Jeep XJ Steering Components Overview

When it comes to enhancing vehicle control and maneuverability, several essential mechanisms work together to ensure a smooth and responsive driving experience. These interconnected elements are vital for the overall stability and handling of the car, playing a crucial role in both safety and performance. Each of these components has its own specific function, contributing to the precise operation of the entire system.

Exploring the different mechanisms that contribute to this area can help you gain a better understanding of how they affect the vehicle’s overall behavior. From maintaining balance during turns to ensuring effective control on various terrains, these elements are designed to provide a dependable and smooth ride.

Whether you are troubleshooting issues or upgrading your system, having a clear overview of these components and their roles is essential. Knowing how these parts interact will not only assist in solving potential problems but also in making informed decisions when it comes to repairs or enhancements.

Understanding the Jeep XJ Steering System

The operation of the front control mechanisms in off-road vehicles is a key element to ensure smooth and precise movement. These systems work in conjunction with various components to manage direction changes and overall stability, especially on challenging terrains. Proper function and balance between these elements are essential for safety and handling during travel.

Primary components responsible for direction control are interconnected and must work in unison to provide responsive handling. If any part of this system experiences wear or malfunction, it can lead to reduced maneuverability or even loss of control. Regular inspection and maintenance are vital to avoid such issues.

Understanding how the entire mechanism operates will help diagnose potential issues and maintain its efficiency. Knowledge of each key element is crucial for ensuring that everything works smoothly under various conditions, providing reliable performance on and off the road.

Main Components of the Steering Assembly

The system responsible for controlling the movement of the vehicle includes several key elements that work together to ensure precise direction and stability. Each component plays a vital role in maintaining control and safety during operation, ensuring that all adjustments to the wheels are accurately translated into movement.

Control Linkages connect the driver’s input to the front wheels, allowing for seamless direction changes. These mechanical connections ensure that movements are both smooth and responsive, contributing to overall maneuverability.

Turning Mechanism is essential for translating rotational input into linear movement, directly influencing the vehicle’s directional shifts. This mechanism ensures that even small adjustments result in precise turns.

Supporting Elements provide the necessary stability and strength to the entire control system, absorbing road shocks and ensuring smooth motion. These parts are crucial for durability and the longevity of the entire assembly.

Steering Gearbox and Its Functions

The gear mechanism responsible for the control of vehicle movement plays a crucial role in the overall handling and stability. Its primary task is to translate driver input into precise motion, ensuring smooth and responsive directional changes. The component manages various forces, directing them to other parts of the system to provide efficient control during operation.

Core Components of the Gear Mechanism

- Input Shaft: Transfers movement from the control device to the internal mechanism.

- Worm Gear: Converts rotational movement into linear force, crucial for the responsiveness of the system.

- Sector Shaft: Responsible for transmitting the converted force to other components, aiding in precise control.

Functions in Motion Control

The gear mechanism ensures that forces applied by the driver are balanced and distributed evenly, allowing for stability and accurate movement. It also minimizes the effort required to make adjustments while driving, enhancing both comfort and control. Proper functionality of this part is essential for maintaining safety and reliability during navigation.

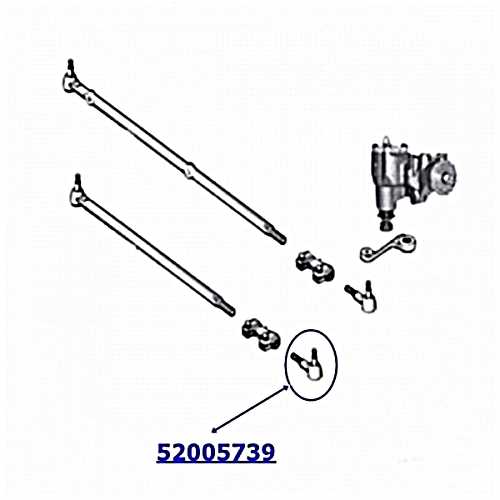

Linkages in the Steering Mechanism

In any vehicle, the system responsible for turning the wheels relies heavily on interconnected components. These linkages work together to transmit motion from the controls inside the vehicle to the front wheels. Their proper alignment and function are essential for accurate handling and stability.

