Understanding the Parts Diagram of Stihl BT 130

In the realm of outdoor machinery, having a comprehensive grasp of the various elements that constitute a high-performing device is crucial. This knowledge empowers users to maintain, troubleshoot, and enhance their equipment effectively. A detailed exploration of these components not only aids in efficient operation but also extends the lifespan of the tool.

Within this section, we will delve into the intricate layout of essential parts, providing insights into their functions and interconnections. Each segment plays a pivotal role in ensuring the overall efficiency and reliability of the machine. Recognizing how these elements interact can significantly improve user experience and operational success.

Furthermore, understanding the configuration of these parts enables users to identify potential issues quickly. With the right information at hand, one can make informed decisions regarding repairs or upgrades, ensuring that the machinery continues to perform at its best for years to come. This knowledge serves as a foundation for both novice and experienced users alike, fostering a deeper appreciation for the craftsmanship behind the tool.

Understanding Stihl BT 130 Overview

This section aims to provide a comprehensive understanding of a popular equipment model used for various outdoor tasks. Known for its reliability and efficiency, this tool is designed to simplify challenging gardening and landscaping activities. Users often appreciate its user-friendly features, which contribute to its widespread adoption among both professionals and hobbyists.

Key Features

Equipped with a powerful engine, this device ensures robust performance, enabling users to tackle different types of soil and vegetation with ease. Its ergonomic design enhances comfort during prolonged use, reducing fatigue and allowing for greater productivity. Additionally, the tool offers various attachments, enhancing its versatility and making it suitable for a range of applications.

Maintenance Considerations

To ensure optimal functioning and longevity, regular maintenance is crucial. This includes routine checks on fuel levels, air filters, and spark plugs. Users are encouraged to follow manufacturer guidelines for upkeep, which can significantly extend the lifespan of the equipment and maintain its efficiency over time.

In summary, understanding the key aspects of this model will empower users to make informed decisions regarding its use and maintenance, ultimately leading to improved performance in their gardening endeavors.

Key Features of the BT 130

The model is designed for those who seek efficiency and reliability in their tasks. Its robust construction and innovative technologies ensure optimal performance across various applications, making it a preferred choice among professionals and enthusiasts alike.

Powerful Engine: The heart of this tool is its high-performance engine, which delivers exceptional torque and speed. This feature allows for quicker and more effective operation, reducing the time spent on projects.

Ergonomic Design: Comfort is paramount, and this model excels in providing a user-friendly experience. Its lightweight structure and adjustable handles minimize strain during prolonged use, allowing for better control and precision.

Versatile Functionality: Adaptability is a key characteristic, as this equipment is suitable for various tasks. Whether it’s drilling in tough soil or landscaping, it proves to be an invaluable asset in diverse environments.

Durable Construction: Built to withstand harsh conditions, the robust materials used in its design enhance longevity. This resilience ensures that users can rely on the tool for years, even with frequent use.

Easy Maintenance: Simple maintenance procedures are integral, making it easy for users to keep the equipment in top condition. Accessible components and clear instructions help in prolonging the life of the machine.

Overall, the highlighted attributes contribute to a superior experience, making this model a standout option in its category. Users can expect performance that meets and exceeds their expectations, regardless of the challenge at hand.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and functionality of complex machinery. These illustrations serve as valuable tools for both professionals and enthusiasts, enabling them to identify, locate, and assess individual elements within a system.

Enhanced Clarity: By providing a clear overview of various components, these visual aids eliminate ambiguity and facilitate better comprehension. Users can easily pinpoint specific items and understand how they fit together, streamlining maintenance and repair tasks.

Effective Troubleshooting: When issues arise, having a visual reference can significantly aid in diagnosing problems. Users can quickly reference the layout and determine which parts may be malfunctioning or require replacement, saving time and effort during the troubleshooting process.

Improved Communication: For teams working on machinery, these visuals serve as a universal language. They allow for precise discussions about components, ensuring that everyone involved is on the same page regarding repairs or modifications.

