Comprehensive Stihl 046 Parts Diagram for Easy Reference

In the world of outdoor machinery, grasping the intricacies of its various components is essential for effective maintenance and repair. A thorough understanding of how each element interacts can lead to enhanced performance and longevity of the equipment. This knowledge empowers users to tackle issues confidently and ensure their tools operate at peak efficiency.

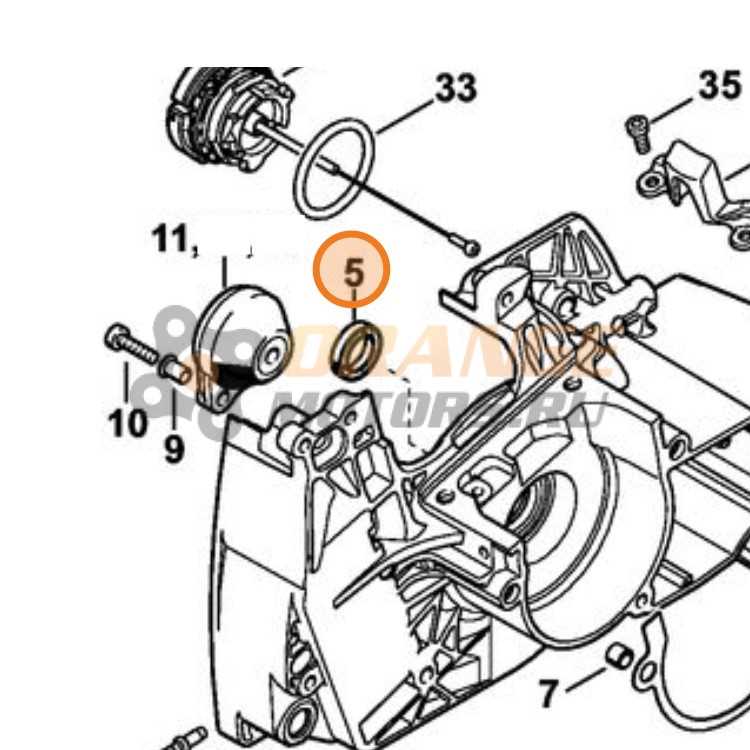

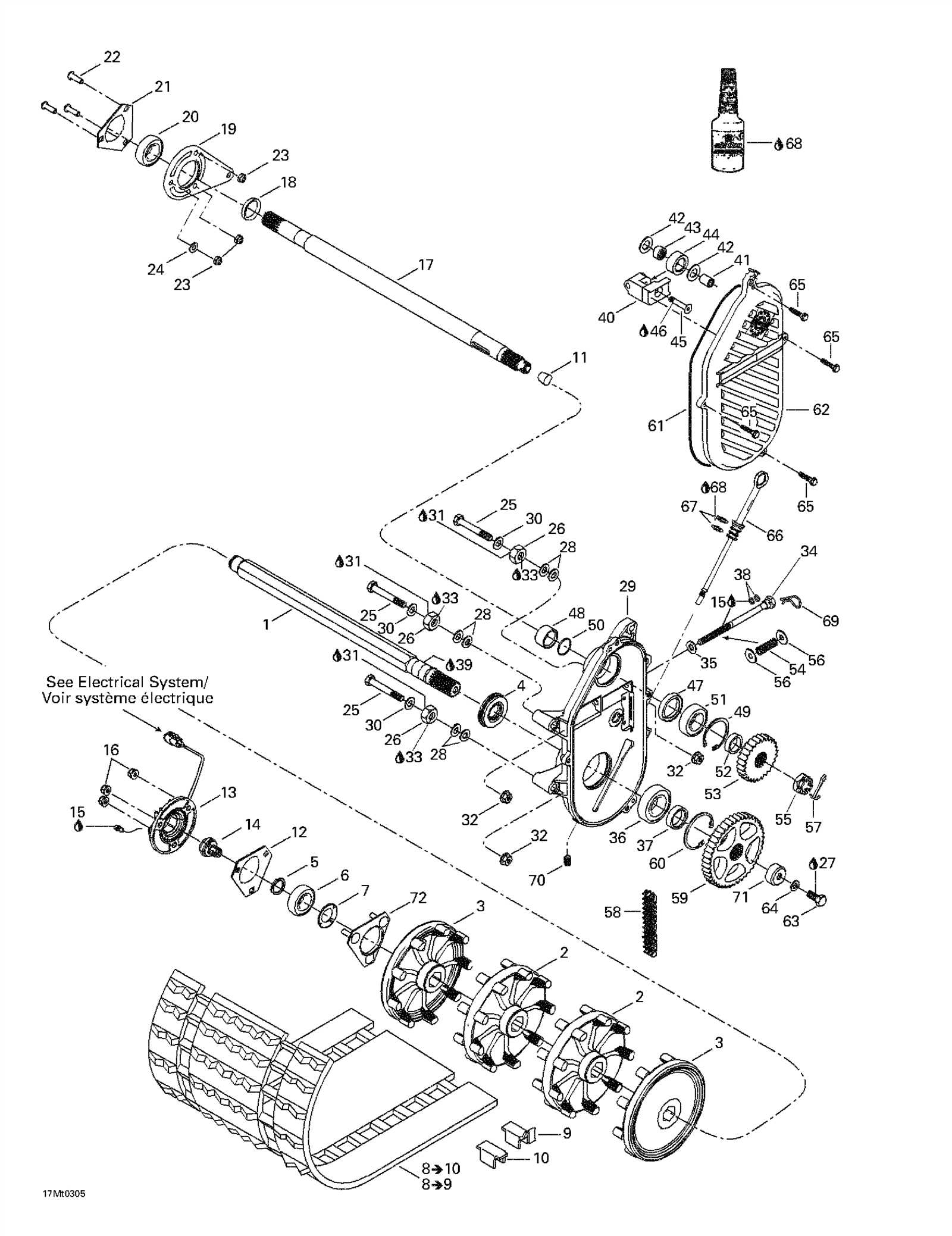

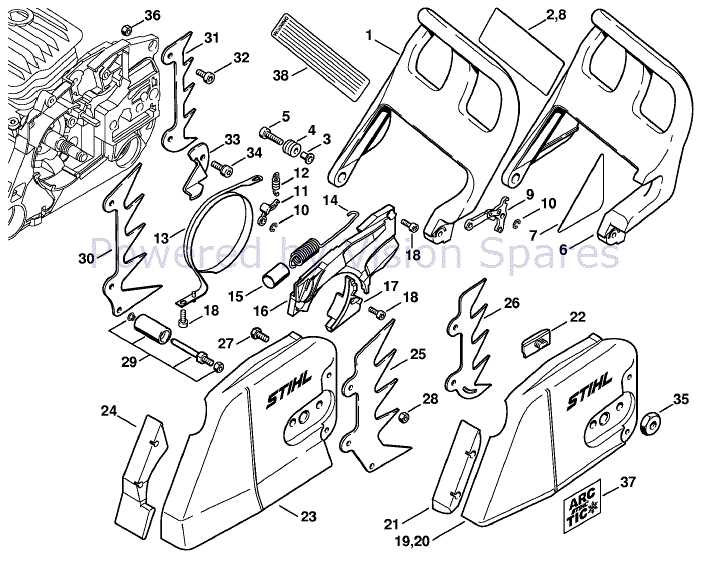

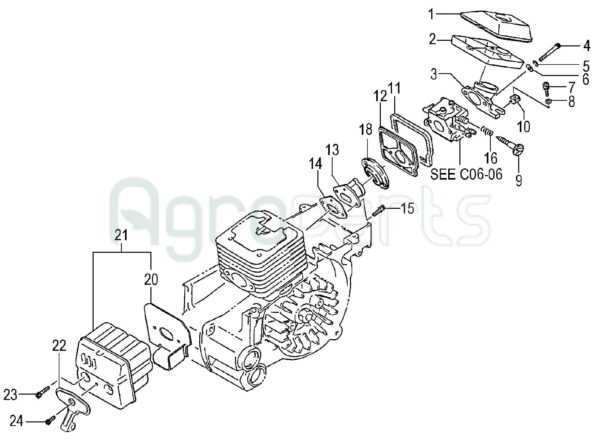

Visual representations of the mechanical structures serve as invaluable resources. They allow enthusiasts and professionals alike to identify individual elements and comprehend their functions within the larger assembly. By examining these illustrations, one can easily navigate the complexities of their equipment.

Moreover, delving into the specifics can reveal potential areas for improvement and customization. Understanding the ultimate layout and connections between parts not only aids in repairs but also enhances the overall user experience. This foundational knowledge paves the way for informed decision-making and optimal tool utilization.

Understanding Stihl 046 Components

Every machine comprises various elements that work in harmony to achieve optimal performance. Recognizing these components is essential for effective maintenance and operation. By delving into the specifics of each part, users can enhance the longevity and functionality of their equipment.

Key Elements and Their Functions

Among the critical components are the engine, fuel system, and cutting mechanism. The engine serves as the heart of the machine, converting fuel into mechanical energy. The fuel system is responsible for delivering the right mixture for efficient combustion, while the cutting mechanism directly impacts performance and precision in tasks. Understanding the role of each of these elements allows for better troubleshooting and repairs.

Maintenance Tips

Regular upkeep is vital to ensure each component operates smoothly. Inspecting the fuel lines and filters periodically can prevent clogs, while cleaning the air filter promotes better airflow and efficiency. Additionally, sharpening the cutting blade is crucial for maintaining cutting quality. Keeping these elements in check leads to improved performance and reduced downtime.

