Understanding the Parts Diagram of Stihl FS45 Trimmer Head

The efficiency of any lawn care device largely hinges on its internal structure and functionality. A well-organized assembly enhances performance and ensures that tasks are executed smoothly. By delving into the intricacies of these essential components, users can better appreciate how each element contributes to the overall effectiveness of the equipment.

For anyone seeking to maintain or troubleshoot their device, familiarizing oneself with the various elements involved is crucial. Knowledge of the specific roles and interactions between these components can significantly simplify repair processes and enhance the longevity of the machine. This understanding empowers users to make informed decisions regarding maintenance and upgrades.

In this article, we will explore a comprehensive layout that illustrates the various segments of a cutting tool assembly. By breaking down each part’s function and significance, we aim to provide a clearer picture that facilitates both understanding and practical application. Whether you are a novice or an experienced user, this guide will equip you with the necessary insights to optimize your equipment’s performance.

Understanding the Stihl FS45 Trimmer

This section provides insight into a popular gardening tool designed for precision and efficiency. With its robust design and user-friendly features, it caters to both novice and experienced users, ensuring that tasks are completed with minimal effort. Whether tackling overgrown areas or maintaining landscaped gardens, this equipment plays a crucial role in outdoor upkeep.

Key Features and Benefits

Equipped with a powerful engine, this machine delivers impressive cutting performance. The lightweight construction enhances maneuverability, allowing users to navigate tight spaces with ease. Additionally, its ergonomic design reduces fatigue during extended use, making it an ideal choice for long sessions of yard work.

Maintenance and Care

Proper upkeep is essential to prolong the lifespan of this tool. Regular cleaning and inspection of its components help prevent wear and tear. Ensuring that the cutting mechanism remains sharp and free of debris enhances efficiency and safety. Following the manufacturer’s guidelines for maintenance will ensure optimal performance throughout the seasons.

Overview of Trimmer Head Components

This section delves into the essential elements that make up the cutting assembly of a lawn maintenance tool. Each component plays a crucial role in ensuring effective performance and durability, contributing to the overall efficiency of the equipment.

| Component | Description |

|---|---|

| Spool | The central unit that holds the cutting line, allowing for easy dispensing during operation. |

| Line | A flexible filament that serves as the primary cutting mechanism, designed for various vegetation types. |

| Cover | A protective shell that secures the spool and line, while preventing debris from escaping. |

| Spring | This component provides tension to ensure proper line feed, facilitating uninterrupted cutting action. |

| Retaining Cap | A fastening piece that holds the spool in place, preventing disassembly during operation. |

Understanding these elements is vital for maintenance and troubleshooting, ensuring optimal performance and longevity of the tool.

