Understanding the Stihl HT 133 Parts Diagram for Efficient Maintenance

Maintaining outdoor tools can be a daunting task, especially when it comes to understanding their components and how they work together. Having a clear reference can simplify repairs and enhance the efficiency of your machinery. This guide aims to provide insights into the various elements that comprise your device, ensuring you can tackle any issue that arises with confidence.

By familiarizing yourself with the intricate layout of your tool, you can better understand its functionality and performance. Each part plays a vital role in the overall operation, and recognizing their positions and interactions is essential for effective troubleshooting and maintenance. Whether you’re a novice user or an experienced operator, having access to a detailed breakdown will empower you to manage your equipment with greater ease.

Moreover, knowing how each section fits into the larger picture can save you time and resources in the long run. This knowledge not only helps you address problems more effectively but also fosters a deeper appreciation for the technology at your fingertips. Dive into this exploration of your machine’s architecture and unlock the potential for better upkeep and longevity.

Understanding the Stihl HT 133 Components

Familiarizing oneself with the various elements of a pole saw can significantly enhance maintenance and operational efficiency. Each component plays a crucial role in ensuring optimal performance, durability, and safety. Grasping how these parts interact will empower users to troubleshoot issues effectively and perform necessary repairs or replacements.

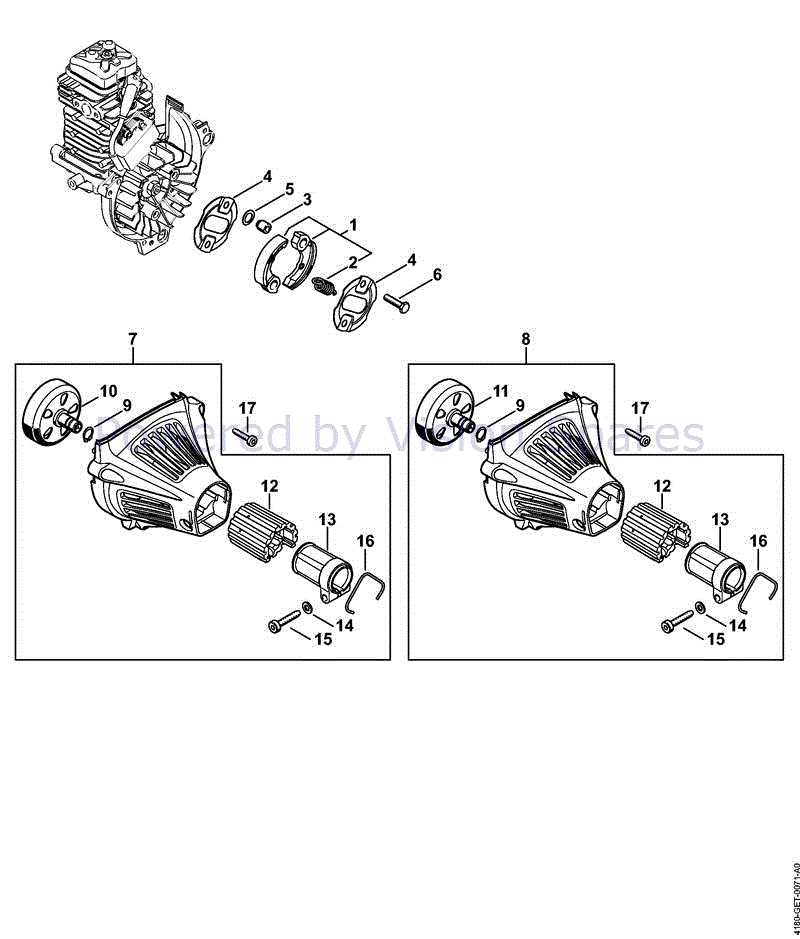

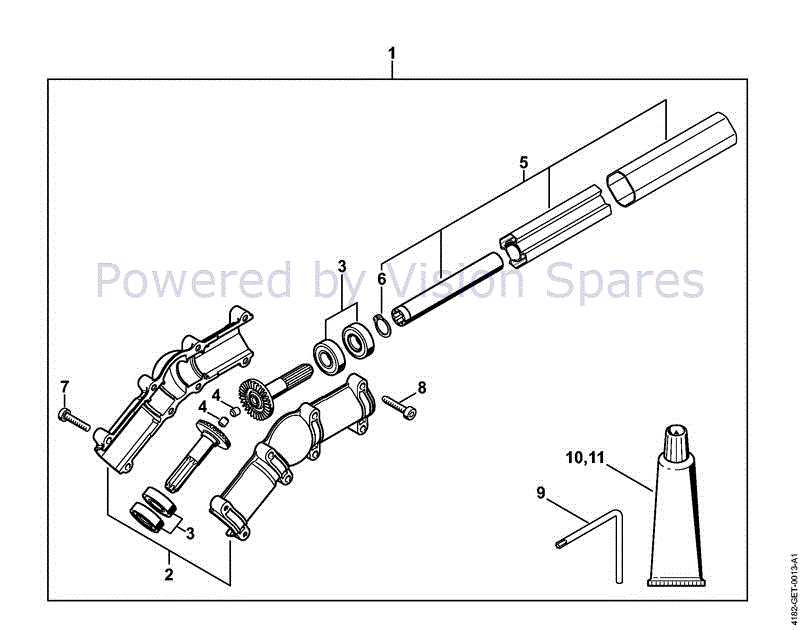

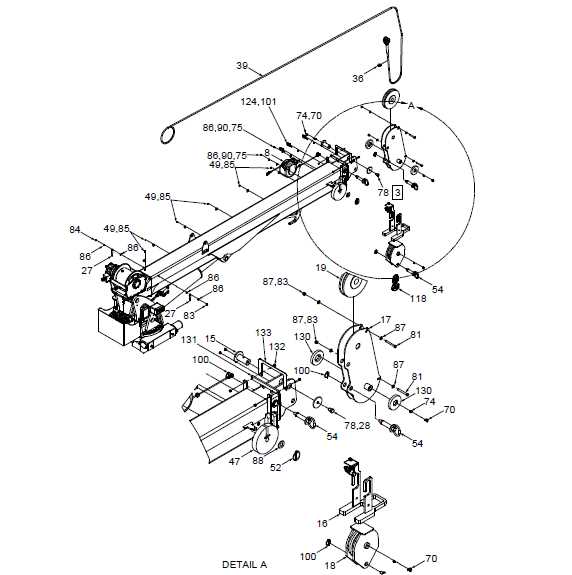

The main sections of this tool include the powerhead, shaft, and cutting attachment. The powerhead houses the engine and provides the necessary force, while the shaft connects the engine to the cutting tool, allowing for extended reach. The cutting attachment, which may vary in design, is essential for achieving precise and efficient cuts.

Understanding the functions of these core components is vital. The engine converts fuel into mechanical energy, driving the saw’s operation. The shaft’s length and flexibility determine maneuverability, making it easier to access hard-to-reach areas. Lastly, the cutting attachment must be chosen carefully based on the specific tasks at hand to ensure optimal results.

Maintaining these elements involves regular inspections and servicing. Users should be aware of wear signs and promptly address any issues to prevent further damage. By taking the time to understand these fundamental parts, operators can ensure their equipment remains in peak condition, enhancing both performance and safety.

