Comprehensive Guide to Stihl HT75 Pole Saw Parts Diagram

When it comes to maintaining outdoor spaces, having the right equipment is essential. A specific type of tool designed for reaching high branches provides convenience and efficiency for both professional landscapers and avid gardeners. Familiarity with the various elements that comprise this tool enhances its usability and ensures optimal performance.

In this section, we will explore the intricate layout of a specific cutting device that enables users to navigate tricky heights. Each component plays a critical role, from the motor to the attachments, making it vital to grasp how these parts work together. A thorough understanding of the assembly will not only aid in effective operation but also assist in troubleshooting and maintenance.

By delving into the various sections of this tool, users can identify the essential features that contribute to its functionality. Whether you’re considering repairs or simply wish to enhance your skills, having a clear visual reference of the components is invaluable. Join us as we uncover the intricate workings behind this essential gardening equipment.

Understanding the Stihl HT75 Pole Saw

This section delves into the intricate workings and components of a specific type of cutting tool designed for reaching elevated branches and foliage. With its robust design and specialized features, this equipment is ideal for both professional landscapers and avid gardeners. By exploring its construction and functionality, users can better appreciate how to maintain and utilize it effectively.

Key Features

Equipped with various functionalities, this cutting apparatus ensures efficiency and precision. Key elements include a powerful engine, adjustable length, and a specially designed cutting head that facilitates smooth operation. Each component plays a vital role in enhancing overall performance and ease of use.

Component Overview

| Component | Description |

|---|---|

| Engine | Delivers powerful performance for heavy-duty tasks. |

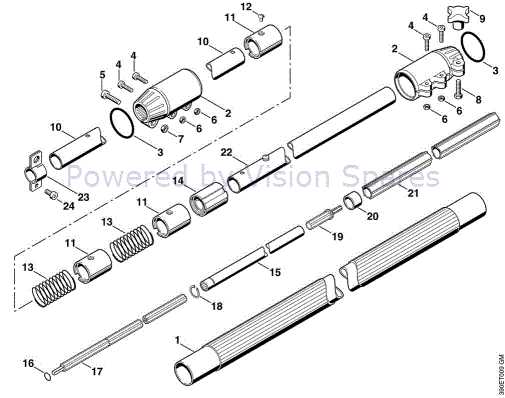

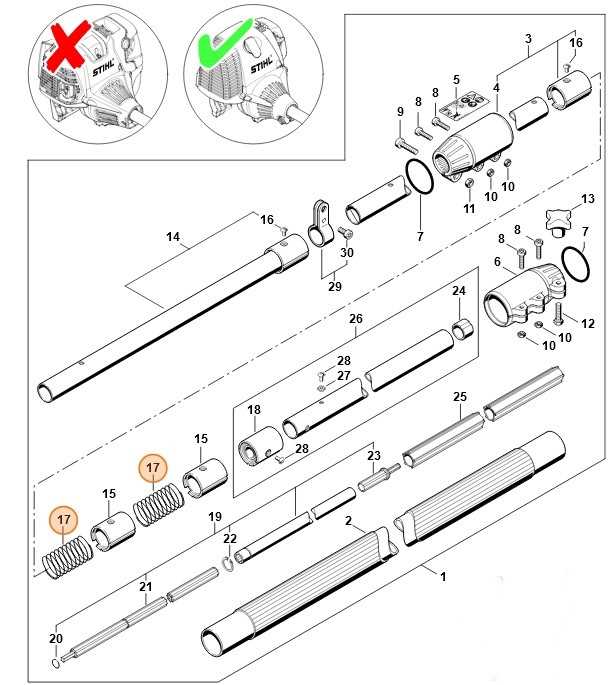

| Extension Shaft | Allows the user to reach high branches without a ladder. |

| Cutting Head | Designed for clean cuts with minimal effort. |

| Handle | Ergonomically shaped for comfort during extended use. |

Understanding these elements not only aids in effective usage but also assists in troubleshooting and maintenance, ensuring longevity and optimal performance of the tool.

