Understanding the Stihl 084 Parts Diagram for Efficient Maintenance

In the realm of heavy-duty equipment, comprehending the intricate layout of individual elements is crucial for effective maintenance and repair. This knowledge not only enhances operational efficiency but also prolongs the lifespan of the machinery. A detailed examination of the various components provides invaluable insights for both seasoned technicians and enthusiastic hobbyists.

When delving into the assembly of such robust machines, it becomes essential to grasp the relationships and functions of each piece. By visualizing how parts interconnect, users can better anticipate potential issues and streamline their troubleshooting processes. This clarity transforms daunting repairs into manageable tasks, empowering users to tackle challenges with confidence.

Moreover, familiarizing oneself with the specific configurations aids in sourcing replacement components when necessary. A comprehensive overview serves as a guide, facilitating the identification of compatible elements and ensuring that repairs meet the required standards for performance and safety. Ultimately, this understanding cultivates a more profound respect for the engineering that drives these powerful tools.

Understanding the Stihl 084 Chainsaw

This section provides an overview of a powerful cutting tool known for its efficiency and durability. Recognized in various industries, this model is designed to handle heavy-duty tasks with ease. Its robust design and performance capabilities make it a preferred choice among professionals and enthusiasts alike.

Key Features

- High-performance engine for maximum cutting efficiency

- Lightweight design for improved maneuverability

- Advanced vibration dampening system for user comfort

- Durable construction to withstand rigorous use

Common Applications

- Forestry operations, including tree felling and limbing

- Landscaping projects that require precision cutting

- Maintenance of large properties and estates

- Emergency services for quick response in disaster scenarios

Understanding the features and applications of this tool enhances the user experience and ensures effective use in various cutting tasks.

Key Features of the Stihl 084

This powerful tool is renowned for its impressive performance and robust design, making it a preferred choice among professionals in forestry and heavy-duty cutting tasks. Its innovative features ensure reliability and efficiency in various demanding environments.

- High Engine Power: Equipped with a strong engine, this machine delivers exceptional cutting performance, allowing users to tackle even the toughest materials with ease.

- Durable Build: Constructed with high-quality materials, the unit is designed to withstand harsh conditions and prolonged use, ensuring longevity and resilience.

- Advanced Vibration Control: The integrated system minimizes vibrations, providing enhanced comfort during operation and reducing operator fatigue over extended periods.

- Easy Maintenance: The user-friendly design allows for straightforward access to components, facilitating quick maintenance and reducing downtime.

- Fuel Efficiency: Engineered to optimize fuel consumption, this model ensures longer operational time with reduced environmental impact.

With its combination of power, durability, and user-focused features, this cutting tool stands out in its class, making it a valuable asset for professionals seeking reliable performance.

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools that facilitate a comprehensive grasp of how individual elements interact within a system. By utilizing these guides, users can ensure proper assembly, troubleshooting, and efficient replacements.

Enhanced Troubleshooting

One of the primary benefits of visual schematics is the ability to quickly identify issues. When components are clearly illustrated, users can locate faults and discrepancies with ease. This clarity reduces the time spent diagnosing problems, leading to faster resolutions and less downtime.

Streamlined Maintenance

Another significant advantage is the promotion of efficient upkeep. With a clear visual reference, individuals can follow maintenance protocols more accurately. This leads to improved performance and longevity of the equipment. Furthermore, recognizing the function of each part helps in making informed decisions during servicing.

In summary, visual representations are indispensable resources that enhance understanding, simplify repairs, and promote effective maintenance practices.

