Stihl 025 Parts Diagram PDF for Easy Reference

When it comes to maintaining and repairing outdoor machinery, having a clear visual representation of the individual elements is crucial. A comprehensive overview not only simplifies the identification of each part but also enhances your ability to troubleshoot and perform necessary maintenance effectively. This resource serves as a valuable guide for anyone looking to optimize the performance and longevity of their tools.

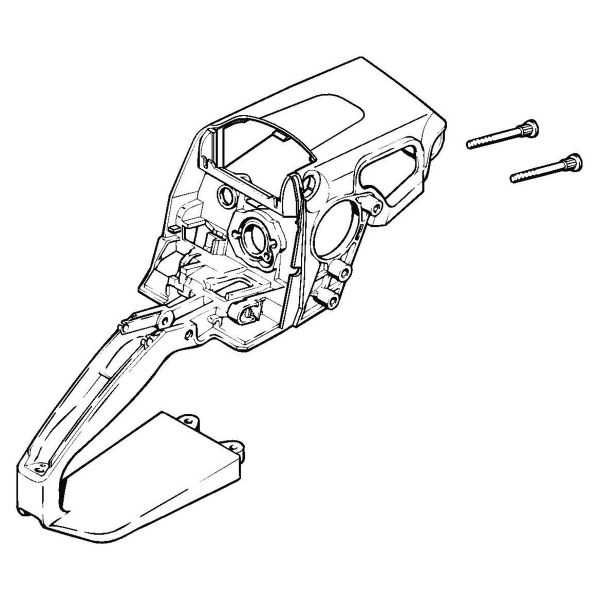

Within this section, you’ll discover detailed illustrations that break down the various components of your machinery. These visuals serve as an essential reference for both novice and experienced users alike, making the process of understanding complex systems much more approachable. With accurate depictions at your disposal, you’ll find it easier to navigate the intricate workings of your equipment.

By familiarizing yourself with these representations, you empower yourself to tackle repairs confidently and efficiently. Armed with this knowledge, you’ll be better prepared to make informed decisions regarding parts replacement and maintenance, ensuring that your equipment continues to perform at its best for years to come. Dive into this resource and enhance your mechanical skills today!