Key Features of the HT75 Model

This model is designed to provide exceptional performance and ease of use for various cutting tasks. Its robust construction ensures durability, while innovative features enhance operational efficiency.

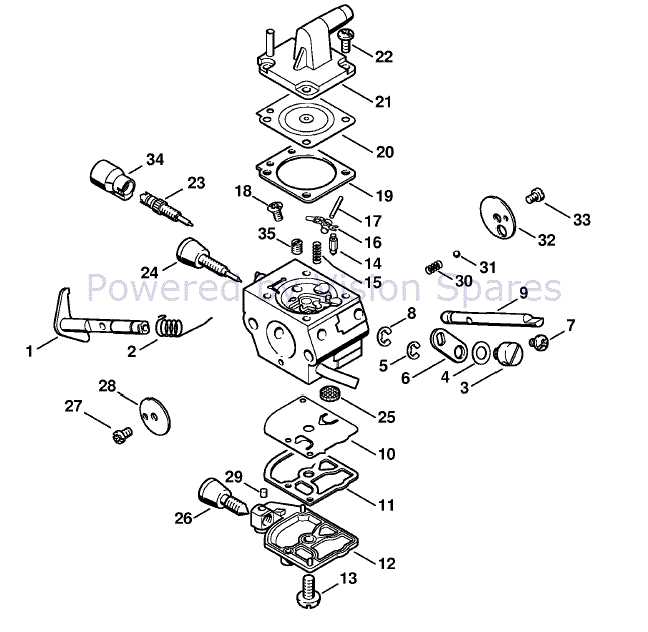

Powerful Engine: The unit is equipped with a high-performance engine that delivers impressive cutting power, making it suitable for both professional and recreational use.

Lightweight Design: With a focus on user comfort, this model boasts a lightweight structure, allowing for extended use without excessive fatigue.

Extendable Reach: The adjustable length enables access to high branches, enhancing versatility and effectiveness during trimming operations.

Easy Maintenance: User-friendly design facilitates straightforward maintenance, ensuring longevity and reliable performance over time.

Safety Features: Incorporating advanced safety mechanisms protects the operator, making the experience secure and worry-free.