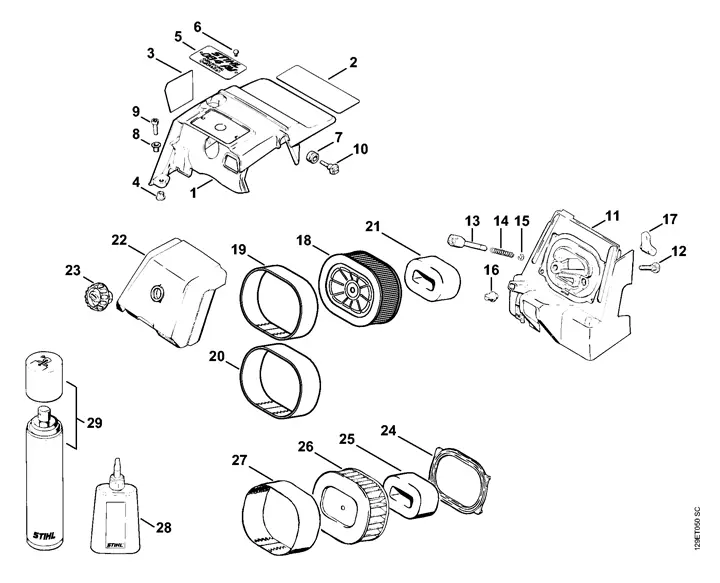

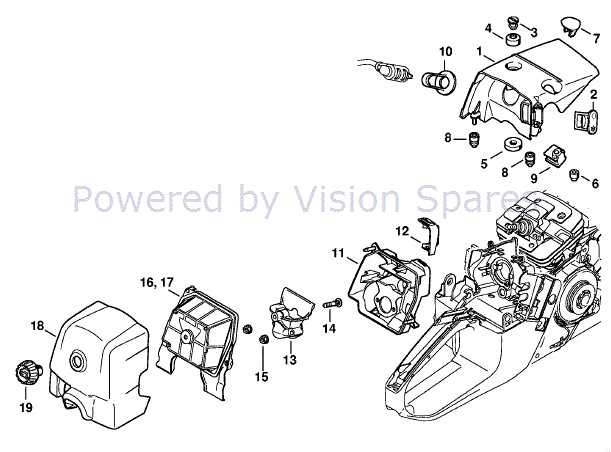

Identifying Stihl 084 Components

Understanding the various elements of a chainsaw is essential for effective maintenance and repair. Each component plays a vital role in the overall functionality of the machine, and being able to identify these parts can significantly enhance your ability to troubleshoot issues. This section focuses on the key features and their locations within the unit, providing a clear overview for better comprehension.

| Component Name | Description |

|---|---|

| Engine | The powerhouse that converts fuel into mechanical energy to drive the chain. |

| Guide Bar | The long metal piece that supports and guides the cutting chain. |

| Chain | The loop of sharpened links that cuts through wood when the engine is running. |

| Air Filter | A protective element that prevents debris from entering the engine. |

| Fuel Tank | Holds the gasoline mixture required for the engine to operate. |

| Oil Pump | Distributes lubricant to the chain and guide bar for smooth operation. |

By familiarizing yourself with these components, you can more easily navigate maintenance tasks and identify potential problems before they escalate. Understanding the layout and function of each part is crucial for anyone looking to optimize the performance and longevity of their equipment.

Common Issues with Stihl 084 Parts

When it comes to power equipment, certain components can experience wear and tear over time, leading to various challenges. Understanding these common problems can help users maintain optimal performance and extend the lifespan of their machinery.

Frequent Component Failures

One of the most prevalent issues involves mechanical failures due to inadequate lubrication or excessive use. This can lead to overheating and eventual breakdown of essential elements. Regular maintenance and timely replacements can mitigate these risks.

Wear and Tear Symptoms

Users often notice performance drops, unusual noises, or vibrations that signal underlying issues. Identifying these symptoms early can prevent more significant damage and costly repairs.

| Issue | Symptoms | Recommended Action |

|---|---|---|

| Overheating | Excessive heat, smoke | Check lubrication and cooling systems |

| Unusual Noises | Grinding, rattling sounds | Inspect for loose or damaged components |

| Vibrations | Increased vibration during operation | Tighten or replace worn-out parts |

How to Read Parts Diagrams

Understanding visual representations of components is crucial for efficient maintenance and repair of equipment. These illustrations serve as a guide, showing how different elements fit together and operate. Familiarizing yourself with their structure can greatly enhance your ability to identify, order, and replace necessary items.

Key Elements of Visual Representations

Each illustration typically includes various features that help users navigate through the components. Here are some essential elements to look for:

| Element | Description |

|---|---|

| Numbers | Each part is usually labeled with a unique identifier for easy reference. |

| Connections | Lines and arrows indicate how different components interact or connect. |

| Legend | A key that explains symbols or color codes used within the illustration. |

| Views | Multiple angles or cross-sections may be provided to give a clearer understanding of the assembly. |

Tips for Effective Interpretation

When analyzing these visuals, consider the following strategies to improve your comprehension:

- Take your time to familiarize yourself with the layout.

- Cross-reference with your equipment manual for additional context.

- Highlight or note key components that you might need to replace.

Replacement Parts for Stihl 084

Ensuring optimal performance and longevity of your equipment requires access to high-quality components. Whether you are conducting routine maintenance or addressing specific issues, knowing the available options is essential for effective repairs.

- Fuel System Components

- Filters

- Pumps

- Carburetors

- Ignition System Components

- Coils

- Spark plugs

- Wiring harnesses

- Mechanical Components

- Chains

- Bars

- Gaskets

- Cooling System Components

- Fans

- Covers

- Hoses

When searching for replacements, it’s advisable to choose genuine or compatible components that meet safety standards and performance criteria. This will ensure your equipment remains reliable and efficient in its operation.

Consulting a comprehensive resource or expert can provide valuable insights into compatibility and installation techniques, making the repair process smoother and more effective.

Maintenance Tips for Longevity

Proper upkeep of your equipment is essential for ensuring its durability and efficient performance. Regular attention not only enhances functionality but also extends the lifespan, allowing you to get the most out of your investment. Here are some key practices to consider for optimal care.

Regular Cleaning

Keeping your machine clean is vital for preventing wear and tear. Dirt and debris can accumulate and lead to mechanical issues. Regularly check and remove any build-up, especially in areas that are prone to clogging.

