Understanding the Stihl FS94R Parts Diagram for Better Maintenance

When it comes to maintaining outdoor machinery, having a clear understanding of its individual elements is crucial. Whether you’re a professional landscaper or a weekend gardener, knowing the specific parts that make up your tools can greatly enhance their performance and longevity. This knowledge enables users to perform repairs, upgrades, and routine maintenance with confidence.

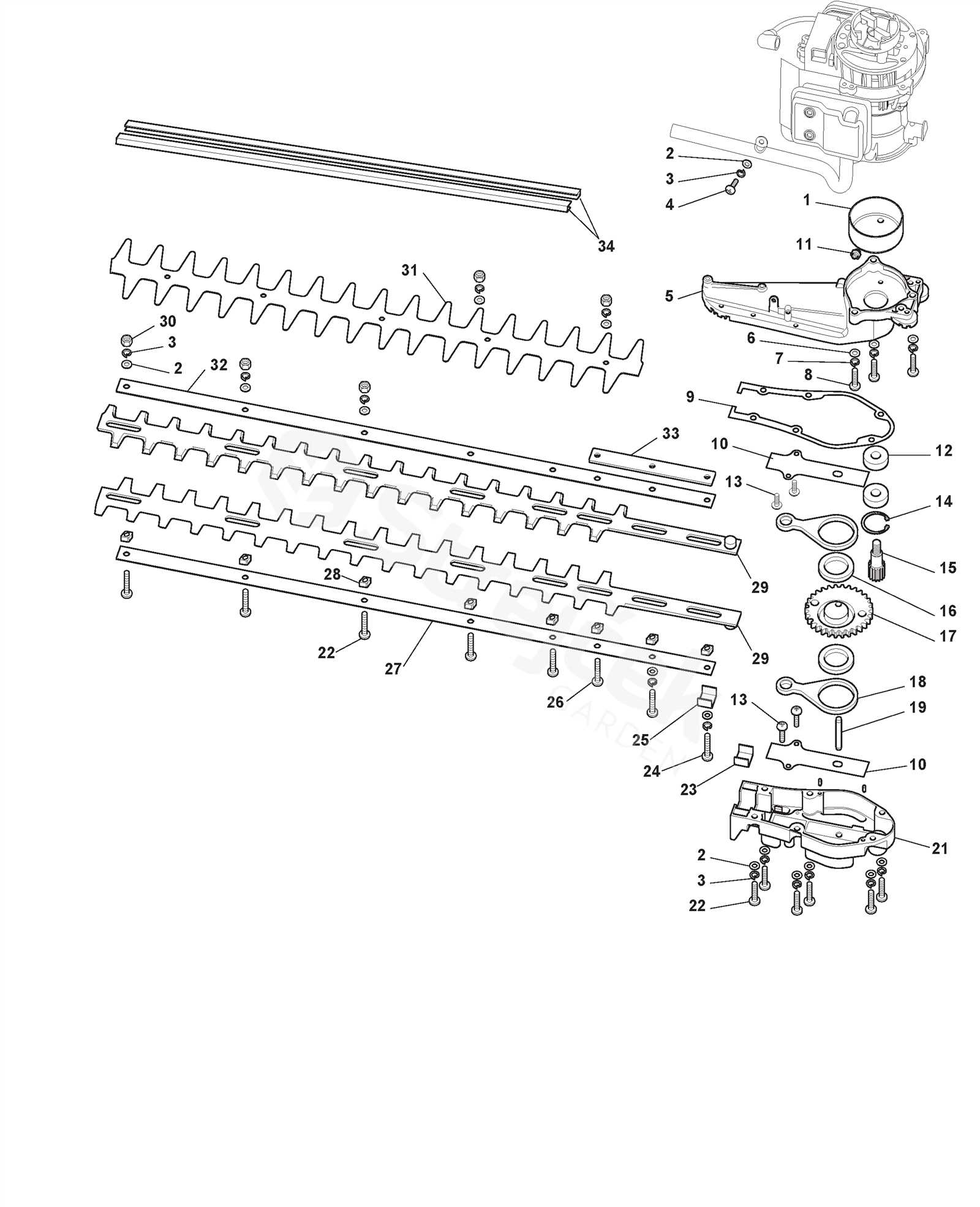

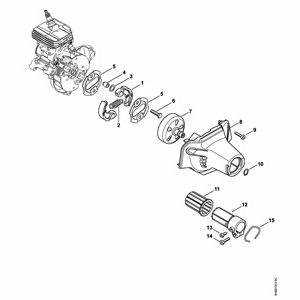

Visual aids play a significant role in grasping how each component interacts within the system. By consulting detailed illustrations, one can easily identify each section of the machinery, facilitating efficient troubleshooting and assembly. These resources serve as a roadmap, guiding users through the complexities of their equipment.