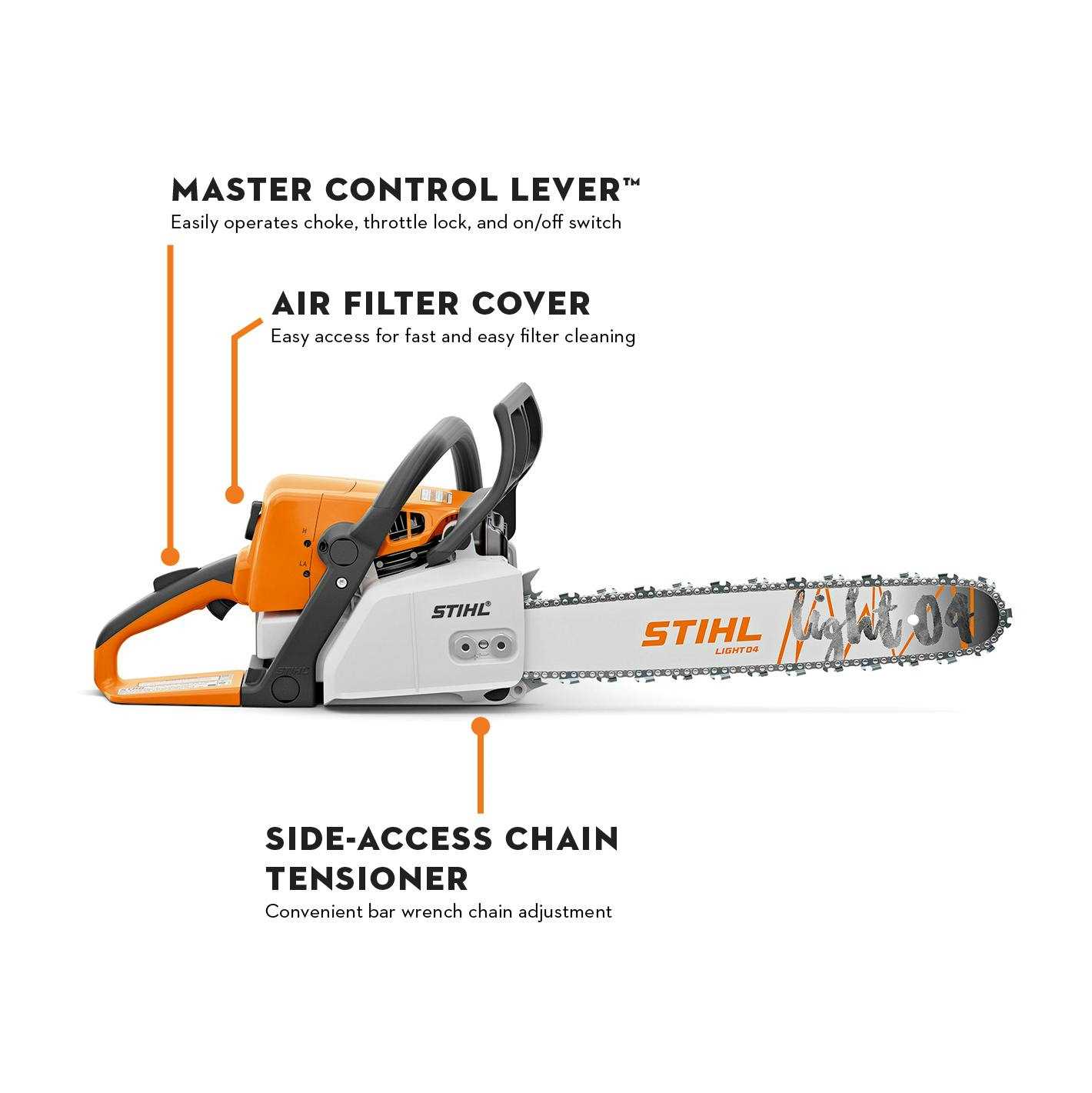

Understanding Stihl 025 Components

When delving into the intricacies of outdoor power equipment, recognizing the various elements that comprise the machine is essential. Each component plays a critical role in the overall functionality and efficiency of the tool, impacting everything from performance to longevity. A solid grasp of these individual parts enables users to maintain and troubleshoot effectively.

Key Elements of the Machine

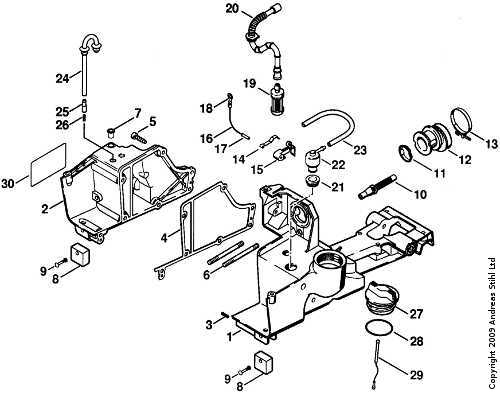

At the core of this machinery are the engine, drive system, and cutting apparatus. The engine serves as the powerhouse, converting fuel into mechanical energy. The drive system, which includes gears and belts, transmits this energy to the cutting apparatus, enabling it to perform its task. Understanding how these systems interrelate is vital for optimal operation.

