Comprehensive Guide to Stihl MS 201 TC Parts Diagram

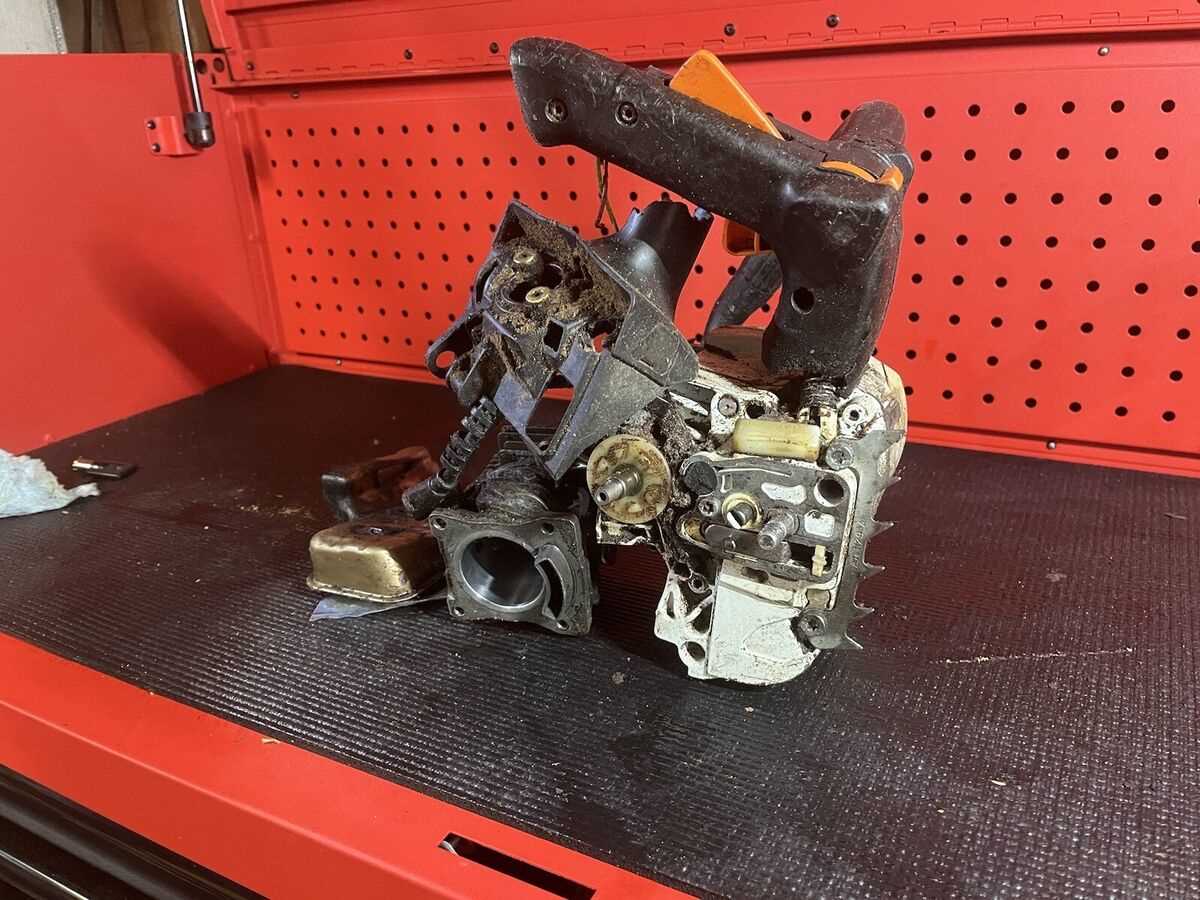

Every chainsaw enthusiast knows the importance of familiarizing oneself with the intricate elements that make up their tool. A comprehensive knowledge of these individual pieces not only enhances performance but also aids in effective maintenance and repairs. Whether you’re a seasoned professional or a casual user, grasping the structure of your saw is essential for its longevity.

