Understanding the Parts Diagram of Stihl FS 110

For those who rely on high-performance gardening equipment, grasping the intricacies of the machinery is essential. Familiarity with the various elements that comprise your tool can significantly enhance maintenance efforts and operational efficiency. This knowledge empowers users to address issues proactively and ensure longevity in performance.

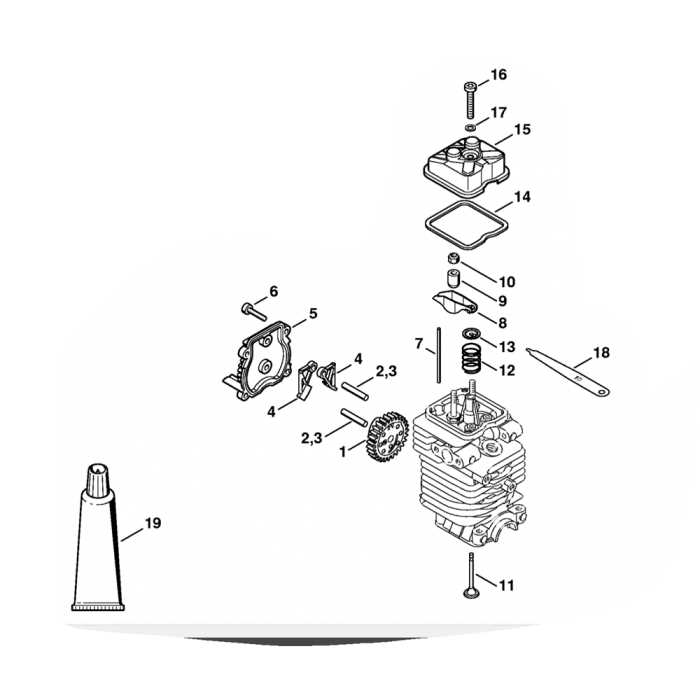

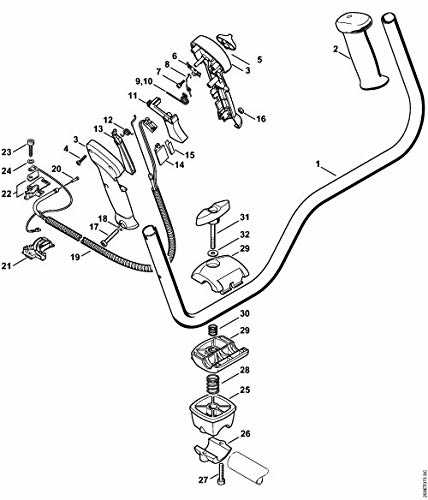

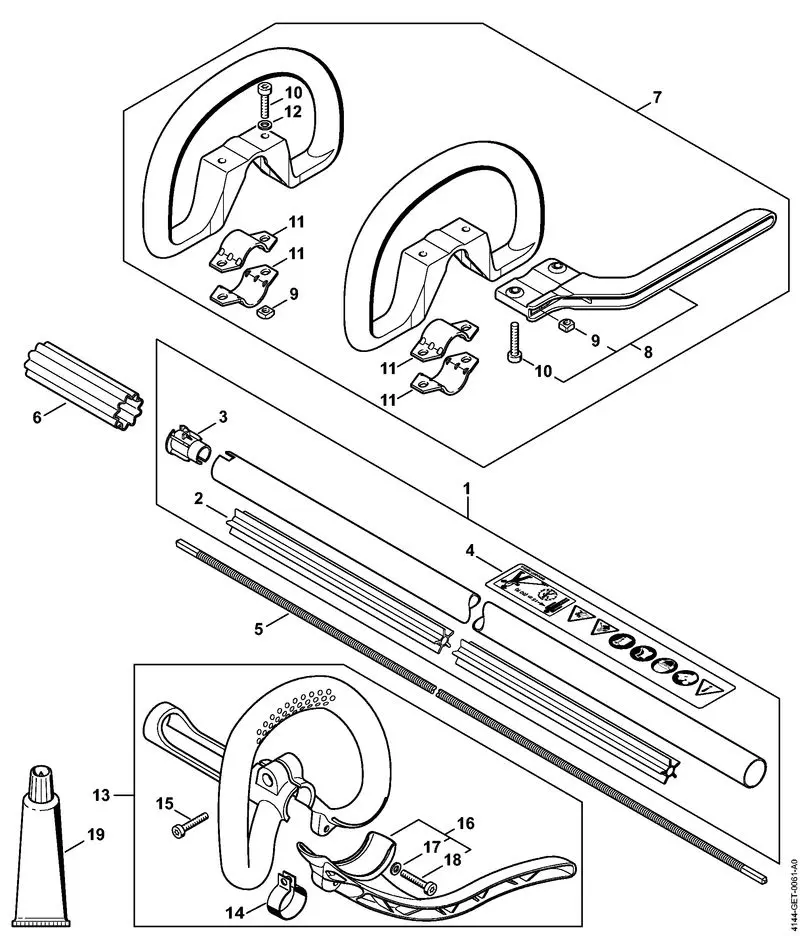

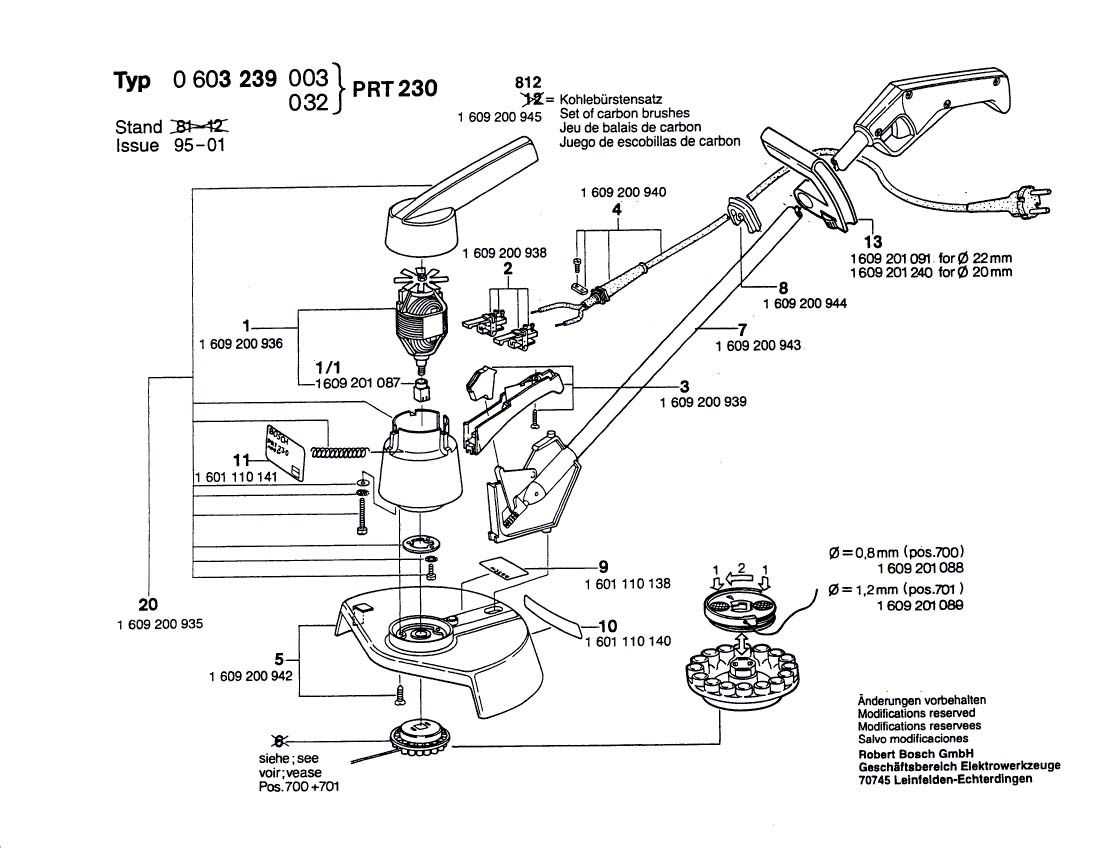

Visual representations of the intricate assembly can serve as invaluable resources. They offer a clear overview of how individual pieces fit together and function in harmony. By exploring these illustrations, operators can better understand which components require regular attention and what to look for during troubleshooting.

Moreover, having access to detailed schematics allows for informed decision-making when it comes to repairs and replacements. This not only saves time and effort but also fosters a deeper appreciation for the technology at hand. As you delve into the specifics, you’ll uncover insights that will enhance both your skills and your experience in using this essential garden tool.