Overview of HT 133 Specifications

This section provides a detailed examination of the key specifications associated with the high-performance pole pruner, designed for both professional and domestic use. Understanding these attributes is essential for users to make informed decisions regarding maintenance, operation, and compatibility with accessories.

Engine Characteristics

- Type: Two-stroke engine

- Displacement: Optimized for power and efficiency

- Power Output: Capable of delivering robust performance

- Fuel Type: Requires a specific fuel-oil mixture for optimal operation

Operational Features

- Weight: Lightweight design for easy maneuverability

- Length: Adjustable shaft to accommodate various reach requirements

- Cutting Head: Equipped with a sharp blade for efficient trimming

- Safety Mechanisms: Features designed to enhance user protection during operation

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations provide clarity on how various elements interact and function together. This knowledge empowers users to troubleshoot issues more efficiently and enhances their ability to perform necessary replacements or repairs.

Facilitating Repairs

Visual aids serve as essential tools for technicians and hobbyists alike. By showcasing the arrangement of components, these illustrations simplify the identification of specific parts that require attention. This can significantly reduce the time spent searching for the right components during repair sessions, ultimately streamlining the maintenance process.

Enhancing User Knowledge

Comprehending the structure of equipment fosters a deeper understanding of its operation. Users become more informed about how different pieces work together, leading to better care and prolonging the lifespan of the machinery. This enhanced knowledge can also encourage proactive maintenance, preventing potential issues before they escalate.

Common Issues and Solutions

When operating a power tool designed for tree maintenance, users may encounter a variety of challenges that can hinder performance and efficiency. Understanding these common problems and their respective solutions is crucial for maintaining optimal functionality and ensuring safety during use.

Engine Starting Difficulties

A frequent issue is trouble starting the engine. This may be caused by a variety of factors, including fuel quality, spark plug condition, or air filter obstruction. Solution: Begin by checking the fuel; it should be fresh and clean. If the fuel is old, replace it. Inspect the spark plug for wear and replace it if necessary. Additionally, ensure that the air filter is clean to allow proper airflow.

