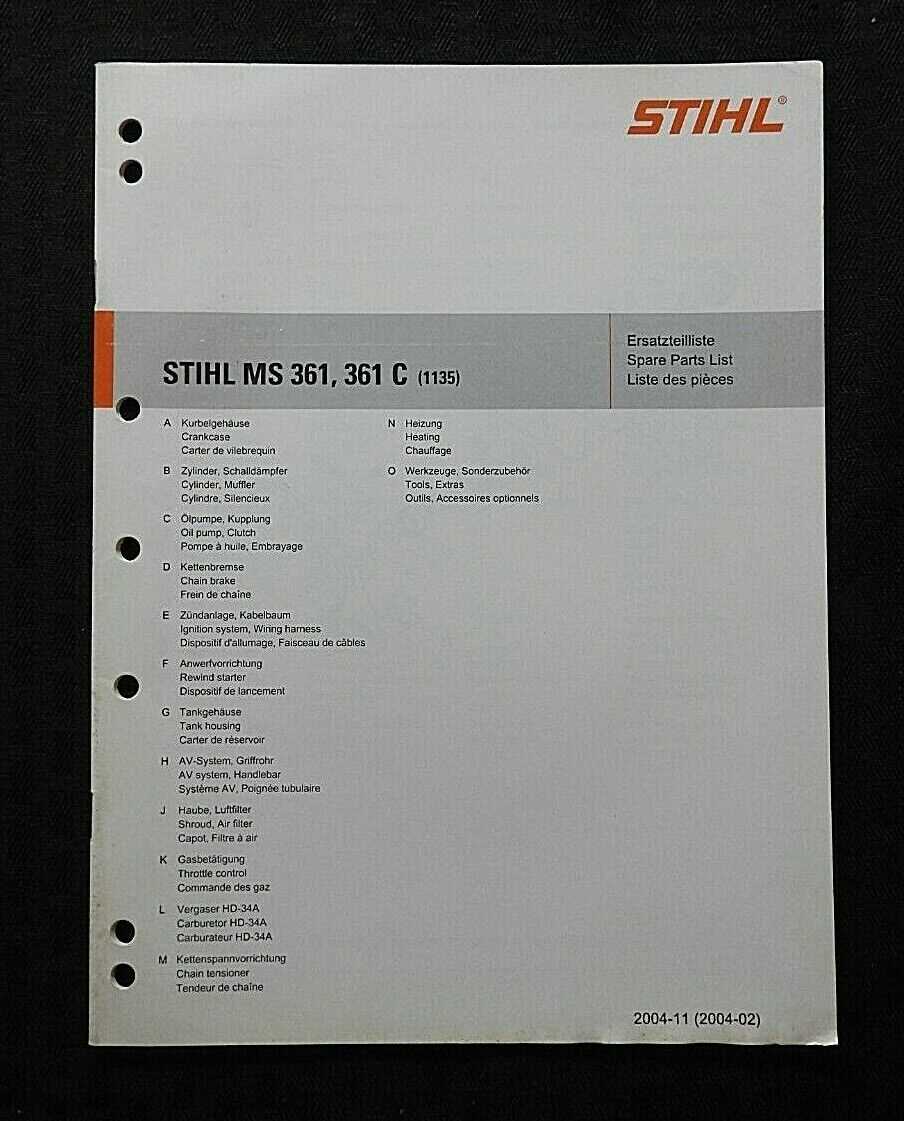

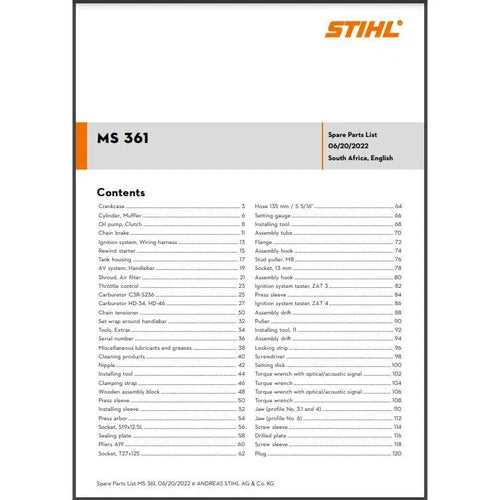

Comprehensive Parts Diagram for Stihl 361 Chainsaw

In the world of outdoor equipment, having a comprehensive grasp of how various components function together is crucial for optimal performance. A well-maintained machine not only enhances productivity but also ensures safety during operation. This section delves into the intricate details of a specific cutting tool, highlighting its essential elements and their roles in achieving efficient cutting tasks.

Exploring the Configuration of this powerful apparatus reveals a meticulous arrangement of mechanical parts, each designed to perform a specific function. Familiarity with these components can significantly aid in troubleshooting issues and conducting maintenance, ultimately extending the lifespan of the equipment.

Whether you are a seasoned professional or a casual user, understanding the layout and interaction of these parts can empower you to make informed decisions about repairs and upgrades. By gaining insight into this assembly, you can enhance your skill set and ensure your tools are always ready for the task at hand.

Understanding the Stihl 361 Chainsaw

This section aims to provide a comprehensive overview of a popular cutting tool known for its efficiency and reliability. Understanding the components and their functions is essential for maintenance and optimal performance. Knowledge of the internal mechanisms can enhance user experience and extend the lifespan of the equipment.

