Understanding the Stihl FS 55 RZ Parts Diagram for Efficient Repairs

When it comes to maintaining your outdoor equipment, a thorough understanding of its inner workings is essential. This knowledge empowers users to perform repairs, ensure optimal functionality, and extend the lifespan of their tools. By examining the intricate assembly of the device, one can quickly identify the individual elements that contribute to its overall performance.

In this section, we delve into the various components that make up a popular model of grass trimming machinery. Each part plays a vital role in ensuring efficiency and effectiveness in tackling overgrown vegetation. Recognizing how these elements interact can significantly enhance your ability to troubleshoot issues and facilitate necessary maintenance.

Whether you are an experienced user or a newcomer to gardening tools, familiarizing yourself with the essential pieces can enhance your confidence and skill set. A well-informed operator is better equipped to handle challenges that may arise during use, making this knowledge not only beneficial but indispensable for any enthusiast.

Understanding the Stihl FS 55 RZ

The FS 55 RZ model is a versatile tool designed for efficient vegetation management. Its robust construction and innovative features make it an essential asset for both professionals and homeowners. This section delves into the various components and functionalities that define this machine, highlighting its practicality and ease of use.

Key features of this equipment include:

- Powerful engine performance for effective cutting

- Lightweight design for enhanced maneuverability

- User-friendly controls for effortless operation

- Adjustable handle for comfort during prolonged use

Understanding the layout and functionality of this tool is crucial for maintenance and troubleshooting. Here are some critical elements to consider:

- Motor: The heart of the machine, providing the necessary power.

- Cutting Head: The component responsible for trimming grass and weeds.

- Fuel System: Essential for delivering energy efficiently.

- Safety Features: Designed to protect the user during operation.

By familiarizing oneself with these aspects, operators can maximize the efficiency and lifespan of this valuable tool, ensuring it remains a reliable companion for outdoor tasks.

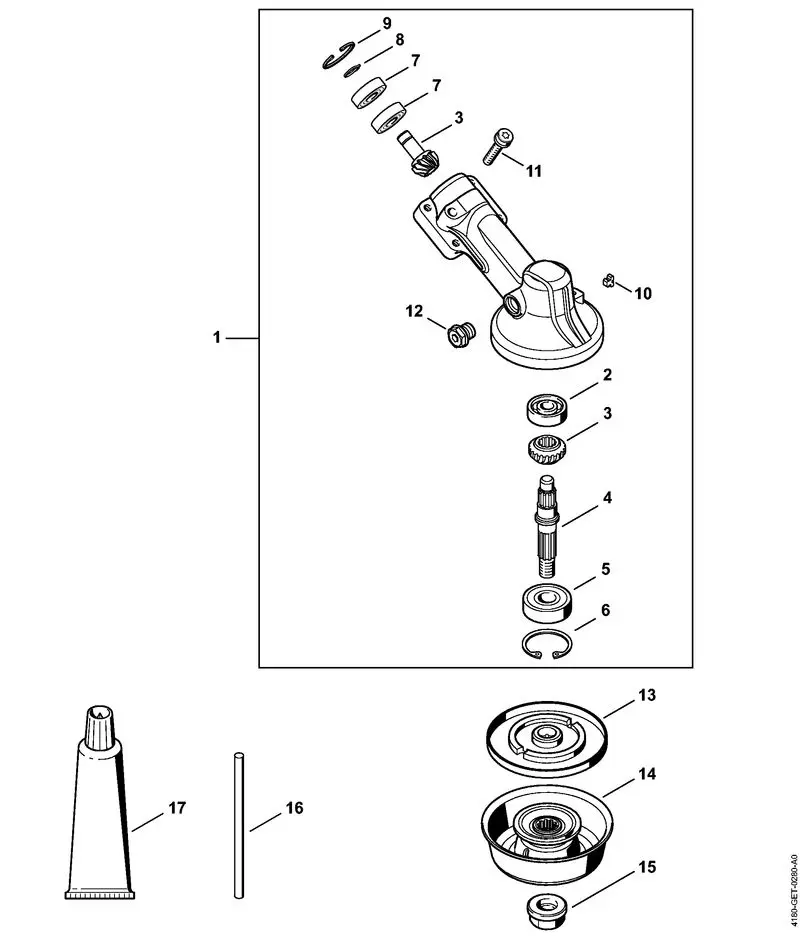

Key Components of the FS 55 RZ

The efficiency and functionality of any outdoor power tool heavily rely on its essential elements. Understanding these components is crucial for optimal performance and maintenance. Each part plays a significant role in ensuring that the equipment operates smoothly, providing users with reliable service and durability.