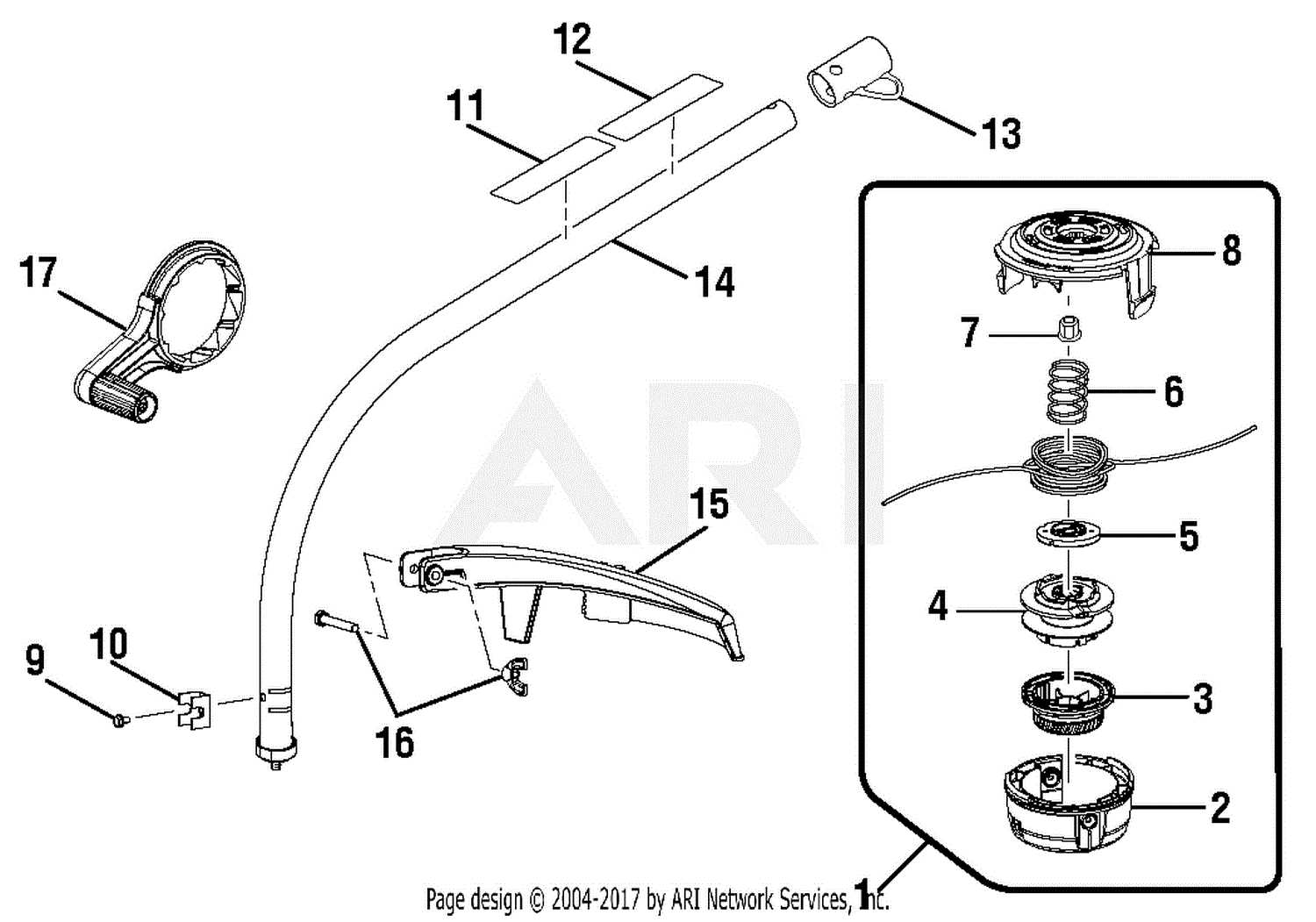

How the Trimmer Head Works

The mechanism responsible for cutting grass and weeds operates through a combination of rotational motion and flexible elements. By utilizing a spool and a line, this system effectively delivers power to the cutting tool, ensuring efficient performance across various landscapes. Understanding this process is essential for proper maintenance and effective use.

Components of the Cutting Mechanism

The primary elements involved in this cutting system include the following:

| Component | Function |

|---|---|

| Spool | Holds and feeds the cutting line. |

| Line | Engages with the vegetation to make cuts. |

| Cap | Secures the spool and prevents line loss. |

| Spring | Maintains tension on the line for optimal performance. |

Operation Process

The cutting tool operates by rotating the spool at high speed. As the spool spins, the flexible line extends outward due to centrifugal force, allowing it to engage with the foliage. This motion not only enhances cutting efficiency but also minimizes resistance. Proper line length and tension are crucial for achieving the best results, ensuring that the mechanism functions seamlessly during operation.