Each segment of the tool plays a crucial role in its overall operation. Familiarizing oneself with these parts can aid in troubleshooting and repair, ensuring smooth functionality. Below is a summary of key components and their purposes:

| Component | Description |

|---|---|

| Engine | Drives the cutting mechanism, providing necessary power. |

| Bar | Guides the chain and supports the cutting action. |

| Chain | Equipped with sharp teeth that perform the actual cutting. |

| Clutch | Engages and disengages the chain based on throttle input. |

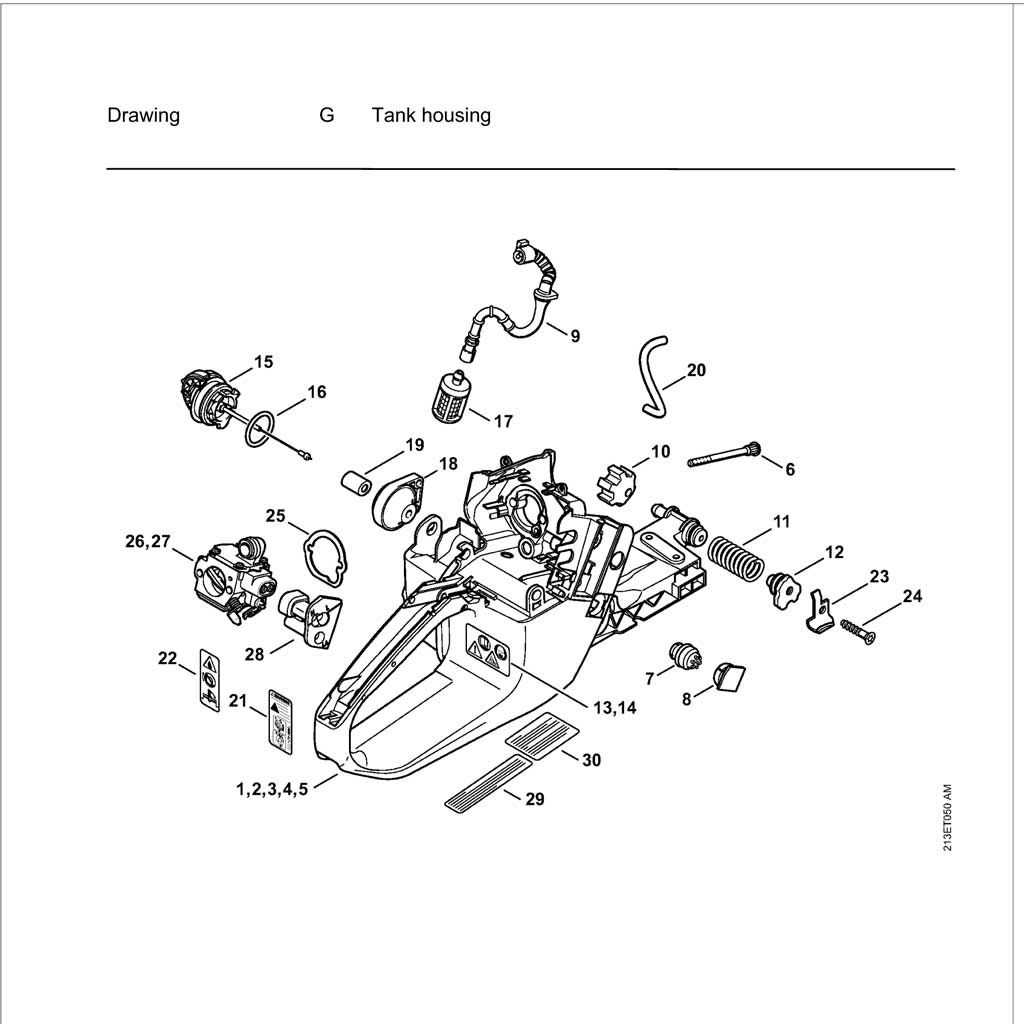

| Fuel System | Supplies the engine with the necessary mixture for operation. |

By understanding these essential components, users can better appreciate the design and functionality of this powerful tool, leading to improved handling and maintenance practices.

Key Components of the Stihl 361

This section focuses on essential elements that contribute to the functionality and efficiency of a popular cutting tool. Understanding these core components enhances maintenance and operational performance, ensuring longevity and reliability during use.