Scheduled Inspections

Conducting routine checks can help identify potential problems before they escalate. Look for signs of wear, loose components, or any irregularities in performance. Addressing these issues promptly will save time and money in the long run.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Clean air filter | Every 10 hours | Replace if damaged |

| Check spark plug | Every 25 hours | Clean or replace as needed |

| Inspect fuel lines | Monthly | Look for cracks or leaks |

| Lubricate moving parts | Every 50 hours | Use manufacturer-recommended lubricant |

By following these maintenance tips, you can ensure that your equipment remains in top condition, ultimately enhancing its performance and longevity.

Where to Find Genuine Parts

When it comes to maintaining your outdoor equipment, sourcing authentic components is crucial for optimal performance and longevity. Genuine replacements not only ensure compatibility but also uphold the manufacturer’s standards, leading to enhanced efficiency and safety.

Authorized Dealers

One of the most reliable avenues for acquiring authentic components is through authorized dealers. These retailers are certified by the manufacturer, guaranteeing that you receive original items that meet quality specifications. It’s advisable to check the dealer locator on the manufacturer’s official website to find a trusted source near you.

Online Marketplaces

In addition to local dealers, various online platforms specialize in genuine components. Ensure that you select reputable sellers with positive reviews to avoid counterfeit products. Look for websites that explicitly mention their affiliation with the manufacturer, providing assurance that the items offered are authentic and backed by warranties.

Tools Needed for Repairing Stihl 084

Proper maintenance and repair of equipment require a specific set of instruments to ensure efficiency and accuracy. Having the right tools not only simplifies the process but also enhances safety during repairs. Understanding the essential equipment can significantly improve the experience for both novice and experienced users alike.

Essential Hand Tools

Begin with a collection of hand tools that are crucial for disassembling and reassembling components. A screwdriver set with various sizes and types, including Phillips and flathead, is indispensable. Additionally, a wrench set will facilitate tightening or loosening bolts and nuts. Don’t forget a pair of pliers, which are useful for gripping and bending various parts.

Power Tools and Accessories

Incorporating power tools can speed up the repair process. A cordless drill is essential for quick fastening, while a multimeter will help in diagnosing electrical issues. For cutting or shaping parts, a rotary tool can be incredibly versatile. Always ensure that any power tools used are appropriate for the task at hand to maintain safety and effectiveness.

Comparing Stihl 084 with Other Models

This section delves into the nuances of a particular high-performance chainsaw, contrasting it with other available models. By examining features, specifications, and user experiences, we aim to provide insights into what makes this machine unique and how it stands up against competitors in the market.

Performance and Efficiency

When evaluating performance, this chainsaw excels in power output and cutting efficiency, making it ideal for heavy-duty tasks. Compared to its counterparts, it often demonstrates superior torque and speed, allowing users to tackle larger projects with ease. Many operators note that while some models may offer similar specifications, the reliability and consistency of this chainsaw give it a competitive edge.

Durability and Maintenance

Durability is another critical aspect where this machine shines. Constructed from high-quality materials, it withstands rigorous use over time. In contrast, other models may require more frequent maintenance or show signs of wear and tear sooner. Users often report lower downtime and maintenance costs, highlighting the long-term benefits of investing in this particular option.

Upgrading Your Stihl 084 Chainsaw

Enhancing the performance and efficiency of your cutting tool can significantly improve your work experience. By carefully selecting and installing various components, you can achieve better power output, smoother operation, and increased durability. This guide provides insights into effective modifications that can elevate your machine’s capabilities.

Key Components for Enhancement

When considering upgrades, focus on the following crucial elements:

| Component | Benefit |

|---|---|

| High-Performance Bar | Increased cutting speed and reduced resistance. |

| Advanced Chain | Improved cutting efficiency and longevity. |

| Upgraded Air Filter | Enhanced airflow for better combustion. |

| Fuel System Modifications | Greater fuel efficiency and power output. |

| Engine Tuning | Optimized performance and responsiveness. |

Installation Tips

Proper installation of new components is essential for achieving desired improvements. Always refer to manufacturer guidelines and ensure compatibility. Additionally, consider professional assistance for complex modifications to maintain safety and performance integrity.

Community Resources for Stihl Owners

For enthusiasts and users of outdoor power equipment, connecting with fellow owners can provide invaluable support and insights. Various platforms and resources are available for sharing knowledge, troubleshooting issues, and enhancing overall experience. Engaging with the community not only fosters a sense of camaraderie but also facilitates the exchange of useful tips and advice.

Here are some key community resources that can help you maximize your experience:

| Resource Type | Description |

|---|---|

| Online Forums | Dedicated discussion boards where users can ask questions, share experiences, and offer advice. |

| Social Media Groups | Facebook and other platforms host groups where members post photos, stories, and troubleshooting tips. |

| YouTube Channels | Many enthusiasts create tutorials and reviews, providing visual guidance for maintenance and repairs. |

| Local Clubs | In-person gatherings that allow members to meet, share knowledge, and organize events related to outdoor equipment. |

| Manufacturer Websites | Official sites often feature user manuals, safety tips, and maintenance guides for equipment owners. |

By tapping into these resources, users can enhance their understanding and enjoyment of their equipment while building lasting connections with like-minded individuals.