Comprehensive Guide to Stihl 291 Parts Diagram

In the world of outdoor equipment, having a thorough comprehension of each element is essential for optimal performance and maintenance. This guide aims to explore the intricate details that make up your machinery, enabling users to grasp the functionality of each component. A deep understanding can significantly enhance the efficiency and longevity of your device.

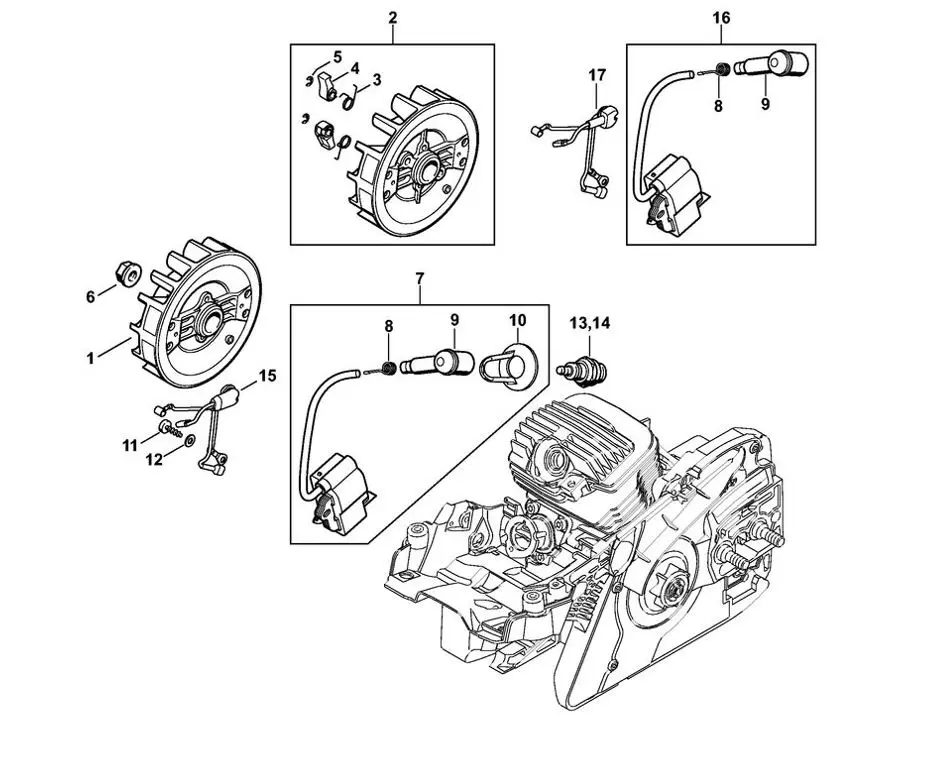

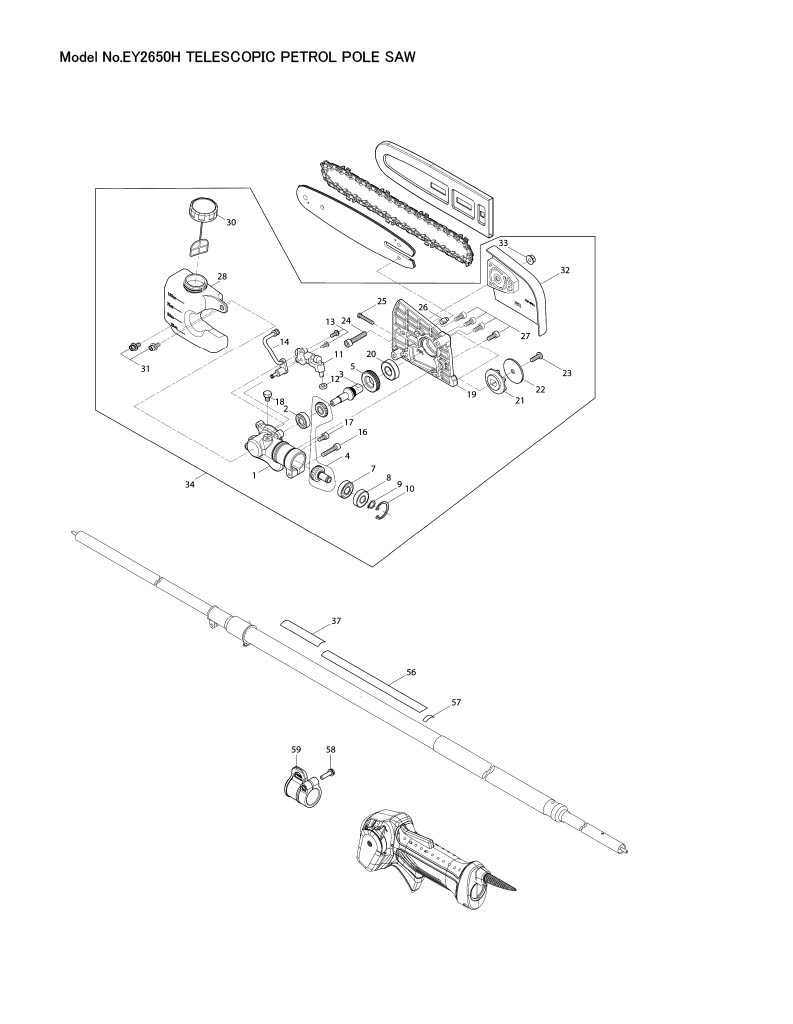

Detailed visual representations serve as valuable resources for both novice and seasoned users alike. By examining these illustrations, one can easily identify the various parts and their respective roles, fostering a greater appreciation for the engineering behind the tool. This knowledge ultimately aids in troubleshooting and repairs, ensuring your equipment remains in peak condition.

Whether you’re a hobbyist or a professional, being able to delve into the specifics of your tool’s anatomy can provide a sense of confidence during maintenance tasks. With the right insights, users can tackle any challenges that arise, empowering them to take control of their machinery’s upkeep.

Understanding Stihl 291 Components

In the realm of outdoor power tools, a comprehensive grasp of the various elements that comprise a machine is essential for optimal performance and maintenance. Each component plays a critical role in ensuring the efficiency and longevity of the equipment. By familiarizing oneself with these intricate parts, users can enhance their experience and troubleshooting capabilities.

Engine: The heart of the machine, responsible for converting fuel into mechanical energy. Understanding its function is vital for maintenance and ensuring smooth operation.

Bar and Chain: These are pivotal for cutting operations. The length and type of chain influence the tool’s effectiveness and suitability for different tasks. Regular inspection and tension adjustments are necessary for safety and performance.

Fuel System: This includes the tank, lines, and filter. A clean and functional fuel system ensures reliable starts and consistent power delivery. Any blockages or leaks can lead to performance issues.

Air Filter: Vital for maintaining engine health, this component prevents debris from entering the combustion chamber. Regular cleaning or replacement is necessary to ensure proper airflow and engine efficiency.

Starter Mechanism: This system initiates the engine’s operation. Familiarity with its components can aid in resolving starting issues, ensuring that users can get to work without unnecessary delays.

By gaining a deeper understanding of these essential components, users can improve their skills in maintenance and repair, ultimately leading to a more satisfying experience with their outdoor machinery.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding complex machinery. They provide a clear and organized way to identify each element, making it easier for users to navigate through the intricate assembly of devices. This clarity can significantly enhance the efficiency of repairs and maintenance tasks.