Maintenance and Troubleshooting

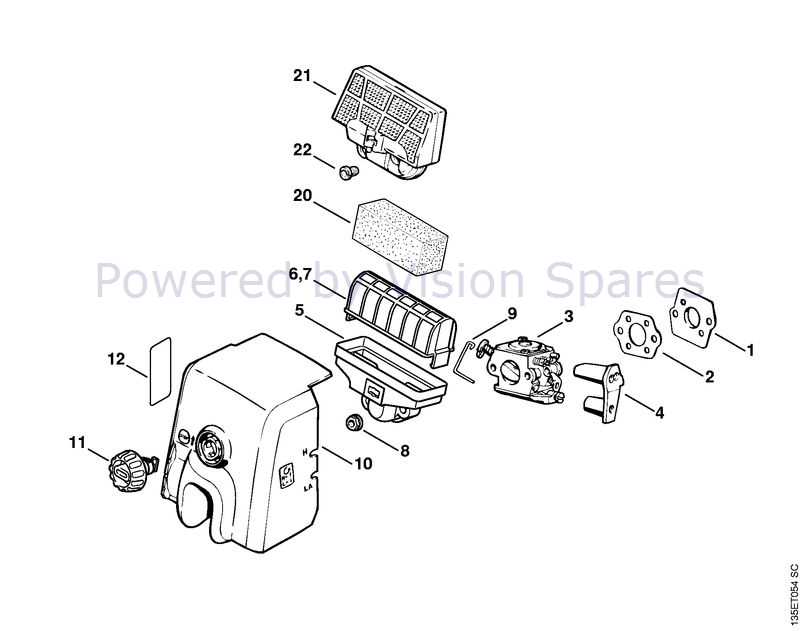

Regular upkeep of the components can prevent common issues and enhance performance. Familiarity with the different sections allows users to identify wear and tear early on. For instance, monitoring the condition of the air filter and spark plug can significantly influence the efficiency of the engine. Furthermore, being able to disassemble and inspect each element promotes a deeper understanding of how to address any mechanical failures that may arise.

Where to Find Parts Diagram PDF

Locating technical schematics for outdoor equipment can significantly enhance maintenance and repair efforts. Understanding where to access these resources is essential for ensuring that machinery operates smoothly and efficiently.

Here are some reliable sources to consider:

| Source | Description |

|---|---|

| Official Manufacturer Website | Many manufacturers provide downloadable resources directly on their websites, offering up-to-date information and guides. |

| Online Retailers | Numerous e-commerce platforms feature technical documents alongside product listings, making it easy to find relevant schematics. |

| Forums and Community Groups | Engaging with online communities can lead to shared resources, including user-uploaded manuals and visual aids. |

| Repair Shops | Local repair shops often have access to detailed schematics and may provide copies upon request. |

Exploring these options will help ensure that you have the necessary information for effective repairs and maintenance of your equipment.

Importance of Accurate Parts Identification

Precise identification of components is crucial for the effective maintenance and repair of any machinery. Ensuring that each element is correctly recognized helps to avoid complications that can arise from using incorrect or incompatible items. This practice not only enhances the efficiency of repairs but also extends the lifespan of the equipment.

Enhancing Operational Efficiency

Using the right components significantly improves the operational performance of machinery. When every element fits and functions as intended, the risk of malfunction decreases. This leads to smoother operation and reduces the likelihood of unexpected breakdowns, ultimately saving time and resources.

Cost-Effectiveness and Longevity

Investing in accurate identification can lead to significant savings over time. Using inappropriate components often results in damage that necessitates costly repairs or replacements. By ensuring the correct selection from the outset, users can enhance the durability of their equipment and reduce overall maintenance expenses.

In conclusion, the importance of accurate component identification cannot be overstated. It is a fundamental practice that promotes reliability, efficiency, and long-term savings in equipment management.

Common Issues with Stihl 025 Parts

When dealing with outdoor power equipment, several common challenges can arise that affect performance and longevity. Understanding these issues is crucial for maintaining efficiency and ensuring a smooth operation.

- Fuel System Problems:

- Clogged filters can restrict fuel flow, leading to poor engine performance.

- Improper fuel mixture may cause starting difficulties and erratic operation.

- Ignition System Failures:

- Worn spark plugs can result in misfiring or complete failure to start.

- Faulty ignition coils may lead to inconsistent firing and loss of power.

- Air Filter Issues:

- A dirty air filter can restrict airflow, causing the engine to run rich.

- Neglecting regular cleaning can result in reduced efficiency and increased wear.

- Chain and Bar Wear:

- Worn chains can decrease cutting efficiency and lead to accidents.

- Improperly maintained bars can cause uneven cuts and premature damage.

Addressing these common concerns proactively can significantly enhance the functionality and durability of the equipment, ensuring that it operates at peak performance for years to come.

