. With the right insights, you can ensure that your machine remains in peak condition, ready to face whatever the winter may bring.

Toro Snowblower Parts Overview

Understanding the components of your winter equipment is essential for maintaining its efficiency and longevity. Each element plays a critical role in ensuring optimal performance, especially during heavy snowfall. Familiarizing yourself with these essentials can help you identify any issues and streamline repairs or replacements when necessary.

Key Components

The primary elements include the engine, auger, and impeller. The engine serves as the powerhouse, driving all functions. The auger is responsible for gathering snow, while the impeller helps to discharge it, directing the flow as needed. Each of these components must be in good working condition to ensure smooth operation.

Maintenance Tips

Importance of Understanding Parts Diagrams

Comprehending the layout of components is crucial for effective maintenance and repair of machinery. Familiarity with these illustrations allows users to identify individual elements and their functions, facilitating informed decision-making when troubleshooting or performing replacements.

In addition to aiding in repairs, knowledge of these visuals enhances overall equipment safety. Understanding how different parts interact can prevent improper handling and potential accidents, ensuring a smoother operation and extending the lifespan of the equipment.

| Benefit | Description |

|---|---|

| Enhanced Troubleshooting | Identifying issues becomes easier when the relationships between components are clear. |

| Informed Replacements | Users can select the correct components for replacement, reducing downtime. |

| Improved Safety | A better understanding minimizes the risk of accidents during repairs. |

| Increased Efficiency | Knowledge of component layout leads to quicker and more effective maintenance. |

Common Toro Snowblower Models Explained

This section delves into various popular models designed for clearing snow, highlighting their features and functionalities. Understanding these distinct varieties can assist users in selecting the right equipment for their needs, ensuring efficient snow removal in various conditions.

One well-known type is the compact model, perfect for residential areas with limited space. These machines are lightweight and easy to maneuver, making them ideal for small driveways and walkways. Users appreciate their efficiency in handling moderate snowfall without the bulk of larger machines.

Another category includes mid-range models, which offer a balance between power and size. Equipped with enhanced engines, these units tackle heavier accumulations while remaining user-friendly. Their versatility allows them to manage various terrains, from sidewalks to larger open areas.

For those facing extreme winter conditions, high-performance models are available. These robust machines come with advanced features such as heated handles and self-propulsion, making them suitable for extensive driveways and commercial use. Their capability to handle significant snow depth sets them apart in challenging weather.

Lastly, electric alternatives are gaining popularity due to their eco-friendly operation and lower maintenance requirements. These quieter machines are particularly favored in urban environments, providing an effective solution for light to moderate snowfall while minimizing noise pollution.

