Exploring the Stihl 088 Parts Diagram for Ultimate Maintenance

In the realm of outdoor machinery, comprehending the intricacies of your equipment is essential for optimal performance and maintenance. A comprehensive overview of individual elements can significantly enhance the longevity and functionality of your device. This exploration serves as a valuable resource for both novice and experienced users alike.

By breaking down the various components, users can gain insights into their respective roles and interrelations. Such knowledge empowers operators to troubleshoot issues effectively and make informed decisions during repairs or upgrades. The ultimate aim is to ensure seamless operation while maximizing the potential of your machinery.

As we delve into the specifics, you’ll discover how understanding these components can lead to improved efficiency and a more enjoyable experience. Familiarizing yourself with the structure not only aids in maintenance but also fosters a deeper appreciation for the engineering behind your tools.

Understanding the Stihl 088 Model

This section delves into the intricacies of a renowned chainsaw model, highlighting its features and functionalities. It serves as an essential guide for both novice and experienced users, aiming to enhance operational knowledge and maintenance practices. Recognizing the components and their interactions is key to optimizing performance and longevity.

Key Features and Specifications

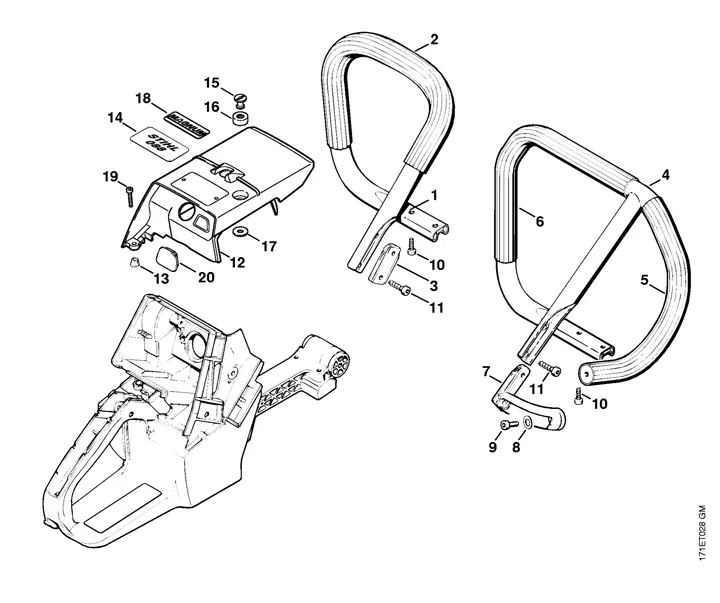

One of the standout characteristics of this chainsaw is its powerful engine, designed for heavy-duty applications. The robust design allows for prolonged use, making it ideal for professional logging and forestry work. Additionally, the ergonomic handle and anti-vibration system contribute to user comfort, reducing fatigue during extended operation.

Maintenance and Care

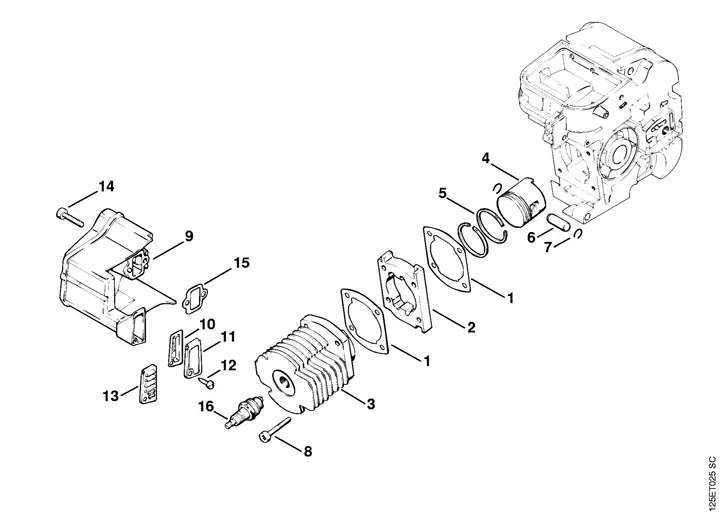

Regular upkeep is crucial for ensuring optimal performance. Users should familiarize themselves with the various elements that require attention, such as the air filter, spark plug, and bar lubrication. By understanding how these parts function, operators can effectively troubleshoot issues and maintain the efficiency of their tool.

