Stihl FS 56 RC Parts Diagram and Manual

When working with a trimmer, having a clear understanding of its individual components is essential for proper maintenance and repairs. Knowing how the different parts fit together and function allows for efficient problem-solving and ensures the tool operates optimally. This section aims to provide a detailed overview of the essential elements, helping users easily identify the necessary parts for any task.

Each element plays a crucial role in the performance of the machine. Familiarity with the specific functions of each component helps in troubleshooting issues and replacing worn-out parts. Whether you are conducting routine maintenance or preparing for a repair, having a comprehensive guide can make the process much more straightforward.

By understanding how each part interacts within the system, you can confidently approach any maintenance or repair task. This knowledge will also help you when it comes to sourcing replacements or upgrades, ensuring that your equipment continues to perform effectively over time.

Key Components of the FS 56 RC

The performance of the FS 56 RC is driven by a set of essential elements working in harmony. Each part plays a critical role in ensuring smooth operation, efficiency, and longevity. Understanding the core components can help users maintain the tool effectively and address any potential issues promptly.

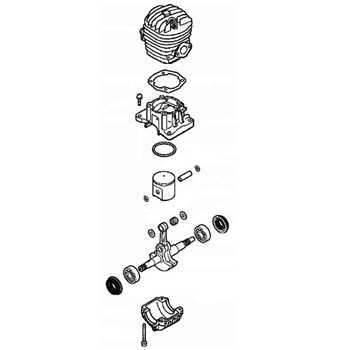

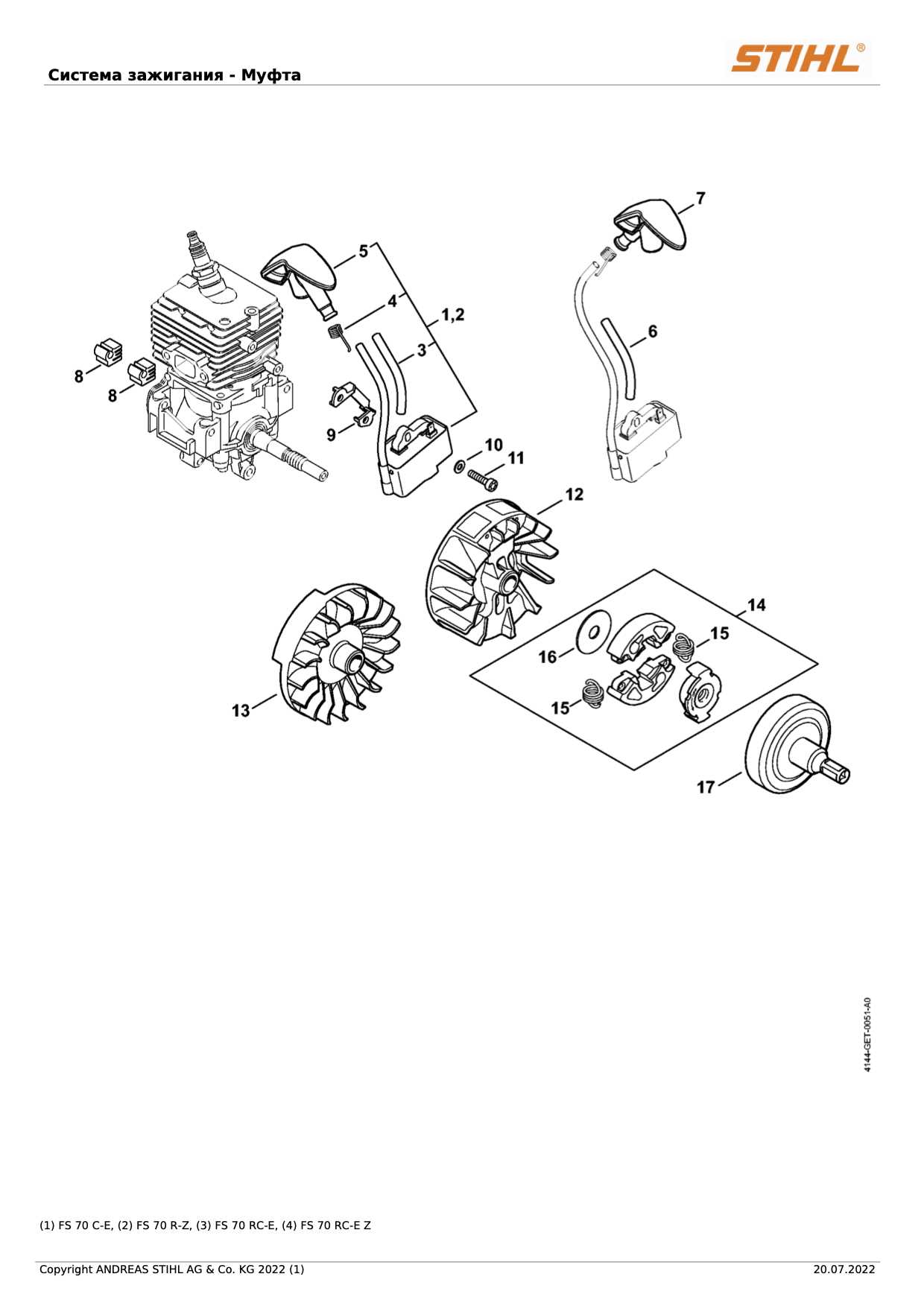

Engine and Power System

At the heart of this device lies the engine, which provides the necessary power for cutting. The engine is designed to deliver strong torque, enabling the machine to tackle dense vegetation with ease. Paired with a fuel system that ensures optimal combustion, these components work together to offer consistent performance over extended periods.

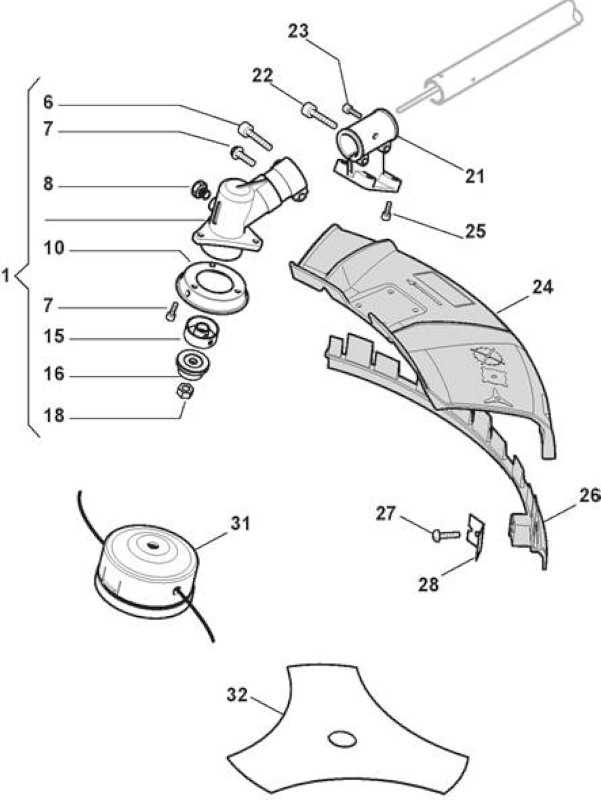

Cutting Mechanism

The cutting mechanism includes the trimmer head and the associated cutting lines or blades. These elements are crucial for achieving precise results in various applications, from trimming grass to clearing weeds. The adjustment and maintenance of these components are vital for maintaining cutting efficiency and ensuring safety during operation.