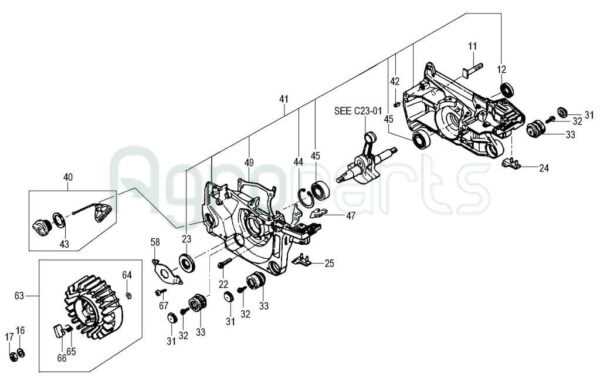

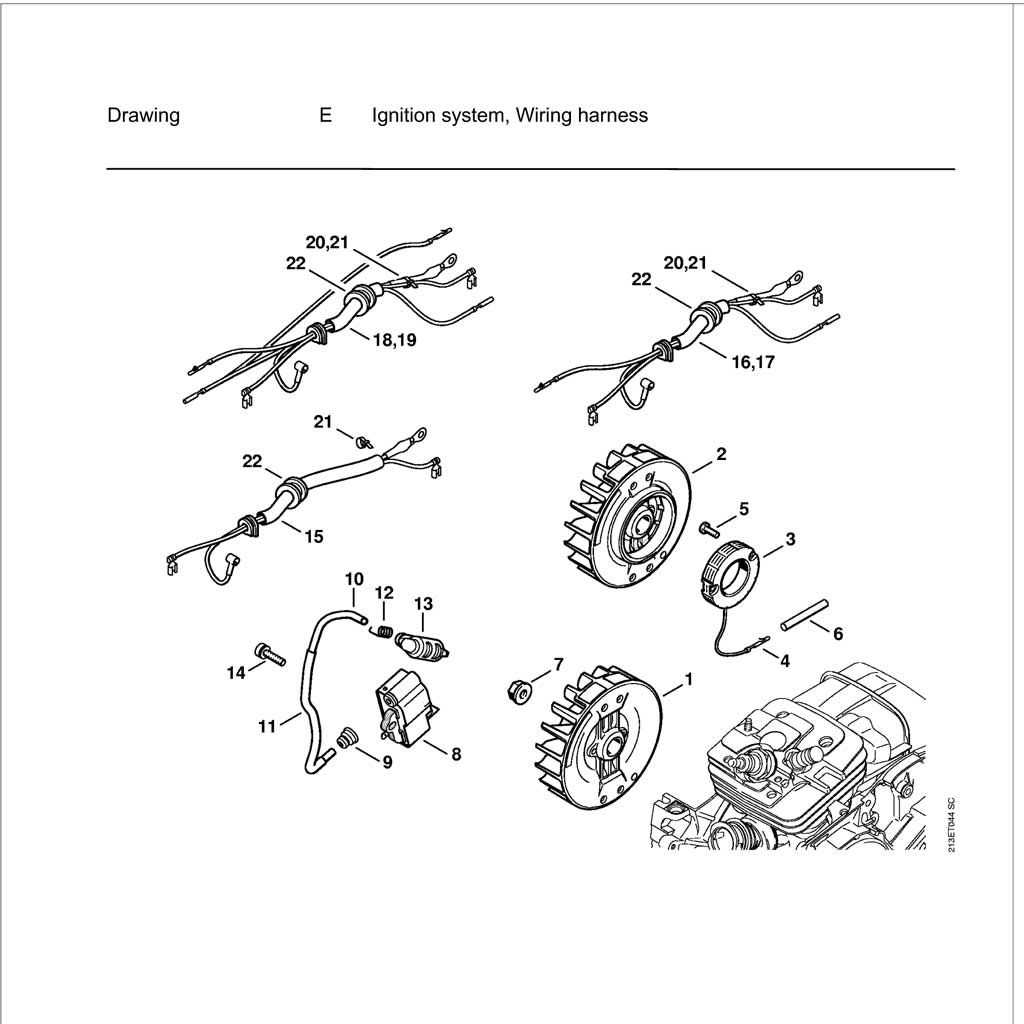

Engine and Power System

The engine serves as the powerhouse, converting fuel into mechanical energy. Key aspects include the cylinder, piston, and spark plug, which work in harmony to initiate combustion and drive the cutting mechanism. A robust power system ensures consistent performance and optimal cutting speed.

Bar and Chain Assembly

The bar and chain assembly is critical for effective cutting. The guide bar provides a stable platform, while the chain, equipped with sharp teeth, slices through wood. Regular inspection and tension adjustments are necessary to maintain peak efficiency and prevent wear.

Regular maintenance of these components is essential to achieve maximum performance and extend the lifespan of the equipment.