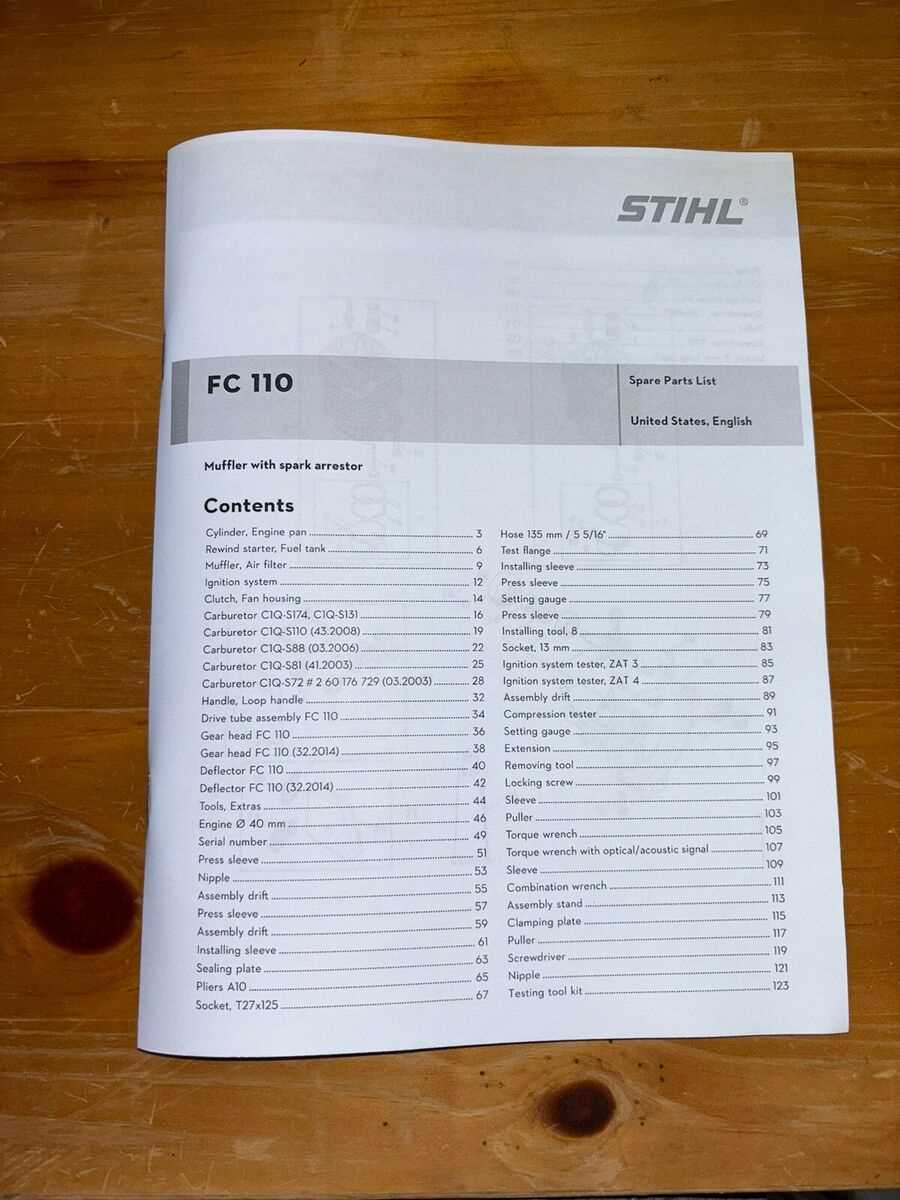

Understanding Stihl FS 110 Overview

This section provides an insight into a popular piece of outdoor equipment known for its efficiency and reliability. Designed for various gardening tasks, it is favored by both professionals and enthusiasts. Understanding its components and functionality can enhance user experience and maintenance practices.

Key Features

- Powerful engine for effective performance

- Lightweight design for ease of handling

- Versatile attachments for different applications

- User-friendly controls for comfortable operation

Applications

- Clearing dense vegetation

- Trimming grass and weeds

- Landscaping tasks

- Maintenance of large areas

By understanding the essential aspects of this equipment, users can maximize its potential and ensure longevity through proper care and usage.