Engine: The heart of the machine, responsible for generating the necessary power to drive the cutting mechanisms. A well-maintained engine ensures effective fuel consumption and longevity.

Trimmer Head: This component holds the cutting line and is vital for achieving the desired cutting performance. Its design allows for easy line replacement, making maintenance straightforward.

Gearbox: A critical part that transfers the engine’s power to the cutting head, enabling efficient operation. A robust gearbox enhances torque and minimizes wear during use.

Handle: The user interface that provides control and stability while operating the equipment. Ergonomically designed handles reduce fatigue and improve maneuverability in various working conditions.

Throttle Control: This mechanism allows the operator to adjust the engine speed according to the task requirements. A responsive throttle enhances precision in operation and contributes to overall efficiency.

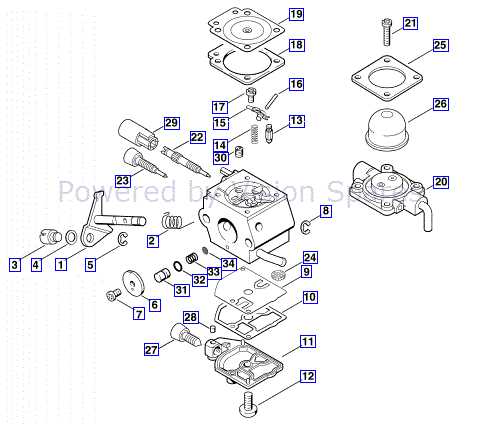

Fuel System: Comprising the fuel tank and lines, this system ensures a steady flow of fuel to the engine. Proper care of the fuel system is essential for reliable starting and performance.

Familiarity with these key elements can empower users to maintain their equipment effectively, leading to enhanced performance and extended lifespan.

