Understanding the Stihl FS86 Parts Diagram for Effective Repairs

When it comes to maintaining and operating your gardening tool effectively, a comprehensive understanding of its individual components is essential. Each element plays a crucial role in ensuring optimal performance, longevity, and ease of use. Familiarizing yourself with these parts allows for better troubleshooting and enhanced functionality.

In this guide, we will explore a visual representation of the various elements that make up this particular model. By breaking down the intricate workings, you can gain insights into how each piece contributes to the overall efficiency of your equipment. Delving into these details can lead to a more informed approach to maintenance and repairs.

Whether you’re a seasoned user or a newcomer, knowing the specific parts of your tool can ultimately enhance your gardening experience. By understanding what each component does, you empower yourself to tackle any challenges that may arise, ensuring that your equipment remains in peak condition.

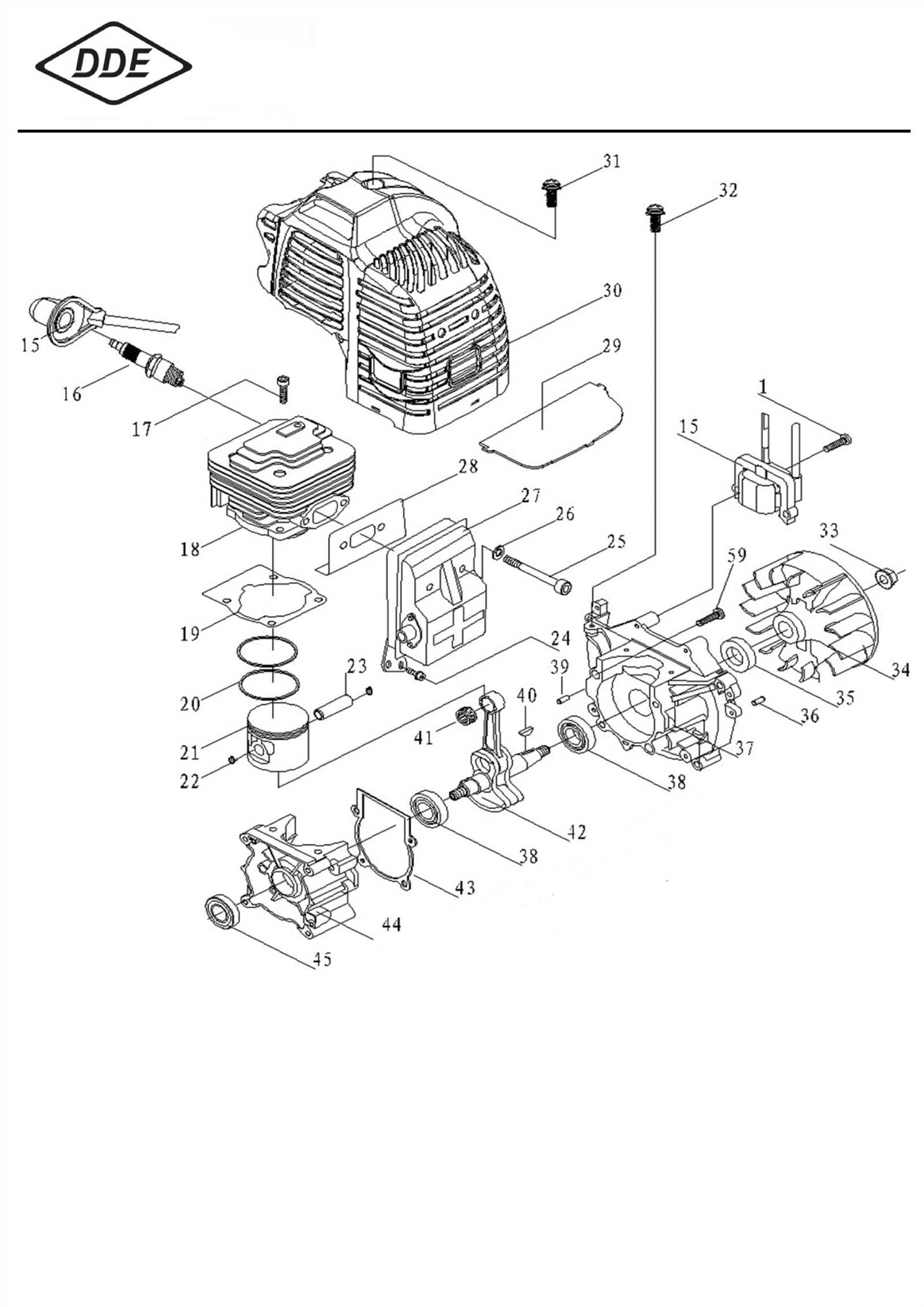

Understanding Stihl FS86 Parts Diagram

Comprehending the components of a power tool is essential for efficient maintenance and repair. By exploring the intricate layout of each element, users can ensure optimal performance and longevity of their equipment. This section aims to elucidate the various parts and their functions, providing clarity on the overall structure.

| Component | Description |

|---|---|

| Engine | The core unit that powers the tool, providing necessary energy for operation. |

| Fuel Tank | Holds the fuel required for the engine, ensuring efficient operation. |

| Handle | Provides grip and control, allowing for ease of use during tasks. |

| Blade | The cutting element that performs the primary function of the tool. |

| Throttle Control | Regulates the engine speed, allowing for precision in operation. |

Importance of Parts Diagrams

Understanding the layout and components of a machine is crucial for effective maintenance and repair. Visual representations serve as essential tools for both professionals and enthusiasts, providing clarity and enhancing comprehension.

- Facilitates quick identification of components.

- Aids in troubleshooting issues efficiently.

- Enhances the learning process for new users.

- Streamlines the ordering of replacements.

Incorporating these illustrations in manuals ensures that users can navigate complex machinery with confidence, ultimately leading to better performance and longevity.