Importance of Parts Diagrams

Understanding the intricate details of machinery is crucial for effective maintenance and repair. Visual representations that illustrate individual components play a vital role in ensuring that users can identify and manage each element with confidence. These resources enhance the ability to diagnose issues and streamline the replacement process, ultimately contributing to the longevity and efficiency of the equipment.

Moreover, detailed schematics serve as invaluable tools for technicians and DIY enthusiasts alike. They not only aid in recognizing the layout of various elements but also provide insights into the assembly and disassembly procedures. This understanding can significantly reduce the risk of errors during repairs, making the entire process more efficient and less time-consuming.

| Benefits | Description |

|---|---|

| Clarity | Visual aids simplify complex structures, making them easier to understand. |

| Efficiency | Streamlined identification of components speeds up repair time. |

| Reduction of Errors | Clear instructions minimize the likelihood of mistakes during assembly. |

| Enhanced Knowledge | Users gain a deeper understanding of how equipment functions. |

In conclusion, utilizing these visual tools significantly enhances the repair process, promoting a deeper comprehension of mechanical systems and fostering effective maintenance practices. By leveraging such resources, users can ensure that their equipment remains in optimal working condition for years to come.

Key Components of FS 110

The efficient operation of any outdoor power equipment relies heavily on its core elements. Understanding these fundamental components is essential for maintenance and effective performance. Each part plays a specific role, contributing to the overall functionality and reliability of the machine.

Major Elements

Among the critical parts are the engine, cutting system, and fuel delivery mechanism. These elements work in harmony to ensure optimal performance and durability during usage. Familiarity with these components allows users to troubleshoot issues and perform necessary repairs with confidence.

Component Table

| Component | Description |

|---|---|

| Engine | Provides the necessary power to drive the equipment. |

| Cutting Head | Houses the cutting line or blade, essential for trimming tasks. |

| Fuel System | Delivers the fuel to the engine for combustion. |

| Air Filter | Prevents debris from entering the engine, ensuring clean air supply. |

| Handle Assembly | Offers control and comfort to the user during operation. |

How to Read Parts Diagrams

Understanding technical illustrations can greatly enhance your ability to maintain and repair equipment. These visual guides offer a detailed breakdown of components, helping you identify each element and its function. By familiarizing yourself with these visuals, you can navigate repairs and replacements more effectively.

First, it’s essential to recognize the layout of the illustration. Typically, components are arranged in a logical manner, often following the assembly order. Familiarize yourself with the symbols and labels used, as they provide crucial information regarding sizes, quantities, and specific parts needed.

Next, pay attention to the callouts associated with each item. These annotations often include part numbers, descriptions, and sometimes even recommended tools for installation or removal. Having this information at hand can streamline the process and ensure you procure the correct items.

Moreover, cross-referencing these visuals with the user manual can enhance your understanding. The manual often provides additional context and instructions, ensuring that you not only identify parts but also comprehend their role within the larger assembly.

Finally, practice makes perfect. The more you engage with these illustrations, the more adept you will become at interpreting them. This skill is invaluable for anyone looking to maintain their equipment efficiently and effectively.

Common Issues with FS 110

When operating outdoor power equipment, certain challenges may arise that can impact performance and efficiency. Understanding these issues is crucial for effective maintenance and troubleshooting, ensuring optimal functionality of the device.

Fuel-Related Problems

One of the most frequent challenges involves fuel quality. Old or contaminated fuel can lead to engine misfires or starting difficulties. It’s essential to use fresh fuel and ensure the proper mix ratio, as specified in the user manual, to avoid complications. Clogged fuel filters may also contribute to these issues, requiring regular checks and replacements.

Starting Difficulties

Users often report issues with starting the machine, which can stem from various factors. A faulty spark plug is a common culprit, as it may not ignite the fuel-air mixture effectively. Additionally, problems with the ignition system or battery can also prevent the engine from starting. Routine inspections and timely replacements of worn parts can mitigate these starting issues.

Replacement Parts for Maintenance

Proper upkeep of your outdoor equipment is essential for optimal performance and longevity. Utilizing quality components during maintenance ensures that your machinery runs smoothly and efficiently. Regularly replacing worn or damaged items not only enhances functionality but also prevents more significant issues from arising.

