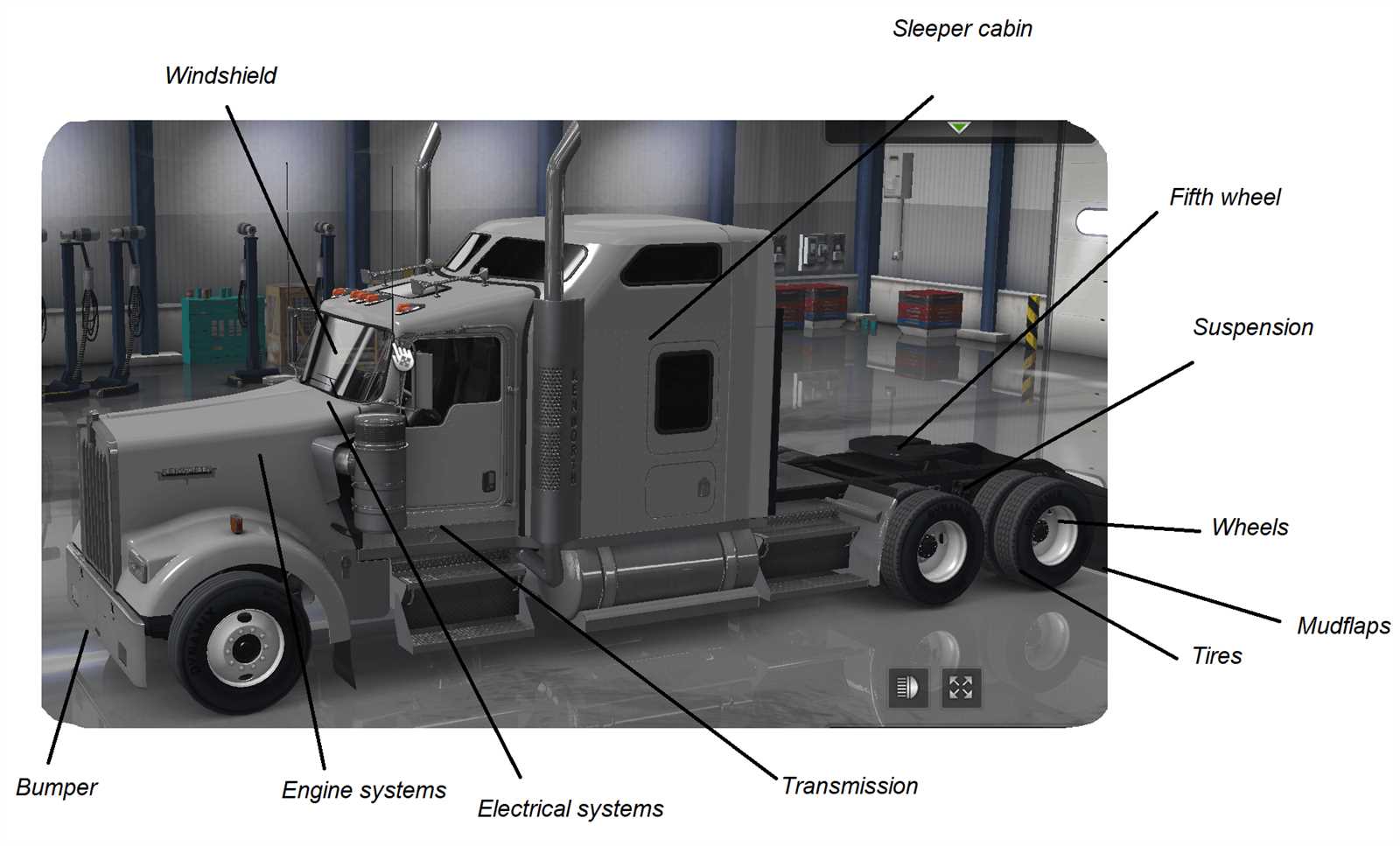

Understanding the Diagram of Semi Truck Steering Parts

The intricate mechanisms behind large vehicles are essential for their effective operation. Grasping how these systems function can enhance safety and performance on the road. The various components work together seamlessly, ensuring precise control and maneuverability, even under challenging conditions.