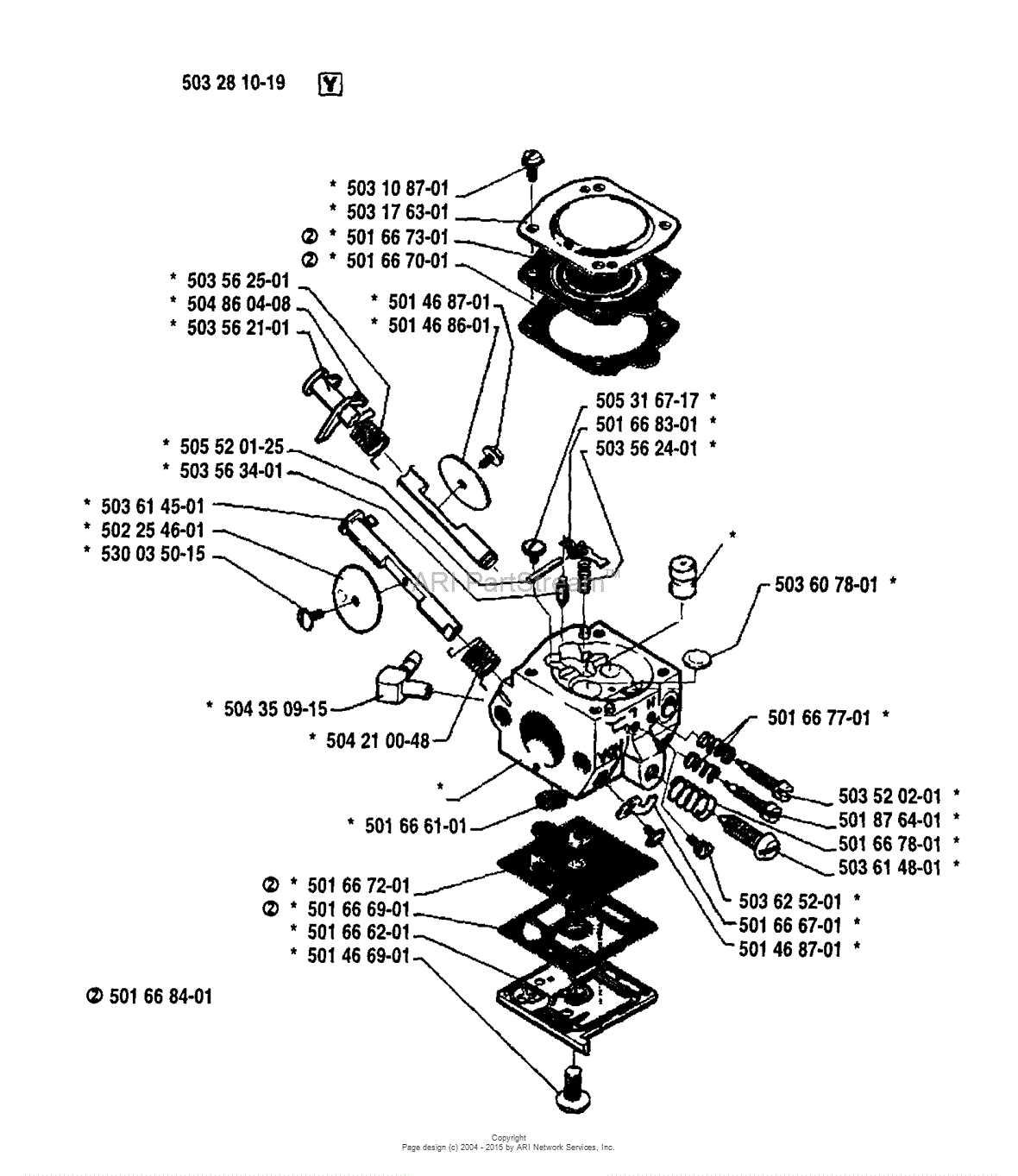

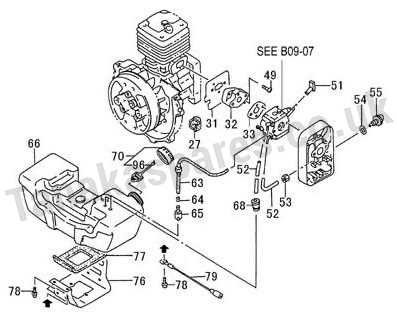

Components of Stihl FS86 Explained

Understanding the essential elements of a brushcutter is crucial for optimal performance and maintenance. Each part plays a significant role in the overall functionality, contributing to the efficiency and durability of the equipment. This section delves into the various components, shedding light on their purposes and interconnections.

Power System

The power system is the heart of the brushcutter, providing the necessary energy to drive the cutting mechanism. This includes the engine and the ignition system, which work in tandem to ensure smooth operation. Regular checks and maintenance of this system are vital for peak performance and longevity.