Enhanced Understanding: These visual aids simplify the learning process for technicians and users alike. By illustrating how different components fit together, they help to demystify the assembly and functionality of the equipment.

Streamlined Repairs: When issues arise, having access to accurate illustrations can expedite the troubleshooting process. Users can quickly pinpoint problematic areas and determine the necessary steps for repair, ultimately saving time and reducing frustration.

Efficient Ordering: For those looking to replace specific elements, these graphics serve as a reference to ensure that the correct items are ordered. This precision minimizes the risk of acquiring incorrect parts, which can lead to further complications.

Maintenance Guidance: Regular upkeep is essential for optimal performance, and visual references assist in identifying which components require attention. They can also highlight wear points and suggest intervals for maintenance, contributing to the longevity of the machinery.

Common Issues with Stihl 291

Many users of this popular outdoor power equipment model encounter a range of common challenges. Understanding these issues can help in maintaining optimal performance and extending the lifespan of the tool. Here, we explore some frequent problems and their potential solutions.

| Issue | Description | Possible Solution |

|---|---|---|

| Starting Problems | Difficulty in initiating the engine can frustrate users. | Check the spark plug, fuel mixture, and air filter for blockages or wear. |

| Engine Stalling | The engine may unexpectedly shut off during operation. | Inspect the fuel supply and ensure proper air intake. Clean or replace filters as needed. |

| Excessive Vibration | Unusual vibrations can lead to discomfort and potential damage. | Examine the mounting screws and rubber components for wear or looseness. |

| Poor Cutting Performance | Insufficient cutting efficiency can hinder tasks. | Sharpen the chain regularly and ensure correct tension settings. |

| Overheating | Overheating may occur during extended use, risking damage. | Take breaks during prolonged operations and check the cooling system for blockages. |

Essential Tools for Repair

When it comes to maintaining outdoor equipment, having the right tools is crucial for efficient and effective repairs. A well-equipped toolbox not only simplifies the process but also ensures that each component is handled with care, prolonging the lifespan of the machinery. Whether you are a professional or a DIY enthusiast, understanding the essential instruments can significantly enhance your repair experience.