In this discussion, we will delve into the specifics of the control mechanisms that allow these vehicles to navigate effectively. Each element plays a vital role in translating driver inputs into movement, contributing to the overall stability and responsiveness of the machine.

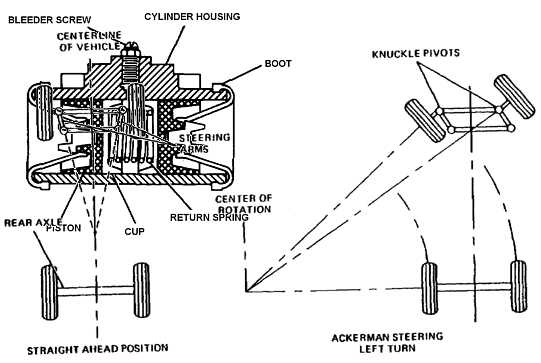

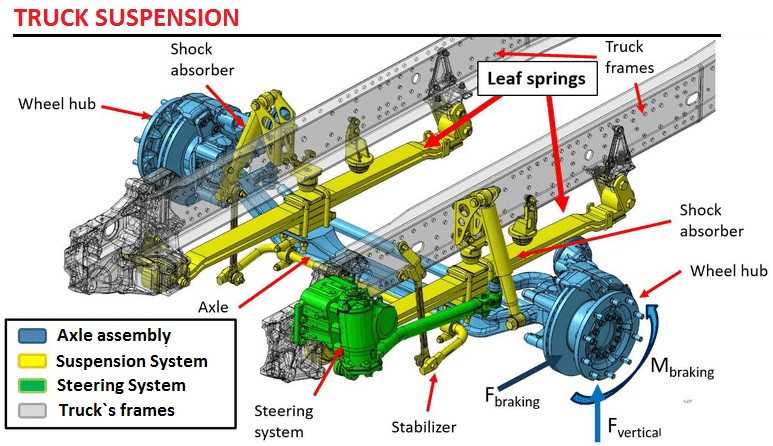

Visual representations of these systems can provide valuable insights into their design and functionality. By examining the arrangement and interaction of each component, one can better appreciate the complexity and engineering prowess involved in crafting these formidable vehicles.

Semi Truck Steering Components Overview

This section provides an insightful look into the various elements that facilitate the navigation and control of large vehicles. Understanding these components is crucial for ensuring optimal performance and safety during operation. Each element plays a significant role in the overall functionality, contributing to a smooth and reliable driving experience.

Key Elements of the Control System

The control mechanism comprises several vital components, including the wheel assembly, linkages, and various hydraulic systems. Each of these parts interacts seamlessly to translate the driver’s input into precise movements of the vehicle. Proper maintenance and timely replacements are essential to prevent malfunctions that could lead to hazardous situations.

Maintenance Considerations

Understanding Steering Mechanisms in Trucks

The intricate systems that enable large vehicles to navigate effectively are crucial for safety and performance. These mechanisms consist of various components working together to provide drivers with control and precision, ensuring smooth maneuverability even under challenging conditions.

Key Components of the Steering System

- Wheel Assembly: The connection between the driver and the vehicle, allowing for direction changes.

- Linkage: A series of rods and joints that transmit movement from the driver to the wheels.

- Gearbox: Converts the rotational motion of the wheel into lateral movement, enhancing responsiveness.

- Power Assist: Hydraulic or electric systems that ease the effort required to turn the wheel.

Types of Steering Mechanisms

- Rack and Pinion: Offers precise control and feedback, commonly used in various vehicle types.

- Recirculating Ball: Provides a more robust system suitable for heavier vehicles.

- Virtual Steering: Integrates electronic controls for improved handling and adaptability.

