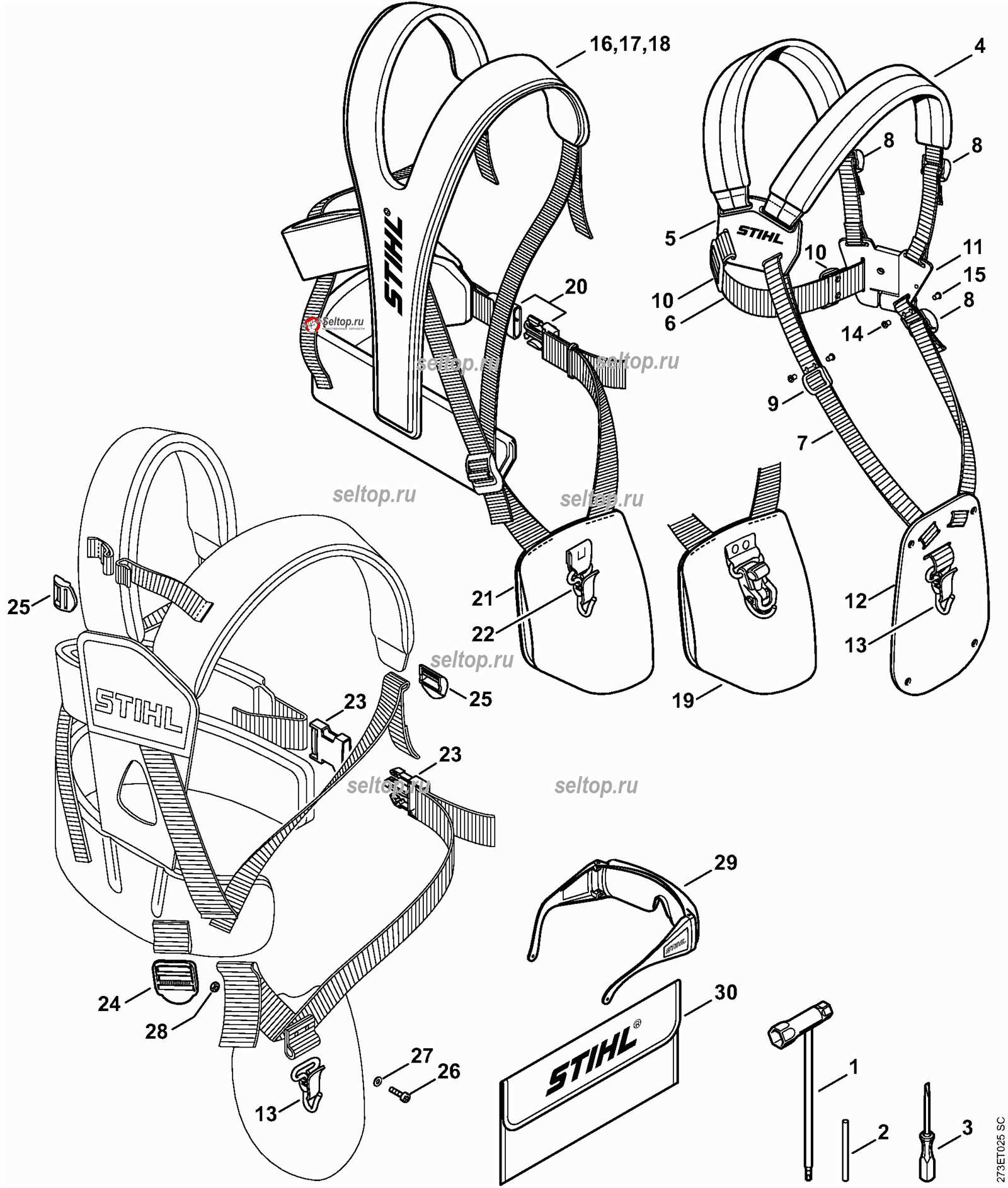

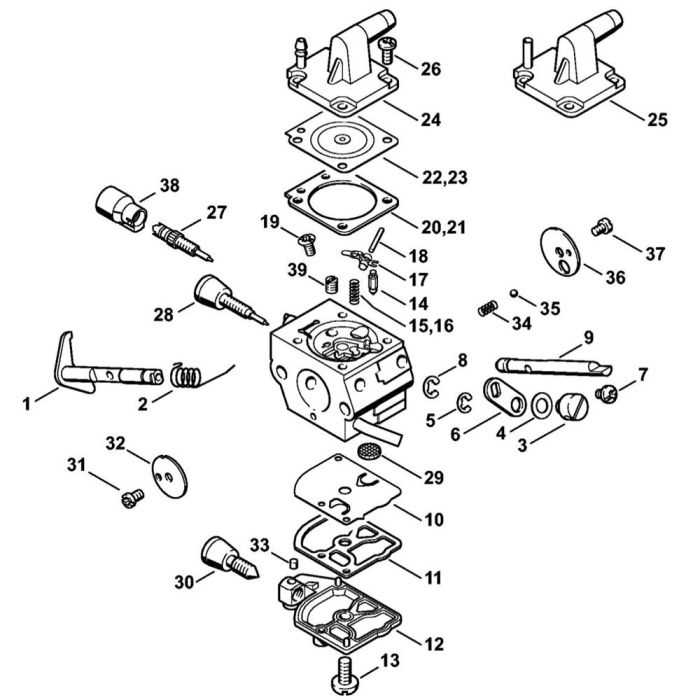

Complete Stihl FS400 Parts Diagram for Easy Reference

When it comes to maintaining and repairing outdoor machinery, having a clear visual reference for the assembly of parts is essential. A well-structured representation of individual components allows users to navigate complex systems with ease, ensuring that each piece is correctly identified and understood. This knowledge can significantly enhance the efficiency of repairs and routine maintenance.

In the world of garden tools and equipment, the interplay between different parts is crucial for optimal performance. Whether you are a seasoned technician or a DIY enthusiast, familiarizing yourself with the arrangement and functionality of various elements can lead to better troubleshooting and effective solutions. This approach not only extends the lifespan of your tools but also contributes to their reliability in the field.

Moreover, having access to detailed layouts can aid in identifying the need for replacements or upgrades. By analyzing how each component interacts within the larger system, users can make informed decisions regarding repairs, enhancing both safety and functionality. Emphasizing the importance of clarity in component illustrations will ultimately foster a deeper understanding of the equipment and improve overall user experience.

Understanding the Stihl FS400 Overview

