Understanding the Seastar Steering Parts Diagram

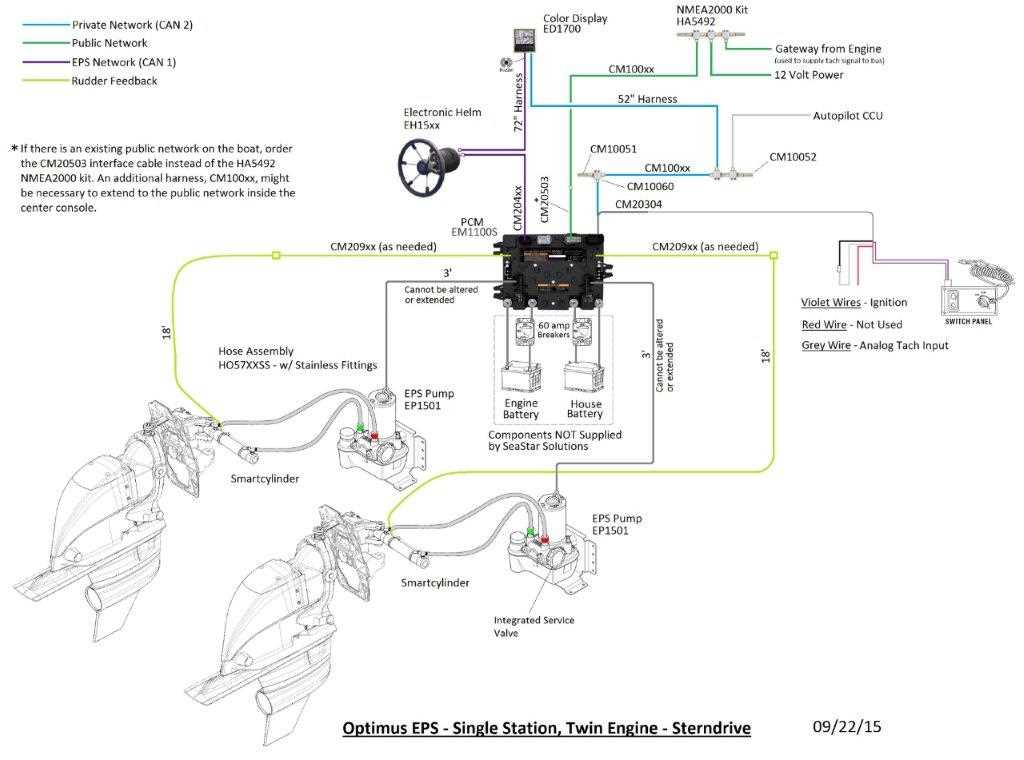

The intricate design of marine control systems plays a vital role in ensuring smooth navigation and maneuverability. A clear comprehension of how various components interact allows for optimal performance and enhances the overall experience on the water. This section delves into the essential elements that contribute to effective steering mechanisms in aquatic vessels.

Visual aids serve as invaluable tools for both professionals and enthusiasts, providing clarity on the relationships between different components. By examining a detailed representation, one can better grasp the functionality and layout of these crucial systems. Understanding these relationships is key to maintenance and troubleshooting, ensuring a safe and enjoyable journey on the high seas.

Additionally, familiarizing oneself with the construction and operation of these systems empowers users to make informed decisions regarding upgrades and repairs. Whether for personal use or commercial applications, knowledge in this area significantly enhances one’s ability to manage marine technology effectively. Embracing this understanding will undoubtedly contribute to safer and more efficient navigation.

Understanding Seastar Steering Systems

This section explores the intricacies of marine control mechanisms, focusing on their functionality and essential components. A reliable system ensures optimal navigation and maneuverability, which are crucial for any vessel’s performance.