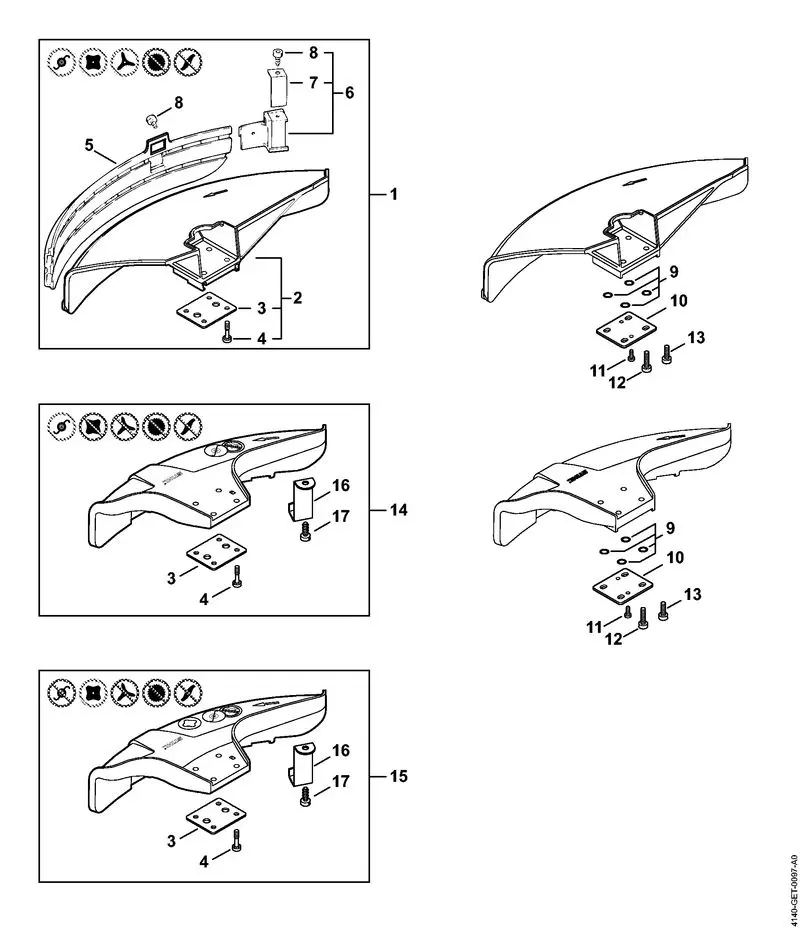

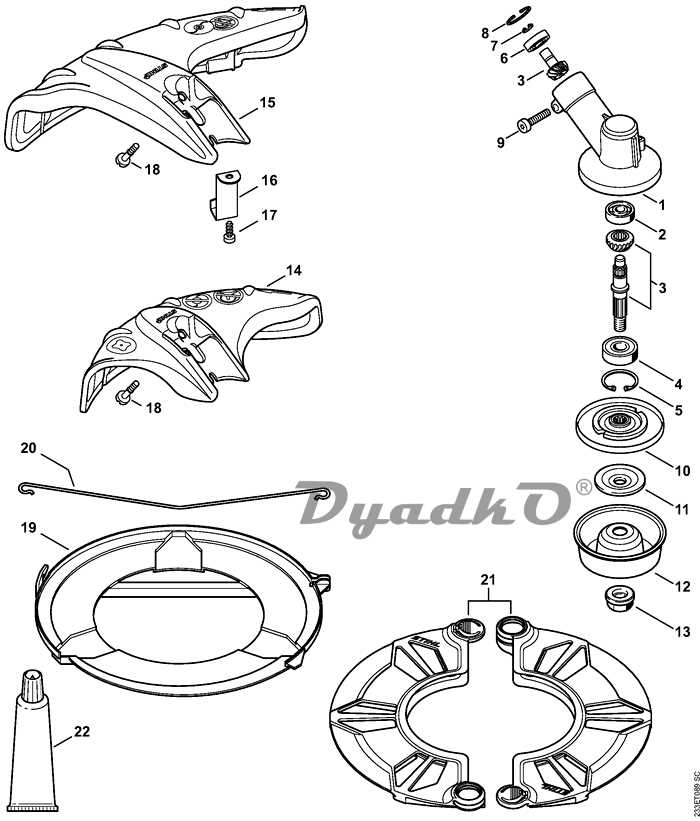

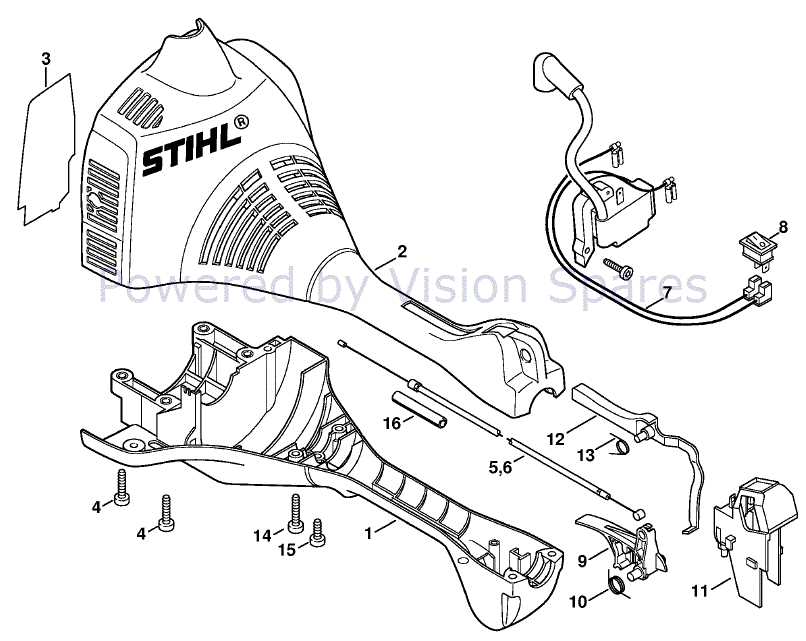

Importance of Parts Diagrams

Understanding the intricate assembly of machinery is crucial for effective maintenance and repair. Visual representations serve as invaluable tools, allowing users to identify components and their relationships within a system. These illustrations enhance clarity, making it easier to comprehend how each element functions and interacts with others.

Moreover, such visuals play a significant role in troubleshooting. When issues arise, having access to a detailed overview can help pinpoint malfunctions quickly. This expedites the diagnostic process, saving time and reducing frustration for the user.

Additionally, these guides foster a deeper knowledge of equipment. By studying the layout and composition of various elements, individuals can develop a greater appreciation for how their tools operate. This knowledge not only aids in maintenance but also empowers users to make informed decisions regarding repairs and upgrades.