In the following sections, we will delve into the intricacies of these visual references, exploring the various components and their functions. Armed with this information, you will be better equipped to keep your tools in optimal condition, ensuring they operate effectively for years to come.

Understanding Stihl FS94R Components

Every piece of equipment consists of various elements that work in harmony to achieve optimal performance. Understanding these components not only aids in effective maintenance but also enhances the user’s ability to troubleshoot issues. By familiarizing oneself with the critical parts, one can ensure longevity and reliability of the machinery.

Key Functional Elements

Among the essential elements, the engine plays a pivotal role, providing the necessary power for operation. Coupled with the ignition system, it ensures smooth starts and reliable function. Additionally, the cutting mechanism is crucial for efficiency, enabling precise work in various applications.

Maintenance and Replacement Insights

Regular upkeep is vital for sustaining performance. Components like filters and spark plugs require periodic checks and replacements to avoid unnecessary downtimes. Understanding the significance of each part empowers users to take proactive measures, ensuring the equipment remains in top condition.

By grasping the intricacies of these components, users can navigate repairs and enhancements with confidence, ultimately leading to a more rewarding experience with their machinery.

Importance of Parts Diagrams

Understanding the components of any machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools for both professionals and enthusiasts, allowing them to grasp the assembly and functionality of different elements within equipment.

Here are several reasons why these visual aids are invaluable:

- Enhanced Clarity: Illustrations provide a clear view of how each component fits together, reducing confusion during repairs.

- Efficient Troubleshooting: Identifying malfunctioning parts becomes easier when one can see the entire layout, enabling quicker diagnostics.

- Improved Communication: Technicians and operators can discuss issues more effectively using a common visual reference.

- Streamlined Repairs: Knowing the exact location and function of each piece aids in efficient disassembly and reassembly.

- Resource Management: Users can easily identify which items need replacement, helping in inventory control and cost management.

In summary, visual representations of machinery components are not just helpful; they are essential for maintaining operational efficiency and ensuring that repairs are conducted swiftly and accurately.

Identifying Key FS94R Parts

Understanding the essential components of your equipment is crucial for effective maintenance and operation. Each piece plays a vital role in ensuring optimal performance and longevity. Familiarity with these elements not only aids in troubleshooting but also enhances your ability to make informed decisions regarding repairs and replacements.

First and foremost, the engine is the powerhouse of the unit, responsible for driving its operations. It is important to recognize its specifications and features for proper care.

Next, the cutting attachment is integral for achieving precise results. Identifying the correct type and size ensures compatibility and efficiency in use.

Furthermore, the handle and harness system contribute significantly to user comfort and control. Being aware of their configuration can enhance the overall experience during operation.

Finally, maintenance accessories like filters and spark plugs are essential for keeping your machine running smoothly. Regular checks and timely replacements of these components can prevent performance issues and extend the life of the equipment.

Common Issues with Stihl FS94R

When it comes to handheld outdoor power equipment, users may encounter several recurring problems that can affect performance and reliability. Understanding these issues is essential for proper maintenance and efficient operation. From engine troubles to cutting challenges, addressing these common concerns can prolong the life of the tool and enhance user experience.

One prevalent issue involves starting difficulties, which can stem from various factors such as fuel quality, spark plug condition, or carburetor blockages. Ensuring that the fuel is fresh and the spark plug is functioning optimally can often resolve these issues.

Another frequent challenge is the tool’s tendency to stall during operation. This can be attributed to a clogged air filter or improper mixing of fuel and oil. Regular cleaning and adhering to the manufacturer’s recommendations for fuel preparation are key preventive measures.

Users may also face problems with cutting efficiency, often linked to dull blades or incorrect line length. Maintaining sharp cutting edges and using the correct line can significantly improve performance and reduce wear on the equipment.

Lastly, overheating can occur if the device is used for extended periods without adequate breaks. Ensuring proper cooling and following recommended usage guidelines can mitigate this risk, leading to better overall functionality.