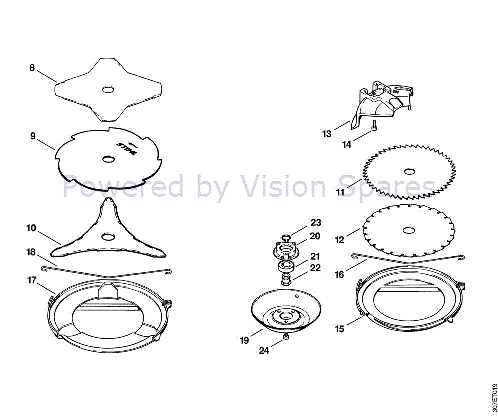

Cutter Assembly

The cutter assembly encompasses the blades and trimmer head, designed for precision cutting. Various types of blades can be utilized, depending on the task at hand, such as trimming grass or clearing thick vegetation. Proper installation and regular inspection of this assembly are essential for effective and safe operation.

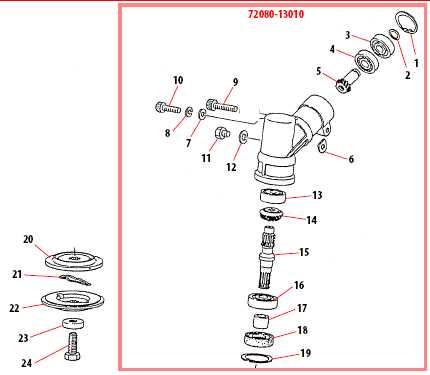

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair tasks. By learning how to interpret these illustrations, you can identify individual elements and their relationships within a machine.