Understanding these components and their functions is essential for maintenance and enhancement of overall vehicle efficiency. Regular inspections and awareness of potential issues can greatly contribute to safety and longevity.

Key Parts of a Steering System

Understanding the essential components that contribute to vehicle maneuverability is crucial for any automotive enthusiast or professional. Each element plays a significant role in ensuring smooth navigation and responsiveness on the road.

1. Rack and Pinion: This mechanism converts rotational motion into linear motion, allowing the wheels to pivot effectively. It is known for its efficiency and compact design, making it a popular choice in modern vehicles.

2. Linkage System: Comprising rods and joints, this assembly connects the control wheel to the wheels themselves. It translates the driver’s inputs into precise movements, ensuring accurate control.

3. Pitman Arm: This lever connects the gearbox to the linkage, playing a vital role in transmitting motion. Its durability and strength are essential for maintaining performance under various conditions.

4. Idler Arm: Working in conjunction with the pitman arm, this component helps stabilize the linkage system, providing support and reducing play during operation.

5. Steering Column: This vertical shaft houses various mechanisms that facilitate driver control, incorporating safety features and adjustments to enhance comfort and accessibility.

Each of these components is designed to work harmoniously, contributing to the overall effectiveness and safety of vehicle navigation. Understanding their functions can aid in better maintenance and troubleshooting of any issues that may arise.

Function of the Steering Wheel

The control mechanism of a vehicle plays a crucial role in guiding its movement and ensuring safe navigation. This component enables the operator to manipulate direction, providing both responsiveness and stability while on the road. Understanding its function is essential for effective vehicle operation and maintenance.

At its core, this control device allows for the transmission of the operator’s intentions to the vehicle’s directional system. It serves as the primary interface between the driver and the machine, facilitating precise movements and adjustments. Here are some key functions:

| Function | Description |

|---|---|

| Directional Control | Enables the operator to guide the vehicle in various directions, adjusting to road conditions. |

| Feedback Mechanism | Provides tactile feedback, allowing the driver to feel the road and make informed decisions. |

| Stability Maintenance | Helps maintain the balance of the vehicle during turns and maneuvers, enhancing safety. |

| Integration with Other Systems | Works in conjunction with other components like suspension and braking systems for optimal performance. |

Overall, the functionality of this control device is vital for ensuring a seamless driving experience, contributing to both vehicle handling and safety on the road.

Role of the Steering Column

The column is a crucial component in a vehicle’s control system, providing the connection between the operator and the mechanism that directs movement. It serves not only as a support structure but also plays an essential role in ensuring that commands are effectively transmitted to the vehicle’s guiding apparatus.

Through its design, the column enhances driver comfort and accessibility, allowing for adjustments that cater to individual preferences. Its integration with other systems further amplifies its significance, contributing to both safety and performance.

| Function | Description |

|---|---|

| Control Transmission | Facilitates the transfer of the operator’s input to the control mechanisms. |

| Driver Comfort | Allows for adjustments in position and angle to accommodate different drivers. |

| Safety Features | Incorporates mechanisms that enhance overall safety during operation. |

| Integration | Works in conjunction with other vehicle systems for improved functionality. |

Importance of Pitman Arm

The Pitman arm plays a crucial role in the overall functionality and performance of a vehicle’s directional control system. Its primary function involves translating rotational movement from the steering column into linear motion, enabling precise handling and maneuverability. This component acts as a vital link between various elements, ensuring smooth and responsive adjustments while navigating different terrains.

Durability is one of the key attributes of the Pitman arm. Given its exposure to constant stress and dynamic forces, a robust construction is essential to withstand wear and tear. Regular inspections can help identify potential issues before they escalate, thereby maintaining vehicle safety and reliability.

Furthermore, an efficient Pitman arm contributes significantly to the overall driving experience. It not only enhances stability but also minimizes the effort required to steer, providing a more comfortable journey for the driver. In essence, the effectiveness of this component directly impacts the vehicle’s handling characteristics, making it a fundamental aspect of automotive design.