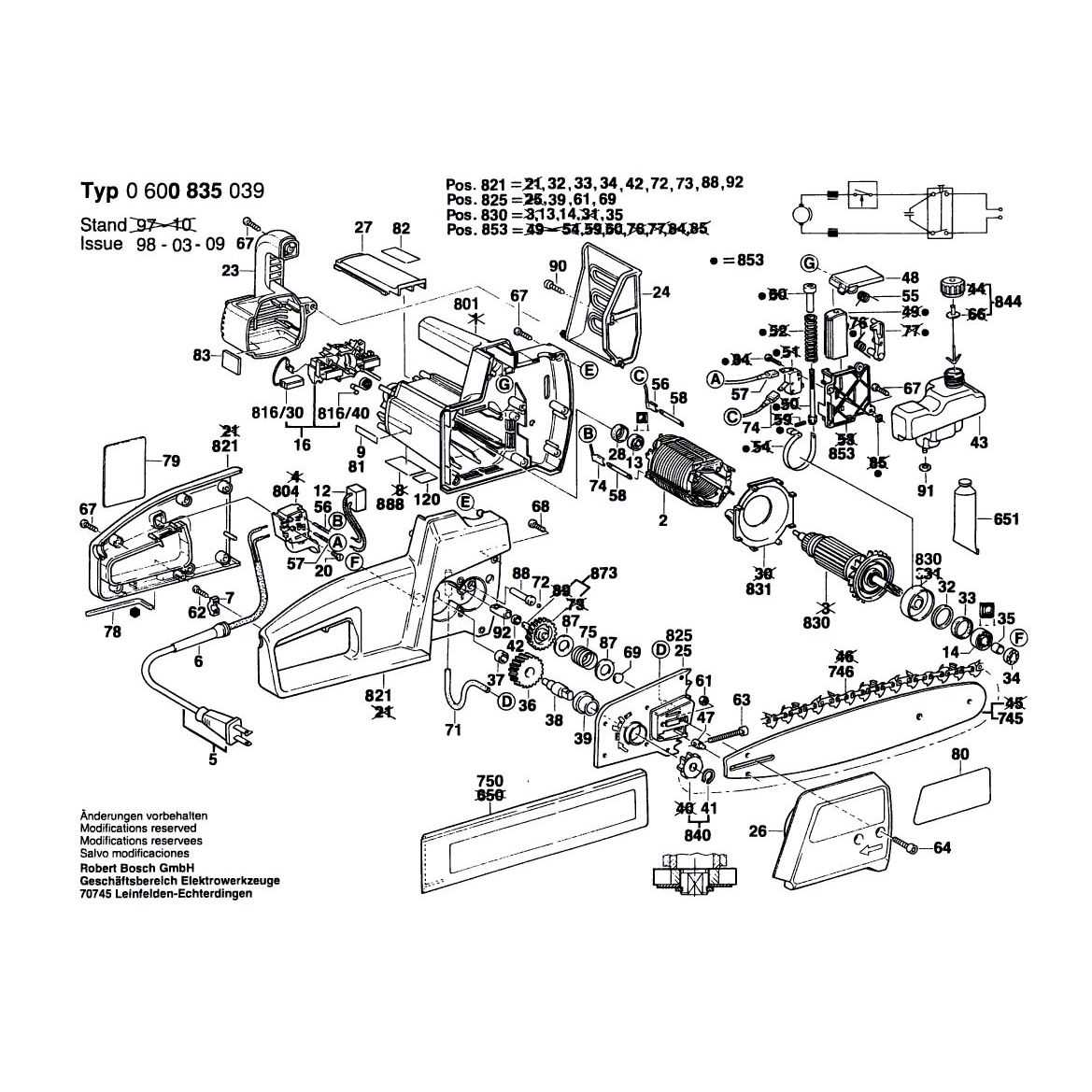

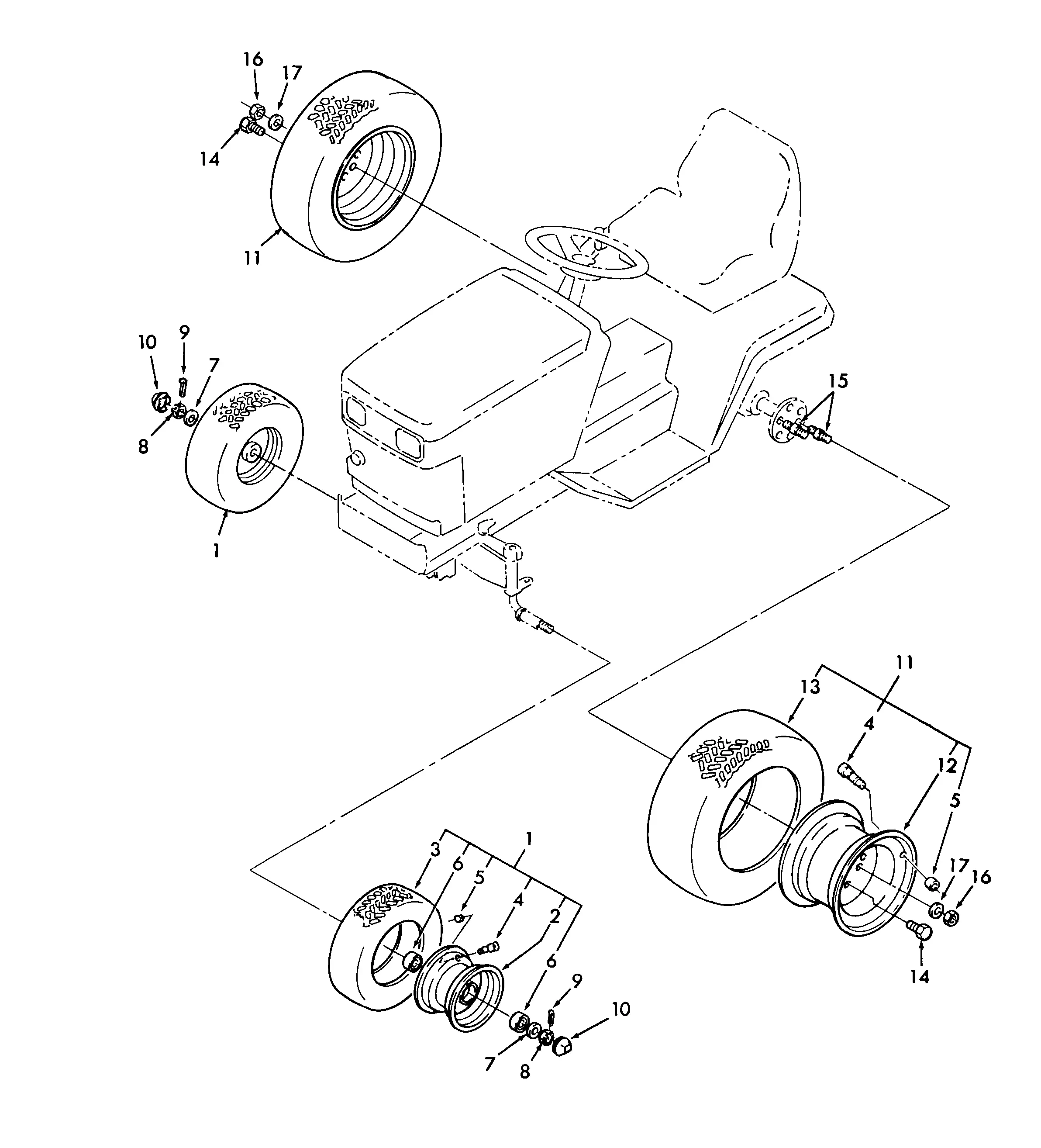

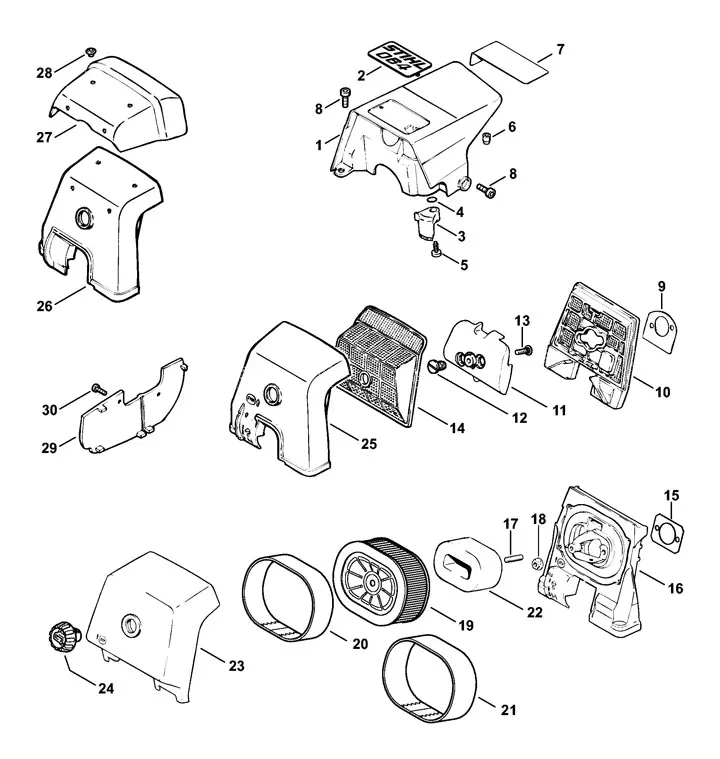

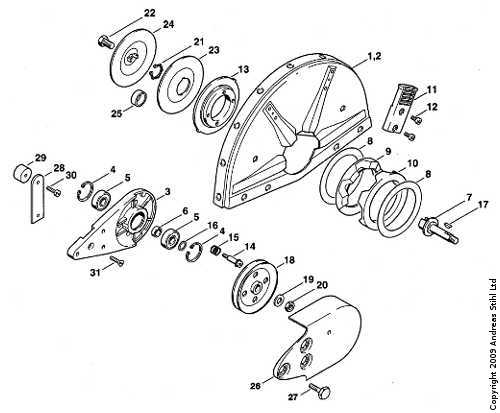

How to Interpret the Diagram

Understanding a schematic representation of mechanical components is essential for effective maintenance and repair. Such illustrations serve as a visual guide, offering insight into how various elements interact within the overall assembly. By grasping the symbols and layouts, users can better navigate the intricacies of the machinery.

Key Components to Focus On

- Labels: Ensure you familiarize yourself with the names and numbers assigned to each part.

- Connections: Pay attention to lines indicating how components link to one another.

- Legends: Use the legend to decode any specific symbols that may appear.

Steps for Effective Interpretation

- Start by identifying the main sections of the illustration.

- Trace the flow from one part to another to understand functionality.

- Refer to the accompanying documentation for additional context on assembly.

Ordering Replacement Parts Online

In today’s digital age, acquiring components for your equipment has become more convenient than ever. Online platforms allow users to explore a vast selection of items, compare prices, and read customer reviews, all from the comfort of their homes. This not only saves time but also ensures access to the best options available.