Facilitating Education: For those new to machinery, these representations act as educational tools, helping users to familiarize themselves with different parts and their functions. This foundational knowledge enhances confidence and competence in handling equipment.

In summary, visual depictions of components are indispensable resources that enhance understanding, troubleshooting, communication, and education, ultimately leading to more efficient operation and maintenance of machinery.

Identifying Components of BT 130

Understanding the various elements of a power tool is essential for effective maintenance and troubleshooting. Each component plays a critical role in the overall functionality, contributing to performance, safety, and longevity. This section aims to provide clarity on the different parts that make up this specific model, ensuring users can recognize and appreciate their significance.

Engine Assembly: The core of the device, this unit is responsible for generating power. Its condition directly impacts the tool’s efficiency and effectiveness.

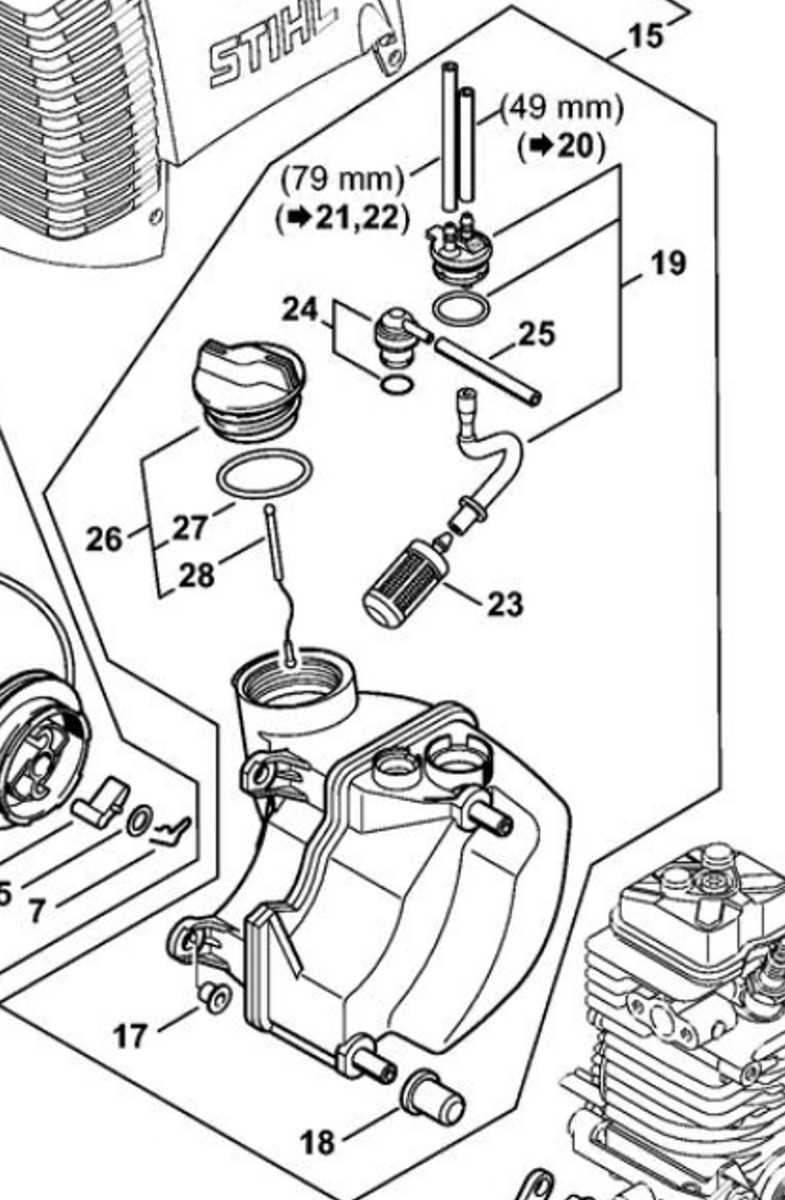

Fuel System: This includes the tank, lines, and filter, all of which work together to supply the engine with the necessary fuel. Proper upkeep of this system is crucial to prevent blockages and ensure smooth operation.

Transmission: This component transmits power from the engine to the working parts. A well-functioning transmission ensures that the tool operates at the desired speed and torque.