Ultimately, clear visual aids are essential for anyone involved in the upkeep of machinery. They not only streamline repair processes but also enhance the overall understanding of equipment functionality.

Common Issues with FS 55 RZ Parts

When operating outdoor power equipment, certain complications can arise that impact performance and efficiency. Identifying these issues is crucial for ensuring smooth operation and extending the lifespan of the machine. This section delves into frequent challenges associated with specific components, highlighting their potential causes and solutions.

Fuel System Troubles

One of the most prevalent issues involves the fuel delivery mechanism. Blockages in the lines or a dirty filter can lead to inadequate fuel reaching the engine. Symptoms include difficulty starting and inconsistent power output. Regular maintenance, such as cleaning the fuel filter and inspecting lines for damage, can help mitigate these problems.

Ignition Failures

Another common complication pertains to the ignition system. Problems with the spark plug can prevent the engine from firing properly. Signs of a failing spark plug include hard starting and poor acceleration. Replacing the spark plug regularly and ensuring proper connections can improve reliability and performance.

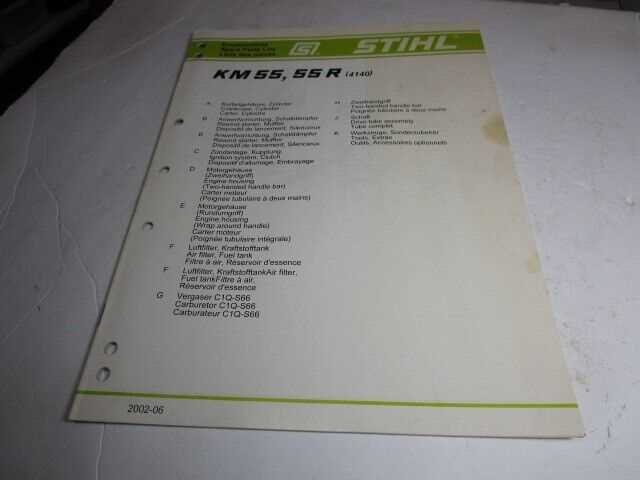

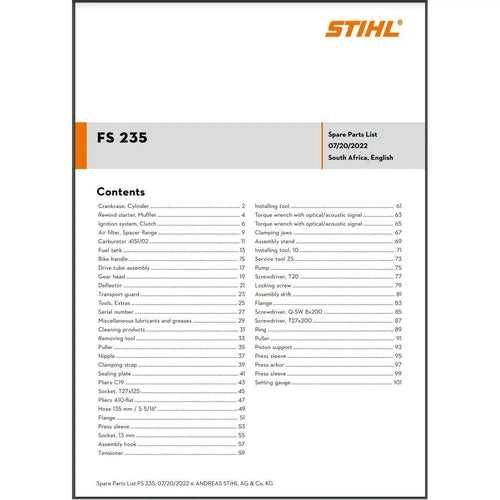

Where to Find Parts Diagrams

Locating detailed illustrations of components for various tools can be essential for maintenance and repair tasks. These resources help users identify specific items and ensure they obtain the correct replacements. Understanding where to access these visuals is crucial for efficient upkeep.

Online Resources

The internet hosts a plethora of websites dedicated to equipment maintenance. Manufacturer websites often provide comprehensive manuals and visual guides. Additionally, forums and community groups can be valuable for finding user-shared resources and tips. Utilizing search engines with relevant keywords can yield quick results for the necessary visual aids.

Local Dealers and Service Centers

Visiting authorized dealers or service centers can also be beneficial. These establishments typically have access to official manuals and visual guides, which can assist in pinpointing the exact components needed. Speaking with knowledgeable staff can further enhance the understanding of the machinery and its parts.

How to Interpret Parts Diagrams

Understanding the layout of components in a mechanical device can be essential for maintenance and repairs. By familiarizing yourself with the visual representations, you can gain insights into how different elements fit together and function collectively. This knowledge is vital for troubleshooting issues and ensuring that every piece is correctly installed and operational.

Breaking Down the Visuals

These illustrations typically showcase various components, often accompanied by reference numbers or labels. Identifying key elements allows for easier navigation when searching for specific parts or understanding their roles. Each section may highlight different assemblies, making it simpler to pinpoint areas of concern during a repair.