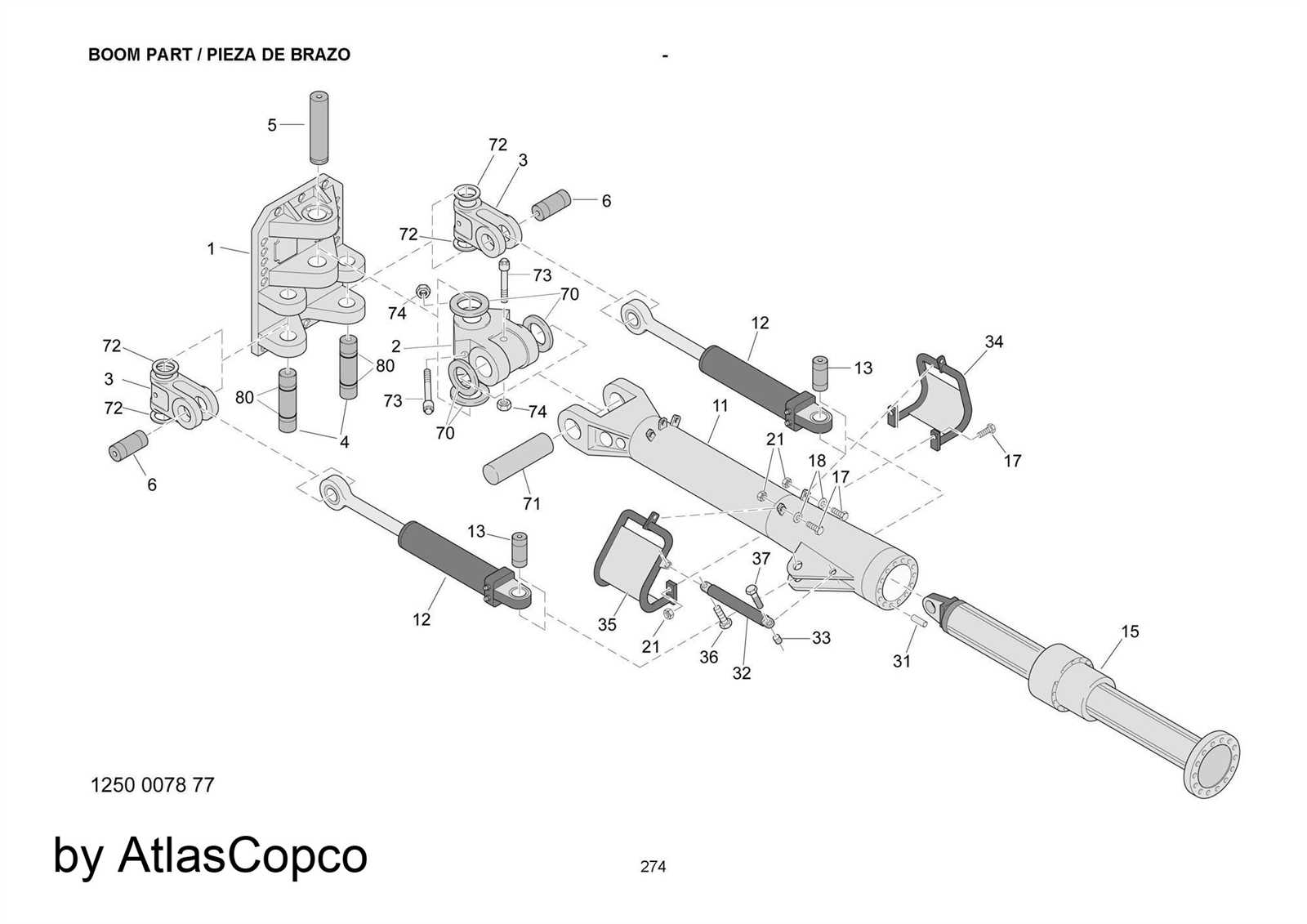

Importance of Parts Diagrams

Understanding the intricate components of any machinery is crucial for effective maintenance and repair. Visual representations that outline the various elements and their arrangements provide invaluable insight for both novice and experienced users. These illustrations serve as a roadmap, guiding individuals through the complex network of parts, ensuring that each piece is recognized and understood.

Efficiency in repairs is significantly enhanced by these visual tools. When users can quickly identify a component’s location and function, they can troubleshoot issues more effectively. This not only saves time but also reduces the risk of errors that could arise from misunderstanding a particular part’s role.

Furthermore, these illustrations foster self-sufficiency. Users gain confidence as they learn to interpret the graphics, enabling them to conduct repairs without constant professional assistance. This empowerment leads to a better understanding of the machinery and promotes a more proactive approach to maintenance.

In summary, visual aids that depict component layouts are essential for anyone looking to enhance their understanding and efficiency in equipment upkeep. Their role in facilitating clear communication about machinery design cannot be overstated.