Finding Reliable Sources

When searching for components online, it is crucial to identify trustworthy vendors. Look for websites with a solid reputation, clear return policies, and responsive customer service. Reading reviews and checking ratings can help you make informed decisions.

Ensuring Compatibility

Before finalizing your order, verify that the chosen item is compatible with your specific model. Cross-referencing with manufacturer specifications or consulting support can prevent costly mistakes. Delve into the details to ensure you receive the ultimate fit for your needs.

Maintenance Tips for Stihl 025

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Implementing a consistent maintenance routine not only enhances efficiency but also minimizes the risk of unexpected breakdowns. By following a few key practices, you can keep your tool in top condition and ready for any task.

Start by keeping the air filter clean and free from debris. A clogged filter restricts airflow, leading to poor performance. Check it regularly and replace it when necessary. Additionally, inspect the spark plug for wear and proper gapping. A well-functioning spark plug ensures efficient combustion and easy starting.

Lubricate moving parts to reduce friction and prevent wear. Pay special attention to the chain and guide bar, ensuring they are adequately oiled. This not only prolongs their life but also enhances cutting efficiency. Don’t forget to periodically tighten the chain to prevent slippage during operation.

Finally, clean the exterior of the unit after each use to remove dirt and grime. This not only improves the appearance but also helps in identifying any potential issues early. Following these maintenance tips will contribute to a reliable and high-performing tool, ready to tackle any project.

Comparing OEM and Aftermarket Parts

When it comes to replacement components for machinery, the choice between original and alternative options can significantly impact performance and longevity. Understanding the differences can help users make informed decisions.

- Quality: Original parts are typically manufactured to meet specific standards, while alternatives may vary in quality.

- Price: Aftermarket options often come at a lower cost, making them appealing for budget-conscious consumers.

- Availability: Alternative components may be easier to find, especially for older models.