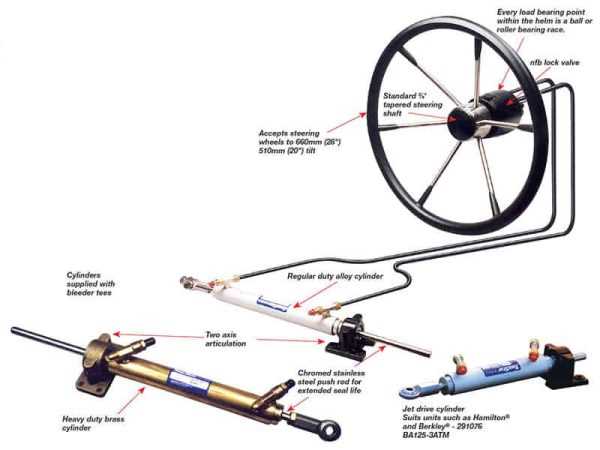

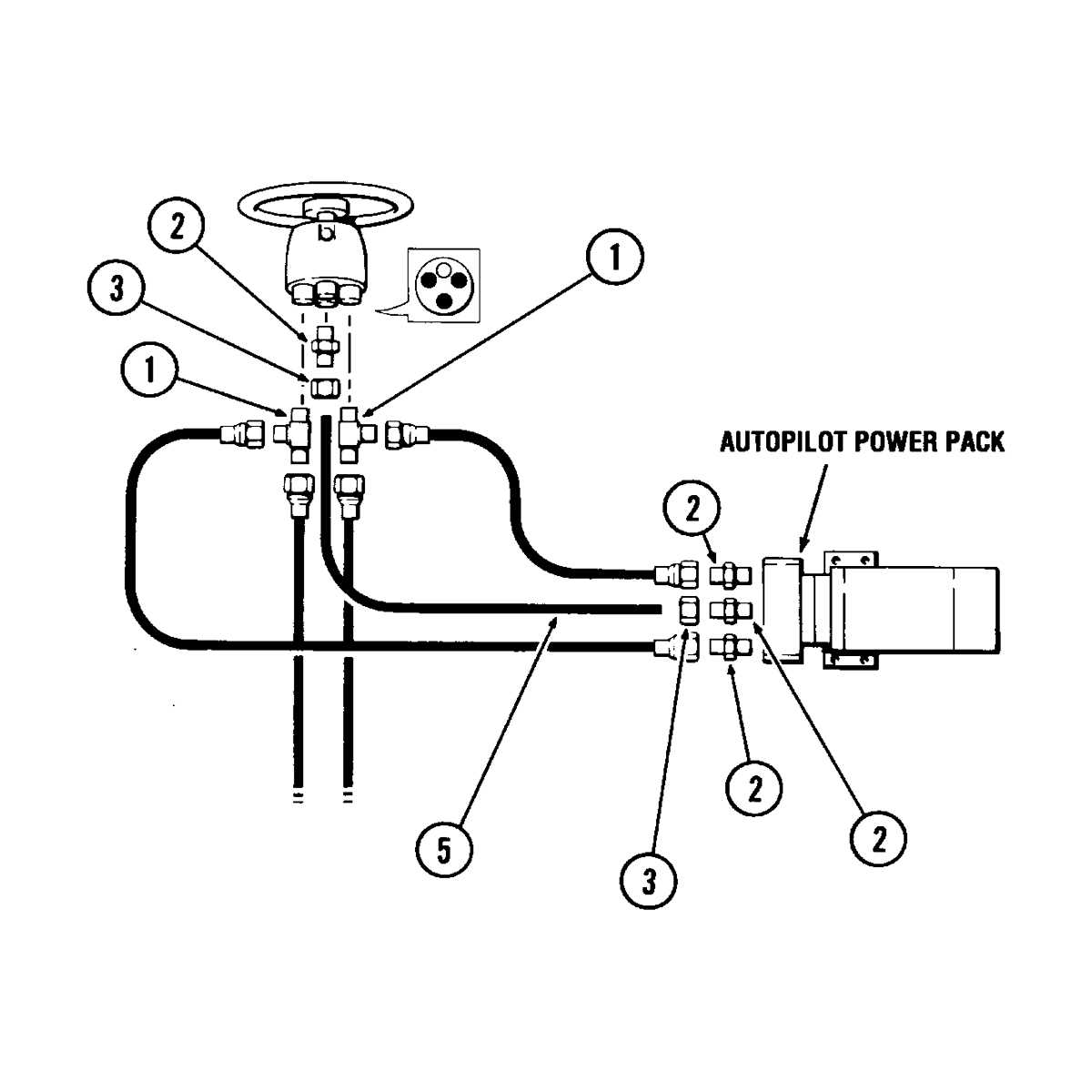

Key Components

- Hydraulic Cylinders

- Control Wheel

- Fluid Reservoir

- Hoses and Fittings

Functionality Overview

The core operation involves transferring force from the control device to the steering apparatus through fluid dynamics. This process allows for precise adjustments, enhancing the overall experience on the water.