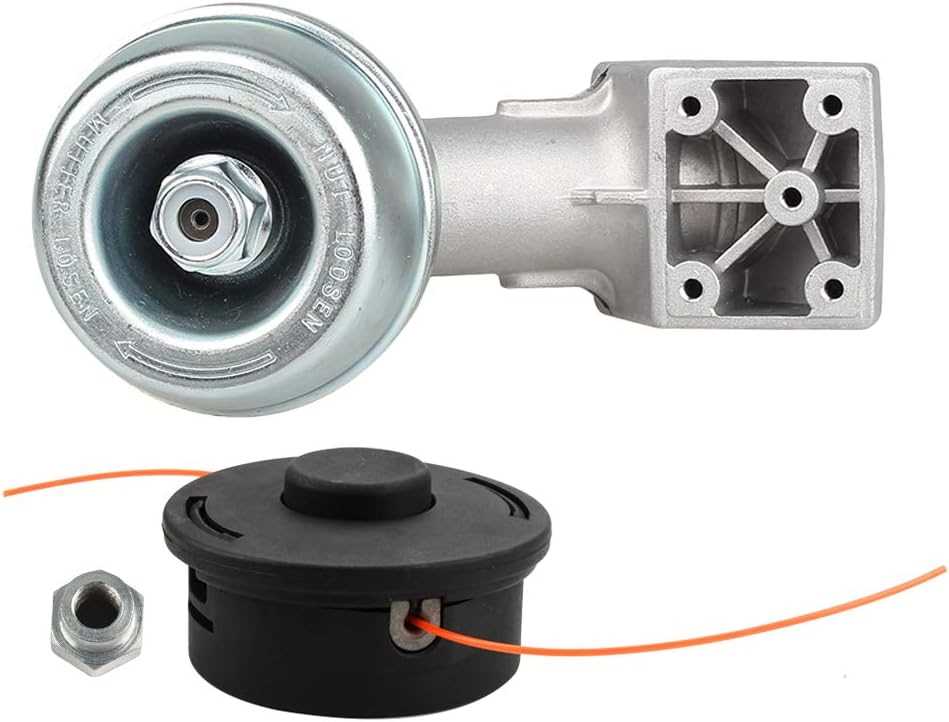

Common Replacement Parts Explained

When maintaining outdoor equipment, understanding the components that may require replacement is essential for optimal performance. Several key elements often wear out over time, impacting efficiency and usability. Here, we explore the most frequently replaced components and their roles in the overall functionality of your machinery.

- Cutting Line: The most critical element for achieving precise cutting. Regularly replacing the line ensures effective trimming and reduces strain on the motor.

- Spool: This component holds the cutting line. A damaged spool can lead to improper line dispensing, causing frustration during operation.

- Drive Shaft: This part transfers power from the motor to the cutting mechanism. Signs of wear can result in decreased performance or complete failure.

- Clutch Assembly: Essential for engaging and disengaging the cutting mechanism. A malfunctioning clutch can prevent the device from operating correctly.

- Protective Guard: Ensures safety while operating. A cracked or broken guard can pose hazards, making it crucial to replace it when damaged.

lessCopy code

Understanding these components allows for proactive maintenance, ultimately extending the lifespan of your equipment and enhancing its performance. Regular inspections and timely replacements can save both time and money in the long run.