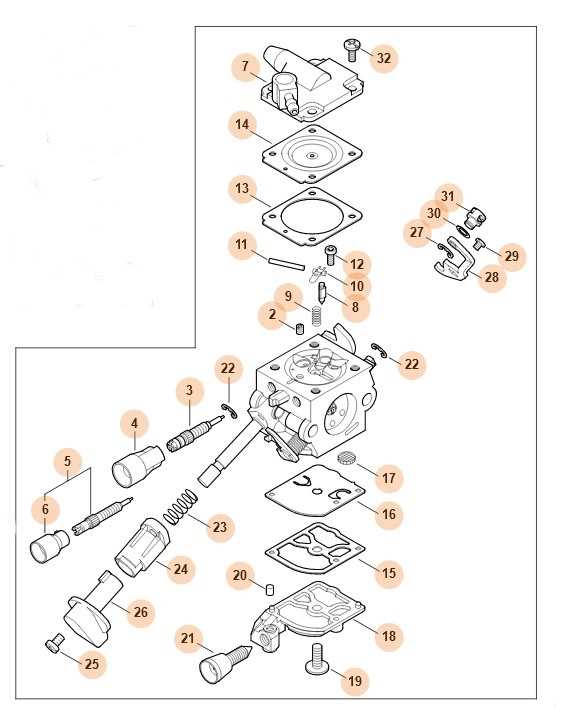

Understanding the Parts Diagram

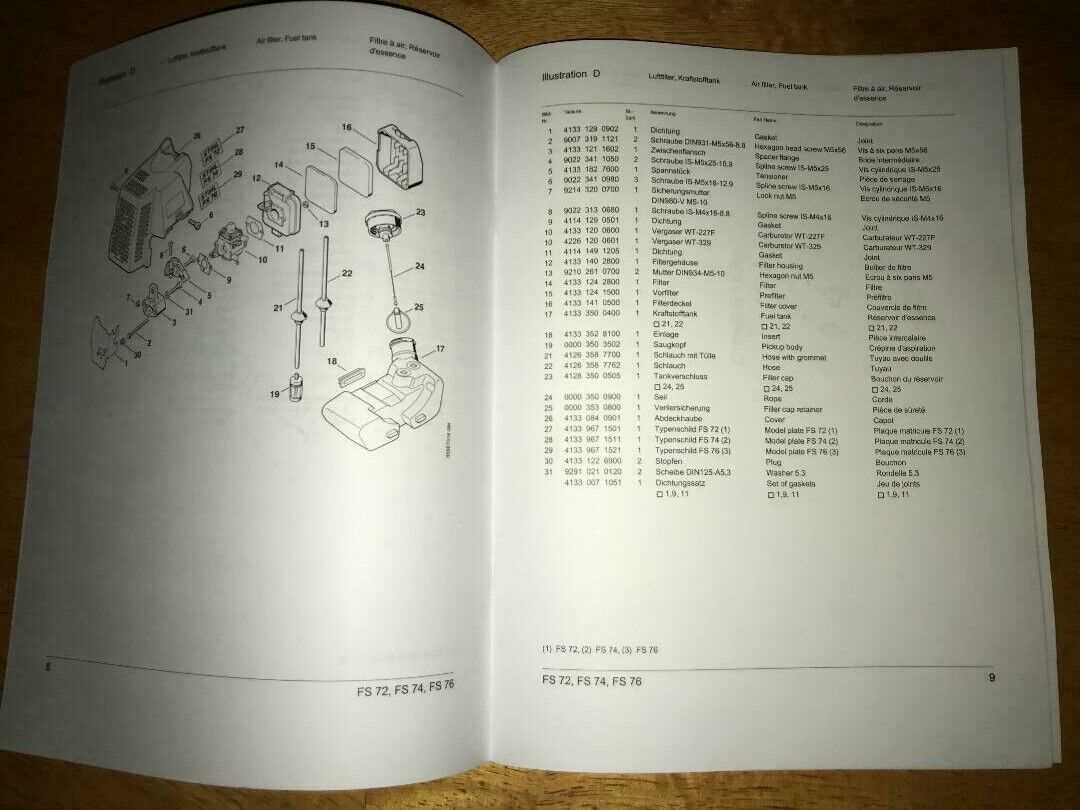

When working with mechanical equipment, it’s essential to have a clear visual reference that shows the various components and their arrangement. This guide will help you navigate through such a reference, ensuring you can easily identify and comprehend each element’s role within the system.