This section provides an insightful look into a specific type of outdoor power equipment known for its efficiency and durability. Designed for various landscaping tasks, this machine is a preferred choice for both professionals and homeowners. Understanding its components and functionality is essential for optimal performance and maintenance.

The key aspects of this equipment include its powerful engine, ergonomic design, and versatile attachments. These features make it suitable for a range of applications, from trimming grass to tackling tougher vegetation. Familiarity with its essential elements can enhance user experience and extend the lifespan of the equipment.

| Component | Description |

|---|---|

| Engine | Delivers robust performance for heavy-duty tasks. |

| Handle | Ergonomically designed for comfort and control. |

| Cutting Head | Compatible with various attachments for different jobs. |

| Fuel System | Efficient design for improved fuel consumption. |

| Safety Features | Includes mechanisms to protect the user during operation. |

By understanding these elements, users can better appreciate the capabilities of this machine and ensure it operates at peak efficiency. Proper knowledge of its structure not only aids in effective use but also facilitates necessary upkeep and repairs.

Importance of Parts Diagrams

Visual representations of components play a crucial role in maintenance and repair processes. They serve as valuable tools for understanding the structure and organization of machinery, enabling users to identify and locate individual elements effectively. This clarity helps ensure that tasks are performed accurately, minimizing errors and improving overall efficiency.