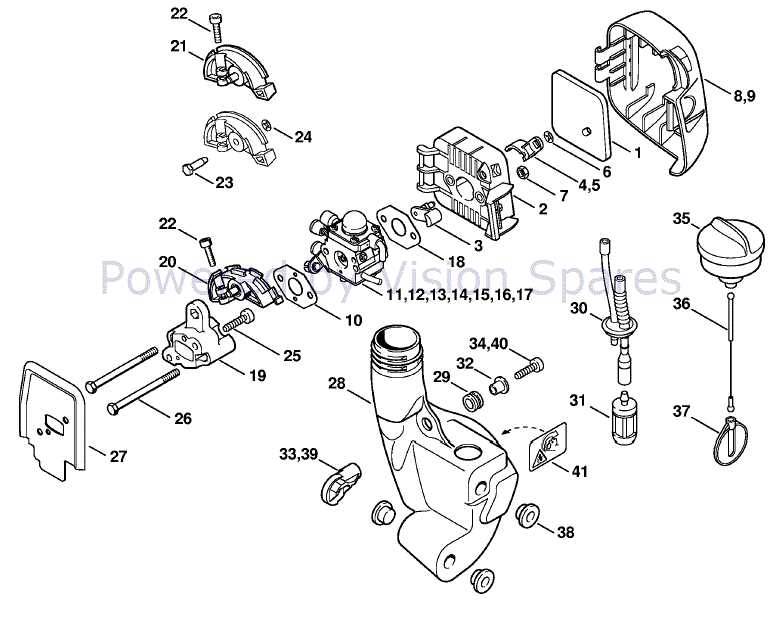

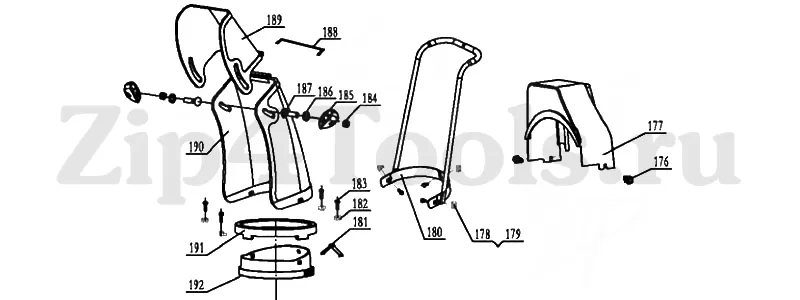

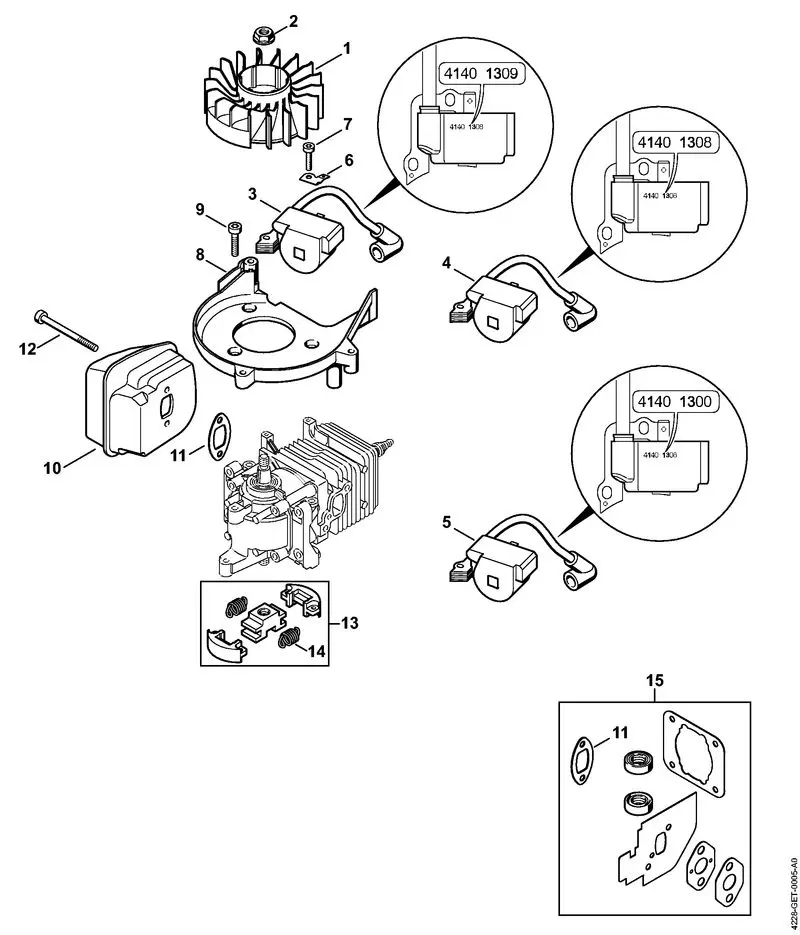

Identifying Each Part in the Diagram

Understanding the various components illustrated in the schematic is essential for effective maintenance and operation. Each element plays a specific role, contributing to the overall functionality of the equipment. Familiarity with these components can enhance troubleshooting and repair processes.

1. Cutting Mechanism: This section is responsible for the actual cutting action. It typically includes a line or blade that performs the trimming of grass or weeds.

2. Spool: The spool houses the cutting line. It allows for automatic line feed during operation, ensuring a consistent length for optimal performance.

3. Housing: The outer shell that encases the inner workings provides protection and structural support, as well as a means for attaching to the main body of the device.

4. Drive Shaft: This component transfers power from the engine to the cutting mechanism, ensuring that the system operates efficiently and effectively.