The central role of these connecting elements is to ensure that the input from the driver’s movements results in smooth and responsive wheel movements. Each linkage, from the main rod to the smaller connectors, plays a specific role in converting force into directional control. Understanding how these parts interact is crucial for maintaining a balanced and efficient control system.

Role of the Pitman Arm in Steering

The Pitman arm plays a crucial role in converting rotational movement into lateral motion, ensuring proper response to driver input. It functions as a key intermediary in the linkage system, transmitting force from one component to another. Without its precise operation, control and maneuverability would be compromised.

One of its primary functions is to maintain synchronization between the control mechanism and the movement of the front wheels. This connection is essential for achieving smooth directional changes and enhancing the overall responsiveness of the vehicle. Its construction is designed to endure significant forces, ensuring durability and reliability.

Proper maintenance and inspection of the Pitman arm are essential to prevent wear that could lead to diminished handling. When operating efficiently, this component guarantees that the system responds effectively to adjustments, providing a more predictable driving experience.

Steering Knuckles: Structure and Importance

The knuckles play a crucial role in the functionality of a vehicle’s front suspension and handling. Their design is essential for maintaining proper alignment and ensuring smooth navigation. Understanding their structure and significance is vital for any automotive enthusiast or technician.

These components are primarily responsible for connecting the suspension system to the wheels. They serve as pivot points for the wheel assembly, allowing for controlled movement while supporting the weight of the vehicle. Here are some key aspects of their structure:

- Material Composition: Typically crafted from durable metals such as cast iron or forged steel, ensuring strength and resilience.

- Design Features: Often designed with specific geometries to facilitate optimal articulation and minimize wear.

- Attachment Points: Include multiple mounting locations for tie rods and shock absorbers, contributing to overall stability.

The importance of these components cannot be overstated. They directly influence handling characteristics and the overall driving experience. Here are some key reasons why their functionality is critical:

- Alignment: Properly functioning knuckles help maintain correct wheel alignment, reducing tire wear.

- Safety: They play a significant role in vehicle control, especially during cornering and emergency maneuvers.

- Durability: High-quality knuckles contribute to the longevity of the suspension system, minimizing the need for frequent repairs.

Common Steering Issues and Their Causes

Vehicle handling can be compromised by various complications, leading to discomfort and safety concerns for the driver. Understanding these common problems and their underlying factors is essential for maintaining optimal control and ensuring a smooth ride.

Typical Problems Encountered

- Difficulty in Turning: This may arise from worn-out components or inadequate lubrication.

- Unusual Noises: Grinding, squeaking, or clunking sounds can indicate loose connections or damaged elements.

- Excessive Vibration: Shaking in the wheel can be a sign of misalignment or unbalanced wheels.

Root Causes of Complications

- Worn Out Components: Over time, the constant stress on the system leads to deterioration, necessitating replacement.

- Poor Maintenance: Lack of regular inspections can result in unnoticed issues escalating into major failures.

- Improper Installation: Components that are not fitted correctly can lead to premature wear and performance issues.

Power Steering Pump Overview

The hydraulic pump is a vital component in modern vehicles, responsible for providing the necessary fluid pressure to facilitate effortless maneuvering. This mechanism enhances the overall driving experience by reducing the effort required to control the vehicle, particularly at low speeds or during sharp turns.

Understanding the function and importance of this device can help vehicle owners maintain optimal performance. Here are some key aspects to consider:

- Functionality: The primary role of the hydraulic pump is to circulate fluid throughout the system, creating pressure that assists in the movement of the steering mechanism.

- Types: There are various types of pumps available, including vane, gear, and piston pumps, each designed for specific applications and efficiency levels.

- Maintenance: Regular checks and maintenance are essential to prevent leaks and ensure the system operates smoothly, including monitoring fluid levels and replacing worn components.