When considering replacements, it is crucial to choose components that meet the original specifications of your equipment. This guarantees compatibility and maintains the integrity of the overall system. Whether you are looking for cutting blades, filters, or spark plugs, selecting the right replacements will significantly impact your machine’s performance.

Additionally, consulting the manufacturer’s recommendations can guide you in sourcing the most suitable items for your needs. Staying informed about the necessary replacements allows for timely interventions, reducing downtime and ensuring that your equipment remains in peak condition throughout its use.

Where to Find Genuine Parts

Finding authentic components for your outdoor equipment is essential for maintaining performance and longevity. High-quality replacements ensure that your machine operates smoothly and efficiently, minimizing the risk of damage or malfunction. This section will guide you through various sources where you can acquire reliable replacements.

Authorized Dealers

One of the most dependable sources for authentic components is through authorized distributors. These retailers are certified to sell genuine items and often have knowledgeable staff who can assist you in selecting the right components for your needs. Additionally, many offer warranties that provide extra peace of mind.

Online Retailers

The internet has made it easier than ever to locate high-quality components. Numerous websites specialize in outdoor equipment supplies, providing a vast selection of authentic items. Be sure to choose reputable sites that guarantee the authenticity of their inventory.

| Source | Advantages | Considerations |

|---|---|---|

| Authorized Dealers | Guaranteed authenticity, expert advice | May have limited stock |

| Online Retailers | Wide selection, convenient shopping | Ensure website credibility |

| Manufacturer’s Website | Direct access to latest components | Shipping times may vary |

DIY Repairs for FS 110

Taking on repairs for your outdoor power equipment can be both rewarding and cost-effective. Understanding the essential components and how they work together allows you to troubleshoot issues and perform maintenance tasks with confidence. Whether you’re addressing minor wear and tear or tackling a more significant malfunction, a little know-how can go a long way.

Common Issues and Solutions

One frequent problem users encounter is difficulty starting the machine. This can often be attributed to fuel system issues or a clogged air filter. Regularly checking and replacing the fuel and ensuring the air intake is clear can resolve many starting problems. Additionally, inspecting the spark plug for wear and replacing it when necessary can improve performance significantly.

Maintenance Tips

Routine maintenance is crucial for keeping your equipment in optimal condition. Cleaning the cutting attachments and checking for damage after each use can prevent larger issues down the line. Lubricating moving parts, such as gears and bearings, will enhance efficiency and extend the lifespan of your machine. Keeping an eye on the fuel lines for cracks or leaks is also essential to avoid fuel loss and potential hazards.

Safety Tips When Working

When engaging in outdoor maintenance tasks, it is crucial to prioritize safety to ensure a smooth and accident-free experience. Proper preparation and awareness of the equipment can greatly reduce the risk of injury. Below are essential guidelines to keep in mind while operating machinery in various environments.

Pre-Operation Checks

Before starting any equipment, perform a thorough inspection to identify any potential issues. Check for loose parts, leaks, or signs of wear. Make sure all safety features are functioning correctly. Wearing appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear is also vital to safeguard against accidents.

Awareness of Surroundings

Maintain awareness of your surroundings while working. Look out for bystanders, obstacles, and uneven terrain that could pose a risk. Keep children and pets at a safe distance from the work area. Staying focused on the task at hand will help prevent distractions that could lead to mishaps.

Maintaining Your Stihl Equipment

Regular upkeep of your outdoor power tools is essential for optimal performance and longevity. Ensuring that each component is in excellent condition not only enhances efficiency but also contributes to safety during use. By following a structured maintenance routine, you can prevent potential issues and enjoy seamless operation throughout the seasons.

Essential Maintenance Tips

To keep your equipment running smoothly, consider the following practices:

| Task | Frequency | Description |

|---|---|---|

| Check Air Filter | Every 25 hours | Ensure the air filter is clean to promote efficient engine performance. |

| Inspect Fuel Lines | Every use | Look for cracks or leaks in fuel lines to prevent fuel wastage. |

| Sharpen Blades | Every 5 hours | Keep cutting edges sharp for better results and reduced strain on the engine. |

| Clean Exterior | After each use | Remove dirt and debris to prevent buildup that could cause overheating. |

Storing Your Equipment

Proper storage is vital to extend the life of your tools. Store in a dry place, away from direct sunlight and moisture. Consider using a protective cover to shield against dust and debris. Regularly inspect your equipment during storage to identify any emerging issues early on.