Importance of Parts Diagrams

Understanding the intricate components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools that enhance comprehension, allowing users to identify and locate individual elements with ease.

Clear visualization of each component aids in troubleshooting issues, ensuring that the right parts are addressed promptly. This clarity minimizes the risk of errors during repairs, ultimately leading to enhanced performance and longevity of the equipment.

Moreover, these illustrations foster a deeper appreciation for the engineering behind the machinery, enabling users to delve into the relationships between different elements. Knowledge of how each part interacts contributes significantly to informed decision-making during repairs or upgrades.

In summary, utilizing these graphical representations is not just a practical necessity; it is an ultimate strategy for achieving optimal functionality and reliability in any mechanical system.

Overview of Stihl 046 Chainsaw

This section provides a comprehensive look at a renowned model of power saw, known for its durability and performance in various cutting tasks. Ideal for both professionals and enthusiasts, it is designed to handle a range of applications with ease.

- Engine Performance: Equipped with a robust engine, it delivers impressive power output for heavy-duty jobs.

- Ergonomic Design: Features an ergonomic handle for enhanced comfort during prolonged use.

- Cutting Efficiency: The blade length and sharpness contribute to smooth and effective cutting.

Whether for logging, gardening, or maintenance, this tool excels in versatility, making it a favorite among users.

Key Parts and Their Functions

This section explores essential components of a popular outdoor tool and their specific roles in ensuring optimal performance and efficiency.

- Engine: The powerhouse responsible for converting fuel into mechanical energy, driving the entire system.

- Bar: The metal arm that supports the cutting chain, essential for guiding the cutting action.

- Chain: A crucial element that rotates around the bar, designed for slicing through various materials with precision.

- Clutch: Engages and disengages the chain from the engine, allowing for safe operation during idle moments.

- Air Filter: Prevents dust and debris from entering the engine, ensuring clean airflow for efficient combustion.

Understanding these key components enhances knowledge of how each contributes to the tool’s overall functionality.

How to Use a Parts Diagram

Understanding the intricacies of machinery requires familiarity with its components and how they fit together. A visual representation can greatly aid in identifying each element, making maintenance and repairs more efficient. By utilizing such a guide, users can ensure they have a clear understanding of the arrangement and functionality of various parts.

Begin by locating the visual aid that corresponds to your equipment model. This resource typically labels each section, allowing you to pinpoint specific pieces you may need to examine or replace. Take your time to study the layout and familiarize yourself with the overall structure.

Next, cross-reference the illustration with your actual equipment. This will help you identify any discrepancies or worn elements. Marking off components as you go can streamline the process and keep you organized, ensuring you don’t overlook any critical parts.

Finally, use the visual guide when ordering replacements. Clear identification of the items needed will facilitate more accurate procurement, reducing downtime. With practice, you’ll find that a well-understood reference becomes an invaluable tool in your maintenance toolkit.

Common Issues with Stihl 046

Many users encounter specific challenges when operating their equipment, which can affect performance and efficiency. Understanding these common problems can help in troubleshooting and maintaining optimal function.

- Starting Difficulties:

- Fuel mixture issues

- Clogged air filters

- Faulty ignition components

- Power Loss:

- Dirty or damaged spark plugs

- Worn piston rings

- Fuel system blockages

- Excessive Vibration:

- Imbalanced cutting chain

- Loose or damaged components

- Poorly mounted engine

- Overheating:

- Insufficient lubrication

- Clogged cooling fins

- Faulty cooling system

By recognizing these common issues, users can take proactive steps to ensure their machinery operates smoothly and efficiently.

Finding Replacement Parts Easily

Locating suitable components for your equipment can be a straightforward process if you know where to look. With the right resources and strategies, you can ensure your machine remains operational without unnecessary delays.

- Utilize Online Retailers: Many websites specialize in machinery supplies, offering a vast selection of alternatives.

- Join Forums: Communities of enthusiasts often share tips on sourcing quality replacements.

- Consult the Manufacturer: Official sources can provide specific recommendations and compatibility information.

- Visit Local Shops: Brick-and-mortar stores may stock essential items and can offer valuable advice.

By leveraging these options, you can navigate the search efficiently and secure the ultimate components for your needs.

Maintenance Tips

Proper upkeep of your equipment is essential for optimal performance and longevity. Regular maintenance helps prevent issues and ensures that your machine operates efficiently. Below are key practices to keep in mind for effective care.

- Regular Cleaning: Keep the exterior and interior free of debris. Clean air filters and check for clogs.

- Chain Inspection: Regularly inspect the cutting chain for wear and damage. Replace it if necessary to ensure safety and performance.

- Lubrication: Ensure all moving parts are well-lubricated. This reduces friction and prolongs the life of your equipment.