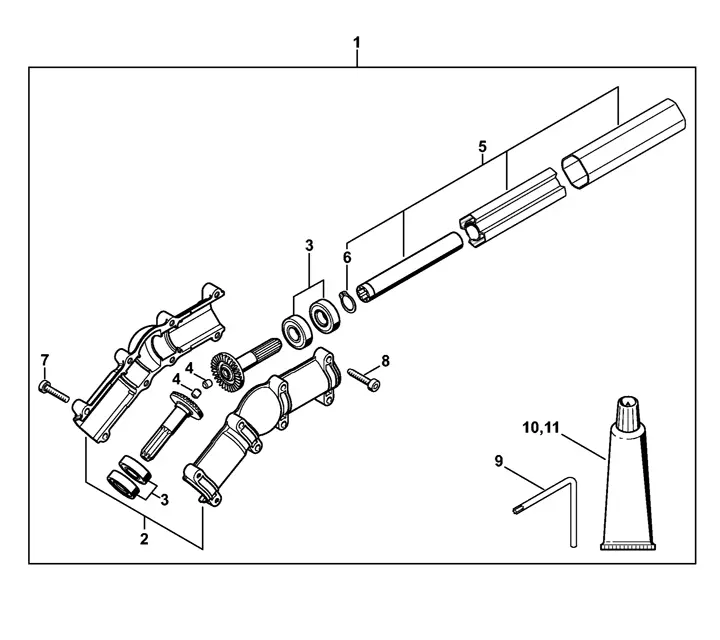

Identifying Common Components

Understanding the various elements of a cutting tool is essential for effective maintenance and operation. Familiarity with these components ensures that users can troubleshoot issues, perform repairs, and enhance the overall performance of their equipment. Below are some key components frequently found in these tools.

- Engine: The powerhouse of the equipment, responsible for driving the cutting action.

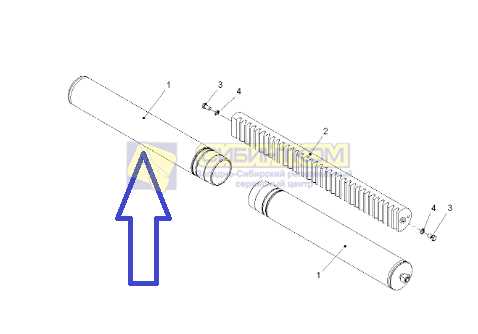

- Bar: A long, flat piece that holds the cutting mechanism in place and provides stability during use.

- Chain: The sharp, moving element that performs the actual cutting, often made of durable metal.

- Handle: Provides grip and control, allowing the user to maneuver the tool safely and effectively.

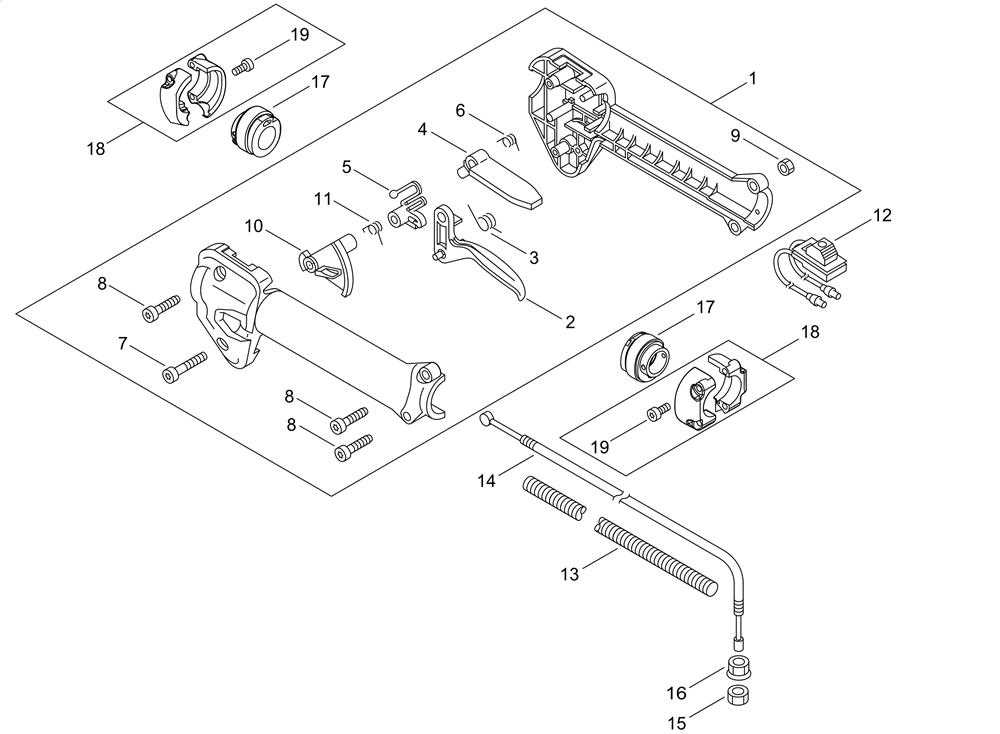

- Throttle Trigger: Controls the speed of the engine, allowing for variable cutting performance.