Key Features of Stihl 088

This powerful machine is designed to tackle demanding tasks with efficiency and reliability. With its robust construction and advanced technology, it provides users with exceptional performance, making it a top choice for professionals in the forestry and landscaping industries.

Durability and Reliability

The build quality of this equipment ensures longevity and resilience even in the most challenging environments. Made with high-grade materials, it withstands heavy usage and adverse conditions, reducing the need for frequent maintenance.

Performance and Efficiency

Equipped with a high-performance engine, this tool delivers impressive cutting power while maintaining fuel efficiency. The advanced design minimizes vibration, allowing for extended use without compromising comfort. Its lightweight construction enhances maneuverability, making it easier to handle during intensive operations.

Overall, this machine stands out for its blend of power, efficiency, and durability, making it an essential asset for those who demand the best in their work.

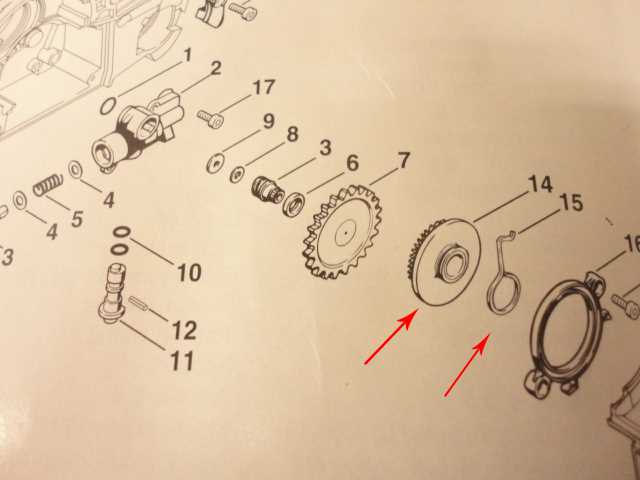