Enhanced Understanding

Detailed illustrations allow for a deeper comprehension of how various elements interact within a system. This understanding is vital for both novice and experienced users, as it fosters better decision-making during repairs and replacements. Key benefits include:

- Improved identification of components

- Streamlined troubleshooting processes

- Clear visualization of assembly and disassembly steps

Increased Efficiency

When working on machinery, time is often of the essence. Having accurate visual aids reduces the time spent searching for specific parts or figuring out how to disassemble a unit. By following a structured guide, users can:

- Quickly locate necessary components

- Ensure proper reassembly

- Minimize downtime of equipment

Overall, these resources significantly enhance both the effectiveness and efficiency of repair and maintenance activities, leading to better performance and longevity of machinery.

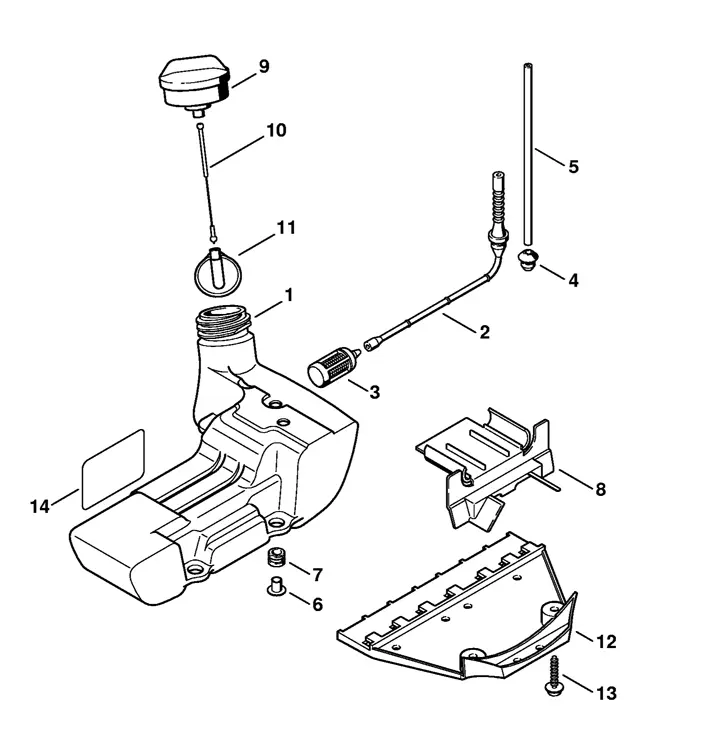

Common Issues with Stihl FS400

This section explores frequent challenges encountered with a popular outdoor power tool. Understanding these common problems can enhance maintenance and improve performance.

- Fuel Problems:

- Incorrect fuel mixture can lead to engine performance issues.

- Old or contaminated fuel may cause starting difficulties.

- Inefficient Cutting:

- Worn blades can reduce cutting efficiency.

- Improperly adjusted cutting height affects performance.

- Starting Issues:

- Problems with the ignition system may prevent starting.

- Clogged air filters can hinder airflow.

- Vibration:

- Loose components may cause excessive vibration during operation.

- Poorly balanced cutting attachments can also contribute.

By addressing these issues, users can ensure optimal performance and longevity of their equipment.