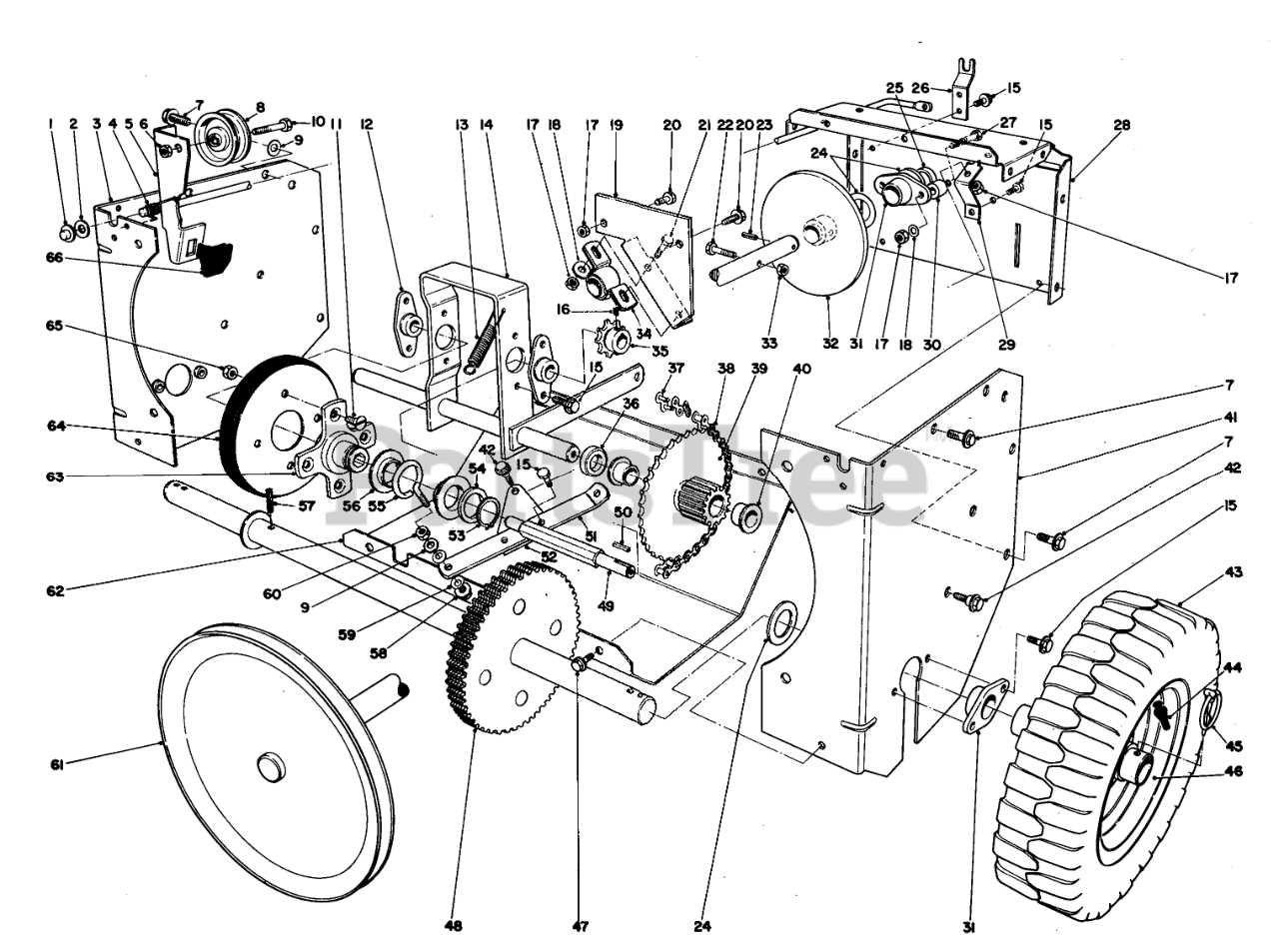

Key Components of Snowblowers

Understanding the essential elements of a snow-clearing machine is crucial for effective operation and maintenance. Each component plays a vital role in ensuring optimal performance during winter conditions. Below are the primary elements that contribute to the efficiency of these devices.