- Signs of Failure: Unusual noises, difficulty in turning, and fluid leaks are common indicators that the pump may require attention or replacement.

In conclusion, the hydraulic pump plays a crucial role in enhancing maneuverability, contributing significantly to a vehicle’s overall performance and safety. Regular maintenance and timely repairs can ensure its longevity and reliability.

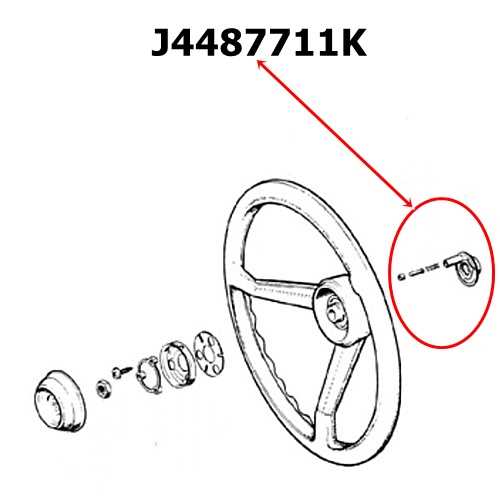

How to Replace Steering Components

Maintaining optimal maneuverability is essential for any vehicle, and replacing worn or damaged elements is a crucial aspect of that process. This section will guide you through the necessary steps to effectively swap out critical components that contribute to your vehicle’s directional control.

Preparation and Tools

Before you start, ensure you have the right tools at hand, including a socket set, wrenches, and a jack with jack stands. Safety should be your top priority, so always wear protective gear and work on a stable surface.

Step-by-Step Replacement

Begin by lifting the vehicle with the jack and securing it with stands. Remove the relevant components carefully, taking note of how they are connected. It’s helpful to take photos during disassembly for reference. Once everything is removed, install the new components by following the reverse order of removal. Ensure all connections are tight, and check for any misalignments before lowering the vehicle back down.

Finally, test the vehicle in a safe area to confirm that everything operates smoothly and as expected.

Upgrading the Jeep XJ Steering System

Enhancing the directional control and response of your vehicle is a worthwhile endeavor for off-road enthusiasts and everyday drivers alike. By improving this crucial system, you can significantly elevate your driving experience, making it more enjoyable and safer. There are various strategies to consider when approaching this upgrade.

- Evaluate Current Components: Begin by assessing the existing system’s condition. Look for any signs of wear or damage that could affect performance.

- Choose Quality Aftermarket Alternatives: Investing in high-quality replacement components can provide better durability and functionality compared to factory options.

- Consider Upgraded Linkage: A robust linkage can enhance responsiveness, ensuring precise handling in various terrains.

- Enhance Fluid Management: Upgrading fluid systems can lead to improved responsiveness and overall performance.

- Alignment and Calibration: After making modifications, ensure that alignment and calibration are performed to maintain optimal handling and tire wear.

By following these recommendations, you can achieve a more robust and responsive system, allowing for a smoother and more controlled driving experience.