How to Use the Diagram Effectively

Understanding the visual representation of components is essential for efficient maintenance and repairs. Utilizing such illustrations can streamline the process, allowing users to identify parts and their functions quickly. This guidance will help you maximize the benefits of these resources.

1. Familiarize Yourself with the Layout

Before diving into repairs, take a moment to study the layout. Recognizing how elements are arranged will assist you in locating specific parts more easily. Pay attention to labels and symbols that denote various components, as this knowledge will save you time during the process.

2. Cross-Reference with Manuals

Using an illustration in conjunction with official manuals enhances your understanding. Manuals often provide detailed explanations of assembly and disassembly procedures, which can clarify the visual guide. This dual approach ensures accuracy and reduces the likelihood of errors.

3. Plan Your Approach

Prior to starting any work, outline your steps based on the visual guide. Having a clear plan helps prevent confusion and allows you to tackle tasks in a systematic manner. Break down complex repairs into smaller, manageable sections by following the illustration.

4. Keep It Accessible

Maintain easy access to the illustration while you work. Whether you print it out or view it on a device, ensure it’s within reach. This accessibility allows for quick reference, minimizing interruptions and enhancing focus during the repair process.

5. Take Notes

As you navigate through repairs, jot down any observations or issues you encounter. This practice not only aids memory but also provides a valuable reference for future tasks. Documenting your experiences can lead to greater efficiency in subsequent repairs.

Replacement Parts for Stihl FS94R

Maintaining optimal performance in your outdoor power equipment requires occasional substitutions of worn or damaged components. Understanding the essential elements that contribute to the efficiency and longevity of your machine is crucial for any operator. This section delves into the various options available for ensuring your equipment runs smoothly and effectively.

Identifying Components: Familiarizing yourself with the critical components of your equipment is the first step towards successful maintenance. These elements include cutting heads, trimmer lines, and protective gear that play vital roles in operation and safety.

Quality Over Cost: When considering replacements, prioritize quality. High-grade materials can significantly enhance performance and durability, often outweighing the initial cost. Investing in reliable components can save time and resources in the long run.

Where to Find Replacements: Numerous retailers specialize in outdoor equipment accessories, both online and in physical stores. Be sure to verify the compatibility of any replacement with your specific model to avoid issues during installation.

Installation Tips: Proper installation is key to ensuring that new components function as intended. Follow the manufacturer’s guidelines meticulously, and do not hesitate to seek professional assistance if needed.

Regular upkeep and timely replacements not only improve performance but also extend the lifespan of your machinery. Equip yourself with the knowledge and resources necessary to keep your outdoor tools in peak condition.

Maintenance Tips for Longevity

Ensuring the long-lasting performance of your equipment requires consistent care and attention. Regular maintenance not only extends the lifespan of your tools but also enhances their efficiency. Below are some essential tips to keep your machinery running smoothly for years to come.

| Maintenance Task | Frequency | Tips |

|---|---|---|

| Check Air Filter | Every 10 hours | Clean or replace to ensure optimal airflow. |

| Inspect Spark Plug | Every 20 hours | Replace if worn or fouled to maintain ignition quality. |

| Sharpen Blades | Every 5 hours of use | Use a proper sharpening tool to ensure clean cuts. |

| Change Oil | Every 50 hours | Use high-quality oil for better engine performance. |

| Clean Exterior | After each use | Remove debris and dirt to prevent corrosion. |

By following these guidelines, you can help ensure your equipment remains reliable and effective, minimizing the risk of breakdowns and maximizing productivity. Regular attention to these details makes all the difference in performance and longevity.

Where to Find Genuine Parts

When it comes to maintaining your equipment, sourcing authentic components is crucial for optimal performance and longevity. Genuine items ensure compatibility and reliability, minimizing the risk of malfunctions. Here are some reliable sources where you can acquire these essential elements.

| Source | Description |

|---|---|

| Authorized Dealers | These retailers are certified to sell original components, providing expert advice and support. |

| Online Retailers | Reputable e-commerce platforms often stock a wide range of authentic items, making it easy to compare options. |

| Manufacturer’s Website | Directly purchasing from the official site guarantees that you receive genuine products. |

| Local Repair Shops | Many repair professionals use and sell authentic parts, ensuring you get quality replacements. |

Investing in genuine components is a wise choice that contributes to the efficiency and durability of your equipment. Always verify the authenticity of the items you are purchasing to avoid subpar substitutes.