Here are some key steps to consider:

- Familiarize Yourself with Symbols: Each illustration uses specific icons to represent various components. Ensure you know what each symbol stands for.

- Identify Key Sections: Look for labeled sections that may group similar components together. This helps in understanding the overall structure.

- Refer to the Legend: Many visual guides include a legend that clarifies the symbols used. Consult it for accurate identification.

- Follow the Numbering System: Components are often numbered sequentially. Following this order can simplify the identification process.

By applying these techniques, you can confidently navigate through any visual representation of machine components, ultimately enhancing your repair and maintenance skills.

Common Replacement Parts for FS86

Regular maintenance of your equipment is essential to ensure optimal performance and longevity. Knowing which components may require replacement can help you keep your tool in top shape, allowing for efficient operation and reduced downtime.

| Component | Description |

|---|---|

| Cutting Blade | Essential for effective trimming; should be checked frequently for wear and damage. |

| Fuel Filter | Prevents debris from entering the fuel system, ensuring smooth engine operation. |

| Air Filter | Maintains engine efficiency by keeping contaminants out; regular cleaning or replacement is recommended. |

| Spark Plug | Critical for ignition; periodic replacement can enhance starting performance and fuel efficiency. |

| Drive Shaft | Transfers power from the engine to the cutting attachment; inspect for any signs of wear. |

Identifying Wear and Tear in Parts

Understanding the signs of deterioration in machinery components is essential for maintaining optimal performance and longevity. Regular inspections can help you recognize issues early, preventing further damage and costly repairs.

One of the primary indicators of degradation is visual inspection. Look for cracks, dents, or unusual wear patterns. Additionally, performance irregularities, such as unusual noises or vibrations, may signal underlying problems. It’s crucial to address these signs promptly to ensure safe and efficient operation.

Another important factor is material fatigue. Components made from metals or plastics can weaken over time, leading to failure. Regularly check for signs of rust, corrosion, or brittleness, as these can greatly impact functionality. Keeping an eye on these aspects will aid in identifying necessary replacements before they fail.

Ordering Genuine Stihl Parts Online

Acquiring authentic components for your outdoor equipment is essential for maintaining performance and longevity. When shopping online, it’s crucial to ensure that you are selecting reliable sources that provide high-quality items tailored for your specific machinery. This section will guide you through the process of purchasing genuine parts with ease.

Here are some tips to help you make informed decisions while ordering:

- Research Reputable Retailers: Look for online stores with positive reviews and a solid reputation in the industry.

- Check for Authenticity: Ensure that the seller offers original components rather than counterfeit options.

- Read Product Descriptions: Pay close attention to details in the descriptions to confirm compatibility with your model.

When placing your order, consider the following:

- Compare Prices: Look at different retailers to find competitive pricing.

- Review Return Policies: Familiarize yourself with the return and exchange policies in case the item does not meet your expectations.

- Utilize Customer Support: Don’t hesitate to reach out to customer service for any inquiries regarding your purchase.

By following these guidelines, you can confidently order authentic components online, ensuring your outdoor equipment remains in top condition.

Maintenance Tips for FS86 Equipment

Regular upkeep of your outdoor power tools is essential for optimal performance and longevity. Proper maintenance ensures efficiency and helps prevent costly repairs down the line. Following a consistent care routine can significantly enhance the functionality of your equipment.

| Task | Frequency | Notes |

|---|---|---|

| Clean the air filter | Every 10 hours of use | Check for dirt and debris; replace if damaged. |

| Inspect cutting blades | Before each use | Ensure blades are sharp and free from damage. |

| Change spark plug | Every 25 hours of use | Replace with an OEM part for best results. |

| Check fuel lines | Monthly | Look for cracks or leaks and replace if necessary. |

| Lubricate moving parts | Every 20 hours of use | Use appropriate lubricant to ensure smooth operation. |

Safety Precautions When Handling Parts

Ensuring safety during maintenance activities is crucial to prevent accidents and injuries. Following specific guidelines can help mitigate risks associated with handling equipment components.

- Always wear appropriate personal protective equipment, including gloves, goggles, and sturdy footwear.