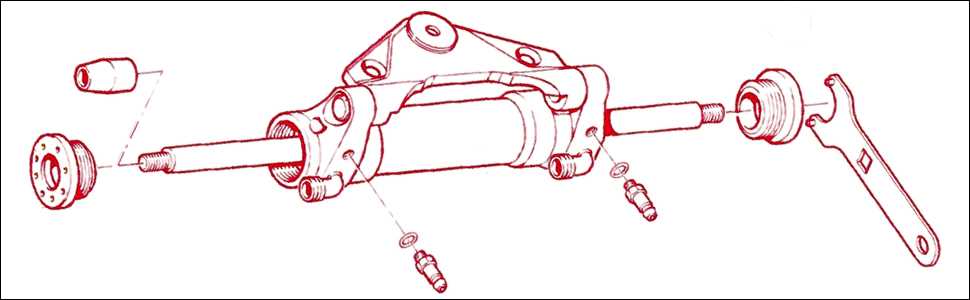

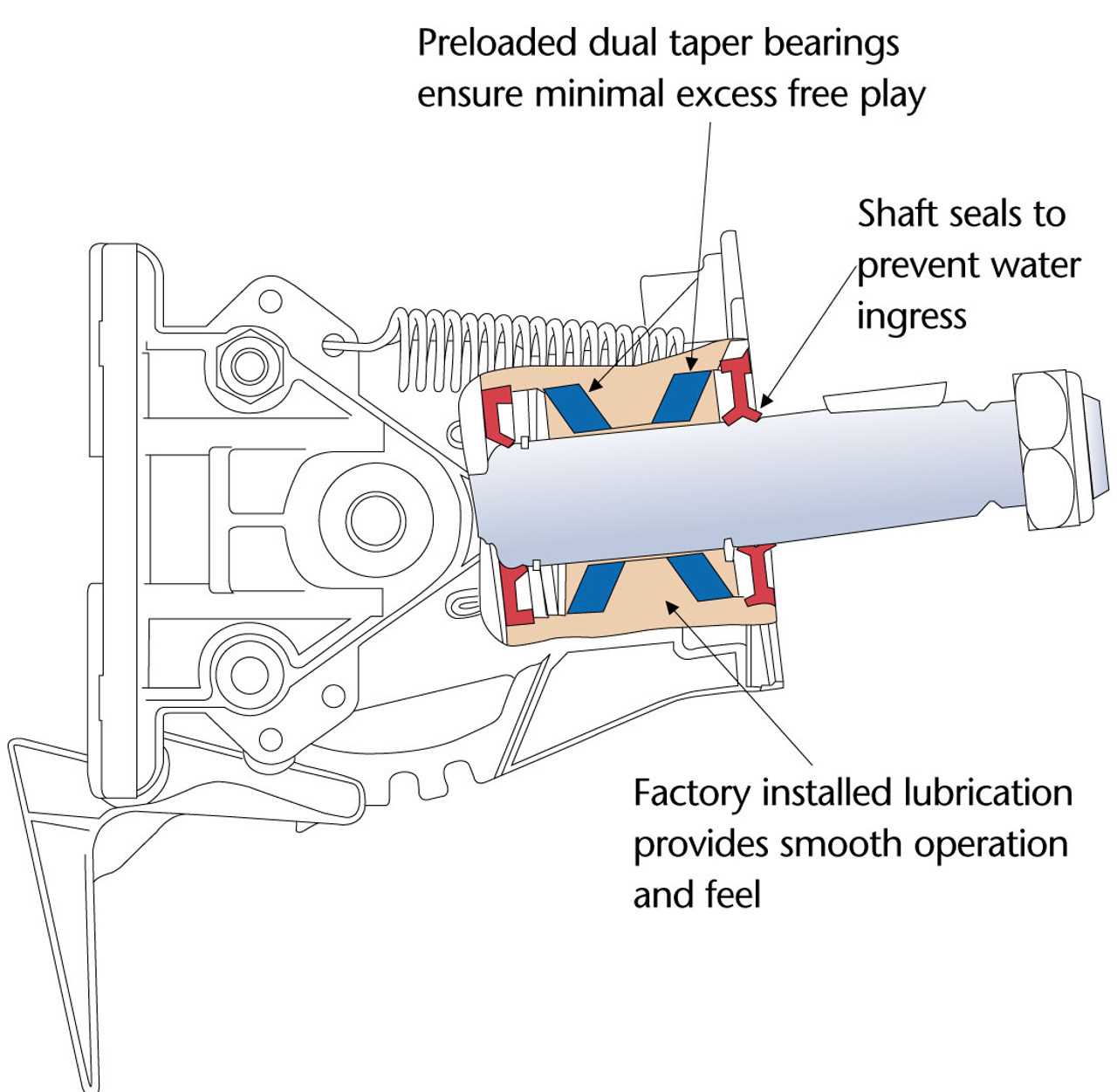

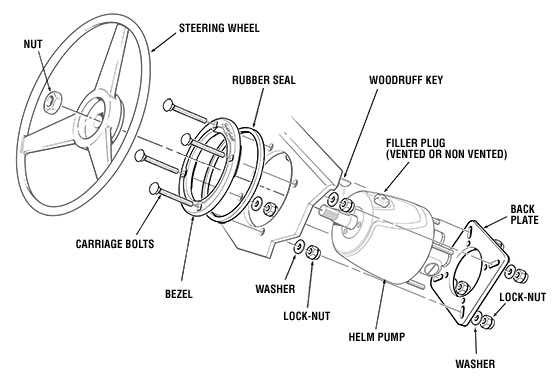

Components of Seastar Steering Mechanism

The functionality of a marine control system relies on several critical elements that work together to provide smooth navigation and maneuverability. Understanding these components is essential for effective maintenance and performance optimization.

Key Elements

- Helm Unit: This is the central interface where the operator exerts force to direct the vessel.

- Cable System: Flexible conduits that transmit input from the helm to the steering gear.

- Steering Gear: Converts rotational movement from the helm into directional movement of the rudder.

- Rudder: The primary device that alters the course of the vessel when turned.

- Support Bracket: Provides structural stability and mounting for the steering mechanism.

Additional Components

- Backlash Adjuster: Helps minimize play in the system, ensuring precise control.

- Hydraulic Fluid: Essential for systems utilizing hydraulic power to enhance steering effectiveness.

- Mounting Hardware: Includes bolts and screws that secure all components together.

Each of these elements plays a vital role in the overall efficiency and reliability of the control system, contributing to a safer and more enjoyable maritime experience.

Importance of Accurate Steering Diagrams

Precision in technical illustrations is essential for ensuring effective operation and safety in various systems. Clear and detailed visuals facilitate understanding of complex mechanisms, allowing users to navigate and maintain their equipment with confidence. When individuals can easily interpret these visuals, they are better equipped to perform necessary tasks and prevent potential issues.