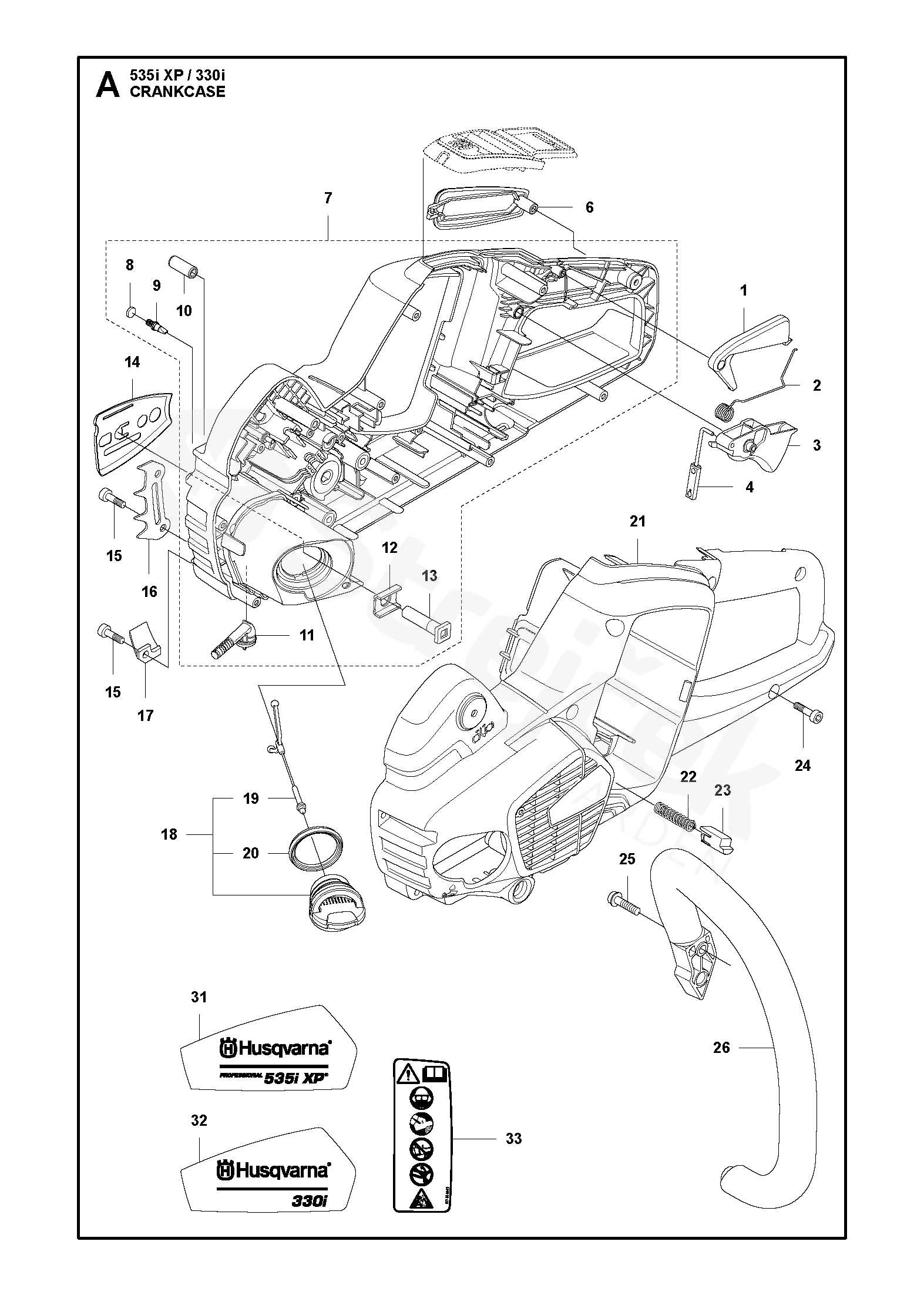

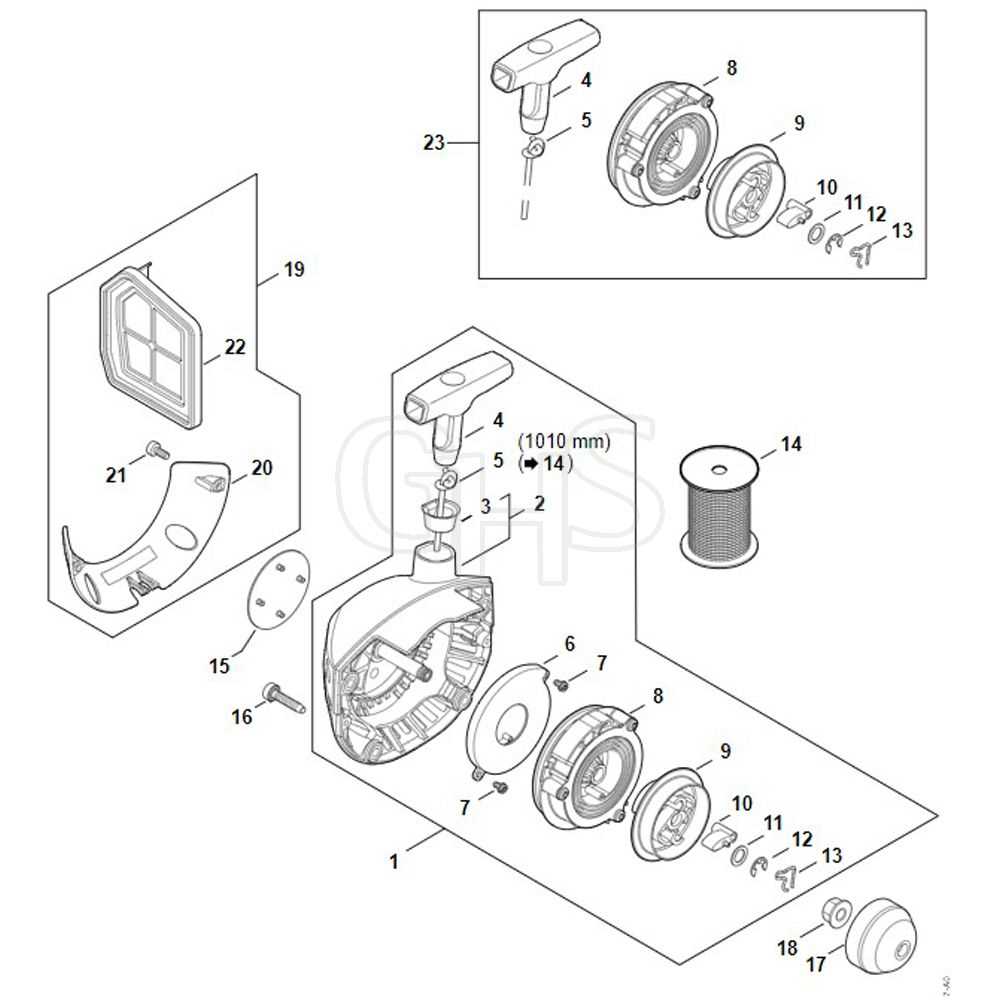

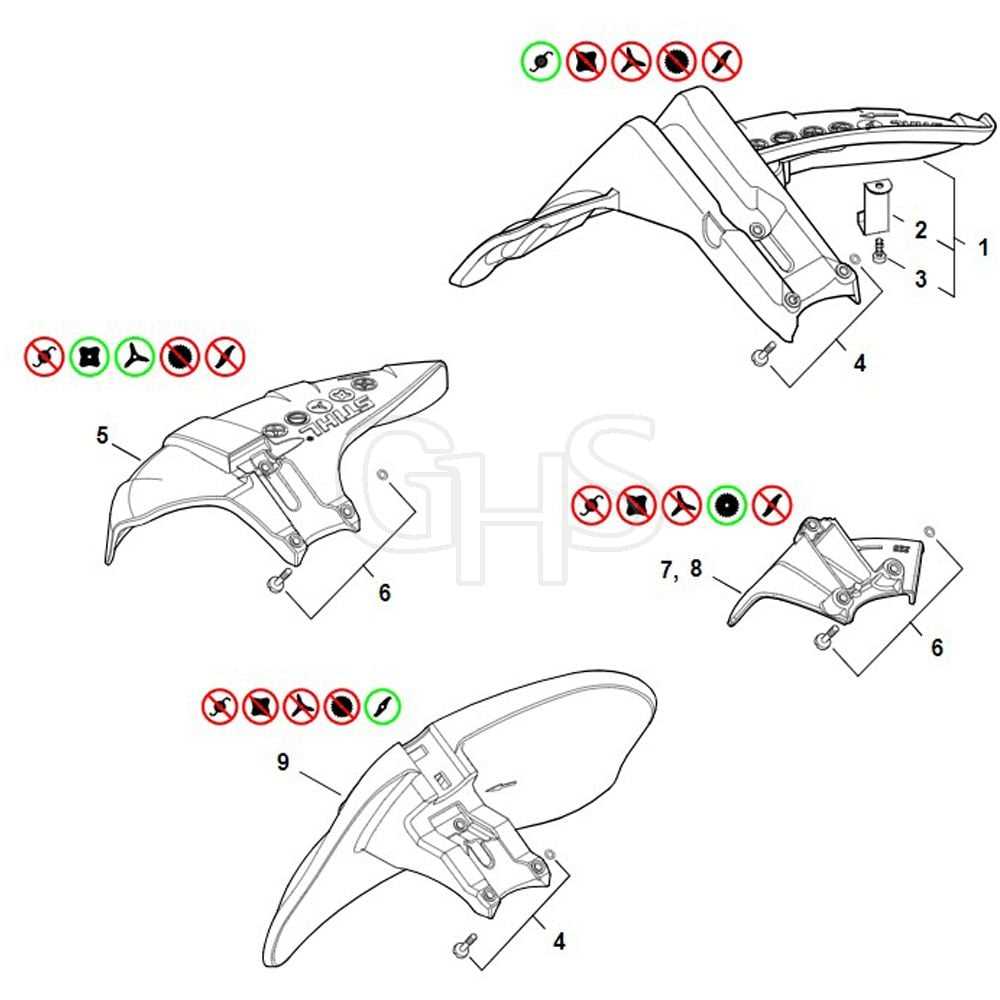

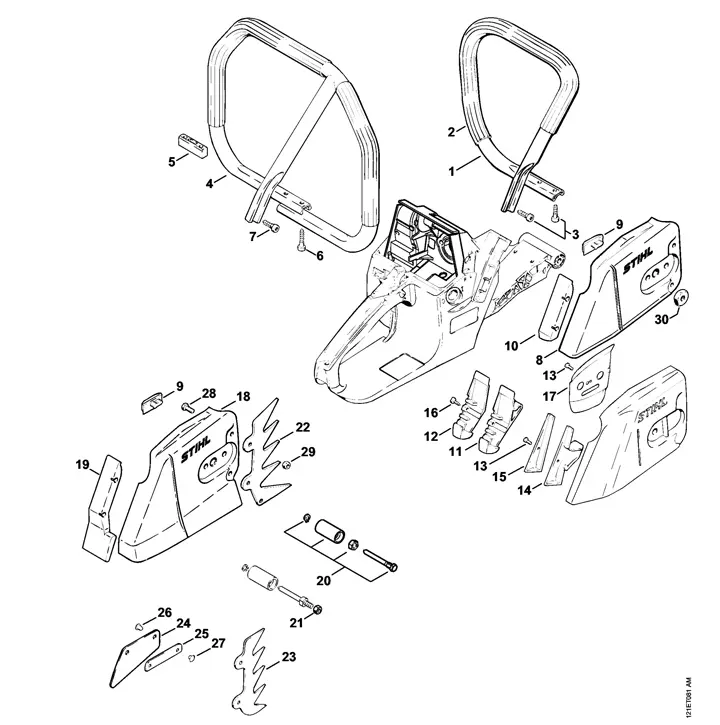

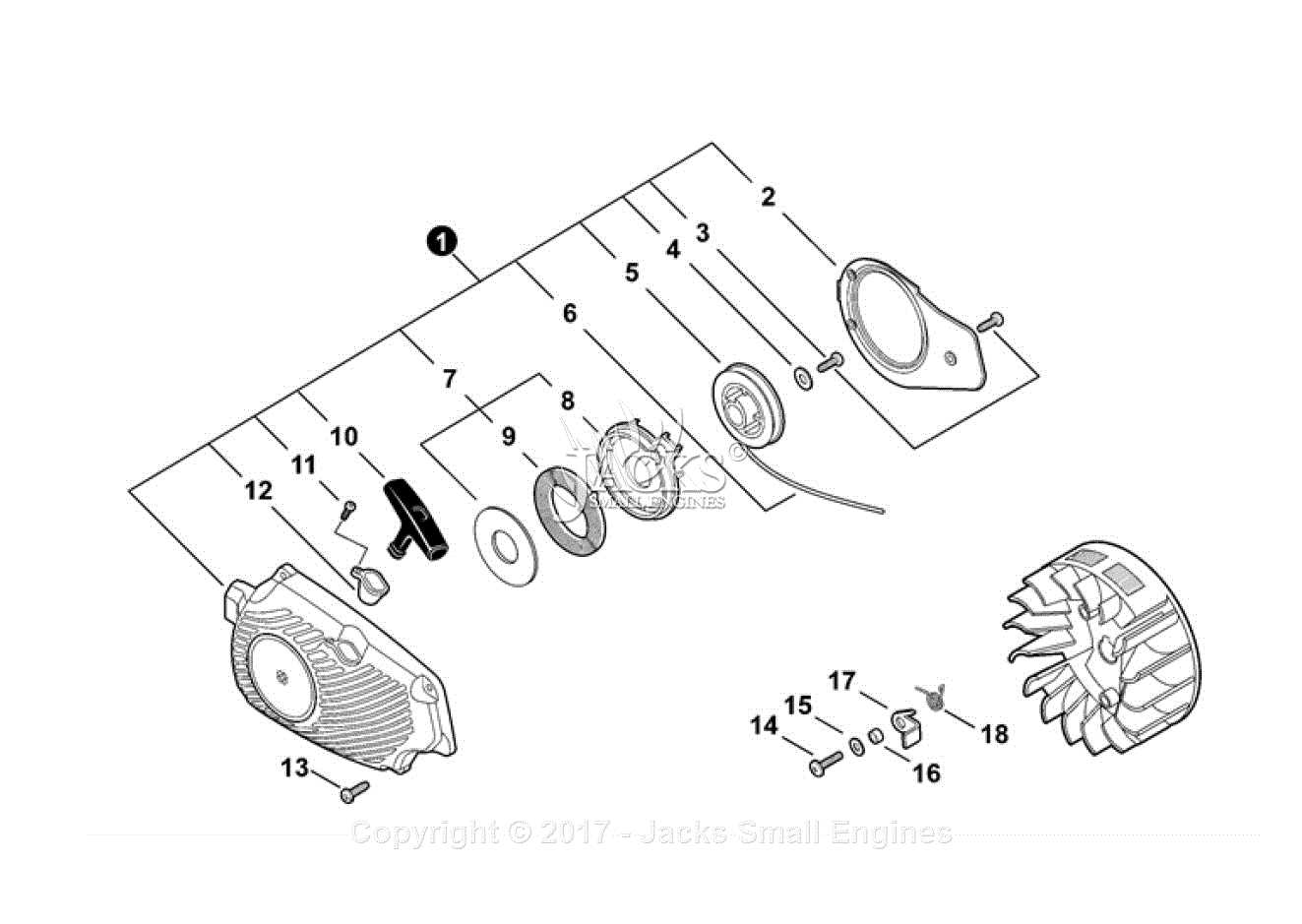

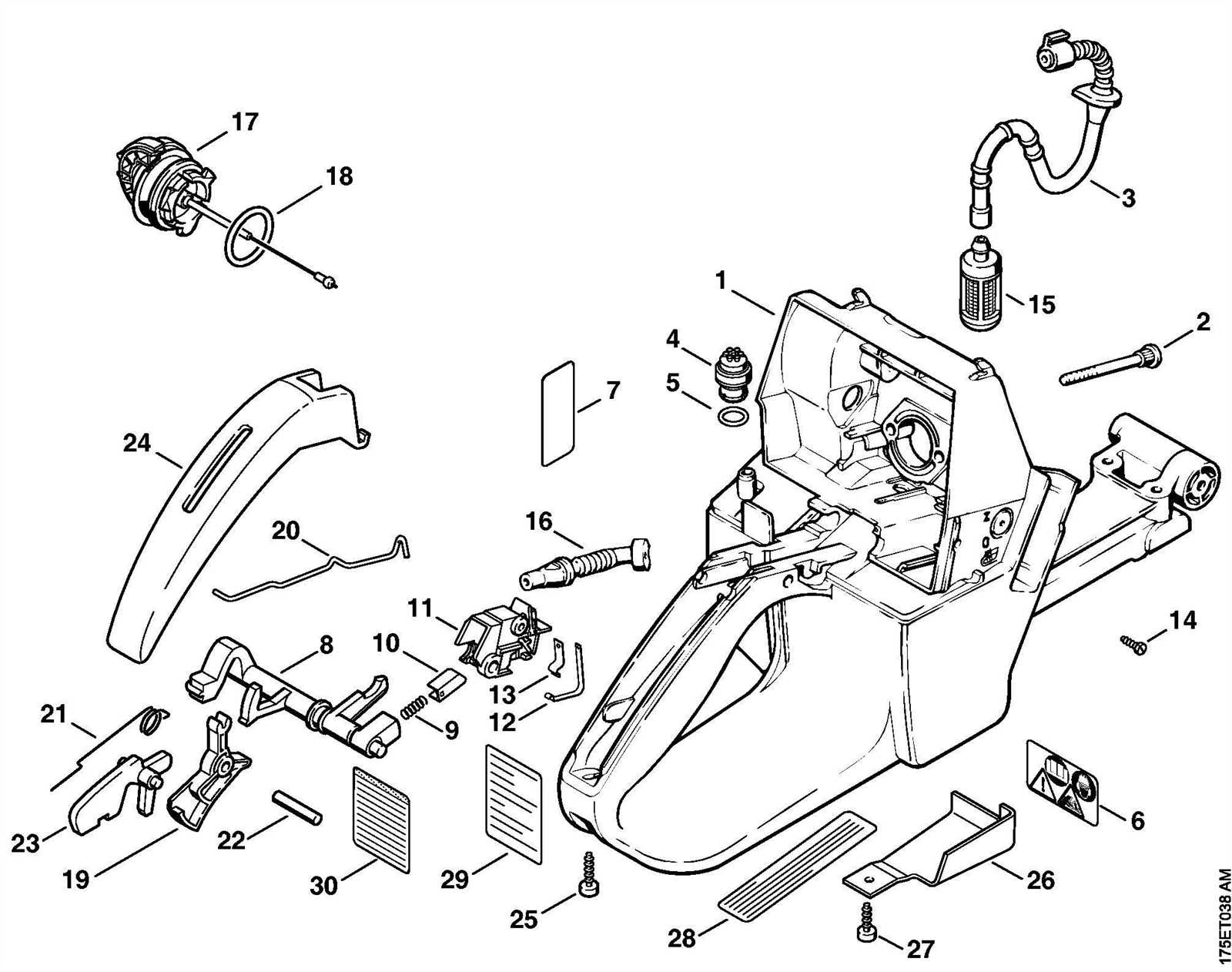

How to Read Parts Diagrams

Understanding technical illustrations can greatly enhance your ability to maintain and repair equipment. These visual guides provide a detailed breakdown of components and their arrangement, making it easier to identify and source replacements. Mastering the interpretation of these visuals is essential for efficient troubleshooting and ensuring the longevity of your machinery.

Begin by familiarizing yourself with the layout of the illustration. Typically, each element is labeled with a reference number that corresponds to a list detailing specifications or descriptions. This numbering system allows for quick identification of specific components and helps in organizing tasks related to repairs or replacements.

Next, pay attention to the relationships between parts. Many illustrations depict how components fit together, illustrating connections, orientations, and potential assembly sequences. This understanding is crucial for effective disassembly and reassembly, ensuring that all pieces function harmoniously.