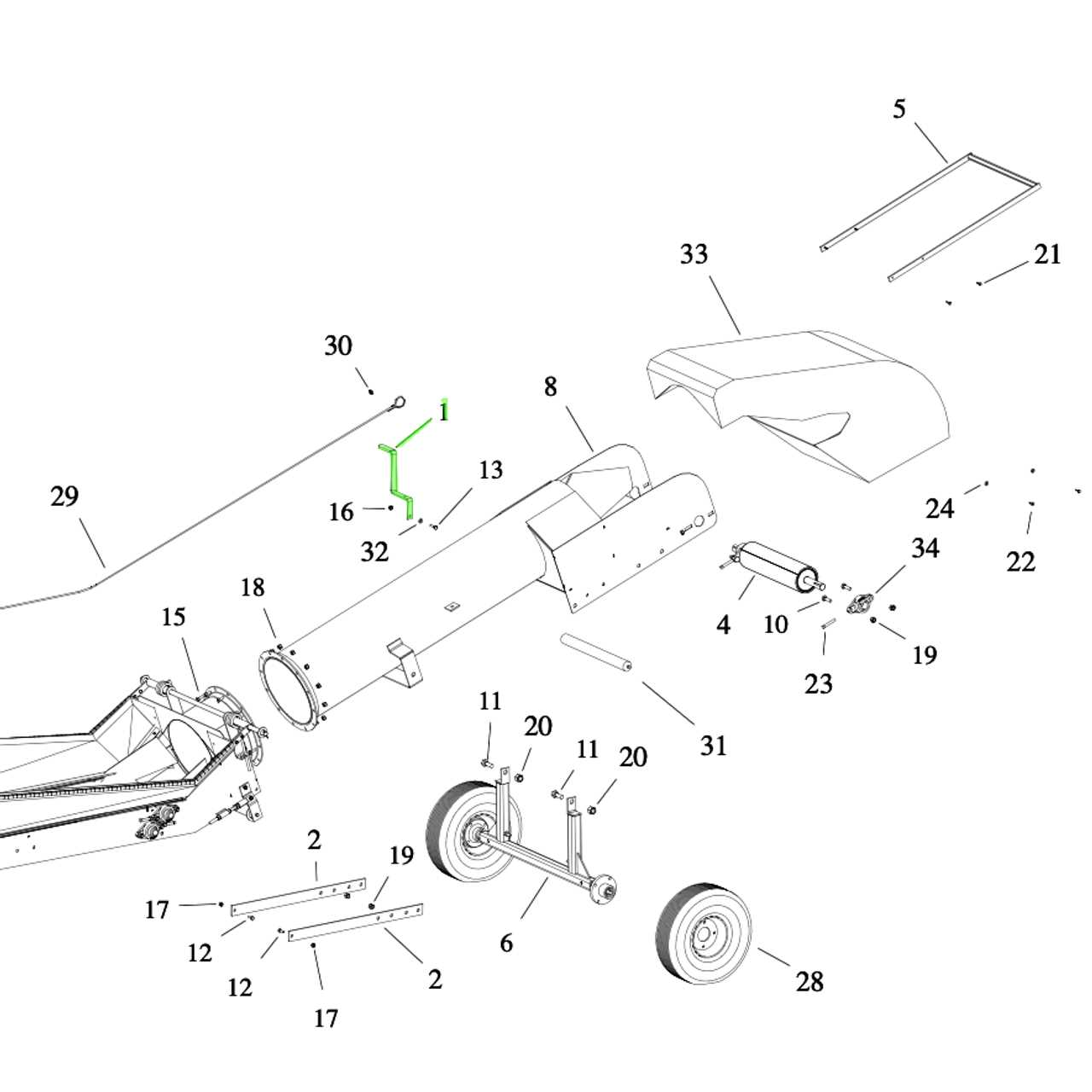

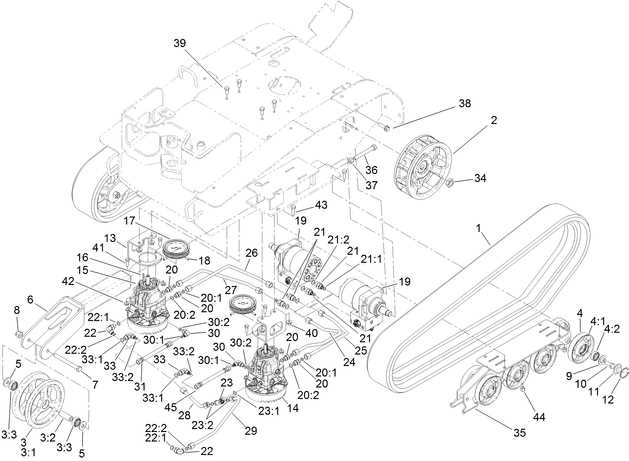

Core Elements

- Engine: The heart of the equipment, providing the necessary power to operate the various functions.

- Auger: This rotating mechanism collects and breaks up the snow, directing it towards the discharge chute.

