Comprehensive Guide to Stihl BG 86 C Parts Diagram

Maintaining any equipment requires a clear understanding of how each element contributes to its overall performance. Whether you’re working on routine upkeep or addressing an issue, knowing the precise structure of a handheld tool can make all the difference. In this section, we will explore the essential features and elements that make up one of the most efficient machines used for yard work and cleaning tasks.

This versatile device relies on a combination of mechanical and functional elements to operate effectively. From the engine to the smaller mechanical connections, each piece plays a role in ensuring seamless functionality. By exploring the layout and connections of these elements, we can gain a deeper understanding of how to maintain and troubleshoot the machine efficiently.

Understanding the Internal Components

The functionality of this type of device relies heavily on the precision and coordination of its internal mechanisms. Every element is engineered to contribute to efficient operation, from the air intake system to the engine’s combustion chamber. Ensuring proper maintenance of these elements can enhance performance and extend the life of the equipment.

Engine Structure: At the core, the power source is designed for maximum efficiency and durability. The arrangement of moving parts allows for smooth operation, reducing wear and tear over time.

Air Flow System: The airflow management is critical in controlling the temperature and optimizing the performance. A well-maintained air system ensures that the engine runs at its optimal temperature, preventing overheating.

Ignition Components: This section powers the system, providing the necessary spark to start the combustion process. It is crucial to keep these parts clean and in good condition to ensure reliable starting and smooth operation.

Vibration Reduction Mechanism: A specially designed system minimizes vibrations during use, making the experience more comfortable for the operator and reducing the stress on the device’s internal structure.

Key Features of the Blower

This versatile tool is designed to make yard maintenance more efficient, offering users a powerful solution for clearing debris. Its ergonomic design ensures comfortable handling, while the internal components are optimized for consistent performance, making it a reliable choice for both casual and heavy-duty tasks.

Efficient Power Output

One of the standout attributes of this model is its remarkable power delivery. With a well-engineered mechanism, it generates high airspeed, ensuring effective removal of leaves, dirt, and other unwanted materials from outdoor surfaces. The tool’s output is balanced, providing strong performance without excessive energy consumption.

Comfort and Usability

In addition to its power, this blower emphasizes user comfort. The intuitive controls are easily accessible, allowing for smooth operation. The lightweight build reduces fatigue during extended use, and the overall design is crafted to minimize vibrations, enhancing the overall user experience.

Breakdown of the Engine Assembly

The internal combustion mechanism consists of several critical components that work in unison to generate the necessary power. Each element plays a key role in converting fuel into energy, driving the machine efficiently. Understanding the layout and interaction between these elements helps in identifying potential issues or conducting repairs.

| Component | Description |

|---|---|

| Crankshaft | Responsible for converting the linear motion of the piston into rotational motion, driving the output shaft. |

| Piston | Moves within the cylinder, driven by the expansion of gases during combustion, transmitting force to the crankshaft. |

| Carburetor | Regulates the air and fuel mixture, ensuring optimal combustion conditions for engine efficiency. |

| Cylinder | Houses the piston, maintaining pressure and guiding its movement during the combustion process. |

| Ignition Coil | Generates the spark needed to ignite the air-fuel mixture, triggering the combustion cycle. |

Fuel System Parts and Functions

The fuel system plays a crucial role in ensuring smooth operation, efficiently delivering the necessary fuel to the engine. Each component within this system is designed to optimize performance and maintain proper functionality. Understanding how these elements interact can provide valuable insight into maintenance and troubleshooting.

Main Components

The primary element responsible for drawing fuel from the tank is a pump, which ensures consistent flow. This flow is regulated by filters that keep impurities from reaching sensitive areas. Another vital component is the valve system, which controls the passage of fuel, ensuring the correct amount is provided to the engine at the right time.