Handle and Controls: The user interface comprises the handle and control mechanisms, allowing for comfortable handling and precise operation. Ensuring these parts are in good condition is vital for safety and ease of use.

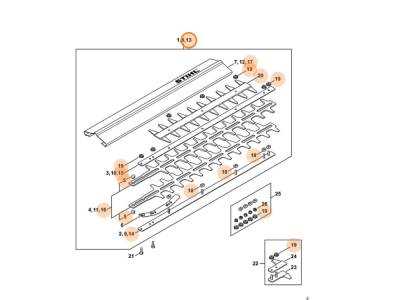

Working Tool: This is the attachment that performs the actual digging or drilling. Choosing the right tool is essential for different tasks, and regular inspection ensures it remains effective.

By familiarizing oneself with these components, users can better manage their equipment, leading to improved performance and extended lifespan.

Common Repairs for Stihl Equipment

Maintenance and repairs are essential for ensuring the longevity and efficiency of outdoor power tools. Understanding the typical issues that may arise can help users troubleshoot effectively and perform necessary fixes. Regular servicing not only enhances performance but also minimizes unexpected breakdowns.

Frequent Issues and Solutions

| Problem | Possible Causes | Recommended Fix |

|---|---|---|

| Starting difficulties | Clogged fuel filter, bad spark plug | Replace fuel filter and spark plug |

| Reduced power output | Dirty air filter, worn carburetor | Clean or replace air filter; adjust or replace carburetor |

| Vibration issues | Loose components, damaged anti-vibration system | Tighten screws and check the anti-vibration mounts |

| Overheating | Insufficient lubrication, blocked cooling fins | Ensure proper lubrication; clean cooling fins |

Preventive Measures

To minimize repairs, it is advisable to perform routine maintenance checks. Regularly inspect components, clean filters, and replace worn parts promptly. Following the manufacturer’s guidelines for usage and storage can significantly extend the life of the equipment.

Where to Find Replacement Parts

When it comes to maintaining outdoor power equipment, sourcing quality components is essential for optimal performance and longevity. Fortunately, there are numerous avenues available for those seeking to replace worn or damaged elements. Understanding where to look can save both time and money while ensuring your machinery continues to function effectively.

Authorized Dealers

One of the most reliable sources for components is through authorized retailers. These outlets often carry a comprehensive selection of original equipment manufacturer (OEM) items, ensuring compatibility and quality. Visiting a local dealer can also provide the benefit of expert advice, helping you to identify the exact component needed for your specific model.

Online Marketplaces

The internet offers a vast array of options for purchasing replacement items. E-commerce platforms and specialized websites dedicated to outdoor machinery can be excellent resources. When shopping online, it’s important to read reviews and verify the credibility of the seller to ensure that you are receiving genuine products. Additionally, some platforms may offer user forums or support that can assist in troubleshooting issues related to your equipment.

Maintenance Tips for BT 130

Regular upkeep is essential for ensuring the longevity and optimal performance of your equipment. By following a few key practices, you can prevent wear and tear, enhance efficiency, and avoid costly repairs. Here are some effective strategies to keep your tool in excellent condition.

Regular Inspections

Conducting routine checks on your device is crucial. Examine all components for signs of damage or excessive wear. Look for any loose screws, frayed wires, or leaks that could affect performance. Promptly addressing minor issues can prevent them from escalating into major problems.

Proper Cleaning and Storage

After each use, clean the machine thoroughly to remove dirt and debris. This not only maintains its appearance but also prevents buildup that can hinder functionality. When storing, ensure it is in a dry, protected space to avoid rust and other environmental damage. Using a cover can also provide additional protection.

Remember: Consistent maintenance is the key to achieving the best results from your equipment. By adopting these practices, you can enjoy reliable performance and extend the lifespan of your tool.