Moreover, well-constructed representations serve as valuable references during installation and troubleshooting. Accurate illustrations help identify components and their relationships, minimizing the risk of errors. This attention to detail not only enhances efficiency but also contributes to the longevity of the equipment by ensuring that all elements function harmoniously.

In addition, the clarity of these visuals fosters improved communication among technicians and engineers. When all parties have access to precise illustrations, collaboration becomes more effective, leading to quicker resolutions and innovations. Ultimately, investing in high-quality representations is crucial for both operational success and overall user satisfaction.

How to Read Steering Diagrams

Understanding the layout of control mechanisms is essential for effective maintenance and operation. These visuals serve as maps, guiding you through the components and their connections. By familiarizing yourself with the symbols and notations, you can ensure optimal functionality and troubleshoot any issues that may arise.

Start by identifying the key elements: Look for the main components represented by specific shapes. Each symbol usually corresponds to a particular item, making it easier to locate them in your setup. Familiarity with these symbols will enhance your comprehension.

Next, examine the connections: Arrows or lines indicate how each component interacts with others. Understanding these relationships helps in grasping the flow of control and diagnosing problems efficiently.

Finally, pay attention to notes: Additional annotations often provide crucial information regarding measurements or specifications. These details can be vital for ensuring proper installation and functionality, allowing you to delve deeper into your system’s workings.

Common Issues with Steering Parts

When navigating the complexities of marine control systems, various challenges can arise that affect performance and safety. These complications may stem from wear and tear, environmental factors, or improper maintenance. Understanding these common pitfalls is essential for ensuring smooth operation and preventing potential hazards on the water.

One prevalent issue is corrosion, which can significantly weaken components exposed to saltwater. This degradation often leads to decreased responsiveness and may require costly replacements. Regular inspections and protective coatings can mitigate this risk.

Another concern is misalignment, which can occur due to improper installation or physical impacts. This misalignment may result in a sluggish response and difficulty in maneuvering, necessitating adjustments to restore proper function.

Additionally, leaks in hydraulic systems can compromise control and lead to dangerous situations. Identifying and addressing leaks promptly is crucial to maintaining system integrity and ensuring reliable operation.

Lastly, wear on cables and linkages can create slack, impacting the overall feel and precision of the system. Routine maintenance and timely replacements are vital to preserving the responsiveness expected during navigation.

Maintenance Tips for Seastar Systems

Proper upkeep of your steering mechanism is crucial for ensuring safety and performance on the water. Regular maintenance not only prolongs the life of the system but also enhances responsiveness and reliability during navigation. Here are essential tips to keep in mind.

- Regular Inspection: Check all components frequently for signs of wear and tear. Look for corrosion, leaks, or any loose connections.

- Fluid Levels: Ensure that hydraulic fluids are at the recommended levels. Top up if necessary, and replace fluids according to the manufacturer’s schedule.

- Cleaning: Keep the system clean from debris, dirt, and salt buildup. Use fresh water to rinse off any contaminants, especially after use in saltwater environments.

- Lubrication: Apply appropriate lubricants to moving parts to minimize friction and wear. Follow the guidelines provided in the user manual.

- Alignment Checks: Regularly check the alignment of the mechanism. Misalignment can lead to uneven wear and can compromise performance.

- Professional Servicing: Schedule professional inspections at least once a year to ensure all aspects of the system are functioning correctly.

By following these guidelines, you can maintain the efficiency and reliability of your steering system, ensuring a safe and enjoyable experience on the water.

Upgrading Your Steering Components

Enhancing the control mechanisms of your vessel can significantly improve performance and maneuverability. By investing in modern technology and materials, you can achieve smoother handling and increased responsiveness, making your outings more enjoyable and safe.

Benefits of Modernization

Updating your control system can provide numerous advantages. Improved precision and durability are often achieved through contemporary designs, which utilize advanced materials that resist wear and corrosion. Furthermore, many upgraded systems offer enhanced ergonomics, allowing for a more comfortable operation during extended periods.