How It Works

The system starts by pulling fuel from the reservoir through a suction mechanism. It is then filtered to remove any contaminants before being sent towards the engine. The fuel mixture is finely tuned to match the engine’s requirements, ensuring optimal combustion. Regular upkeep of these elements helps prevent malfunctions and extends the life of the equipment.

Air Filter Structure and Maintenance

The air filter plays a crucial role in ensuring optimal performance and longevity of any engine by preventing dirt and debris from entering the internal components. Regular maintenance of this system is essential to maintain peak functionality and prevent engine wear caused by contamination. Understanding how to inspect and care for this component is key to extending the life of the equipment.

Key Components of the Filter

- Filter element: The main barrier that captures impurities from the air.

- Housing: Protects the element and ensures it fits securely in place.

- Sealing gasket: Prevents unfiltered air from bypassing the filtration system.

Steps for Proper Maintenance

- Remove the filter from its housing carefully to avoid damaging the seal.

- Inspect the filter for visible debris, tears, or excessive wear.

- Clean the filter using compressed air or a soft brush, depending on the type of material.

- If the filter is heavily clogged or damaged, replace it to ensure optimal performance.

- Reassemble the system, making sure the seal is intact and the filter fits properly.

Regular inspection and care of the air filter is a simple yet vital task that helps keep the engine running smoothly, while preventing long-term damage caused by dirt and debris. Proper maintenance can also improve efficiency and reduce the need for repairs.

Fan and Impeller System Overview

The fan and impeller mechanism plays a crucial role in the efficient operation of outdoor power equipment. This assembly is designed to optimize airflow, enabling the effective expulsion of debris and ensuring optimal performance during use. Understanding the components and their functions is essential for maintaining the equipment’s overall efficiency and longevity.

Components of the Fan and Impeller Mechanism

This system typically consists of a fan and an impeller, each serving distinct purposes. The fan is responsible for creating airflow, while the impeller directs this airflow toward the desired area. Together, they enhance the device’s ability to handle various tasks effectively.

Importance of Proper Maintenance

Regular maintenance of the fan and impeller assembly is vital for ensuring peak performance. Neglecting this system can lead to decreased efficiency, increased wear, and potential malfunction. Routine inspections and cleaning can help extend the lifespan of these components and maintain optimal operation.

Ignition System Components Explained

The ignition system plays a crucial role in ensuring the efficient operation of small engines by initiating the combustion process. Understanding the various components involved can help in diagnosing issues and performing maintenance effectively. Each element of the ignition setup works together to produce a reliable spark that ignites the fuel-air mixture within the combustion chamber.

Key components of the ignition assembly include the following:

| Component | Description |

|---|---|

| Ignition Coil | Transforms battery voltage into a high-voltage pulse to create a spark. |

| Spark Plug | Delivers the electrical spark to ignite the fuel-air mixture. |

| Flywheel | Contains magnets that generate electrical current as the engine rotates. |

| Ignition Module | Regulates the timing of the spark and coordinates with the coil. |

| Wiring Harness | Connects all electrical components, facilitating signal transmission. |

Each of these parts is integral to the ignition system’s functionality. Regular inspection and maintenance of these components can prevent engine performance issues and enhance longevity.

Throttle Mechanism and Control

The throttle system is a crucial component that governs the operation of small engine tools. This mechanism regulates the airflow and fuel mixture delivered to the engine, directly impacting its performance and responsiveness. Understanding how this control works is essential for optimizing engine efficiency and achieving desired operational outcomes.

The mechanism consists of various elements that work in tandem to adjust the throttle position. When the operator engages the control, it prompts the throttle plate to open or close, allowing for varying levels of airflow. This adjustment is vital for maintaining the appropriate speed and power output of the engine during use.

In addition to the mechanical aspects, control cables play a significant role in transmitting the operator’s commands to the throttle mechanism. These cables must be properly maintained to ensure smooth operation and prevent any delays in response. Regular inspection and adjustment can enhance overall performance and prolong the lifespan of the equipment.