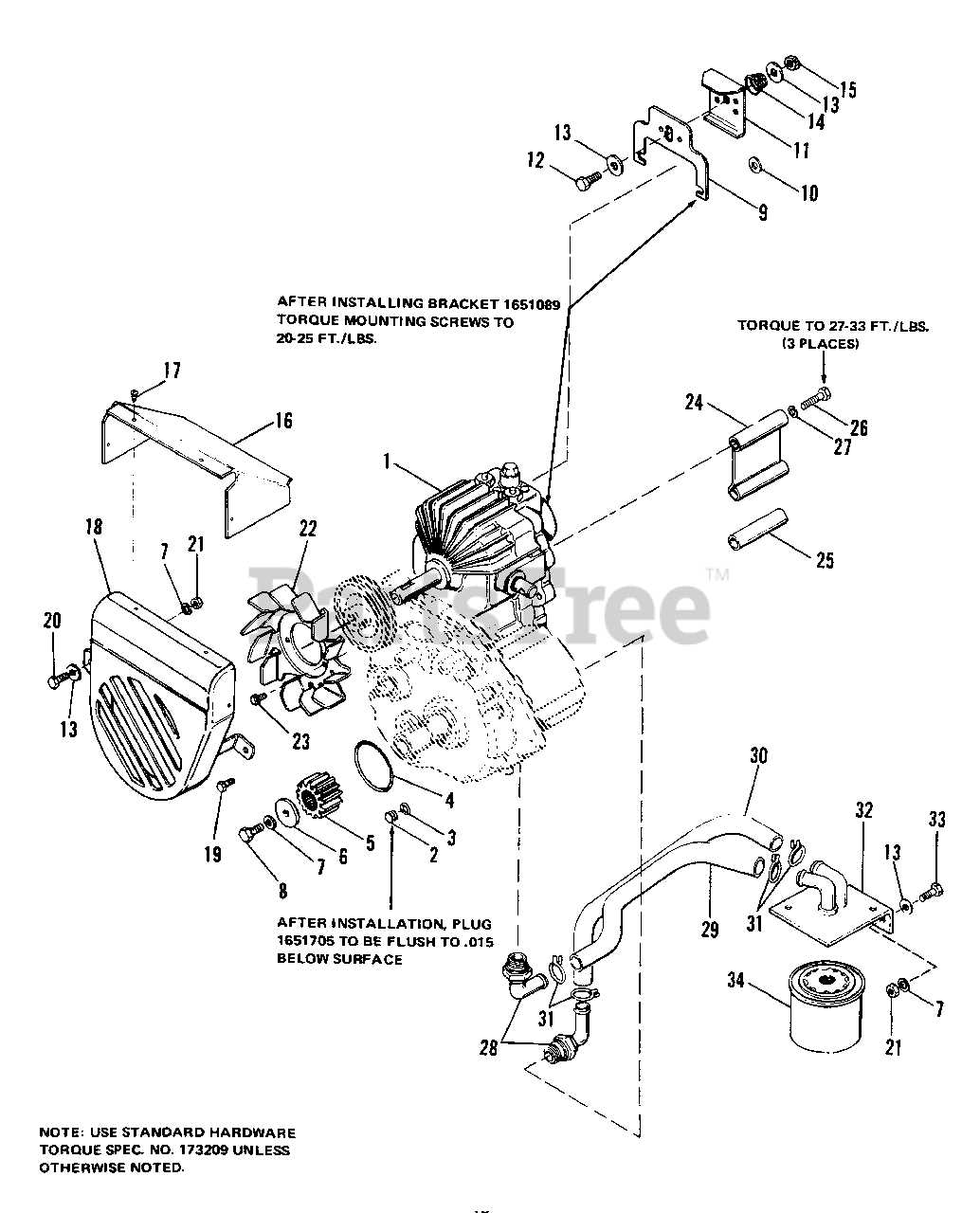

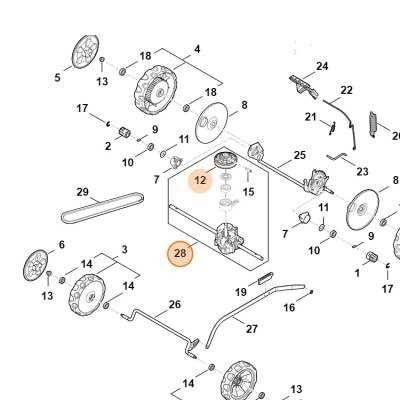

Identifying Key Components

Understanding the essential elements of a mechanical device is crucial for effective maintenance and operation. Each component plays a significant role in the overall functionality, and recognizing these parts helps in troubleshooting and repairs. By familiarizing oneself with these vital elements, users can enhance performance and extend the lifespan of the equipment.