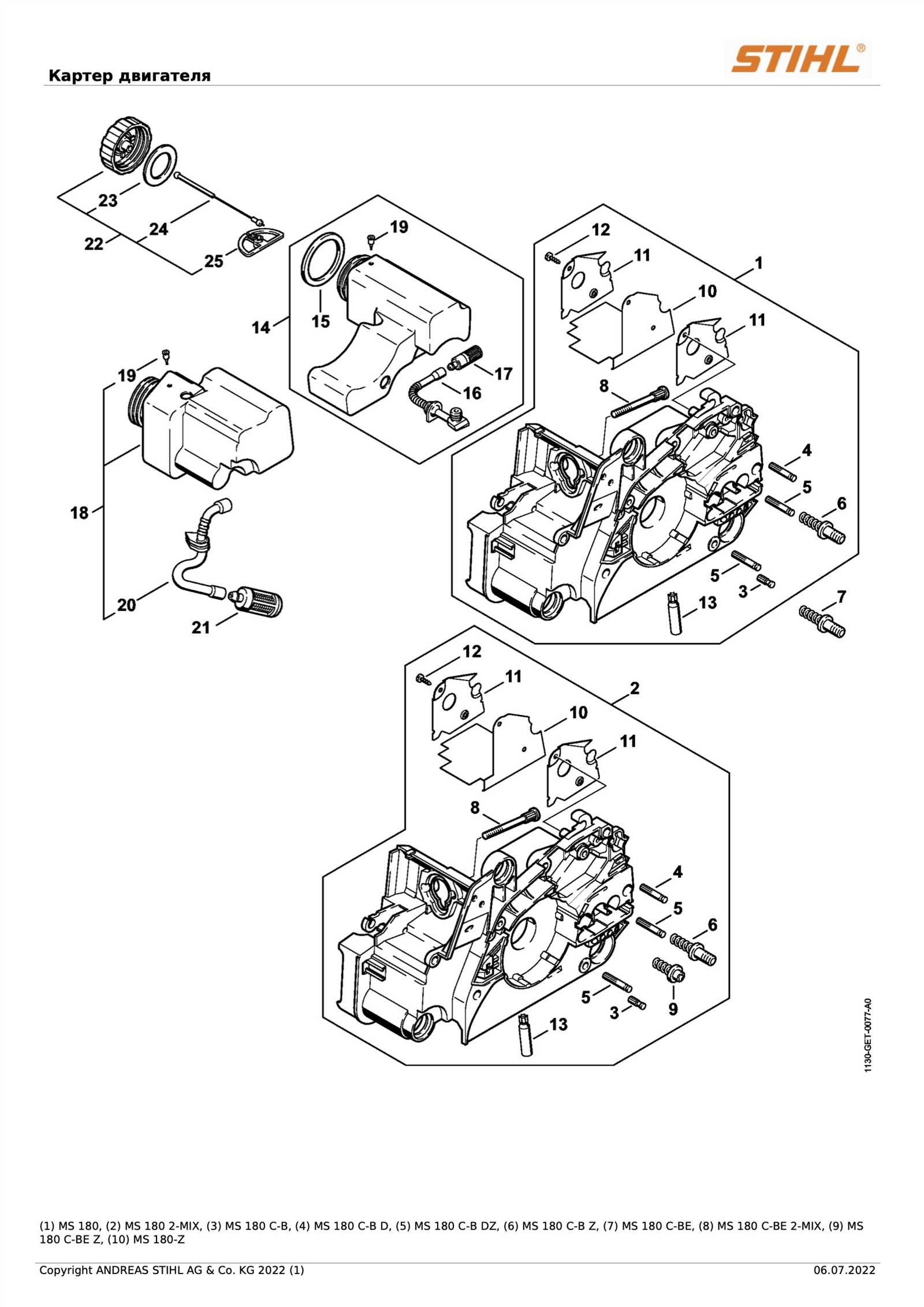

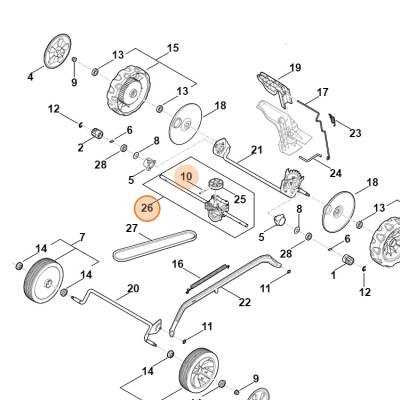

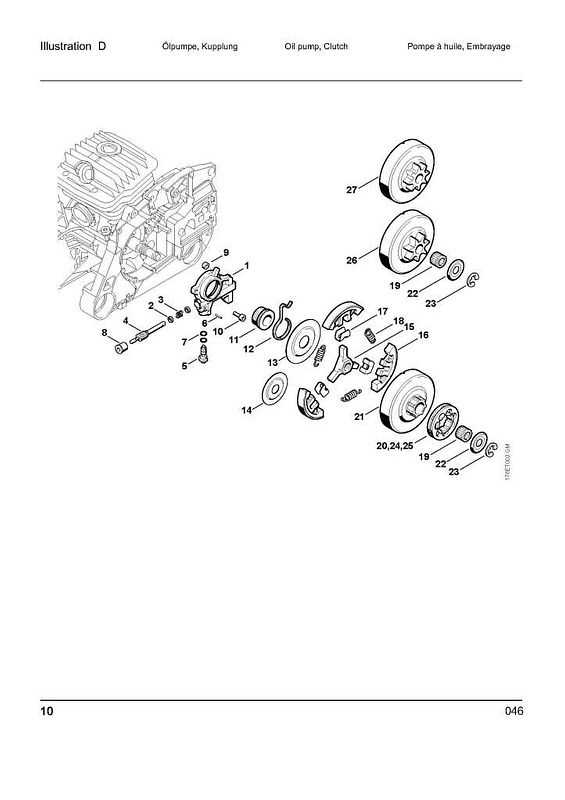

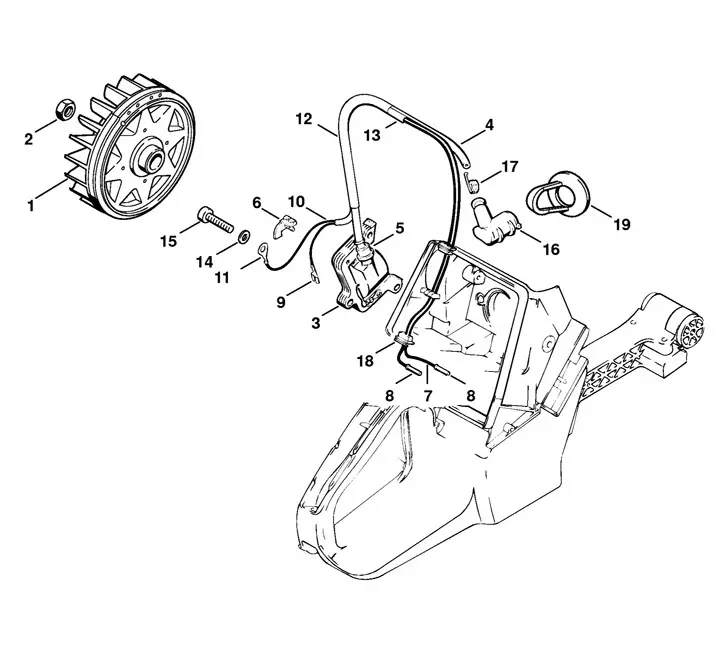

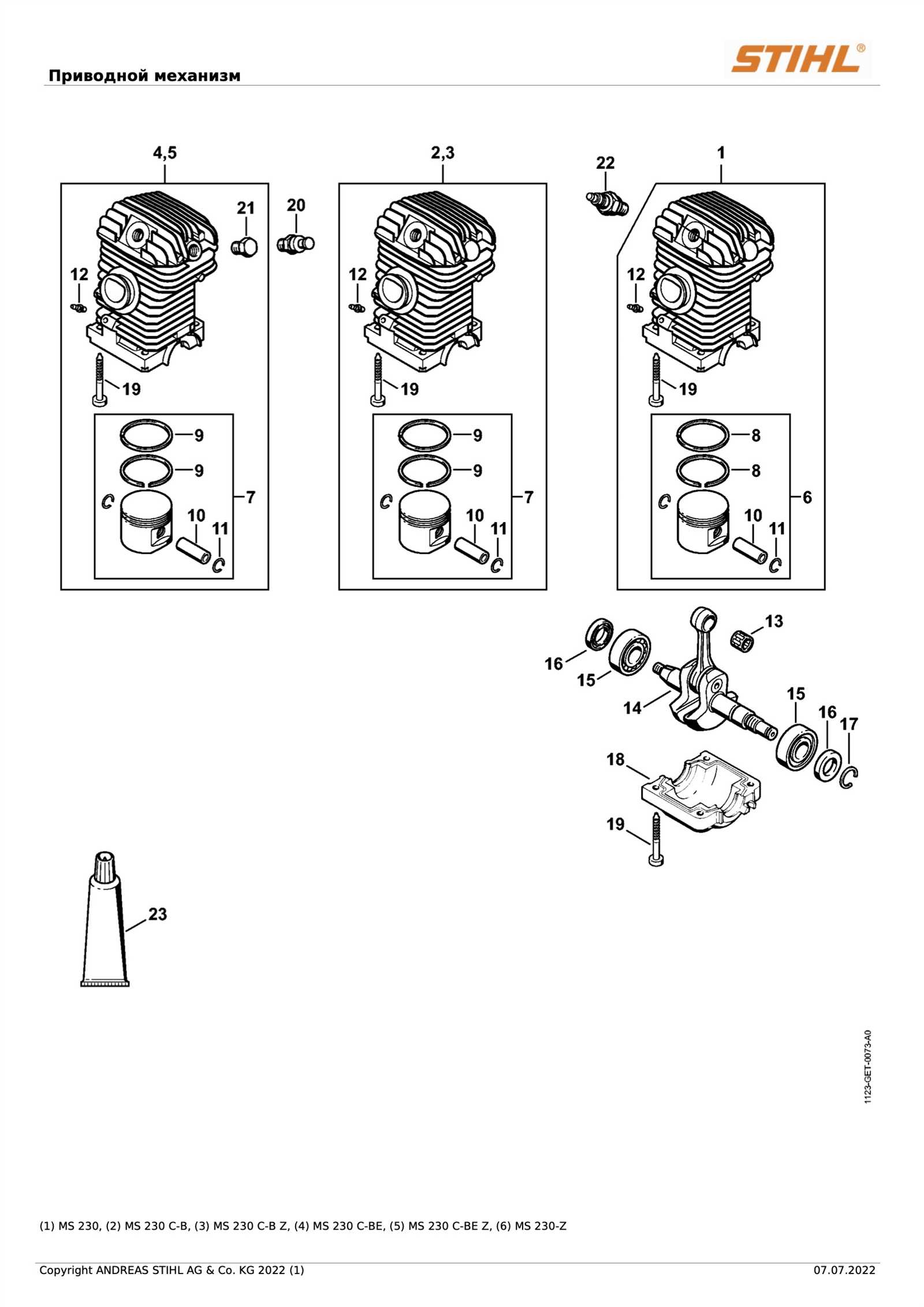

Importance of Parts Diagrams

Understanding the components of a machine is crucial for effective maintenance and repair. Visual representations serve as essential tools, providing clarity and aiding in the identification of individual elements within complex systems. By illustrating how parts fit together, these guides enable users to navigate repairs with confidence.

Comprehension is significantly enhanced when users can see how different components interact. This visual aid not only reduces the chances of errors during assembly or disassembly but also speeds up the repair process. When working with machinery, the ultimate goal is to ensure functionality and longevity, making these illustrations invaluable.

Additionally, these resources foster a deeper appreciation for the craftsmanship involved in machinery design. As users delve into the intricacies of each component, they gain insight into the engineering principles that govern performance, ultimately enhancing their skills and knowledge.