By carefully studying this reference, you can gain insights into how all the components interact, which is crucial for efficient maintenance and troubleshooting. Here’s how to approach the guide:

- Start by familiarizing yourself with the overall structure of the device.

- Pay attention to the labels that correspond to specific elements, as these are crucial for identifying individual pieces.

- Look for groupings of related components to understand their functionality within the system.

Understanding this visual reference is a critical step in maintaining or repairing your device, ensuring that you handle each piece correctly without unnecessary confusion or errors.

How to Use the Parts PDF

When working with your equipment, having a detailed reference guide is essential for identifying components and understanding their functions. A comprehensive document containing illustrations and part names can greatly assist in the maintenance and repair processes. By studying this visual guide, users can pinpoint the specific elements needed for tasks, ensuring accuracy and efficiency.

To make the most of this reference tool, start by locating the section relevant to the specific maintenance or repair task you are undertaking. The document will typically feature clear drawings with labels, helping you quickly recognize each piece. It’s also important to cross-check the provided part numbers with those on the machine itself or your inventory to ensure compatibility.

Additionally, paying attention to any instructions or notes within the document can provide helpful tips for assembly, disassembly, or proper usage. Whether you’re replacing a worn-out element or assembling new parts, this guide serves as a practical roadmap to ensure you’re using the correct pieces and following best practices.

Common Issues with FS 56 RC Parts

When working with outdoor tools, certain components often experience wear and tear, leading to operational issues. These problems can manifest in various ways, including poor performance, malfunctioning, or even complete breakdowns. Recognizing and addressing these challenges early can prevent more significant damage and extend the lifespan of the equipment.

One common problem is the difficulty in starting the engine, which can often be attributed to fuel system issues or spark plug malfunctions. Another frequent issue involves the cutting mechanism, where improper alignment or wear may reduce efficiency and lead to uneven cutting. Additionally, vibration and noise can increase if the mounting system or other essential connections become loose or damaged.

Regular maintenance and timely replacement of worn-out elements are crucial to avoid such complications. Ensuring the proper alignment of all mechanical components and checking for any visible damage or cracks can help identify problems before they escalate.

Replacing Broken or Worn Parts

When equipment components become damaged or excessively worn, it is crucial to address the issue promptly to ensure optimal performance. Replacing faulty elements prevents malfunction and prolongs the lifespan of the machine. Proper maintenance and timely replacements also contribute to smoother operation and prevent further damage to the remaining system.

Identifying the Damaged Components

- Inspect the tool regularly for signs of wear and tear.

- Look for cracks, loose fittings, or abnormal sounds during operation.

- Pay attention to any decline in performance or efficiency.

Steps for Replacement

- Disconnect the device from power sources or fuel supply for safety.

- Remove the broken or worn elements carefully, following the manufacturer’s recommendations.

- Install the new components, ensuring correct alignment and secure fastening.

- Test the device to confirm proper functionality after the replacement.

FS 56 RC Tools and Accessories

When operating the FS 56 RC, having the right tools and attachments can greatly enhance the efficiency and versatility of your equipment. Various implements and accessories are available to help tackle different tasks with precision, ensuring that the machine adapts to a variety of gardening or landscaping needs.

Essential Attachments

To get the most out of your equipment, consider essential attachments that can perform tasks ranging from trimming and cutting to edging and brush clearing. Each attachment is designed to provide optimal performance and ensure that the device can handle specific jobs with ease.