Core Elements

The core components include the engine assembly, cutting mechanism, and fuel system. The engine assembly provides the necessary power, while the cutting mechanism is designed for efficient performance. The fuel system ensures optimal operation by delivering the required energy source, making each of these parts indispensable for smooth functioning.

Supporting Parts

In addition to the primary elements, several supporting parts contribute to the overall efficiency. These include the ignition system, which initiates engine operation, and the air filter, which maintains optimal airflow. Understanding these supporting components is essential for regular maintenance and can significantly impact the performance of the equipment.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your outdoor equipment requires regular attention and care. By following a few essential maintenance practices, you can extend the lifespan of your machinery, reduce the risk of malfunctions, and maintain its efficiency. Consistency in maintenance not only preserves functionality but also enhances safety during use.

Regular Inspections

Conduct frequent inspections of all components to identify signs of wear and tear. Look for cracks, loose parts, and any accumulation of debris that could impact performance. Addressing small issues promptly can prevent more significant problems in the future.

Proper Cleaning and Storage

After each use, ensure that your equipment is thoroughly cleaned to remove dirt, grass, and other residues. Storing your machinery in a dry, protected area will prevent corrosion and damage from the elements. Consider using protective covers to shield against dust and moisture when not in use.

Where to Find Replacement Parts

Locating high-quality components for your equipment can significantly enhance its performance and longevity. Various sources provide options to obtain the necessary items, whether for routine maintenance or repairs. Understanding where to search can save both time and money while ensuring your machinery runs smoothly.

Authorized dealers often stock genuine components, ensuring compatibility and reliability. Visiting a local distributor can offer personalized service and expert advice. Additionally, many manufacturers have online platforms where you can order directly, making it convenient to find specific items without leaving your home.

For those seeking more economical choices, aftermarket suppliers provide a range of alternatives that can be suitable for different models. Online marketplaces and auction sites also feature numerous listings from various sellers, allowing you to compare prices and availability.

Lastly, local repair shops or service centers can be invaluable resources. They frequently have access to parts and can even assist with installation, ensuring you make the right choice for your needs.

Using the Diagram Effectively

Utilizing an illustrated representation of components can greatly enhance your understanding and maintenance of machinery. By familiarizing yourself with the layout and function of various elements, you can streamline repairs and ensure optimal performance. This visual guide serves as a crucial tool for both novice and experienced users, allowing for quick identification and troubleshooting of issues.

Identifying Components

When approaching the visual guide, start by locating the specific sections that correspond to the areas of your machine you are working on. Each segment usually contains detailed labels that describe the function and placement of individual parts. This helps in not only recognizing parts but also understanding their roles within the overall system.

Enhancing Repair Efficiency

By referencing the illustrated layout during disassembly and reassembly, you can minimize the risk of misplacing components. It’s advisable to follow the sequence indicated in the guide, as this often reflects the manufacturer’s recommendations for efficient maintenance practices. A clear plan reduces the likelihood of errors and saves valuable time.

| Component | Description | Function |

|---|---|---|

| Housing | Outer shell protecting internal mechanisms | Provides structural integrity |

| Blade | Cutting element | Performs cutting tasks |

| Fuel Tank | Container for fuel | Powers the engine |

How to Read Parts Numbers

Understanding the identification codes associated with various components is crucial for effective maintenance and repair. These alphanumeric sequences serve as a universal language, conveying essential information about the item, its specifications, and compatibility. Knowing how to decode these numbers can save time and prevent errors during the purchasing process.

Breaking Down the Codes

Each section of a component’s identifier typically represents different attributes. The initial digits often indicate the model or type, while subsequent numbers may refer to the specific version or variant. It is essential to pay attention to any letters included, as they can denote particular features or functionalities that are vital for proper assembly.

Cross-Referencing with Manuals

For clarity, always cross-reference the identification sequences with the appropriate manuals or catalogues. This practice ensures that you are selecting the correct items for your specific machine. Additionally, consulting official resources can provide further insights into any updates or changes in the numbering system.