Additionally, consider the accompanying notes or legends often found alongside the visual representation. These annotations can provide invaluable insights regarding installation, maintenance tips, or warnings about common issues. They serve as a quick reference to prevent mistakes during the repair process.

Lastly, practice makes perfect. The more you work with these technical illustrations, the more adept you will become at deciphering them. Over time, you will develop an intuitive understanding of how various components interact, leading to more efficient repairs and a deeper appreciation for the machinery you work with.

Common Issues with Stihl 361 Parts

When operating any cutting tool, certain components may present challenges that can impact performance and safety. Understanding these potential problems is essential for maintenance and troubleshooting. From wear and tear to improper assembly, various factors can lead to decreased efficiency or malfunction.

Frequent Wear and Tear

Components such as the bar and chain often experience significant wear due to constant friction and stress. Regular inspection is necessary to identify signs of deterioration, which can lead to inefficient cutting and increased risk of damage to surrounding elements. Replacing worn parts promptly can restore optimal function.

Fuel and Air Mixture Issues

An improper mixture of fuel and air can result in poor engine performance. If the combustion chamber isn’t receiving the right ratio, it may lead to hard starts, stalling, or even overheating. Regularly checking filters and making adjustments to the mixture can prevent these issues and ensure smoother operation.

Identifying Replacement Parts Easily

Finding the right components for your equipment can be a straightforward process if you know where to look. Understanding the layout and function of each element is crucial for ensuring optimal performance and longevity of your machine. This guide will help you navigate the essential aspects of identifying the necessary pieces quickly and efficiently.

Utilizing Resourceful Guides

One effective approach is to consult detailed manuals or reference materials that provide clear illustrations and descriptions of each item. These guides typically categorize components, making it easier to locate what you need based on function or location within the assembly. A well-structured manual serves as a valuable tool for both novices and seasoned users alike.

Consulting Online Communities

Engaging with online forums and community groups can also be beneficial. Enthusiasts often share their experiences, offer advice, and post valuable tips for identifying and sourcing specific elements. By tapping into collective knowledge, you can streamline your search and ensure that you acquire the correct replacements for your machinery.

Maintenance Tips for Your Chainsaw

Regular upkeep is essential for ensuring the longevity and efficiency of your cutting tool. By adhering to a structured maintenance routine, you can prevent potential issues, enhance performance, and ensure safety during use. Below are some effective practices to keep your equipment in optimal condition.

Regular Inspection

- Check the chain tension and adjust as needed.

- Inspect the bar for wear or damage.

- Examine the air filter for dirt and debris.

- Look for leaks in fuel and oil lines.

Cleaning and Lubrication

- Clean the cutting chain after each use to remove sawdust and debris.

- Apply lubricant to the bar and chain regularly.

- Ensure the oil reservoir is filled with the appropriate lubricant.

Following these maintenance tips will help extend the life of your tool and improve its performance, making your cutting tasks safer and more efficient.

Where to Buy Genuine Parts

When it comes to maintaining your equipment, sourcing authentic components is essential for optimal performance and longevity. Quality replacements not only ensure reliability but also help to prevent potential issues that can arise from using substandard alternatives. Knowing where to find these genuine items can make a significant difference in your maintenance routine.

One of the best options is to visit authorized dealers, which provide a wide selection of original components and offer expert advice on selection and installation. Additionally, reputable online retailers often stock a variety of authentic items, making it convenient to browse and order from the comfort of your home.