Useful Tools for Maintenance

Routine maintenance is crucial for keeping the FS 56 RC running smoothly. Having the right tools, such as replacement heads, string lines, and protective gear, can make maintenance more straightforward and extend the life of your equipment. Regular checks and the use of appropriate tools also help prevent damage and costly repairs.

Note: Investing in high-quality accessories can lead to better results and increase the longevity of your machine, ensuring it operates efficiently for years to come.

Maintenance Tips for Longevity

To ensure your equipment remains in optimal condition and performs efficiently over time, regular care is essential. Simple maintenance practices can significantly extend its life and reduce the need for costly repairs. By adhering to a few key steps, you can keep your tool working at its best for years to come.

1. Regular Cleaning: After each use, thoroughly clean the tool to remove debris, dirt, and residues. This prevents build-up that can lead to rust or clogging, which may impair its performance.

2. Check for Wear: Inspect the components regularly to identify signs of wear and tear. Early detection of damaged parts can help you address issues before they cause further damage.

3. Proper Lubrication: Keeping moving parts lubricated is crucial for reducing friction and ensuring smooth operation. Use appropriate lubricants recommended by the manufacturer for best results.

4. Storage Conditions: Store your equipment in a dry, cool place to protect it from harsh weather conditions. Avoid leaving it exposed to moisture or extreme temperatures, which can accelerate deterioration.

5. Replace Consumables: Regularly replace items such as filters, lines, or belts that are prone to wear. These components play a vital role in maintaining overall performance, so ensuring they are in good condition is essential.

Following these simple steps will not only keep your tool running smoothly but also enhance its durability and efficiency for years to come.

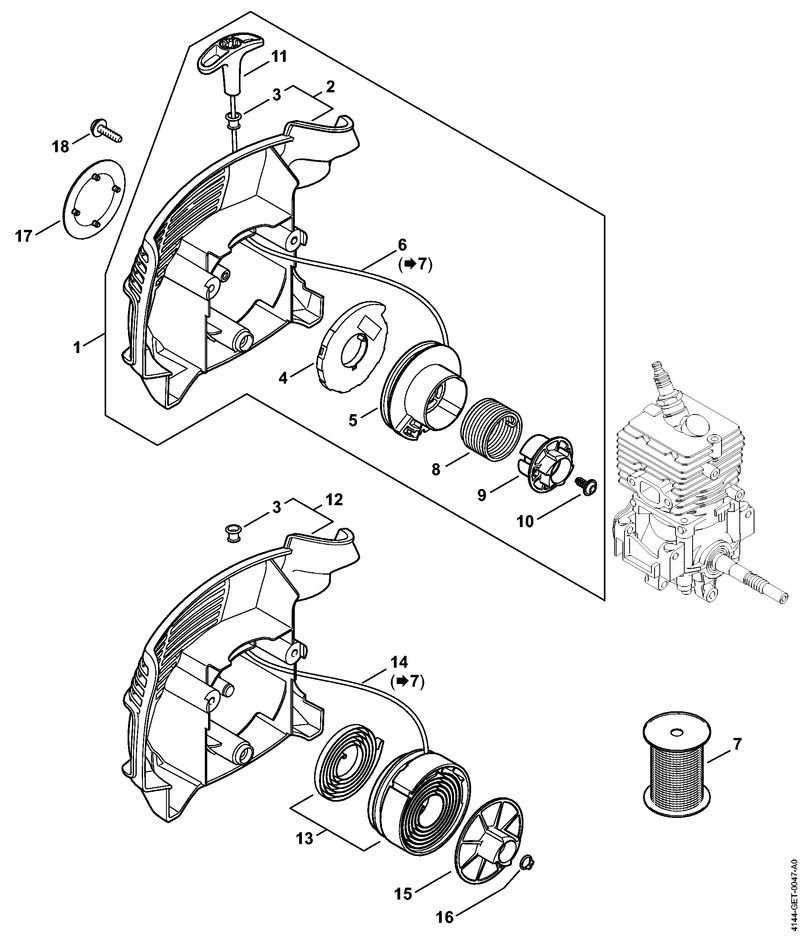

Assembly and Disassembly Instructions

Proper assembly and disassembly of the equipment ensure smooth operation and longevity. Follow the steps carefully to avoid any damage to the components. It is essential to have all the necessary tools and safety gear before beginning the process.