- Gearbox: Transfers power from the engine to the cutting mechanism, ensuring efficient operation.

- Safety Guard: Protects the user from debris and accidental contact with the cutting chain.

Each of these components plays a vital role in the functionality of the device, contributing to its efficiency and safety. Recognizing these parts not only aids in proper usage but also facilitates informed decisions regarding maintenance and repairs.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your equipment. Regular attention to maintenance tasks not only enhances performance but also minimizes the risk of unexpected failures. By following a few straightforward guidelines, you can ensure your tool remains in peak condition, ready to tackle any task at hand.

| Tip | Description |

|---|---|

| Regular Cleaning | Remove debris and dirt from the exterior and moving parts to prevent buildup that can cause wear and tear. |

| Inspect Components | Periodically check for signs of damage or wear in all components, replacing any parts that show significant deterioration. |

| Lubrication | Apply appropriate lubricant to moving parts as recommended in the user manual to ensure smooth operation. |

| Fuel Management | Use high-quality fuel and adhere to the mixing ratios for optimal performance and to avoid engine problems. |

| Storage | Store your equipment in a dry place, away from extreme temperatures, and consider using a cover to protect it from dust and moisture. |

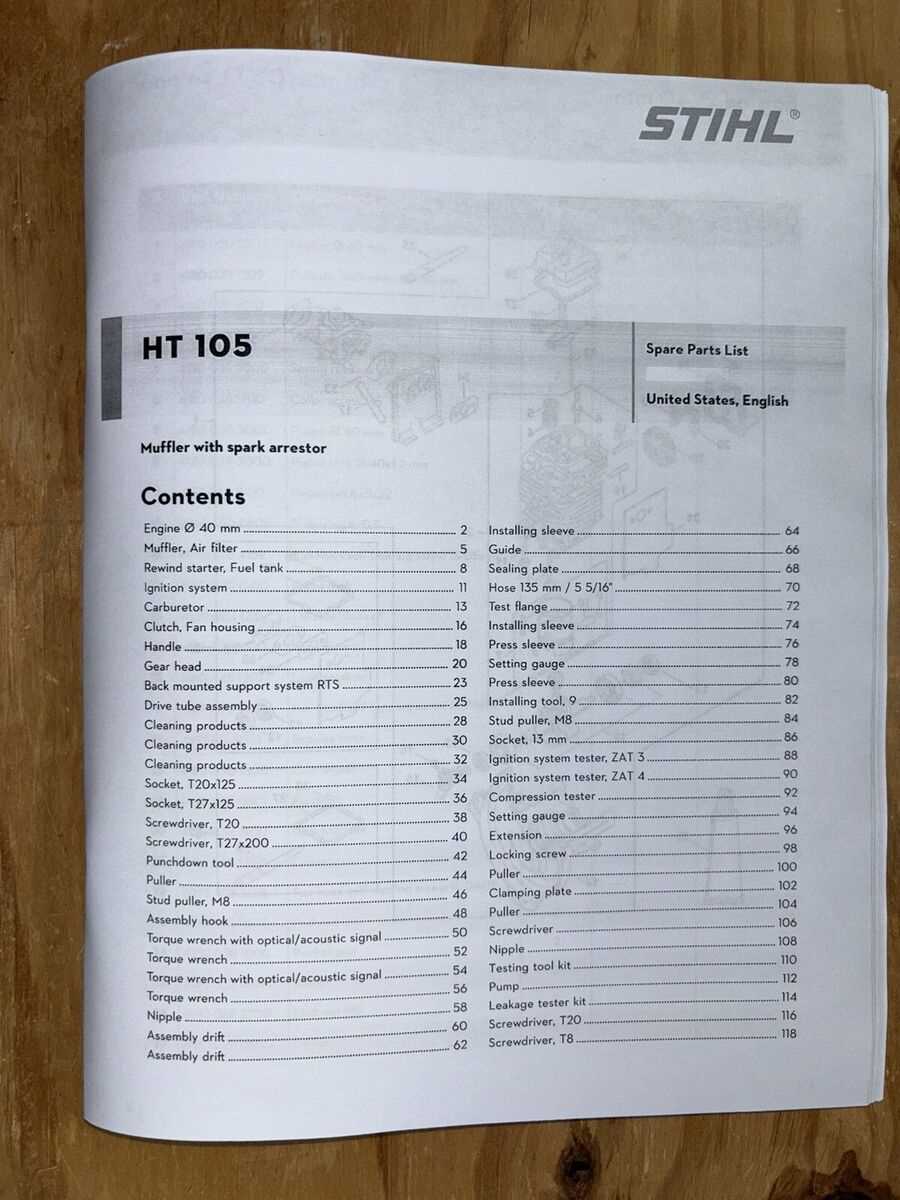

How to Access the Diagram

Accessing the schematic representation of your tool can greatly enhance your understanding of its components and functionality. By utilizing the right resources, you can find detailed illustrations that will assist in maintenance, repairs, and assembly.

Start by visiting the official website of the manufacturer, where you can often find a dedicated section for manuals and technical documents. Look for the support or resources tab, which usually houses the necessary information. You may need to enter the model number to narrow down the search results.

In addition to the manufacturer’s site, various online forums and user groups provide valuable insights. These platforms often share links to diagrams and troubleshooting guides, created by experienced users. Engaging with the community can lead to discovering hidden resources that might not be readily available.

Lastly, consider downloading a PDF version of the manual. Many manufacturers offer these files for free, which can be easily saved for future reference. This can be especially useful if you prefer offline access to the information.