Another valuable resource is local repair shops, which may carry genuine inventory or can order specific components on your behalf. Always verify that any source you consider is known for its commitment to quality and customer service. Investing time in finding authentic replacements will ultimately enhance the performance and safety of your equipment.

Aftermarket Parts: Pros and Cons

When it comes to maintenance and repair of outdoor power equipment, the choice between original and alternative components can significantly impact performance and longevity. Understanding the advantages and disadvantages of using substitute items is essential for making informed decisions.

Advantages of Aftermarket Components

One of the primary benefits of opting for alternative items is cost-effectiveness. Typically, these substitutes are available at lower prices, making them more accessible for budget-conscious users. Additionally, a broader selection may be available, allowing for customization and potentially improved performance. Many alternative manufacturers focus on enhancing specific features, which can lead to better efficiency or durability.

Disadvantages of Aftermarket Components

On the flip side, the quality of substitute items can vary widely. Some may not meet the same standards as original components, leading to reliability issues. There is also a risk of voiding warranties if these alternatives are used, which can result in higher long-term costs. Compatibility is another concern; not all substitutes fit perfectly, which might lead to operational problems or increased wear on the equipment.

| Pros | Cons |

|---|---|

| Cost-effective options | Variable quality |

| Wider selection available | Risk of voiding warranties |

| Potential for enhanced performance | Compatibility issues |

Safety Features of the Stihl 361

When operating powerful cutting tools, prioritizing safety is essential to ensure both user protection and efficient performance. Various mechanisms are integrated into these devices to minimize risks and enhance user confidence during operation.

Chain Brake System: This feature provides immediate stopping of the cutting chain in case of kickback or sudden movements. The quick response of the brake is crucial for preventing injuries.

Vibration Dampening: Equipped with advanced dampening technology, these tools reduce the vibration experienced by the user, which not only enhances comfort but also decreases the likelihood of fatigue, allowing for safer operation over extended periods.

Throttle Lock: The throttle lock is designed to prevent accidental engagement of the cutting mechanism. This feature ensures that the tool remains inactive until the user deliberately engages it, providing an added layer of safety.

Safety Guard: A robust safety guard shields the user from debris and potential hazards during operation. This protective barrier is an essential component that enhances overall safety.

Ergonomic Design: The thoughtful design of the handles promotes a secure grip, reducing the chance of slippage during use. This ergonomic approach plays a vital role in maintaining control and preventing accidents.

Tools Needed for Assembly

When it comes to assembling your equipment, having the right tools is essential for a smooth and efficient process. Using appropriate instruments not only ensures a secure fit but also enhances the longevity and performance of your machinery. Below is a list of essential tools that will aid you in this task.

Basic Tools

To begin with, a set of standard hand tools is necessary. This typically includes a screwdriver set, wrenches, and pliers. A combination of flathead and Phillips screwdrivers will allow you to handle various screws, while wrenches will enable you to tighten or loosen bolts effectively.

Specialized Equipment

In addition to basic tools, some specialized instruments can greatly enhance your assembly experience. A torque wrench is crucial for applying the correct amount of force to fasteners, ensuring they are not over-tightened. A hex key set is also beneficial for dealing with hex screws commonly found in many assemblies. Lastly, consider having a workbench or sturdy surface to keep your components organized and easily accessible during the process.

How to Assemble the Chainsaw

Assembling your cutting tool correctly is essential for optimal performance and safety. Understanding the various components and their functions will help ensure a smooth assembly process. This guide outlines the steps to put together your equipment efficiently, ensuring each element is securely in place.

Gather Necessary Tools and Components

Before starting, collect all the required items and tools. You’ll need the following:

- Engine unit

- Guide bar

- Cutting chain

- Chain tensioning mechanism

- Protection cover

- Basic hand tools (screwdriver, wrench)

Step-by-Step Assembly Process

1. Attach the Engine Unit: Begin by securing the engine unit to the main body. Align the mounting points and use screws to fasten them tightly.

2. Install the Guide Bar: Position the guide bar on the designated slot, ensuring it fits snugly. Be mindful of its orientation for proper cutting direction.

3. Fit the Cutting Chain: Carefully thread the cutting chain around the guide bar, making sure it loops in the correct direction. This is crucial for effective operation.

4. Adjust the Chain Tension: Utilize the tensioning mechanism to adjust the chain’s tightness. A well-tensioned chain enhances safety and efficiency.

5. Secure the Protection Cover: Once everything is in place, attach the protective cover. This component safeguards the user from any accidental contact with the moving parts.

By following these steps, you can successfully assemble your tool, ready for use in various cutting tasks. Always remember to refer to the specific guidelines provided for your model for additional details and safety precautions.

Frequently Asked Questions about Stihl 361

This section addresses common inquiries regarding a specific model of a popular outdoor power tool. Users often seek clarity on performance, maintenance, and troubleshooting to enhance their experience and ensure longevity of their equipment.

What is the recommended fuel mixture for optimal performance?

For best results, it is essential to use the correct fuel blend. Typically, a mixture of high-quality gasoline and a designated two-stroke oil in a specific ratio is advised. Refer to the user manual for precise measurements to ensure efficient operation and avoid engine damage.

How can I troubleshoot starting issues?

If you’re experiencing difficulties with ignition, first check the fuel supply and ensure the mixture is fresh. Inspect the spark plug for wear and replace it if necessary. Additionally, verify that the air filter is clean to promote proper airflow. If problems persist, consider consulting a professional for further assistance.