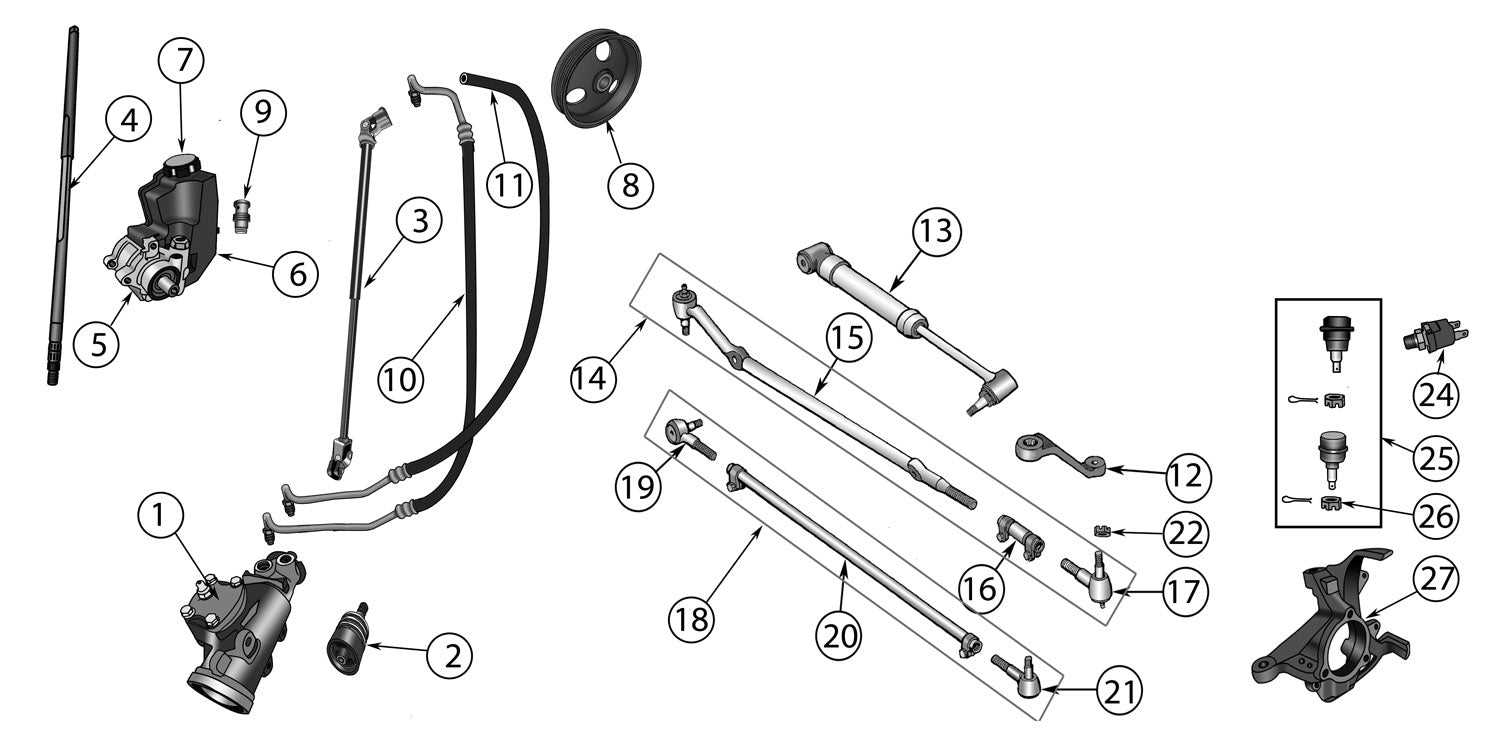

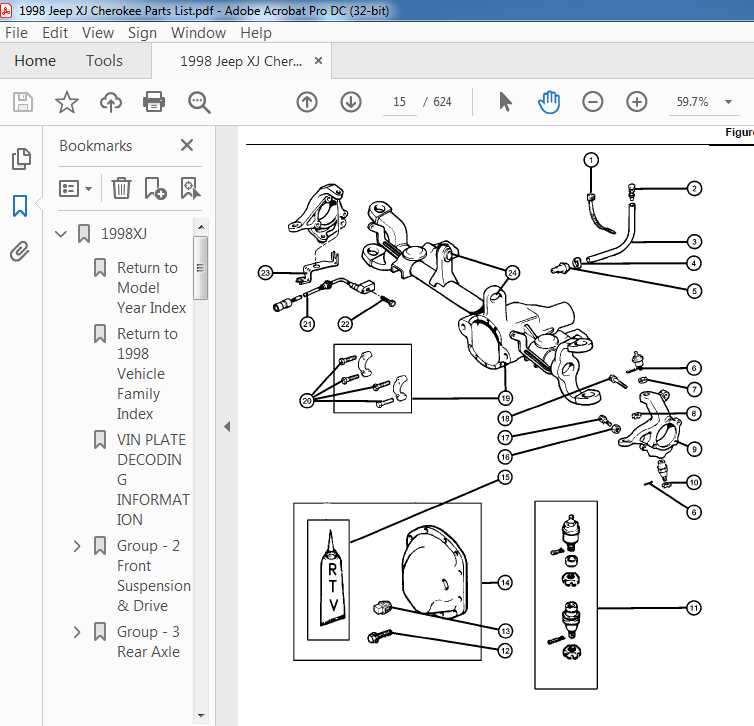

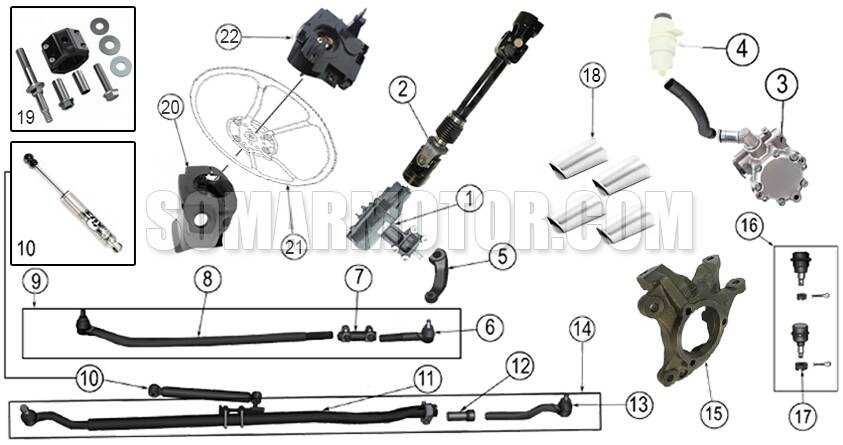

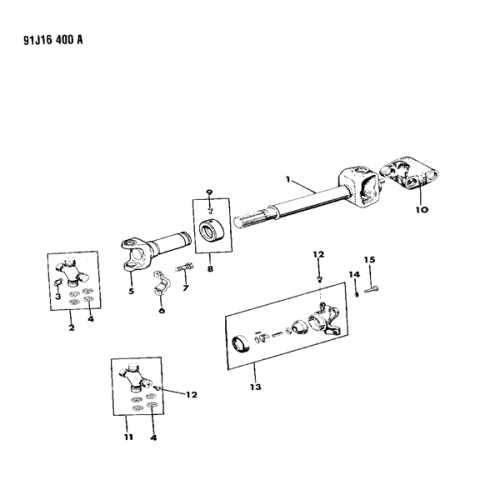

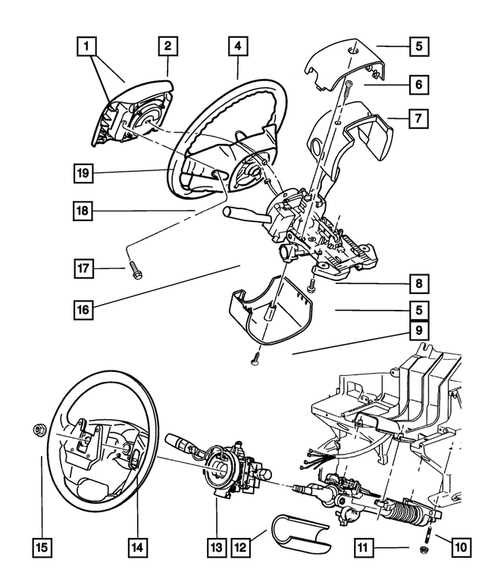

Steering Diagram for Repair Reference

This section provides a visual representation crucial for understanding the components involved in the directional control mechanism of the vehicle. Having a clear illustration can significantly aid in maintenance and troubleshooting efforts.

Below are key elements that should be considered when referencing the visual layout:

- Connection Points: Identify where various components link to ensure proper assembly and function.

- Component Identification: Recognize each element’s role, aiding in quick diagnosis and replacement if necessary.

- Adjustment Areas: Mark specific locations for tuning and calibration to enhance performance.

Utilizing a comprehensive representation allows for efficient repairs, ultimately leading to improved handling and safety on the road.