Common Issues with Stihl 088

Users often encounter several typical problems with their powerful cutting tools, which can affect performance and efficiency. Understanding these common challenges can aid in effective maintenance and troubleshooting, ensuring that the equipment runs smoothly for an extended period.

Engine Performance Problems

One of the frequent issues is related to engine performance. Users may notice difficulties in starting or maintaining a steady idle. This can be caused by clogged fuel filters or air intakes. Regular inspection and cleaning of these components are crucial for optimal function.

Bar and Chain Wear

Another concern is the wear and tear of the cutting bar and chain. Over time, these parts can become dull or damaged, leading to inefficient cutting and increased effort required by the operator. Regular sharpening and timely replacement are essential to prevent such problems and ensure smooth operation.

By being aware of these issues and performing routine checks, users can prolong the lifespan of their tools and enhance their overall performance.

Identifying Essential Components

Understanding the crucial elements of a powerful machine is vital for optimal performance and maintenance. Recognizing each part and its function not only aids in effective troubleshooting but also enhances the overall efficiency of the equipment. This knowledge empowers users to tackle issues proactively and ensure longevity.

| Component | Description |

|---|---|

| Engine | The core element responsible for power generation. |

| Chain | Essential for cutting, connecting to the drive system. |

| Bar | Supports the chain and determines cutting length. |

| Fuel Tank | Holds the mixture needed for operation. |

| Air Filter | Ensures clean air intake for optimal combustion. |

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring that equipment operates efficiently and lasts longer. By adhering to a structured maintenance routine, users can enhance performance and prevent potential issues.

- Clean the air filter regularly to ensure proper airflow.