- Impeller: Responsible for propelling the snow out of the machine once it has been processed by the auger.

- Chassis: The main framework that supports all components, ensuring durability and stability.

- Controls: The user interface that allows for easy operation and adjustment of settings during use.

Supporting Components

- Wheels or Tracks: Provide mobility and traction, essential for navigating various terrains.

- Skid Shoes: Help adjust the height of the machine above the ground, preventing damage to surfaces.

- Discharge Chute: Directs the expelled snow away from the path, allowing for clear and efficient clearing.

- Fuel System: Supplies the engine with necessary fuel, influencing performance and runtime.

- Electrical System: Powers lights and electric start options, enhancing usability during low-visibility conditions.

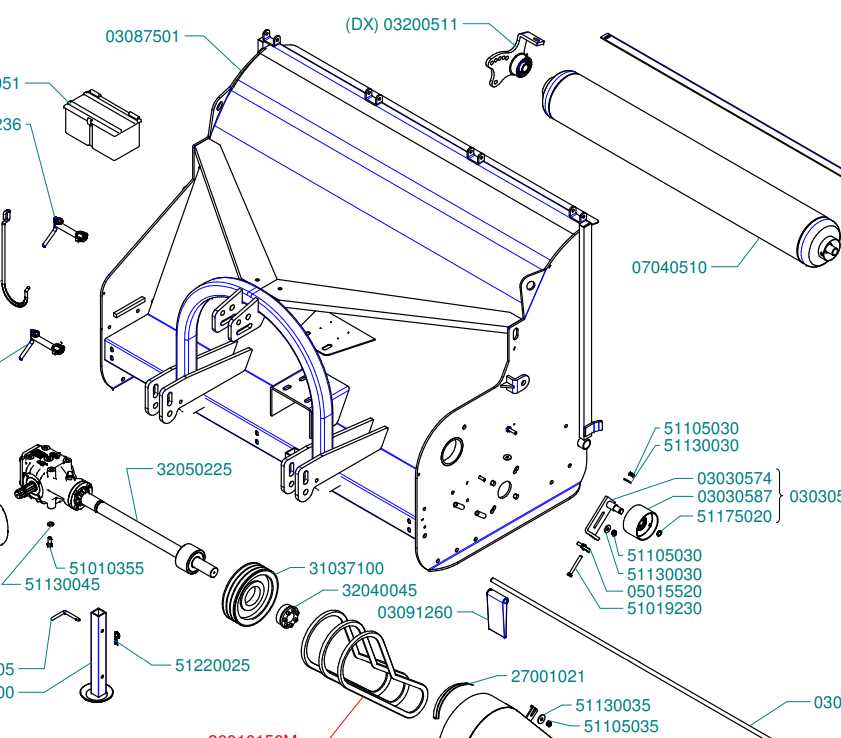

How to Read Parts Diagrams

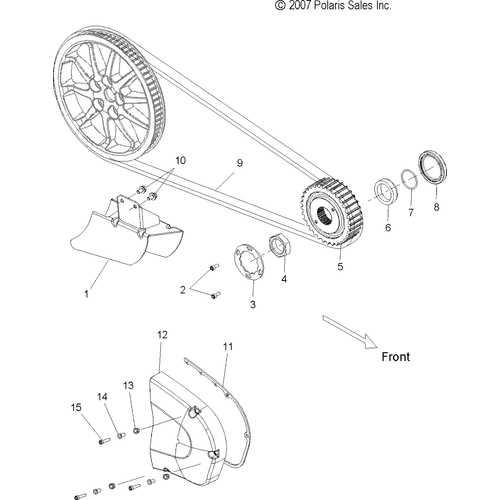

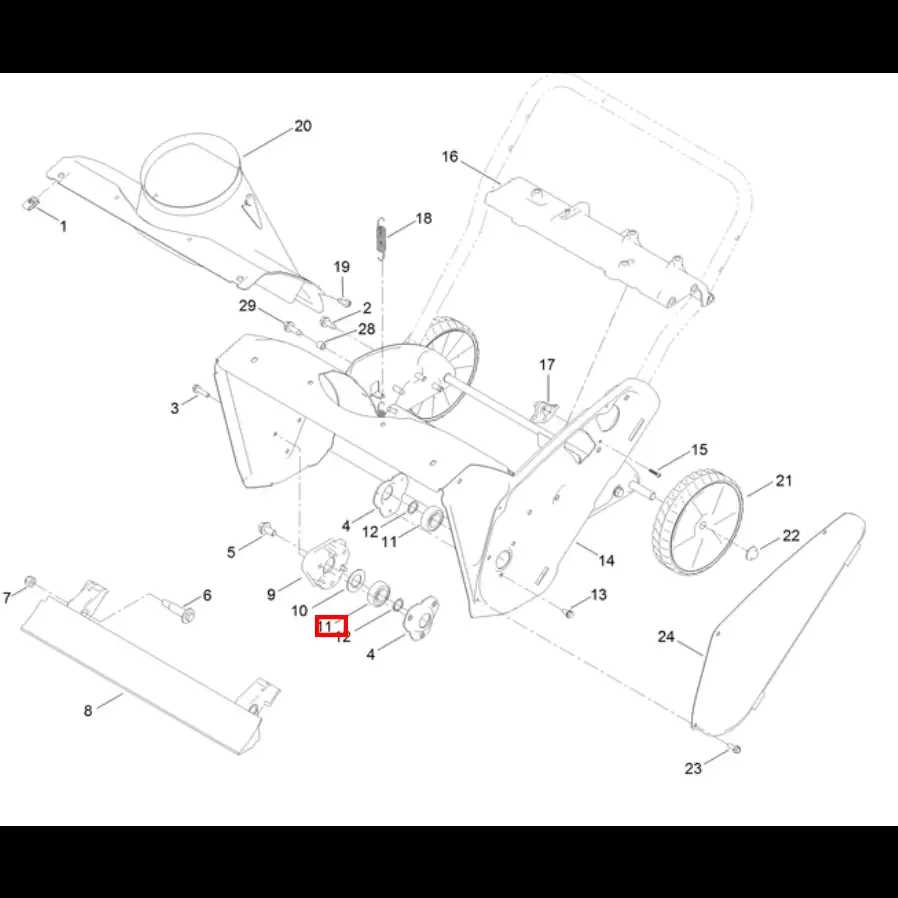

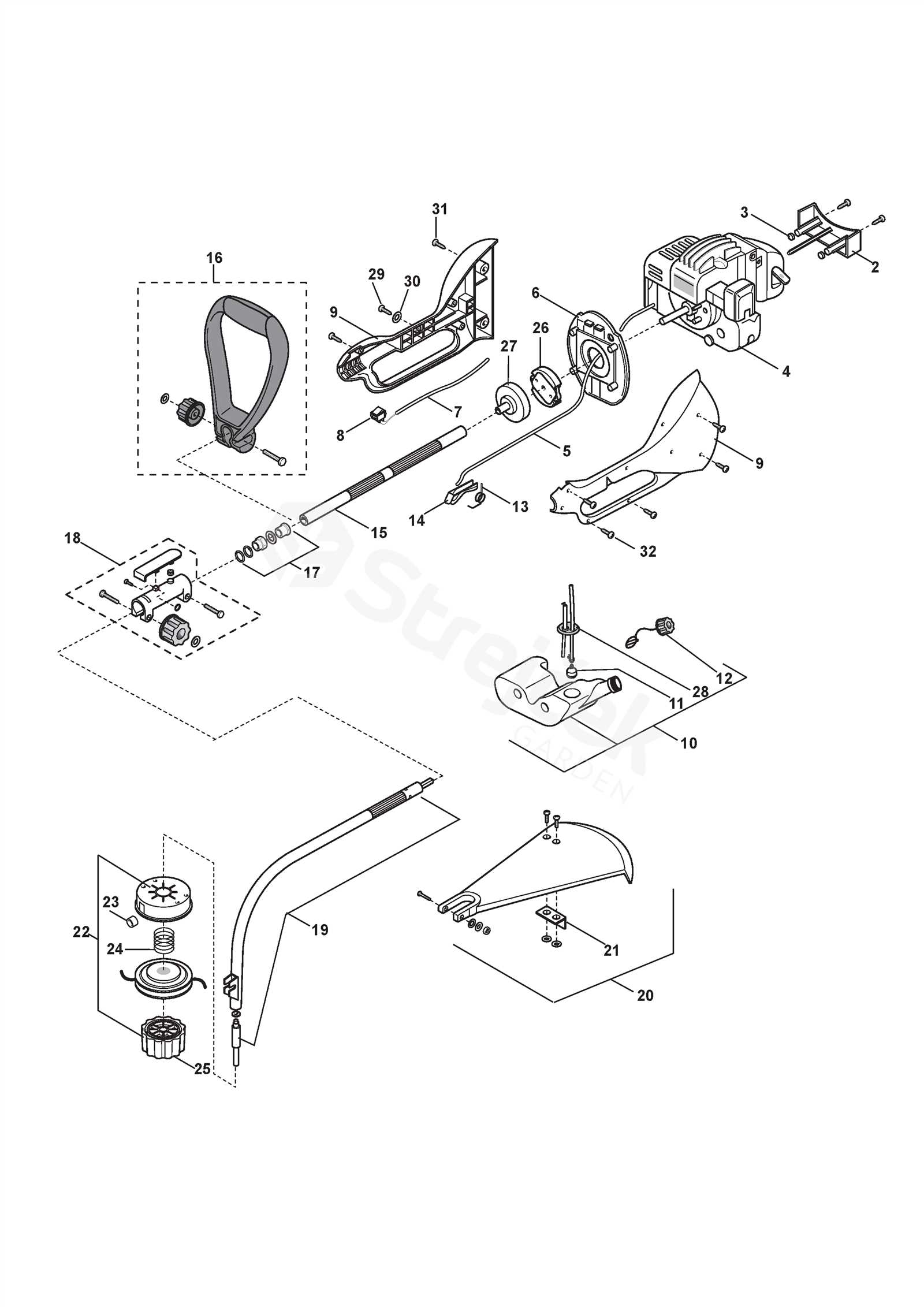

Understanding the layout of a mechanical assembly can significantly enhance your ability to maintain and repair equipment. These visual representations serve as valuable guides, illustrating how components fit together and interact. By mastering the interpretation of these visuals, you can efficiently identify necessary elements and streamline the repair process.

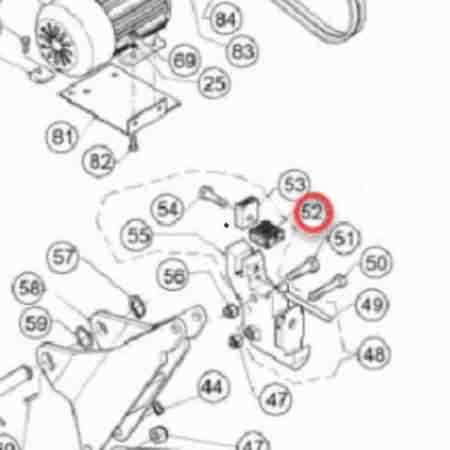

Initially, it’s crucial to familiarize yourself with the overall structure presented in the illustration. Look for a legend or key that explains the symbols used; this can clarify what each part represents. Typically, components are numbered or labeled, providing an organized way to reference them. Take note of any lines or arrows, as they often indicate relationships or movements between different elements.

Next, focus on grouping similar items together. Recognizing clusters of components can help in understanding how they function collectively within the assembly. Pay attention to any exploded views, as these can offer a clearer perspective on how parts are arranged and how they can be disassembled for repair.