Overheating Concerns

Another common problem is overheating, which can lead to serious damage if not addressed promptly. Factors contributing to overheating include insufficient lubrication or clogged cooling fins. Solution: Regularly check the oil levels and replenish as needed. Ensure that the cooling fins are free of debris and dirt, allowing for effective heat dissipation.

How to Interpret Parts Diagrams

Understanding the visual representations of components is crucial for effective maintenance and repair. These illustrations serve as a guide, allowing users to identify each element and comprehend how they interact within the overall system. Familiarity with these schematics can streamline the repair process, ensuring efficiency and accuracy.

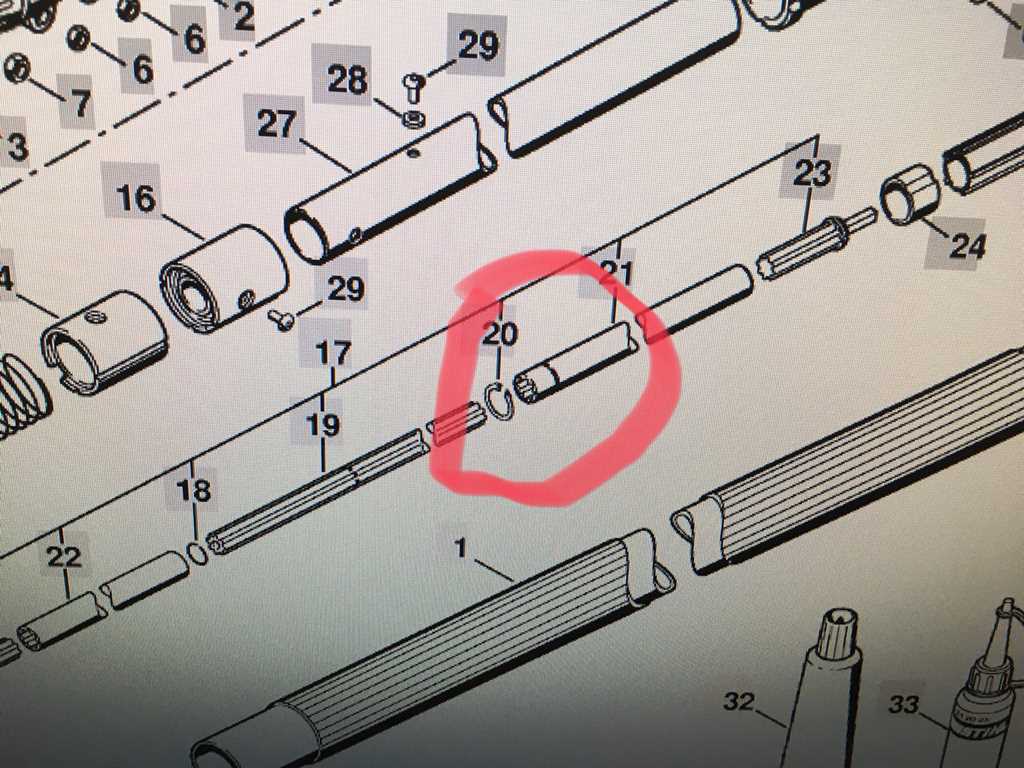

Reading the Key Symbols

Every illustration comes with a set of symbols and labels that denote specific pieces and their functions. It is essential to familiarize yourself with these markings, as they provide critical information about the arrangement and connections. Pay attention to any color coding or numbering that can simplify the identification of components.

Locating Components in Context

Once you grasp the symbols, the next step is to understand the layout of the illustration. Visualize how each part fits into the whole assembly. This contextual awareness can aid in recognizing which elements may need replacement or adjustment, thereby facilitating a smoother repair experience.

Where to Find Genuine Parts

When it comes to maintaining your outdoor equipment, sourcing authentic components is crucial for optimal performance and longevity. Genuine replacements ensure compatibility and reliability, allowing your tools to operate at their best. Here are some effective avenues for locating high-quality replacements.

| Source | Description |

|---|---|

| Authorized Dealers | Visiting official retailers guarantees access to original components, along with knowledgeable staff to assist you. |

| Online Stores | Many websites specialize in authentic replacements. Ensure the site is reputable to avoid counterfeit items. |

| Manufacturer’s Website | Directly purchasing from the manufacturer’s site often provides the latest models and an assurance of authenticity. |

| Local Repair Shops | Reputable repair facilities usually stock genuine replacements and can offer expert installation services. |

Utilizing these resources not only enhances the functionality of your equipment but also extends its lifespan, ensuring you get the most out of your investment.