Assembly: Start by connecting the main components, ensuring that each part clicks or locks into place securely. Begin with the base and move toward attaching the handle, ensuring all bolts are tightened to the recommended torque. Pay attention to alignment as improper assembly may affect performance.

Disassembly: Reverse the steps carefully when removing the components. Begin by loosening and detaching the handle, followed by the main body. Make sure to keep all fasteners organized for easy reassembly. Always handle parts with care to avoid damaging sensitive areas.

For both assembly and disassembly, regular inspection and cleaning are recommended to maintain optimal function and safety.

Identifying Genuine Stihl Parts

When working with outdoor equipment, it is essential to ensure that all components are of high quality and match the original specifications. Genuine replacements not only guarantee optimal performance but also extend the lifespan of your tool. Recognizing authentic items can sometimes be challenging, but knowing the key characteristics can help you make an informed decision.

Look for Manufacturer Labels

The easiest way to determine authenticity is by examining the manufacturer’s markings. Authentic items usually have clear branding, model numbers, and production codes visible on the components. These details are often found in specific places, such as near the handle or the base of the item, and should be consistent with those listed in the product manual.

Check for Quality and Build

Genuine components are known for their superior craftsmanship. When inspecting the item, look for precise molding, sturdy material, and well-finished edges. In contrast, counterfeit alternatives often display inconsistencies in material quality, such as brittleness or poorly executed designs.

Lastly, always purchase from authorized dealers or official outlets. This ensures that the equipment you receive meets the safety standards and performance expectations.

FS 56 RC Troubleshooting Guide

This section offers practical advice for diagnosing common issues with your equipment. Whether you’re dealing with power loss, starting difficulties, or performance irregularities, this guide provides a step-by-step approach to identifying and resolving problems efficiently.

Begin by ensuring that all components are in good condition. Regular maintenance checks can prevent many issues before they occur. If problems persist, follow these troubleshooting steps:

- Starting Problems:

- Check the fuel level and ensure the mixture is correct.

- Inspect the air filter for dirt or clogs. Replace if necessary.

- Examine the spark plug for wear or damage. Clean or replace it as needed.

- Loss of Power:

- Ensure the fuel is fresh and the tank is free from debris.

- Check for blockages in the exhaust system or air intake.

- Inspect the ignition system for faults, such as a weak spark or damaged wiring.

- Unusual Vibrations:

- Verify that the cutting head is securely fastened and not damaged.

- Inspect the handle and body for loose or worn parts.

- Check for worn bearings or other moving components that might cause imbalances.

- Excessive Smoke:

- Ensure the fuel mixture is properly adjusted to prevent excessive smoke.

- Check for oil leaks and inspect the muffler for blockages.

By following these steps, you can address common issues and ensure smooth operation of your machine. Regular upkeep is key to extending its lifespan and maximizing performance.

Where to Find FS 56 RC Parts

When searching for components to maintain or repair your equipment, it is essential to know where to look for the right items. There are several reliable sources where you can find quality replacements for your machine, ensuring its optimal performance. Whether you’re looking for online stores, authorized distributors, or local repair shops, it’s important to choose reputable outlets that offer genuine, durable, and compatible items.

Online retailers are often the first option for those seeking convenience and variety. Many websites specialize in offering replacement items for various models, making it easy to browse through the available selections. Additionally, authorized dealers and service centers offer expert advice and often stock original equipment. Visiting a physical store can also be an option if you prefer to see items in person and get immediate assistance. Finally, specialty forums and communities may provide valuable insights, with members sharing links and recommendations for trusted sellers.