Finally, always cross-reference the visual with the accompanying text or list, which may provide additional details about specifications or part numbers. This thorough approach will ensure that you fully grasp the information presented, ultimately aiding in efficient maintenance or repairs.

Finding Replacement Parts Easily

Locating the necessary components for your equipment can be a straightforward process if you know where to look. With the right resources and a bit of guidance, you can efficiently identify and obtain the specific items you need to keep your machinery in optimal condition.

Utilizing Online Resources

The internet offers a wealth of information and options for sourcing components. Numerous websites provide catalogs, user manuals, and forums where enthusiasts share their experiences. Search engines can help you find retailers that specialize in the equipment you are working with, allowing you to compare prices and availability easily.

Consulting Local Experts

If online searches don’t yield satisfactory results, visiting local retailers or repair shops can be beneficial. Knowledgeable staff can assist in identifying the right items and may even have access to inventory not listed online. Additionally, they might offer valuable advice on installation and maintenance, ensuring your machinery runs smoothly.

Maintenance Tips for Snowblower Longevity

Proper care and regular upkeep are essential for ensuring that your equipment operates efficiently and lasts for many seasons. Implementing a systematic maintenance routine can help prevent breakdowns and enhance performance during harsh weather conditions.

Start by inspecting the machinery before each use. Check the oil levels, ensuring they are within the recommended range, and change the oil periodically to keep the engine running smoothly. Additionally, examine the fuel system for any signs of leaks or contamination, as fresh fuel can significantly improve performance.

Cleaning the exterior and interior components is equally important. Remove any accumulated debris, snow, or ice that may hinder functionality. Pay special attention to the auger and impeller areas, as blockages can lead to decreased efficiency and potential damage.

Sharpening blades and replacing worn-out components will also extend the life of your equipment. Dull blades can cause strain on the motor, while damaged parts can lead to further issues down the line. Regularly consulting the user manual for recommended replacement intervals is a wise practice.

Lastly, store the equipment in a dry and sheltered environment when not in use. Proper storage prevents rust and other forms of deterioration, ensuring that it remains in excellent working condition for the next snow season.

Common Issues and Troubleshooting Guide

When operating outdoor equipment, encountering certain challenges can be common. Understanding these issues and how to address them can enhance performance and prolong the life of your machinery. This guide outlines frequent problems and offers practical solutions to ensure smooth operation.

Starting Difficulties

One of the most prevalent concerns is the difficulty in starting the engine. This can be attributed to a range of factors, such as fuel quality, battery charge, or ignition system failures. Check the fuel level and ensure that it is fresh and appropriate for your equipment. Additionally, inspect the battery connections and test the ignition components to pinpoint the issue.

Poor Performance

If your device is running unevenly or lacks power, it may indicate issues such as clogged filters or worn-out components. Regular maintenance is crucial; clean or replace air and fuel filters as needed. Furthermore, examine belts and blades for wear and tear, as these can significantly impact performance. Addressing these concerns promptly can prevent more serious damage.

Where to Purchase Toro Parts

Finding high-quality components for your outdoor equipment is essential for maintaining its performance and longevity. Whether you’re looking for specific replacements or upgrades, there are several reliable sources to consider for your needs.

Authorized Dealers are often the best starting point. These retailers specialize in genuine items and can provide expert advice on compatibility and installation. Their knowledgeable staff can help you navigate through the various options available.

Online Retailers also offer a convenient alternative. Websites dedicated to outdoor machinery often feature extensive inventories, making it easier to find the exact items you require. Be sure to check for customer reviews and ratings to ensure the reliability of the seller.

Local Repair Shops can be a hidden gem for sourcing necessary components. They frequently have a selection of parts on hand and can sometimes provide refurbished options at a lower cost. Additionally, the technicians can offer valuable insights based on their experience.

Manufacturer’s Website is another excellent resource. Many manufacturers have online stores where you can order directly. This option often ensures that you are getting authentic components designed for optimal performance with your equipment.