5. Adapter: This piece allows for the attachment of various cutting implements, making the tool versatile for different tasks.

By recognizing and understanding these individual components, users can ensure their equipment runs smoothly and can address any issues that may arise during use.

Tools Needed for Assembly

Assembling gardening equipment requires specific tools to ensure a smooth and efficient process. Having the right instruments at hand not only simplifies the assembly but also enhances safety and precision. Below is a list of essential tools you will need to successfully put together your device.

First, a standard screwdriver set is crucial for securing various components. Both flathead and Phillips screwdrivers will be necessary, depending on the types of screws used. Additionally, a pair of pliers can help with gripping and tightening parts that may be difficult to handle with fingers alone.

Another important tool is a wrench set, which is useful for adjusting nuts and bolts to the proper tightness. Depending on the model, you may need different sizes, so having a complete set will ensure you’re prepared for any requirement.

Don’t forget about safety equipment, such as gloves and goggles. These items will protect you while you work, minimizing the risk of injury from sharp edges or flying debris.

Finally, having a clean workspace with adequate lighting will make the assembly process much more manageable. A well-organized area allows for easy access to tools and parts, helping you stay focused on the task at hand.

Step-by-Step Assembly Instructions

This section provides a clear and concise guide for assembling the essential components of your gardening tool. Following these instructions will ensure that each element is correctly fitted, optimizing performance and longevity.

Required Tools and Materials

Before starting the assembly, gather the following tools and materials:

| Tool/Material | Description |

|---|---|

| Wrench | For tightening bolts and nuts. |

| Screwdriver | To secure screws in place. |

| Replacement Components | Ensure you have all necessary parts for assembly. |

Assembly Steps

Follow these steps to successfully assemble the components:

- Begin by laying out all components on a clean surface.

- Attach the main body to the power unit, ensuring a snug fit.

- Secure the locking mechanism to prevent any disconnections during use.

- Install the protective cover, aligning it with the designated slots.

- Finally, double-check all connections and tighten any loose parts.

Completing these steps will help you effectively prepare your tool for operation, ensuring optimal functionality for your gardening tasks.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of your gardening equipment. Regular maintenance not only enhances performance but also extends the lifespan of your tools, allowing you to enjoy their benefits for many seasons to come. Here are some practical tips to keep your equipment in optimal condition.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Clean the Exterior | After Each Use | Remove dirt and debris to prevent corrosion and damage. |

| Inspect the Blade | Weekly | Check for dullness or damage; sharpen or replace as needed. |

| Check Fuel Quality | Monthly | Ensure fuel is fresh; stale fuel can cause starting issues. |

| Examine Cables and Hoses | Monthly | Look for signs of wear or cracks; replace if necessary. |

| Change Air Filter | Every 25 Hours | Replace to maintain optimal airflow and engine performance. |

| Lubricate Moving Parts | Seasonally | Apply lubricant to reduce friction and wear. |

By adhering to these maintenance practices, you will significantly enhance the reliability and performance of your equipment. Consistency is key to avoiding costly repairs and ensuring your tools serve you well for years to come.

Troubleshooting Common Issues

Maintaining outdoor equipment can sometimes present challenges, particularly when it comes to performance problems. Understanding potential issues can help users quickly identify and resolve them, ensuring optimal functioning. Common complications can range from improper operation to unexpected mechanical failures, which can hinder productivity.

One frequent concern is difficulty in starting the machine. This can often stem from fuel issues, such as stale or contaminated gasoline. Checking the fuel quality and ensuring proper mixture ratios is essential. Additionally, examining the ignition system for wear can also provide insights into starting troubles.

Another common problem is the equipment not cutting effectively. This can result from dull cutting elements or improper tension in the line. Regularly inspecting these components and replacing them when necessary can greatly enhance performance. Furthermore, ensuring that the device is being used at the correct angle and speed can prevent ineffective cutting.

Finally, unusual noises during operation can indicate underlying mechanical issues. Users should be vigilant about any abnormal sounds, as they may signify wear on moving parts or a need for lubrication. Regular maintenance checks can help identify and address these concerns before they lead to more significant repairs.