Wrenches are fundamental for loosening and tightening bolts. It’s advisable to have both metric and imperial sizes to accommodate various fasteners. In addition, screwdrivers–including flathead and Phillips–are indispensable for adjusting and securing parts.

For more intricate tasks, pliers are invaluable. They provide a firm grip, making it easier to manipulate small components. Furthermore, a good socket set can speed up the process, allowing for quick changes and reducing the risk of stripping bolts.

Don’t overlook the importance of a workbench. A sturdy surface can significantly enhance stability while working, making it safer and more comfortable to focus on the task at hand. Lastly, a toolbox for organization will keep everything accessible and in order, saving time and effort during repairs.

Where to Find Replacement Parts

Finding suitable components for your equipment can be a daunting task, but there are several reliable avenues to explore. Understanding where to look can save you time and ensure you obtain quality items for your machinery.

Online Retailers

- Manufacturer’s Official Website

- Third-party E-commerce Platforms

- Specialized Tool Supply Stores

Local Options

- Authorized Dealers

- Repair Shops

- Local Hardware Stores

Exploring these resources can help you locate the necessary components efficiently, ensuring your tools remain in optimal condition for years to come.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. Such illustrations provide a clear overview of various elements, helping users identify and locate each piece within a larger assembly. Familiarizing yourself with the symbols and layouts can greatly enhance your ability to work with machinery.

1. Familiarize Yourself with the Layout: Begin by examining the overall structure. Most visual aids will display a main component with connected elements branching off. This allows for a quick understanding of how parts interact and fit together.

2. Identify Symbols and Labels: Each component will typically have a unique identifier, often represented by numbers or letters. Cross-reference these with accompanying documentation to ensure accuracy in your understanding of each part’s function.

3. Pay Attention to Relationships: Observe how the various pieces connect to one another. Some components may be crucial for the operation of others, so understanding these relationships is vital for troubleshooting issues or planning repairs.

4. Note Scale and Orientation: Visuals may vary in scale, which is important when determining the size of components. Additionally, orientation can affect assembly; ensure that you understand how parts should align for proper functionality.

By mastering these skills, you’ll be better equipped to navigate any visual representation of components, leading to more efficient repairs and maintenance.

Maintenance Tips for Longevity

Ensuring the extended life of your equipment requires consistent care and attention. Proper maintenance not only enhances performance but also minimizes the likelihood of breakdowns and costly repairs. Following a systematic approach to upkeep can significantly contribute to the reliability and efficiency of your tools.

Regularly check and replace worn components to prevent further damage. This includes inspecting filters, spark plugs, and chains for signs of wear. Cleanliness is vital; dirt and debris can lead to overheating and inefficiency, so make it a habit to keep all parts free from grime.

Lubrication is another critical aspect of maintenance. Utilizing the appropriate oils for moving parts reduces friction and wear, ensuring smooth operation. Additionally, adhering to the manufacturer’s recommendations regarding fuel mixtures will promote optimal performance and longevity.

Seasonal checks are beneficial, particularly before extended periods of use. Examine all systems for potential issues and address them promptly. Storing equipment in a dry, protected space during off-seasons helps prevent rust and other environmental damage.

Finally, familiarize yourself with the operating manual. Understanding the specific needs of your equipment allows for more effective maintenance routines, ultimately resulting in a longer lifespan and enhanced functionality.

Identifying OEM vs. Aftermarket Parts

When maintaining or repairing equipment, understanding the distinction between original components and those produced by third parties is crucial. Each option has its own set of characteristics that can influence performance, reliability, and cost. Knowing how to differentiate between these alternatives can help in making informed decisions that affect both longevity and efficiency.

Original components are crafted by the manufacturer and are designed to meet specific standards, ensuring optimal compatibility and performance. In contrast, third-party offerings may vary in quality and specifications, often presenting a cost-effective solution but lacking the assurance of the original design.

| Feature | OEM Components | Aftermarket Components |

|---|---|---|

| Quality Assurance | High | Varies |

| Compatibility | Perfect fit | May require adjustments |

| Warranty | Often includes | Limited or none |

| Cost | Generally higher | More affordable |

| Availability | Usually available from manufacturer | Widely available from various suppliers |

Ultimately, the choice between original and third-party components depends on individual priorities, including budget constraints, desired performance, and long-term maintenance plans. Assessing these factors can lead to a more satisfying and successful repair or upgrade experience.

Step-by-Step Repair Guide

This guide provides a systematic approach to addressing common issues encountered with outdoor power tools. By following these detailed instructions, you can enhance the longevity and efficiency of your equipment while saving time and money on repairs.

1. Preparation: Before starting any repair, ensure you have a clean workspace. Gather all necessary tools, including screwdrivers, wrenches, and replacement components. Familiarize yourself with the equipment to understand its basic functions.