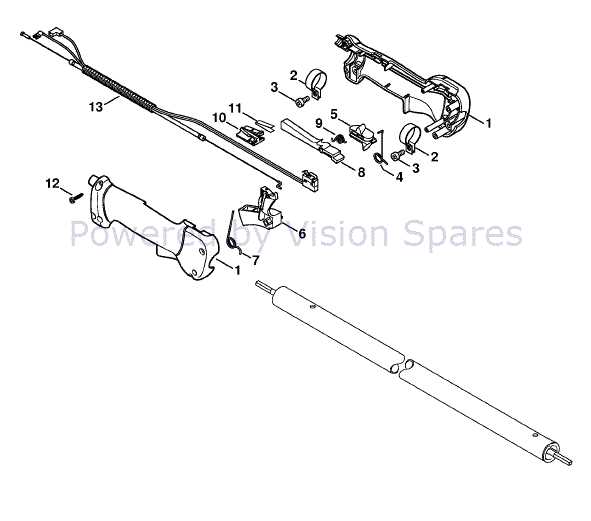

Using the Parts Diagram Effectively

Understanding the visual representation of components is essential for efficient maintenance and repair tasks. Such illustrations provide a clear view of how each element interacts within the overall system, enabling users to identify, source, and replace items as needed. Mastery of these visuals can greatly enhance the user experience and prolong the lifespan of equipment.

To make the most of these resources, start by familiarizing yourself with the layout and numbering system. Each part is typically labeled, allowing for quick reference to specific items. When troubleshooting, cross-reference any malfunctioning components with the illustration to pinpoint the issue accurately.

Moreover, having a comprehensive understanding of the assembly can aid in reassembly after maintenance. Carefully follow the sequence indicated in the illustration to avoid any misalignment or improper fitting. This practice not only ensures optimal performance but also minimizes the risk of future issues.

Lastly, keep this visual aid handy during your maintenance sessions. Whether you are replacing a worn-out element or performing routine checks, having a reference at your fingertips can save time and reduce frustration. A proactive approach using these visuals fosters better care and understanding of your equipment.

Comparing BT 130 with Similar Models

When evaluating tools for earth drilling, it is essential to compare various models to determine the best fit for specific needs. This section examines one particular model alongside its competitors, highlighting their unique features and capabilities.

Power and Performance: The machine in question offers robust power output, making it suitable for demanding tasks. However, similar devices from other brands may provide comparable performance while varying in engine efficiency and torque. Users should consider how each option meets their workload requirements.

Weight and Maneuverability: Weight plays a crucial role in user comfort and handling. While this model is designed to strike a balance between stability and ease of use, alternatives might be lighter or heavier, impacting overall maneuverability. Evaluating these aspects can help potential buyers find a tool that suits their physical capabilities and working conditions.

Durability and Build Quality: Longevity is a significant factor when investing in equipment. The construction materials and design can vary widely among similar machines. Understanding the durability of each model will aid users in making an informed decision regarding maintenance and lifespan expectations.

Features and Accessories: Different models often come equipped with various features that enhance usability. Some may include advanced vibration reduction systems, while others offer a range of compatible accessories. Assessing these additional functionalities can provide insights into which option offers the best value for specific tasks.

In summary, comparing this tool with its counterparts allows potential buyers to assess performance, weight, durability, and additional features effectively. This thorough evaluation can lead to a more informed purchase decision that aligns with individual preferences and requirements.

Benefits of Genuine Stihl Parts

Using authentic components in your equipment ensures optimal performance and longevity. These high-quality pieces are designed specifically for your machinery, providing a seamless fit and functionality that generic alternatives often fail to deliver.

Enhanced Performance

When you choose original components, you can expect superior performance. Each part is engineered to work harmoniously with others, resulting in improved efficiency and reliability. This synergy helps prevent unexpected breakdowns and keeps your machinery running smoothly.

Longevity and Durability

Investing in genuine replacements extends the lifespan of your equipment. Authentic components are crafted from high-quality materials, ensuring they withstand the rigors of demanding tasks. By avoiding subpar imitations, you minimize wear and tear, saving both time and money in the long run.

In summary, opting for authentic components is a wise choice for maintaining your machinery. Their benefits in performance and durability significantly outweigh the initial cost, ultimately leading to a more efficient and reliable operation.