Exhaust System Design and Purpose

The exhaust system in a combustion engine plays a crucial role in ensuring optimal performance and efficiency. It is responsible for directing harmful gases produced during the combustion process away from the engine and out of the vehicle. This component not only protects the engine from back pressure but also enhances overall functionality by minimizing emissions and noise.

Engineered with precision, the exhaust system typically comprises various elements such as manifolds, pipes, and mufflers. Each part serves a distinct function in the expulsion of exhaust gases. The manifold collects gases from the cylinders and channels them into a single pathway, while pipes facilitate the flow towards the muffler, which reduces noise levels. The design of this system is critical in meeting environmental standards and improving fuel economy.

Moreover, the effectiveness of the exhaust system significantly influences engine performance. A well-designed exhaust can improve horsepower and torque by optimizing the flow of gases, allowing the engine to breathe better. By enhancing these parameters, the overall driving experience is also elevated, making it essential for both everyday use and high-performance applications.

Carburetor Setup and Adjustments

The carburetor is a crucial component that regulates the air-fuel mixture in the engine, ensuring optimal performance. Proper setup and adjustments are essential for efficient operation, fuel efficiency, and emission control. Understanding how to fine-tune this element can significantly enhance the overall functionality of the equipment.

Initial Setup: Begin by ensuring that the carburetor is clean and free from any debris. Check all gaskets and seals for damage. When mounting the carburetor, ensure it is securely attached to prevent air leaks that could affect performance.

Adjustment Procedures: Most carburetors have three main adjustment screws: the idle speed, low-speed mixture, and high-speed mixture. Start by adjusting the idle speed screw to achieve a smooth idle. Next, fine-tune the low-speed mixture by turning the screw clockwise or counterclockwise until the engine runs smoothly at lower speeds. For high-speed adjustments, gradually increase the throttle while making slight adjustments to the high-speed mixture until the engine operates efficiently at full throttle.

Final Checks: After adjustments, test the equipment under various loads to ensure consistent performance. Listen for any irregularities in the engine’s sound, as these may indicate further adjustments are necessary. Regular maintenance of the carburetor will help sustain optimal performance and prolong the life of the engine.

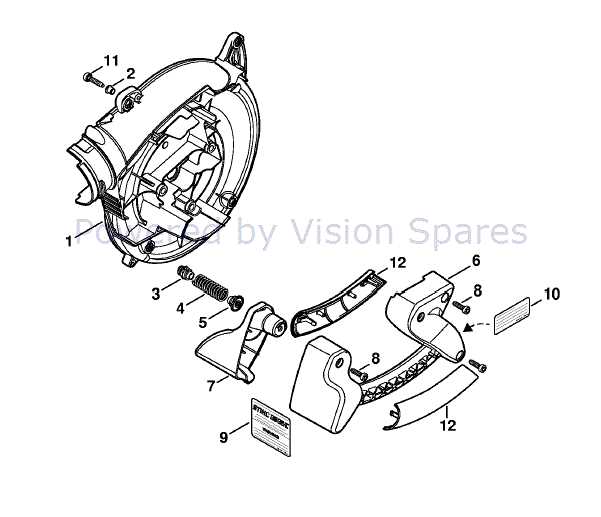

Housing and Exterior Parts Layout

This section provides an overview of the configuration and arrangement of the casing and outer components of a specific model. Understanding the structure of these elements is crucial for effective maintenance and repair, as they play a vital role in the overall functionality of the device.

The housing serves as the primary structure, safeguarding internal mechanisms from external elements while providing support for various attachments. Additionally, it is designed to facilitate airflow and cooling, ensuring optimal performance during operation. The exterior components include elements such as the handle, throttle control, and exhaust outlet, all of which are strategically placed for user convenience and safety.

Each segment of the outer assembly is engineered for durability and ease of access, allowing users to perform routine checks and maintenance efficiently. Moreover, the layout contributes to the balance and ergonomics of the equipment, enhancing the overall user experience.