2. Safety First: Always prioritize safety. Disconnect the power source and wear protective gear such as gloves and goggles. This minimizes the risk of injury while handling machinery.

3. Disassembly: Carefully remove any covers or housing to access internal parts. Take notes or photos of the arrangement to facilitate reassembly. Keep screws and small components organized to avoid losing them.

4. Inspection: Examine all accessible parts for wear and damage. Look for cracks, breaks, or excessive wear. Identifying issues early can prevent further damage and costly repairs.

5. Replacement: If you identify any faulty components, replace them with high-quality substitutes. Ensure that new parts are compatible and fit securely to maintain optimal performance.

6. Reassembly: Once repairs are made, carefully reassemble the tool by reversing the disassembly steps. Double-check connections and ensure all screws are tightened properly to avoid future malfunctions.

7. Testing: After reassembly, conduct a thorough test of the equipment. Observe its functionality and listen for unusual noises. This step is crucial to ensure that repairs were successful and that the tool is operating safely.

8. Maintenance: Regular maintenance is key to prolonging the life of your machinery. Clean and lubricate parts as needed and check for any signs of wear periodically.

Customer Reviews of Stihl 291 Parts

Feedback from users plays a crucial role in understanding the quality and reliability of components for outdoor power equipment. The insights shared by customers help potential buyers make informed decisions about their purchases. This section highlights the experiences and opinions of users regarding various components, shedding light on their performance and durability.

Many users appreciate the reliability of the components, noting that they significantly enhance the performance of their machines. Common points raised in reviews include:

- Durability: Several customers mentioned that the components withstand heavy use and harsh conditions without failing.

- Ease of Installation: Many found that replacement and installation processes were straightforward, allowing them to get back to work quickly.

- Performance Improvement: Users often report noticeable enhancements in efficiency and operation after replacing older or worn-out parts.

However, some reviews highlight areas for improvement:

- Cost: A few users expressed concerns about the price, feeling that it was higher compared to alternatives.

- Availability: Some customers noted difficulties in finding specific components locally, leading to delays in repairs.

Overall, the reviews reflect a generally positive sentiment towards the quality of the components, with many users recommending them to others in need of reliable replacements for their outdoor tools.

Comparing Stihl 291 to Other Models

When evaluating various outdoor power tools, it’s essential to understand how different models stack up against each other. Each machine offers unique features, performance capabilities, and intended applications, making direct comparisons vital for users aiming to select the best option for their specific needs. This section highlights key distinctions and similarities between a popular model and its competitors.

Performance and Efficiency

One critical aspect to consider is the power output and efficiency of the machines. Users often prioritize tools that deliver robust performance while maintaining fuel efficiency. Here’s a comparative analysis of performance metrics among selected models:

| Model | Engine Power (HP) | Fuel Efficiency (MPG) | Weight (lbs) |

|---|---|---|---|

| Model A | 3.0 | 25 | 12.0 |

| Model B | 3.5 | 30 | 11.5 |

| Model C | 2.8 | 28 | 13.0 |

Features and Usability

In addition to performance, the usability of each machine plays a significant role in user satisfaction. Features such as ease of starting, vibration reduction, and maintenance requirements are crucial for long-term ownership. Here’s a quick overview of how various models fare in terms of user-friendly features:

| Model | Easy Start | Vibration Control | Maintenance Needs |

|---|---|---|---|

| Model A | Yes | Advanced | Low |

| Model B | Yes | Moderate | Medium |

| Model C | No | Basic | High |

Resources for Stihl Owners

For enthusiasts and users of outdoor power equipment, having access to reliable information and resources is crucial for optimal performance and maintenance. This section aims to provide a variety of tools and references that can enhance the ownership experience, ensuring that every user can find the support they need.

Online Forums and Communities: Engaging with fellow users can be invaluable. Many online platforms host discussions where you can share experiences, ask questions, and learn from others’ expertise. These communities often feature troubleshooting tips and maintenance advice tailored to specific models.

Manufacturer Websites: The official sites of equipment manufacturers typically offer a wealth of resources, including user manuals, maintenance guides, and instructional videos. These documents are essential for understanding your machine’s specifications and best practices for care.

Local Dealers and Service Centers: Building a relationship with your local dealer can provide access to expert knowledge and personalized service. They can offer hands-on assistance, repair services, and the latest product updates, ensuring that your equipment remains in top condition.

Instructional Videos: Visual learners will benefit from the plethora of online video tutorials. Platforms like YouTube host a variety of channels dedicated to outdoor equipment maintenance, showcasing step-by-step guides for repairs and enhancements.

Maintenance Apps: There are numerous mobile applications designed to help track maintenance schedules and parts inventory. These tools can remind you when it’s time for service and keep your equipment running smoothly.

By utilizing these resources, users can enhance their knowledge and skills, ensuring that their outdoor power tools operate efficiently and last for years to come.