Where to Buy Replacement Parts

When seeking components for your gardening equipment, finding reliable sources is essential. Numerous options are available for purchasing quality replacements that ensure optimal performance and longevity. Whether you prefer online shopping or visiting a local retailer, knowing where to look can make the process smoother.

Online marketplaces offer a wide range of products, often at competitive prices. Websites dedicated to outdoor equipment frequently carry a variety of replacements, providing detailed specifications and user reviews to help you make informed choices. Additionally, manufacturer websites may have exclusive parts that are specifically designed for your machine.

For those who prefer a hands-on approach, local hardware stores or specialized gardening supply shops can be valuable resources. Staff members are often knowledgeable and can assist you in finding the right components. Furthermore, these stores may carry aftermarket options that can be both affordable and effective.

Don’t forget to explore second-hand options as well. Online classifieds and auction sites can sometimes yield hidden gems at reduced prices. Always ensure that the components are in good condition before making a purchase.

Regardless of the source you choose, it’s vital to verify compatibility with your specific equipment to avoid issues down the line. Investing time in research will pay off in the long run, ensuring that your tools remain functional and efficient.

Comparing Stihl FS45 with Other Models

When evaluating different landscaping tools, it’s essential to understand how various models stack up against one another. Each device offers unique features that cater to specific needs, making it crucial to identify the strengths and weaknesses of each option. This comparison focuses on power, efficiency, and usability, providing insights for potential buyers.

Power and Performance

In terms of power output, some models may excel with higher horsepower, resulting in faster and more efficient cutting. However, others may prioritize fuel efficiency, allowing for extended use without frequent refueling. Weight and balance also play significant roles in overall performance, impacting maneuverability and user fatigue during prolonged tasks.

Usability and Features

Different options come with varying features that enhance user experience. For example, certain models include adjustable handles for personalized comfort, while others may offer quick-release systems for easy line replacement. Ergonomics and overall design can significantly affect how a tool feels in hand, making some choices more appealing for residential users compared to commercial landscapers.

Upgrades for Enhanced Performance

Improving the functionality of your outdoor equipment can significantly enhance efficiency and ease of use. Upgrades not only optimize performance but also prolong the lifespan of your tools. Here are some key enhancements to consider for a more powerful and effective experience.

1. High-Quality Cutting Line

Using a superior cutting line can dramatically improve cutting capabilities. Look for options that offer:

- Increased durability to withstand tough vegetation.

- Thicker gauge for better resistance against wear.

- Specialized shapes, such as multi-sided or twisted designs, for enhanced cutting action.

2. Efficient Motor Upgrades

Upgrading the motor can lead to better performance and energy efficiency. Consider the following:

- Choosing a motor with higher torque for improved power delivery.

- Installing a lightweight flywheel to enhance rotational speed.

- Implementing advanced cooling systems to prevent overheating during extended use.

Investing in these upgrades will result in a noticeable boost in the effectiveness of your equipment, allowing for quicker and more precise work in your outdoor tasks.

Frequently Asked Questions About FS45

This section addresses common inquiries regarding a specific model of outdoor power equipment. Users often seek clarity on maintenance, functionality, and compatible components to enhance their experience and ensure optimal performance.

What maintenance is required for my equipment? Regular upkeep includes cleaning the air filter, checking the spark plug, and ensuring the cutting mechanism is sharp. Following the manufacturer’s recommendations will prolong its lifespan.

How do I troubleshoot starting issues? If your machine won’t start, check the fuel, ensure the spark plug is in good condition, and inspect the choke settings. A clogged fuel line can also prevent ignition.

What fuel mixture should I use? It’s crucial to use the correct fuel-to-oil ratio as specified in the manual. This ensures efficient operation and reduces engine wear.

Are there compatible accessories available? Yes, there are numerous attachments and accessories designed for versatility. Always verify compatibility with your specific model before purchasing.

How can I improve cutting efficiency? Keeping the cutting line at the proper length and ensuring it’s well-maintained can significantly enhance performance. Additionally, using the right technique while operating can lead to better results.

Where can I find replacement components? Authorized dealers and various online retailers offer a range of replacement items. It’s advisable to choose genuine parts for reliability and performance.