- Work in a well-lit area to enhance visibility and minimize hazards.

- Ensure that the equipment is powered off and disconnected from any power source before starting work.

Additionally, it’s important to handle items with care to avoid damage and potential injuries.

- Use tools designed for specific tasks to reduce strain and improve efficiency.

- Be cautious of sharp edges and moving parts that may cause cuts or bruises.

- Keep your workspace organized to prevent tripping or dropping components.

By following these precautions, you can create a safer environment for yourself and others while conducting maintenance tasks.

Tools Needed for Disassembly

When it comes to taking apart your equipment, having the right tools on hand is essential for a smooth and efficient process. The correct implements not only simplify the task but also minimize the risk of damaging components. Below is a guide to the necessary tools you will need for a successful disassembly.

Essential Tools

Start with a basic set of hand tools, which typically includes a variety of wrenches, screwdrivers, and pliers. These items are vital for loosening and removing fasteners. A socket set can be particularly useful for reaching tight spots and providing extra torque when needed.

Specialized Equipment

In addition to standard tools, some specialized equipment may enhance your disassembly experience. A torque wrench ensures that components are tightened to the correct specifications during reassembly. Furthermore, a parts tray can help keep small pieces organized, preventing loss and confusion.

Common Issues and Troubleshooting

When operating outdoor power equipment, various challenges may arise that can affect performance and efficiency. Understanding these common problems and knowing how to address them can significantly enhance the user experience and prolong the lifespan of the device.

- Engine Won’t Start:

- Check the fuel level and ensure it is fresh.

- Inspect the spark plug for wear or damage.

- Ensure the choke is in the correct position.

- Excessive Vibration:

- Examine the cutting attachment for damage or debris.

- Verify that all fasteners are tight and secure.

- Check for bent or worn shafts.

- Power Loss:

- Clean or replace the air filter.

- Inspect the fuel system for clogs.

- Look for issues with the ignition system.

- Overheating:

- Ensure adequate airflow around the engine.

- Check for blockages in cooling fins.

- Monitor the fuel mixture to ensure it’s correct.

By addressing these issues promptly and effectively, operators can maintain optimal performance and extend the lifespan of their equipment. Regular maintenance checks and adherence to manufacturer guidelines are also crucial in preventing many of these common problems.

Where to Find FS86 Manuals

For those seeking detailed guidance on maintenance and operation, locating the appropriate instructional literature is essential. These manuals serve as comprehensive resources, offering insights into troubleshooting, assembly, and proper usage. Understanding where to find these documents can significantly enhance your experience and ensure optimal performance of your equipment.

Official Manufacturer Website

The most reliable source for obtaining manuals is the official website of the manufacturer. Typically, they provide downloadable PDFs that cover various models and their specifications. Accessing the site allows users to find the latest information and updates directly from the source, ensuring accuracy and relevancy.

Online Retailers and Forums

In addition to the manufacturer’s site, numerous online retailers and dedicated forums can be valuable resources. Many retailers offer digital copies of manuals as part of their customer service. Furthermore, community forums often have sections where enthusiasts share documents and tips, providing a wealth of shared knowledge from experienced users.

Upgrades and Modifications for Performance

Enhancing the efficiency and functionality of outdoor power equipment can significantly improve its usability and lifespan. By implementing various upgrades and modifications, users can achieve better performance, increased power output, and improved handling. This section explores several options to consider for those looking to optimize their machines.

Engine Enhancements

One of the most effective ways to boost performance is by focusing on engine upgrades. Installing a high-performance air filter can enhance airflow, leading to improved combustion efficiency. Additionally, considering a more efficient spark plug can result in better ignition and smoother operation. These changes can contribute to increased power and responsiveness, making tasks easier and more efficient.

Cutting System Improvements

Upgrading the cutting mechanism is another crucial area for performance enhancements. Opting for a lightweight, durable cutting head can reduce strain during operation and improve maneuverability. Moreover, using high-quality cutting lines designed for specific tasks can enhance cutting precision and effectiveness. Implementing these modifications not only boosts performance but also ensures a cleaner and more efficient work process.