Choosing the Right Components

When selecting new components, it is essential to consider compatibility with your existing setup. Research various brands and models, and consult with experts to determine which options best suit your specific needs. Investing time in proper selection can lead to significant long-term benefits, enhancing both performance and safety on the water.

Tools Needed for Steering Repairs

Effective maintenance of marine control systems requires specific implements to ensure precision and safety. Having the right equipment on hand can make the process smoother and more efficient.

- Wrenches: Essential for loosening and tightening various fittings.

- Screwdrivers: Needed for adjustments and securing components.

- Pliers: Useful for gripping and manipulating small parts.

- Torque wrench: Ensures that all connections are tightened to the manufacturer’s specifications.

- Grease gun: Important for lubrication, enhancing performance and longevity.

- Measuring tape: Helps in ensuring proper alignment and spacing.

- Safety goggles: Protects eyes during repair work.

Having these tools readily available can significantly improve the repair process, leading to optimal functionality and reliability.

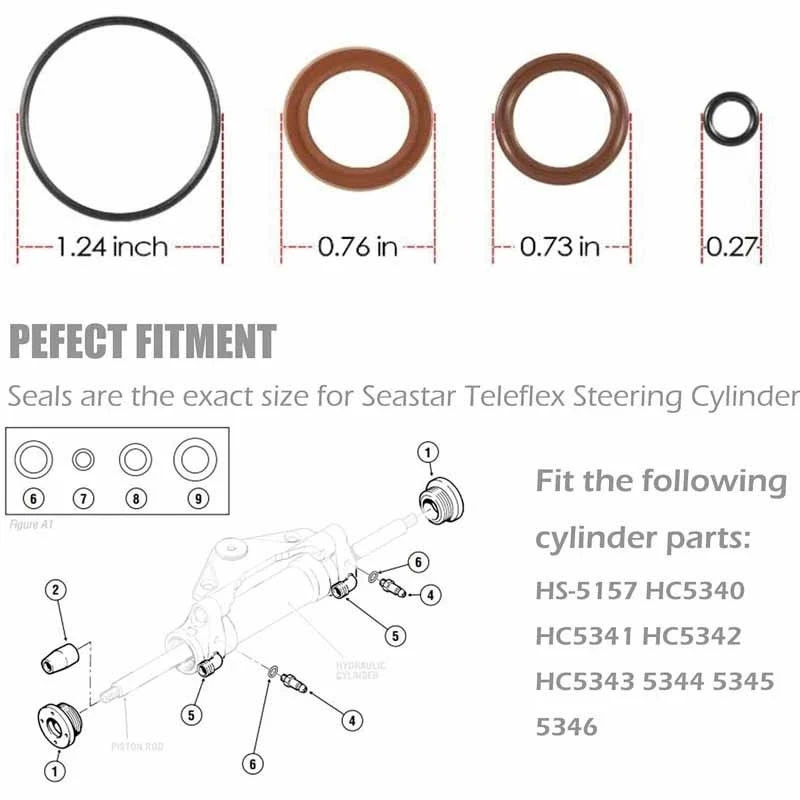

Identifying Parts in Steering Diagrams

Understanding the components involved in navigational systems is crucial for effective maintenance and troubleshooting. By recognizing various elements and their functions, one can ensure optimal performance and address issues promptly. This section will provide insights into the different elements commonly found in schematics related to control mechanisms.

Common Components and Their Functions

Each item depicted in these illustrations plays a significant role in the overall functionality. Familiarity with these components aids in identifying wear and tear, ensuring timely replacements, and enhancing user experience.

| Component | Description |

|---|---|

| Wheel | The main interface for manual control, allowing the operator to direct movement. |

| Rod | Connects the wheel to the mechanism, transmitting force for directional change. |

| Pulley | Facilitates smooth movement through the use of cables, reducing friction. |

| Lever | Acts as a control device, often providing mechanical advantage for ease of operation. |

| Joint | Allows for flexible movement between components, accommodating various angles. |

Tips for Effective Identification

To accurately recognize these elements, it is beneficial to reference comprehensive illustrations and consult manuals. Additionally, hands-on experience with the system enhances one’s ability to identify and understand each component’s role within the whole structure.