Replacing Worn-Out Parts

Maintaining optimal performance of your equipment often requires the timely substitution of aged components. Regular inspections are crucial to identify elements that have deteriorated due to usage or environmental factors. By ensuring that every part functions effectively, you not only enhance efficiency but also extend the lifespan of your tool.

Below is a table outlining common components that may need replacement, along with signs of wear and suggestions for action:

| Component | Signs of Wear | Recommended Action |

|---|---|---|

| Chain | Dullness, uneven cuts | Sharpen or replace |

| Guide Bar | Cracks, bending | Replace immediately |

| Drive Shaft | Excessive vibrations | Inspect for damage, replace if necessary |

| Trigger Mechanism | Sticking or non-responsiveness | Clean or replace |

By proactively addressing these issues, you can ensure that your tool remains reliable and efficient for years to come. Regular maintenance checks and timely replacements will ultimately save you time and money in the long run.

Tools Needed for Repairs

When it comes to maintaining and fixing outdoor equipment, having the right tools is essential for a successful repair process. A well-equipped toolkit not only facilitates efficiency but also ensures that tasks are completed safely and effectively. Below is a list of essential tools commonly required for such repairs.

| Tool | Description |

|---|---|

| Screwdriver Set | Includes various sizes and types for loosening and tightening screws. |

| Wrench Set | Used for fastening and loosening nuts and bolts of different sizes. |

| Torque Wrench | Ensures bolts are tightened to the manufacturer’s specifications. |

| Pliers | Useful for gripping, twisting, and cutting wires and other materials. |

| Cleaning Brushes | Helps remove debris and build-up from various components. |

| Lubricants | Essential for maintaining smooth operation of moving parts. |

| Safety Gear | Includes gloves, goggles, and ear protection to ensure safe working conditions. |

Troubleshooting Common Issues

Maintaining equipment often involves addressing a range of challenges that can arise during operation. Understanding these common problems and their potential solutions can enhance performance and prolong the lifespan of your tools.

Engine Won’t Start

If the engine fails to ignite, check the fuel level and ensure the mixture is fresh. Inspect the ignition system for faults, including the spark plug, which may require cleaning or replacement.