- Compatibility: OEM parts are designed to fit perfectly, while alternatives may require adjustments.

Ultimately, weighing the benefits and drawbacks of each type can guide users toward the best choice for their needs.

Tools Needed for Stihl Repairs

When tackling repairs on outdoor power equipment, having the right tools at your disposal is essential for effective maintenance and restoration. A well-equipped toolkit not only streamlines the repair process but also ensures that tasks are completed safely and efficiently. From basic hand tools to specialized instruments, understanding the necessary equipment can make a significant difference in achieving optimal performance.

Basic hand tools such as wrenches, screwdrivers, and pliers are fundamental for most repair jobs. These tools allow for easy disassembly and assembly of various components. Additionally, a quality set of sockets can be invaluable for reaching tight spaces and applying the right amount of torque. For more intricate tasks, you might need specialized items like carburetor adjustment tools or spark plug wrenches to ensure precision and reliability.

Safety gear is equally important when working on machinery. Protective eyewear and gloves should always be worn to safeguard against debris and sharp edges. Furthermore, using a workbench with adequate lighting can enhance visibility, reducing the risk of errors during repairs. By investing in the right tools and safety equipment, you set yourself up for success in maintaining and restoring your equipment effectively.

Step-by-Step Repair Guide

This guide provides a systematic approach to restoring your equipment to optimal functionality. By following these detailed instructions, you can address common issues effectively, ensuring a smooth repair process.

Begin by gathering the necessary tools and safety gear. Ensure you have a clean workspace to keep all components organized and accessible. Start with a thorough inspection to identify the specific problems that need attention.

Next, disassemble the unit carefully, taking note of each part’s position and condition. It’s essential to document this process, as it will aid in reassembly. Clean any dirt or debris from components to prevent further issues.

Once disassembled, examine each part for wear or damage. Replace any faulty components with quality replacements. If repairs are needed, follow the manufacturer’s guidelines to ensure proper techniques are applied.

After repairs and replacements, reassemble the unit in reverse order of disassembly. Double-check that all parts are securely attached and functioning correctly. Finally, conduct a test run to confirm that everything operates as intended.

Cost Analysis of Stihl 025 Parts

This section delves into the financial considerations associated with various components used in a popular model of outdoor power equipment. Understanding the expenses involved can aid users in making informed decisions regarding maintenance, repairs, and overall budget management.

Analyzing the costs related to different components can help users anticipate expenses and determine whether to purchase original or aftermarket alternatives. Below is a breakdown of typical costs for essential items:

| Component | Average Cost (USD) | Notes |

|---|---|---|

| Engine Assembly | 250 | Crucial for performance; consider professional installation. |

| Fuel Tank | 30 | Check for leaks; easy to replace. |

| Chain Bar | 45 | Varies by length; essential for cutting efficiency. |

| Air Filter | 10 | Regular replacement improves engine life. |

| Sprocket | 20 | Wear and tear; inspect regularly for optimal performance. |

Overall, evaluating these costs allows users to balance quality and budget, ensuring that their equipment remains in optimal condition without unnecessary expenditures.

User Experiences and Reviews

This section explores the insights and opinions of users regarding a specific power tool model. Collecting feedback from individuals who have utilized this equipment provides a valuable perspective on its performance, reliability, and overall user satisfaction. The shared experiences often highlight both the strengths and weaknesses, helping potential buyers make informed decisions.

Positive Feedback

Many users express their satisfaction with the tool’s ease of use and efficiency. Several highlight its lightweight design, which allows for prolonged operation without causing fatigue. Others appreciate the powerful engine, which facilitates quick and effective cutting.

| Feature | User Comments |

|---|---|

| Weight | Lightweight, easy to handle for extended periods. |

| Power | Exceptional cutting speed; handles tough jobs effortlessly. |

| Maintenance | Simple upkeep; parts are easily accessible. |

Constructive Criticism

Despite the numerous positive remarks, some users provide constructive feedback. A few have mentioned that the initial setup can be somewhat complex for beginners. Additionally, there are comments regarding noise levels, with some users finding it louder than anticipated.

| Issue | User Comments |

|---|---|

| Setup Difficulty | Initial configuration can be challenging for novices. |

| Noise | Can be louder than expected during operation. |