- Fuel Quality: Use fresh, high-quality fuel to prevent engine issues. Old or contaminated fuel can lead to performance problems.

- Spark Plug Maintenance: Inspect and replace the spark plug periodically to ensure smooth ignition and optimal engine function.

- Check Bolts and Screws: Regularly tighten any loose fasteners to maintain structural integrity and performance.

Implementing these tips will help ensure that your machinery remains in top condition, providing reliable service for years to come.

Identifying Authentic Stihl Parts

Ensuring the use of genuine components in your equipment is crucial for optimal performance and longevity. Counterfeit or substandard items can lead to malfunctions and increased wear. This section will guide you in recognizing original items through specific features and characteristics that distinguish them from imitations.

When evaluating the authenticity of components, consider the following criteria:

| Feature | Authentic Item | Counterfeit Item |

|---|---|---|

| Packaging | High-quality packaging with clear branding | Poor quality, often generic packaging |

| Labeling | Precise labeling with part numbers and logos | Inconsistent or missing labels |

| Material Quality | Durable materials, well-crafted | Subpar materials, flimsy construction |

| Price Point | Consistent with industry standards | Significantly lower than average |

| Vendor Reputation | Authorized dealers with positive reviews | Unknown sellers with questionable practices |

By adhering to these guidelines, you can confidently choose the right components for your machinery, ensuring its reliability and efficiency in operation.

Tools Required for Repairs

When embarking on maintenance or fixing machinery, having the right equipment is crucial for efficient and effective work. This section outlines the essential tools that will facilitate the repair process, ensuring that tasks are completed with precision and care.

Basic Hand Tools

First and foremost, a set of basic hand tools is necessary. This includes screwdrivers, wrenches, and pliers. These items allow for the loosening or tightening of various components, making them indispensable for any repair job.

Specialized Equipment

In addition to standard tools, having specialized equipment can greatly enhance repair capabilities. Items such as torque wrenches and feeler gauges ensure that adjustments are made to precise specifications, contributing to the ultimate performance and longevity of the machinery.

Step-by-Step Repair Guide

Repairing outdoor power equipment can seem daunting, but with the right approach, it becomes manageable. This guide outlines essential steps to help you navigate through the repair process effectively, ensuring your machine operates at its peak performance.

1. Gather Necessary Tools: Before beginning, collect all required tools such as wrenches, screwdrivers, and safety gear. Having everything on hand will streamline the process.

2. Identify the Issue: Carefully examine the equipment to pinpoint the problem. Look for visible damage or signs of wear, and take notes for reference during the repair.

3. Disassemble Carefully: Start disassembling the machine by removing screws and components in the order specified in your reference material. Keep parts organized to avoid confusion later.

4. Replace Faulty Components: Once disassembled, replace any damaged or worn-out parts with high-quality replacements. Ensure compatibility to avoid future issues.

5. Reassemble with Precision: Carefully reassemble the machine, following the reverse order of disassembly. Make sure all screws and components are secured properly to maintain stability.

6. Perform a Function Test: After reassembly, conduct a test run to confirm that everything functions as intended. Monitor for any unusual noises or performance issues.

7. Regular Maintenance: To prolong the lifespan of your equipment, schedule regular maintenance checks and keep an eye on wear and tear. This proactive approach will save time and money in the long run.

Upgrading Stihl 046 Components

Enhancing the performance of your outdoor power equipment can significantly improve efficiency and extend its lifespan. By focusing on specific elements within the machinery, you can achieve better power output, improved reliability, and a smoother operation. This section will delve into various components that can be upgraded for optimal performance.

| Component | Benefits |

|---|---|

| Cylinder | Increases power and torque, enhances combustion efficiency. |

| Piston | Improves engine responsiveness and reduces wear and tear. |

| Air Filter | Enhances airflow, resulting in better fuel efficiency and power. |

| Carburetor | Optimizes fuel-air mixture, leading to improved throttle response. |

| Chain | Offers smoother cutting performance and reduces vibration. |

By carefully selecting and upgrading these crucial components, operators can ensure their equipment runs at its peak, maximizing productivity while minimizing downtime.

Resources for Stihl Enthusiasts

For those passionate about outdoor power tools, having access to reliable resources is essential. This section aims to guide you towards valuable information, communities, and tools that enhance your experience and knowledge.

- Online Forums: Join discussions with fellow aficionados to share tips and troubleshooting advice.

- Official Websites: Explore manufacturer sites for manuals, safety guidelines, and product specifications.

- Instructional Videos: Platforms like YouTube offer a plethora of tutorials for maintenance and repairs.

- Local Workshops: Look for classes or meet-ups where you can learn hands-on skills and techniques.

- Social Media Groups: Engage with communities on platforms like Facebook and Instagram for updates and insights.

Utilizing these resources can deepen your understanding and appreciation of your tools, making your outdoor projects more enjoyable.