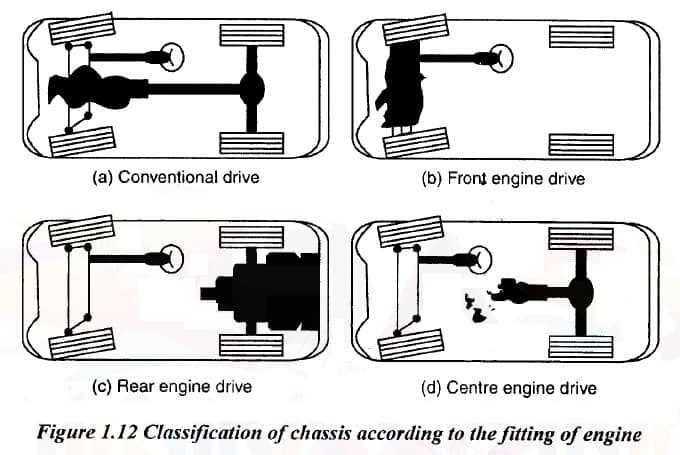

How the Gearbox Works

The gearbox is a crucial component that facilitates the transfer of rotational motion and force within a vehicle’s control system. It transforms the input from the steering mechanism, allowing for precise maneuverability and responsiveness. Understanding its function is essential for comprehending the overall dynamics of vehicle navigation.

The design of the gearbox often includes various types of gears, such as spur, helical, or bevel gears, each chosen for their specific advantages in durability and performance. The arrangement and interaction of these gears determine how effectively the motion is translated, impacting the overall feel and handling of the vehicle.

Additionally, lubrication plays a vital role in the gearbox’s operation. Proper fluid levels and quality ensure smooth gear engagement and reduce wear, prolonging the lifespan of this essential assembly. Regular maintenance is key to keeping the gearbox functioning optimally, thus ensuring safe and reliable navigation.

Significance of Drag Link Assembly

The drag link assembly plays a crucial role in the overall functionality and safety of heavy-duty vehicles. This component serves as an essential connector, facilitating the transfer of movement and force between various elements of the control mechanism. Understanding its significance allows for better maintenance practices and enhances the reliability of the vehicle’s maneuverability.

Functionality and Performance

The primary function of the drag link assembly is to ensure that the driver’s input is accurately translated into directional movement. This connection allows for precise handling and control, essential for navigating various terrains and road conditions. A well-functioning drag link assembly contributes to improved performance, stability, and safety during operation.

Maintenance Considerations

| Maintenance Check | Frequency | Notes |

|---|---|---|

| Visual Inspection | Every 5,000 miles | Look for signs of wear or damage. |

| Lubrication | Every 10,000 miles | Ensure all moving parts are adequately lubricated. |

| Alignment Check | Every 15,000 miles | Verify proper alignment for optimal handling. |

Impact of Tie Rods on Steering

Components responsible for connecting the wheels to the control system play a crucial role in maneuverability and overall vehicle handling. Their functionality directly influences the driver’s ability to navigate and maintain stability on the road.

Role of Tie Rods in Vehicle Control

These crucial elements serve multiple purposes that enhance performance:

- Provide structural support, ensuring alignment between the wheels and the control mechanism.

- Facilitate precise movement, translating the driver’s inputs into effective wheel rotation.

- Absorb shocks and vibrations, contributing to a smoother ride experience.

Consequences of Worn Tie Rods

Neglecting the condition of these components can lead to significant issues:

- Increased wear on tires due to misalignment.

- Compromised handling, resulting in decreased safety during maneuvers.

- Heightened risk of complete failure, potentially leading to loss of control.

Regular maintenance and timely replacement of these connections are essential for ensuring reliable operation and enhancing overall performance on the road.

Identifying the Steering Knuckles

Understanding the components that facilitate vehicle maneuverability is crucial for effective maintenance and repair. Among these elements, the knuckles play a pivotal role in connecting various mechanisms that allow for smooth directional control.