Differences with Other Models

When examining the various offerings within the brand’s lineup, it’s crucial to recognize the distinct features and functionalities that set each model apart. While many share similar foundational characteristics, unique specifications cater to different user needs, making some more suitable for particular tasks than others.

Engine Performance

One of the most significant differences lies in engine performance. Certain models boast higher horsepower, enabling them to tackle tougher vegetation or larger areas more efficiently. Conversely, others are designed for lighter, more delicate work, providing a balance between power and control. This variation ensures that users can select a tool that aligns perfectly with their intended use.

Weight and Maneuverability

Another key aspect is the weight and overall design. Some versions are engineered to be lightweight and highly maneuverable, ideal for prolonged use without fatigue. In contrast, heavier models may offer enhanced stability and durability, which can be advantageous for rigorous tasks. Understanding these differences allows users to choose the right equipment for their specific applications.

DIY Repairs: Pros and Cons

Taking on repairs yourself can be both rewarding and challenging. Engaging in this hands-on approach offers an opportunity to save money and gain a deeper understanding of the tools and equipment you use. However, it also comes with its own set of risks and limitations that every DIY enthusiast should consider.

One of the primary advantages of performing repairs independently is cost savings. Hiring professionals can be expensive, and many routine fixes can be managed without professional assistance. Additionally, tackling repairs yourself allows for a flexible schedule, letting you work at your own pace and convenience.

On the other hand, DIY repairs can lead to complications if you’re not well-versed in the specifics of the equipment. Mistakes may not only prolong the repair process but could potentially cause further damage, resulting in higher costs down the line. Moreover, certain tasks might require specialized tools or knowledge that the average person may not possess.

Ultimately, weighing the benefits against the drawbacks is essential. Understanding your own skill level and the complexity of the task at hand will help you make an informed decision about whether to proceed with a DIY approach or seek professional help.

Tools Needed for Assembly

When assembling machinery, having the right equipment on hand is essential for ensuring a smooth and efficient process. Proper tools not only facilitate the construction but also enhance safety and precision during the task. Below is a list of essential instruments that will aid in the assembly procedure.

Essential Hand Tools

Start with basic hand tools, which are vital for any assembly project. These include:

- Wrenches: Adjustable wrenches are necessary for tightening and loosening various fasteners.

- Screwdrivers: Both flat-head and Phillips screwdrivers will cover a wide range of screws.

- Pliers: Useful for gripping and manipulating small parts.

Specialized Equipment

In addition to basic tools, specialized equipment can significantly improve efficiency. Consider the following:

- Torque Wrench: Ensures that screws are tightened to the correct specifications.

- Measuring Tools: A tape measure or caliper can help ensure precise alignment.

- Safety Gear: Protective eyewear and gloves are essential for safety during assembly.

Equipping yourself with these tools will streamline the assembly process and contribute to a successful outcome.

Enhancing Performance with Upgrades

Improving the efficiency and functionality of your equipment can significantly impact its overall performance. By focusing on key enhancements, users can optimize their machines for better output and longevity. Upgrading components is not just about replacing old parts; it’s about making informed choices that lead to superior results.

One of the most effective ways to boost performance is by investing in high-quality aftermarket accessories. These parts are often designed with advanced materials and technology, allowing for increased durability and efficiency. Additionally, upgrading the fuel delivery system can enhance combustion, leading to improved power and reduced emissions.

Another critical aspect to consider is the maintenance of your equipment. Regularly replacing worn-out components with premium alternatives can prevent performance dips and extend the lifespan of the machine. By paying attention to every detail, from the cutting mechanisms to the air filtration systems, users can ensure optimal operation in various conditions.

Finally, exploring modifications that enhance ergonomics can lead to a more comfortable user experience, allowing for longer and more productive work sessions. Small changes can make a significant difference, helping users achieve their tasks more efficiently.