Poor Cutting Performance

When the cutting efficiency diminishes, it may be due to a dull blade or improper tension. Regularly examine the cutting component and adjust or sharpen it as necessary to maintain optimal functionality.

Benefits of Genuine Stihl Parts

Using authentic components for your equipment ensures optimal performance and longevity. These original elements are designed to meet specific standards, providing reliability and efficiency that counterfeit options simply cannot match.

Here are some key advantages of choosing genuine components:

| Benefit | Description |

|---|---|

| Quality Assurance | Original components undergo rigorous testing to guarantee their durability and effectiveness. |

| Enhanced Performance | Genuine parts are crafted to fit perfectly, ensuring your equipment operates at its peak. |

| Longer Lifespan | Utilizing authentic elements can significantly extend the life of your machinery. |

| Safety | Original parts are designed with safety in mind, reducing the risk of malfunction. |

Where to Purchase Components

Finding the right components for your outdoor tools can significantly enhance their performance and longevity. It’s essential to know where to acquire high-quality replacement items that ensure compatibility and reliability. By exploring various options, you can secure the necessary components to keep your equipment running smoothly.

Authorized Dealers: One of the best options is to visit authorized dealers. These establishments often carry a comprehensive selection of original components, ensuring that you receive the highest quality available. Their staff can also provide expert advice on installation and compatibility.

Online Retailers: Numerous online platforms specialize in outdoor equipment accessories. Websites dedicated to tool supplies often have extensive catalogs, allowing you to compare prices and find the specific items you need. Always check reviews to gauge the reliability of the seller.

Local Hardware Stores: Don’t overlook local hardware stores, as many stock essential components or can order them for you. Establishing a relationship with your local store can lead to helpful insights and tips for maintenance.

Second-Hand Market: For those on a budget, the second-hand market can be a treasure trove. Websites and local classifieds often list gently used items at a fraction of the cost. Just be sure to verify the condition before purchasing.

By exploring these avenues, you can ensure you have access to the necessary components to maintain and optimize your outdoor equipment.

Online Resources for DIY Repairs

In today’s digital age, a plethora of online platforms provides valuable guidance for those eager to tackle their own maintenance tasks. Whether you are seeking step-by-step tutorials, video demonstrations, or user forums, the internet is a treasure trove of information that empowers individuals to repair equipment with confidence.

Video Tutorials

Platforms like YouTube host countless instructional videos that cover a wide range of maintenance procedures. These visual aids allow users to follow along in real-time, making complex tasks more approachable.

Community Forums

Engaging in online forums can also enhance your repair knowledge. These communities often feature experienced members who are willing to share insights, troubleshooting tips, and detailed advice based on real-world experience.

| Resource Type | Examples |

|---|---|

| Video Tutorials | YouTube, Vimeo |

| Community Forums | Reddit, Specialized websites |

| DIY Guides | Blog Posts, E-books |

Customer Reviews and Experiences

This section delves into the feedback and insights shared by users of the tree trimming equipment. Their experiences highlight the performance, reliability, and ease of use of these tools in various situations, offering potential buyers valuable information to consider before making a purchase.

Many users appreciate the efficiency of their equipment, often noting how it has simplified their outdoor maintenance tasks. From residential gardens to professional landscaping projects, customers frequently mention the significant time savings and the quality of results achieved. Below is a summary of common themes found in customer reviews:

| Aspect | Positive Feedback | Negative Feedback |

|---|---|---|

| Performance | Powerful and effective for high branches | Occasional overheating during extended use |

| Ease of Use | Lightweight and manageable | Some users found assembly challenging |

| Durability | Long-lasting and sturdy construction | Minor wear and tear reported after heavy use |

| Customer Support | Responsive and helpful service team | Delayed responses during peak seasons |

Overall, the collective experiences of users serve as a testament to the quality and functionality of the equipment, reinforcing its reputation as a valuable tool for both amateur and professional gardeners alike.