These components can be recognized by their distinctive characteristics and functions:

- Location: Typically situated at the intersection of the suspension and wheel assembly, they act as a pivotal point.

- Shape: Often resembling a fork or L-shape, they provide a strong connection while allowing for rotation.

- Material: Generally crafted from durable metals, they must withstand significant stress and strain during operation.

When inspecting these components, consider the following steps:

- Check for any signs of wear or damage, such as cracks or deformation.

- Ensure that the attachment points are secure and free from rust or corrosion.

- Observe the alignment to confirm proper functionality during movement.

By focusing on these aspects, one can ensure that the knuckles are in optimal condition, contributing to the overall performance and safety of the vehicle.

Maintenance Tips for Steering Parts

Regular upkeep of your vehicle’s maneuvering components is essential for ensuring optimal performance and safety on the road. Proper care not only extends the lifespan of these crucial elements but also enhances overall driving experience and responsiveness.

1. Regular Inspections: Frequently examine all related components for signs of wear or damage. Look for leaks, unusual noises, and any loose connections. Early detection can prevent more serious issues down the line.

2. Lubrication: Keeping joints and linkages well-lubricated is vital. Use appropriate grease to minimize friction and wear. Follow manufacturer guidelines for specific lubrication points and intervals.

3. Alignment Checks: Ensure that your vehicle is properly aligned. Misalignment can lead to uneven tire wear and affect handling. Schedule alignment checks regularly, especially after any significant impact or if you notice any pulling to one side.

4. Replace Worn Components: Be proactive about replacing any components that show significant wear. This includes bushings, bearings, and any flexible connections. Using quality replacements is crucial for maintaining performance.

5. Monitor Fluid Levels: Regularly check hydraulic fluid levels if applicable. Low fluid can lead to reduced functionality and increased wear on components. Ensure that you are using the recommended type of fluid.

6. Professional Maintenance: Consider seeking professional help for complex issues or routine maintenance. Technicians can provide thorough inspections and address problems that may not be apparent during casual checks.

By following these maintenance tips, you can ensure that your vehicle’s handling systems operate smoothly, providing a safer and more enjoyable driving experience.

Common Issues in Steering Systems

In the realm of vehicle control, various complications can arise that affect maneuverability and safety. Understanding these prevalent challenges is essential for effective maintenance and repair. Below are some common issues that may occur, along with their potential causes and solutions.

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Excessive play in the wheel | Worn linkages, loose connections | Inspect and replace worn components, tighten connections |

| Difficulty in turning | Low fluid levels, damaged pump | Check fluid levels, inspect and replace pump if necessary |

| Uneven tire wear | Misalignment, improper inflation | Perform wheel alignment, check tire pressure regularly |

| Strange noises while turning | Worn bearings, damaged bushings | Inspect for wear and replace affected parts |

| Vibration in the wheel | Unbalanced tires, faulty suspension | Balance tires, check suspension components |

Upgrading Your Truck’s Steering System

Enhancing the control and handling of your vehicle can significantly improve your driving experience. By focusing on the mechanisms that guide your wheels, you can achieve a smoother ride and increased responsiveness. This section delves into the benefits of modernizing these essential components and how it can positively impact performance.

Benefits of Modern Components

Investing in advanced mechanisms can lead to numerous advantages. Improved precision is one of the most notable outcomes, allowing for more accurate navigation on various terrains. Additionally, upgrading to lighter materials can reduce strain on the overall structure, enhancing fuel efficiency and extending the lifespan of other related systems. Safety is another critical factor, as contemporary designs often incorporate better materials and technology that mitigate risks on the road.

Choosing the Right Upgrades

When selecting enhancements, consider options that align with your driving style and requirements. Consulting with professionals can provide valuable insights into the most effective choices for your specific model. Focus on reputable brands known for their quality and durability, ensuring that your investment will stand the test of time. A well-planned upgrade not only revitalizes your vehicle but also enhances your overall driving experience.