Maintenance Tips for HT 133

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By following a few simple practices, you can enhance efficiency and minimize the risk of unexpected issues. Here are some effective maintenance strategies to consider.

- Inspect the Cutting Head: Regularly check for any wear or damage. Ensure that blades are sharp and properly aligned.

- Clean the Air Filter: A clean air filter allows for better airflow, improving performance. Remove and clean it according to the manufacturer’s recommendations.

- Check Fuel Quality: Always use fresh fuel to prevent engine problems. Dispose of any old or contaminated fuel safely.

- Examine Cables and Hoses: Look for any signs of wear, fraying, or leaks. Replace damaged components promptly to avoid further issues.

- Lubricate Moving Parts: Apply lubricant to all moving components to reduce friction and wear, ensuring smooth operation.

Following these maintenance tips can significantly extend the life of your equipment, allowing you to work efficiently and effectively. Make a habit of scheduling regular checks to keep everything in top shape.

Tools Needed for Repairs

When it comes to maintaining and fixing your outdoor equipment, having the right tools is essential for effective and efficient repairs. This ensures that the process runs smoothly and helps in achieving the best results without causing further damage to the machinery.

Essential Tools

- Wrenches: Various sizes to loosen and tighten bolts.

- Screwdrivers: Both flathead and Phillips for different types of screws.

- Socket Set: For handling nuts and bolts in tighter spaces.

- Pliers: For gripping, twisting, and cutting wires or other materials.

- Utility Knife: Useful for cutting through various materials.

- Cleaning Brushes: To remove debris and dirt from components.

Safety Gear

- Gloves: Protect your hands from sharp edges and chemicals.

- Safety Glasses: Shield your eyes from dust and debris.

- Ear Protection: Useful when working with loud machinery.

Gathering these tools and safety gear beforehand will make your repair tasks much more manageable and help you work with confidence.

Comparing HT 133 with Similar Models

When evaluating different tools designed for tree maintenance and pruning, it’s essential to consider various models that offer similar functionalities. Each model comes with its unique features, strengths, and potential drawbacks, making a side-by-side comparison valuable for users seeking the most suitable option for their needs.

Performance and Efficiency

One of the critical aspects to assess is the performance and efficiency of these tools. The engine power and cutting capacity can significantly affect how quickly and effectively tasks are completed. For instance, while some models excel in raw power, others may focus on lightweight designs that enhance maneuverability. Users should consider their specific requirements–whether they prioritize speed, ease of use, or a balance between the two.

Features and Ergonomics

Another crucial factor is the range of features and overall ergonomics. Many devices in this category offer adjustable poles, varying blade types, and different safety mechanisms. Comfort during extended use is paramount, so exploring the weight distribution, grip design, and ease of handling can make a significant difference. Additionally, some models might include innovative technologies that improve user experience, which can sway the decision for potential buyers.

In conclusion, comparing similar models allows users to identify the best fit for their individual needs, ensuring effective and efficient tree care.

User Reviews and Experiences

Feedback from users can provide valuable insights into the performance and reliability of equipment designed for tree maintenance and landscaping. Understanding the experiences of others helps potential buyers make informed decisions, while current owners can share tips for optimizing their tools’ efficiency.

Positive Experiences

Many users praise the effectiveness and ease of use of their machines, highlighting features such as lightweight design and powerful engines. Enthusiasts often note how these devices have improved their productivity, allowing them to tackle larger tasks with minimal effort. Reliability is frequently mentioned, with owners expressing satisfaction regarding the longevity of their equipment even under rigorous conditions.

Challenges and Considerations

While the overall feedback is positive, some users report challenges related to maintenance and troubleshooting. Common issues include difficulty in sourcing specific components or navigating repair processes. Additionally, a few have mentioned that understanding the user manual can be daunting, emphasizing the need for clearer instructions for optimal usage. Sharing these experiences fosters a community where users can support each other in overcoming obstacles.

Frequently Asked Questions About HT 133

This section addresses common inquiries regarding a popular tool designed for tree care and maintenance. Understanding the nuances of operation, maintenance, and available components can enhance user experience and ensure optimal performance.

What maintenance is required for optimal performance?

Regular maintenance is essential for longevity and efficiency. This includes checking and replacing the cutting attachments, ensuring proper lubrication, and inspecting the air filter and spark plug. Keeping the tool clean and free from debris also contributes significantly to its performance.

Where can I find replacement components?

Replacement components can be sourced from various authorized dealers, online retailers, or specialty shops that focus on outdoor equipment. Always ensure that the parts you purchase are compatible with your specific model for seamless integration and functionality.