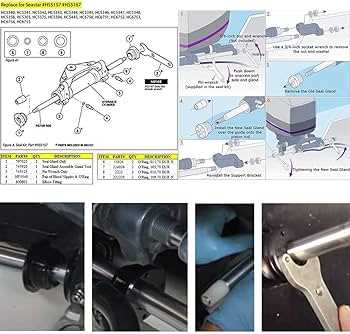

Typical Installation Procedures Explained

This section provides a comprehensive overview of standard methods for implementing essential components in marine vessels. Understanding these procedures ensures optimal performance and safety during operation.

Preparation Steps

- Gather all necessary tools and components.

- Review the manufacturer’s instructions carefully.

- Inspect the installation area for any potential issues.

Installation Process

- Secure the unit in the designated location.

- Connect the necessary lines and fittings, ensuring tight seals.

- Adjust alignment as required for smooth functionality.

- Test the setup before finalizing to confirm proper operation.

Following these steps will help achieve a reliable installation that enhances the overall efficiency of the vessel.

Benefits of Proper Steering Alignment

Achieving optimal directional control is crucial for any vehicle, ensuring a smooth and safe ride. When the components are aligned accurately, it leads to enhanced performance, increased safety, and prolonged lifespan of the system.

Enhanced Handling and Safety

Correct alignment contributes significantly to vehicle handling, allowing for precise maneuverability. This minimizes the risk of accidents, as drivers can maintain better control, especially in challenging conditions.

Cost Efficiency and Longevity

Maintaining proper alignment not only improves performance but also reduces wear and tear on tires and other critical components. This leads to lower maintenance costs and ultimately extends the lifespan of the vehicle. Investing in alignment is investing in longevity.

Safety Considerations for Steering Systems

Ensuring optimal functionality in navigational mechanisms is crucial for both performance and safety. Various factors must be taken into account to minimize risks associated with mechanical failure or user error. Regular maintenance and adherence to manufacturer guidelines play a significant role in preventing accidents.

Regular Inspections: Routine checks of the system components help identify wear and tear before they lead to malfunctions. Look for signs of corrosion, leaks, or loose connections.

Proper Installation: Following installation instructions precisely is essential. Incorrect assembly can compromise the entire system’s integrity, leading to potential hazards.

Understanding Limitations: Every mechanism has its limitations, including weight capacity and operational range. Familiarizing oneself with these factors is vital for safe navigation.

Training and Education: Proper training for users enhances safety by ensuring that all operators are aware of best practices and emergency procedures. Knowledge is the ultimate tool in preventing incidents.

Environmental Awareness: Navigating in adverse weather conditions or challenging environments requires additional caution. Adapting strategies to current conditions can prevent dangerous situations.

Resources for Seastar Parts and Diagrams

This section aims to provide valuable information and resources for individuals seeking components and schematics for marine control systems. Understanding where to find accurate and detailed resources is essential for maintenance and upgrades, ensuring optimal performance on the water.

Online Retailers

Numerous online platforms specialize in marine accessories, offering a wide array of components and illustrations. Websites such as MarinePartSource.com and BoatParts.com are excellent starting points, as they provide detailed catalogs and user-friendly search functions to help locate specific items quickly.

Manufacturer Resources

Accessing official websites of manufacturers can yield comprehensive resources, including technical manuals and installation guides. These documents often contain detailed schematics and part numbers, making it easier to ensure compatibility. It’s advisable to explore sections dedicated to support and documentation on these sites.

Additionally, forums and community groups can be invaluable for gathering insights and recommendations from experienced users. Engaging with fellow enthusiasts may uncover alternative resources and practical tips for sourcing and maintaining these essential components.