- Inspect and sharpen cutting tools frequently to maintain effectiveness.

- Check fuel and oil levels before each use to avoid engine strain.

- Examine all components for wear and replace them as necessary.

- Keep the exterior free of debris and grime to prevent overheating.

Following these guidelines will help maintain peak performance and extend the lifespan of your equipment.

Where to Find Replacement Parts

When your equipment requires new components, knowing where to seek them can significantly enhance its performance and longevity. Various sources offer the essential elements needed for repairs and maintenance, ensuring your machine runs efficiently.

| Source | Description |

|---|---|

| Authorized Dealers | These retailers provide genuine items and often have knowledgeable staff to assist with your needs. |

| Online Marketplaces | Websites like eBay and Amazon can offer a vast selection, often at competitive prices. |

| Local Repair Shops | Independent workshops frequently stock or can order components, providing personalized service. |

| Manufacturer’s Website | The official site may feature a catalog of available items along with ordering options. |

Comparing Stihl 088 to Other Models

This section explores the distinctions and similarities between a powerful cutting tool and its contemporaries, focusing on performance, durability, and user experience. By examining various features, users can make informed decisions on the best option for their needs.

| Feature | Powerful Model | Competitor A | Competitor B |

|---|---|---|---|

| Engine Power | High | Medium | High |

| Weight | Heavy | Light | Medium |

| Vibration Control | Advanced | Standard | Basic |

| Fuel Efficiency | Moderate | High | Moderate |

Benefits of Using OEM Parts

Utilizing original components in machinery maintenance offers numerous advantages that enhance performance and longevity. These items are specifically designed to meet the exact specifications of the equipment, ensuring optimal functionality and reliability.

Quality Assurance

One of the primary benefits of original components is their superior quality. These items are manufactured under strict quality control measures, resulting in:

- Consistent performance

- Durability under various operating conditions

- Precision engineering that matches the original design

Long-term Savings

Investing in original components can lead to significant cost savings over time. While initial prices may be higher, the benefits include:

- Reduced frequency of replacements

- Decreased likelihood of mechanical failures

- Improved efficiency, leading to lower operating costs

In summary, choosing original components not only enhances the reliability of the equipment but also proves to be a wise financial decision in the long run.

Step-by-Step Repair Guide

This guide provides a comprehensive approach to restoring your equipment efficiently. By following a systematic method, you can ensure that every component is addressed properly, minimizing downtime and enhancing performance.

Begin by gathering all necessary tools and replacement components. Create a clean workspace to keep everything organized and accessible. Carefully examine the device to identify the specific issues that need attention.

Next, disassemble the unit, taking care to document the arrangement of parts for easier reassembly. Use the appropriate tools to avoid damaging any components. Clean each part thoroughly to remove debris and old lubricants.

Once cleaned, inspect the components for wear or damage. Replace any faulty parts with new ones, ensuring compatibility with your model. Reassemble the device according to the documentation you prepared earlier, making sure everything fits snugly.

After reassembly, conduct a thorough inspection to confirm that all fastenings are secure. Finally, perform a test run to ensure the equipment operates smoothly and efficiently. Make adjustments as necessary to achieve optimal performance.

Resources for Stihl Enthusiasts

For those passionate about outdoor power tools, a wealth of information and materials is available to enhance your experience. From detailed guides to online forums, these resources foster a community where enthusiasts can share insights, tips, and tricks related to maintenance and operation.

Numerous websites offer comprehensive manuals and schematics that help users understand their equipment better. You can find tutorials that cover everything from routine care to advanced troubleshooting techniques, ensuring you get the most out of your machines.

Engaging with dedicated online communities provides a platform to exchange experiences and solutions with like-minded individuals. Social media groups and specialized forums are excellent places to ask questions, seek advice, and discover the latest innovations in the industry.

Additionally, local dealers often host workshops and events that allow enthusiasts to learn hands-on skills, gain insights from experts, and connect with fellow users. Exploring these opportunities can deepen your understanding and appreciation for your tools.