Utilizing Reference Information

Alongside the visuals, detailed descriptions often provide additional context. This information can include specifications, compatibility notes, and assembly instructions. Familiarizing yourself with these notes can enhance your comprehension, ensuring that you select the correct replacements and understand the assembly process more thoroughly.

Replacement Parts for Optimal Performance

Ensuring the peak functionality of your equipment requires the timely replacement of various components. Regular maintenance and the use of quality substitutes play a crucial role in maintaining efficiency and longevity. By addressing wear and tear with suitable replacements, you can achieve optimal operation and prevent costly repairs down the line.

Identifying Key Components is essential for effective upkeep. Understanding which elements are prone to deterioration allows you to plan for timely replacements. Focus on parts that undergo the most strain, as these are likely to affect overall performance significantly.

Quality Matters when selecting replacements. Opting for high-grade materials can enhance durability and reliability, ensuring your machinery operates at its best. Cheaper alternatives may save money initially but can lead to more significant issues over time, proving detrimental to performance.

Regular inspections will help in anticipating Needs. By closely monitoring the condition of your equipment, you can proactively replace components before they fail. This not only maintains efficiency but also provides peace of mind during use.

In conclusion, investing in quality substitutes and staying vigilant about maintenance will ensure that your equipment remains reliable and efficient, enabling you to tackle any task with confidence.

Maintenance Tips for FS 55 RZ

Proper upkeep is essential for ensuring optimal performance and longevity of your outdoor equipment. Regular maintenance not only enhances efficiency but also minimizes the risk of unexpected failures. This guide provides crucial insights into maintaining your trimmer to keep it running smoothly.

Follow these essential practices to ensure your equipment remains in top condition:

| Task | Frequency | Description |

|---|---|---|

| Inspect Air Filter | Every 10 hours | Check for dirt and debris. Clean or replace as needed to maintain airflow. |

| Check Spark Plug | Every 25 hours | Inspect for wear and carbon buildup. Replace if necessary for better ignition. |

| Clean Fuel System | Every 20 hours | Ensure fuel lines and filter are free from clogs to maintain fuel flow. |

| Sharpen Cutting Blades | As needed | Keep blades sharp for efficient cutting and to reduce strain on the engine. |

| Inspect Cables and Hoses | Monthly | Look for wear and tear. Replace damaged parts to prevent accidents. |

By adhering to these maintenance practices, you can significantly extend the life of your equipment and ensure it operates at peak performance. Regular checks will save you time and money in the long run, providing a reliable tool for your outdoor tasks.

Upgrading Your Trimmer

Enhancing the performance of your trimming device can significantly improve your gardening experience. By selecting the right components and accessories, you can boost efficiency, reduce maintenance time, and achieve a more polished finish in your yard work. Whether it’s increasing power, enhancing usability, or simply refreshing the look of your tool, there are numerous options available to elevate your trimming game.

Performance Enhancements

Consider investing in a high-performance cutting head or upgraded line that can handle tougher vegetation. This can lead to quicker and more efficient cutting, allowing you to tackle larger areas with ease. Additionally, replacing the spark plug and air filter regularly can ensure your equipment runs smoothly and maintains optimal power output.

Comfort and Usability

To make your trimming tasks less strenuous, look into ergonomic handles and padded straps. These upgrades can reduce fatigue during extended use, making your gardening sessions more enjoyable. Furthermore, consider adding a debris shield for better protection while you work, enhancing both safety and comfort.

Resources for DIY Repairs

When it comes to maintaining and fixing outdoor equipment, having the right resources at your fingertips can make all the difference. Whether you are a seasoned enthusiast or a beginner, access to reliable information, tools, and community support can empower you to tackle repairs confidently and efficiently. From manuals and online guides to forums and video tutorials, there are numerous avenues to explore that can simplify the repair process.

Online Guides and Manuals

One of the most valuable resources available is the variety of online guides and manuals tailored for specific models. These documents typically provide step-by-step instructions, troubleshooting tips, and maintenance schedules. Familiarizing yourself with these resources can enhance your understanding of the equipment and streamline your repair efforts.

Community Forums and Video Tutorials

Engaging with community forums and watching video tutorials can offer practical insights and solutions from fellow enthusiasts. These platforms allow users to share their experiences, tips, and tricks, creating a wealth of knowledge that can assist in overcoming common challenges. By participating in these communities, you can gain valuable feedback and support, making your DIY repairs more manageable.