Finally, consider second-hand marketplaces. While caution is advised, these platforms can yield significant savings. Just ensure you verify the condition and compatibility of the items before purchasing.

DIY Repairs: What You Need to Know

Performing maintenance and fixing equipment can be a rewarding experience that not only saves you money but also enhances your skills. Understanding the components and how they work together is essential for successful repairs. This section will guide you through the fundamentals of troubleshooting, identifying issues, and executing repairs efficiently.

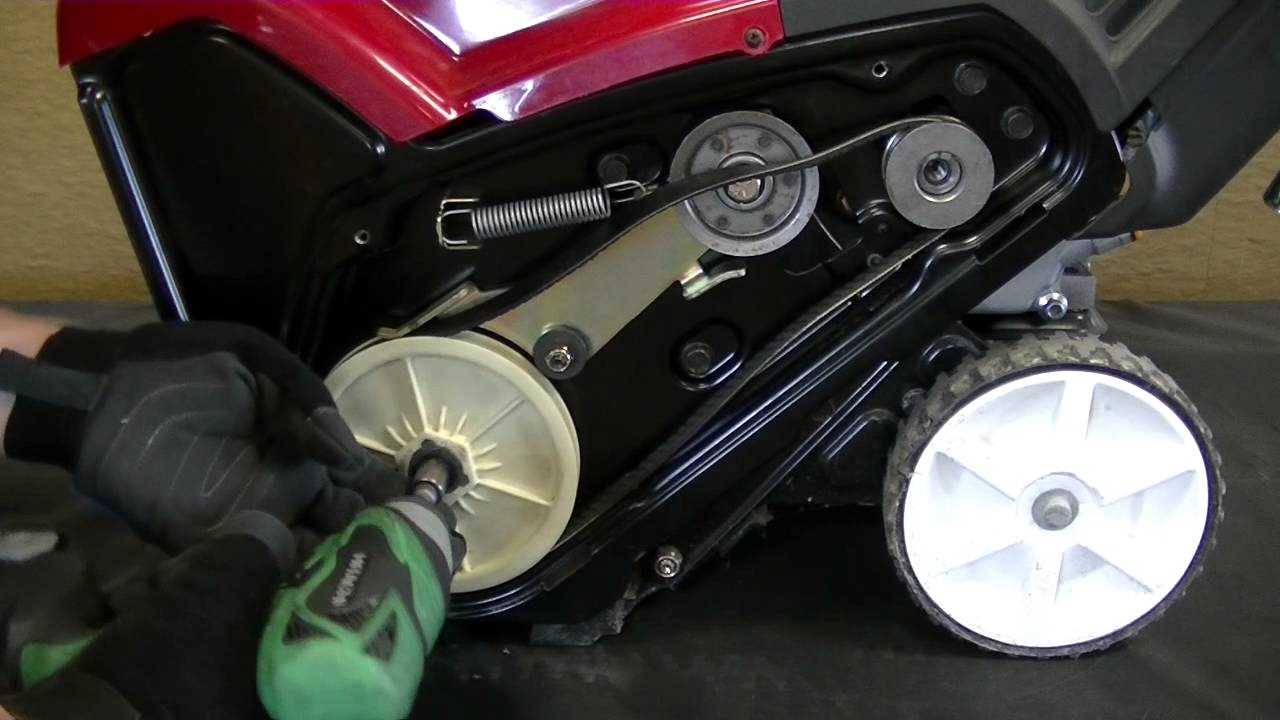

Gathering the Right Tools

Before diving into any repair task, it’s crucial to have the appropriate tools on hand. Basic equipment may include screwdrivers, wrenches, pliers, and specialized tools designed for specific components. Additionally, having a reliable repair manual or online resources can provide invaluable guidance and ensure you approach the task correctly.

Safety First

When undertaking any repair project, prioritize safety to prevent accidents. Always disconnect power sources before beginning work and wear protective gear such as gloves and goggles. Familiarize yourself with the equipment and follow safety protocols to create a secure working environment.