Assembly Instructions for FS94R

Putting together your equipment can seem daunting, but with the right approach, it becomes a straightforward task. This section will guide you through the essential steps needed to successfully assemble your machine, ensuring optimal performance and longevity.

Step 1: Begin by laying out all components on a flat surface. This allows you to verify that you have every piece necessary for assembly. Familiarize yourself with each part to ensure a smooth process.

Step 2: Follow the manufacturer’s guidelines closely. Each component should be connected as per the instructions provided, ensuring that all fasteners are tightened securely. Pay special attention to the alignment of parts to avoid any operational issues.

Step 3: After connecting the main sections, check all connections for stability. A well-assembled unit will function more efficiently, reducing the risk of wear or malfunction.

Step 4: Finally, perform a thorough inspection before usage. Look for any loose elements and confirm that everything is in place. This final check can save you from future headaches and enhance the lifespan of your machine.

By following these assembly instructions, you can ensure that your equipment is ready for action and performing at its best.

Tools Needed for Repairs

When it comes to maintaining and fixing outdoor power equipment, having the right tools at your disposal is essential for efficient and effective repairs. Proper equipment ensures that tasks are completed safely and accurately, minimizing the risk of damage to the unit or injury to the user.

Below is a list of essential tools that will help you tackle various repair tasks:

- Screwdrivers: A set of both flathead and Phillips screwdrivers is crucial for removing and tightening screws.

- Wrenches: Adjustable and socket wrenches will help you work with various nuts and bolts effectively.

- Pliers: Needle-nose and slip-joint pliers are useful for gripping, twisting, and cutting wires or small parts.

- Fuel and Oil Containers: For proper maintenance, having clean containers for fuel and oil is necessary to avoid contamination.

- Cleaning Tools: Brushes and cloths for removing dirt and debris ensure your equipment runs smoothly.

In addition to these basics, some repairs may require specialized tools:

- Torque Wrench: Essential for ensuring that bolts are tightened to the manufacturer’s specifications.

- Multimeter: Helpful for diagnosing electrical issues by measuring voltage and continuity.

- Parts Puller: Useful for removing stubborn components without causing damage.

By equipping yourself with these tools, you’ll be well-prepared to handle a variety of maintenance and repair tasks, keeping your outdoor equipment in optimal condition.

Understanding Warranty Coverage

Warranty coverage is a crucial aspect for consumers, providing peace of mind and security for their investments. It outlines the conditions under which repairs or replacements are available, ensuring that the product maintains its performance and reliability over time. Knowing the extent of this protection can save both time and money, as well as enhance overall satisfaction with the purchase.

Typically, a warranty includes details about the duration of coverage, the specific components or issues it addresses, and any exclusions that might apply. It is essential for users to familiarize themselves with these terms to understand their rights and responsibilities fully. Reading the fine print can reveal important information that impacts the usability and longevity of the product.

In many cases, the warranty will specify the type of service provided–whether it includes parts replacement, labor costs, or both. Additionally, certain conditions may need to be met, such as proper maintenance practices, to ensure the warranty remains valid. Consumers should keep records of their purchases and any service performed, as this documentation can be vital in case of claims.

Overall, being aware of warranty coverage empowers users to make informed decisions and can enhance their overall experience with the product, leading to greater confidence in their purchase.

Resources for Troubleshooting Problems

When dealing with equipment malfunctions, having the right resources at your disposal can significantly streamline the process of identifying and resolving issues. Various tools and references are available to assist users in diagnosing problems effectively, ensuring a more efficient approach to maintenance and repairs.

One of the most valuable resources is the user manual, which provides essential insights into the device’s components and operational guidelines. Additionally, online forums and community groups can offer practical advice from experienced users who have encountered similar challenges.

| Resource Type | Description | Where to Find |

|---|---|---|

| User Manual | A comprehensive guide detailing specifications, maintenance tips, and troubleshooting steps. | Manufacturer’s website or included with the purchase |

| Online Forums | Community-driven platforms where users share experiences and solutions. | Social media groups, dedicated forums, or websites |

| Video Tutorials | Visual guides that demonstrate troubleshooting techniques and repairs. | YouTube or educational websites |

| Technical Support | Professional assistance from experts who can provide personalized guidance. | Manufacturer’s customer service or authorized dealers |

| Replacement Parts Catalogs | Lists of available components and accessories that may be necessary for repairs. | Manufacturer’s website or repair shops |