Exploring the assembly of your device provides insights into how each segment interacts with the others, ultimately affecting the overall functionality. From the cutting mechanism to the power source, understanding these components empowers users to troubleshoot issues and perform necessary upgrades confidently.

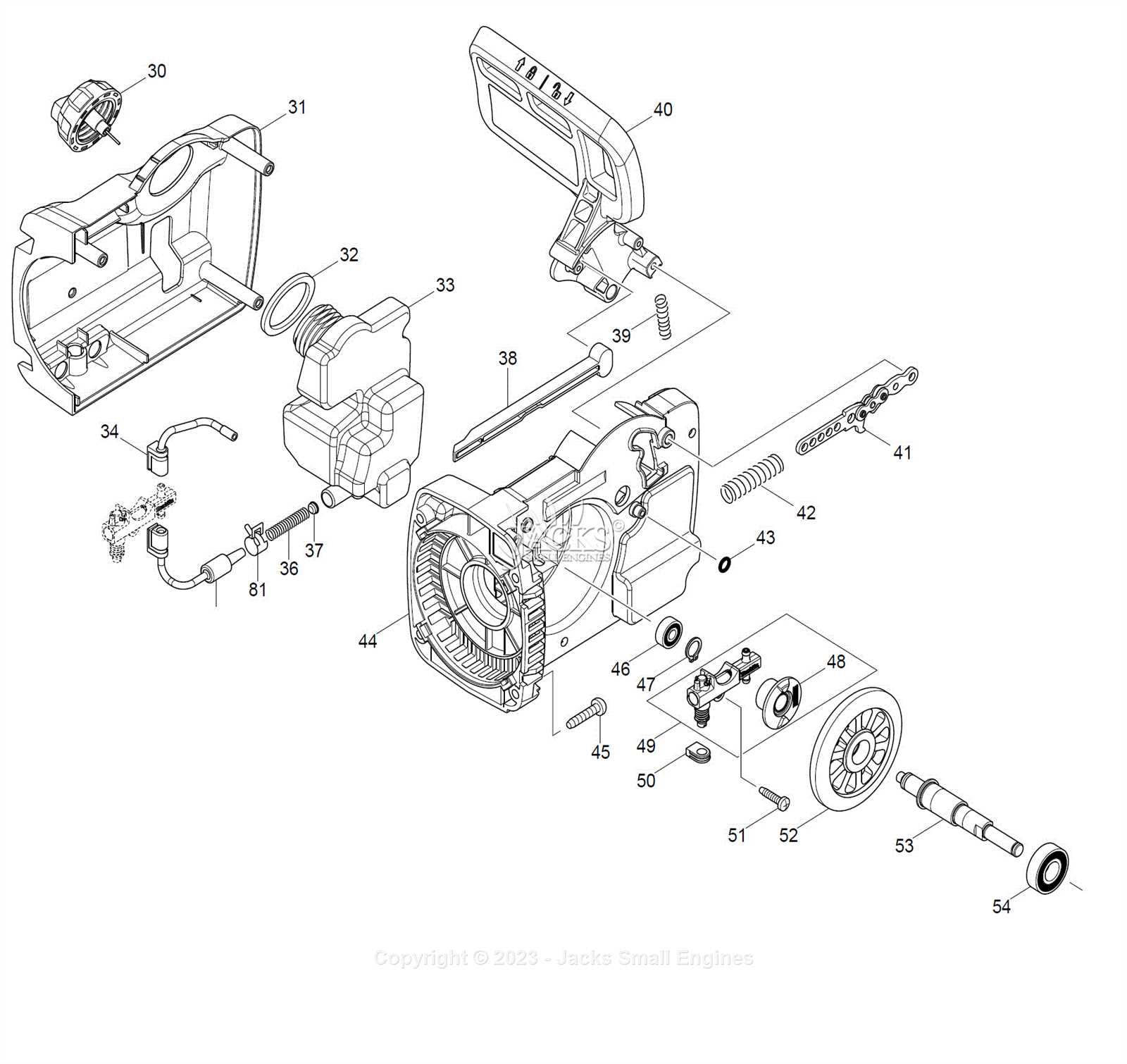

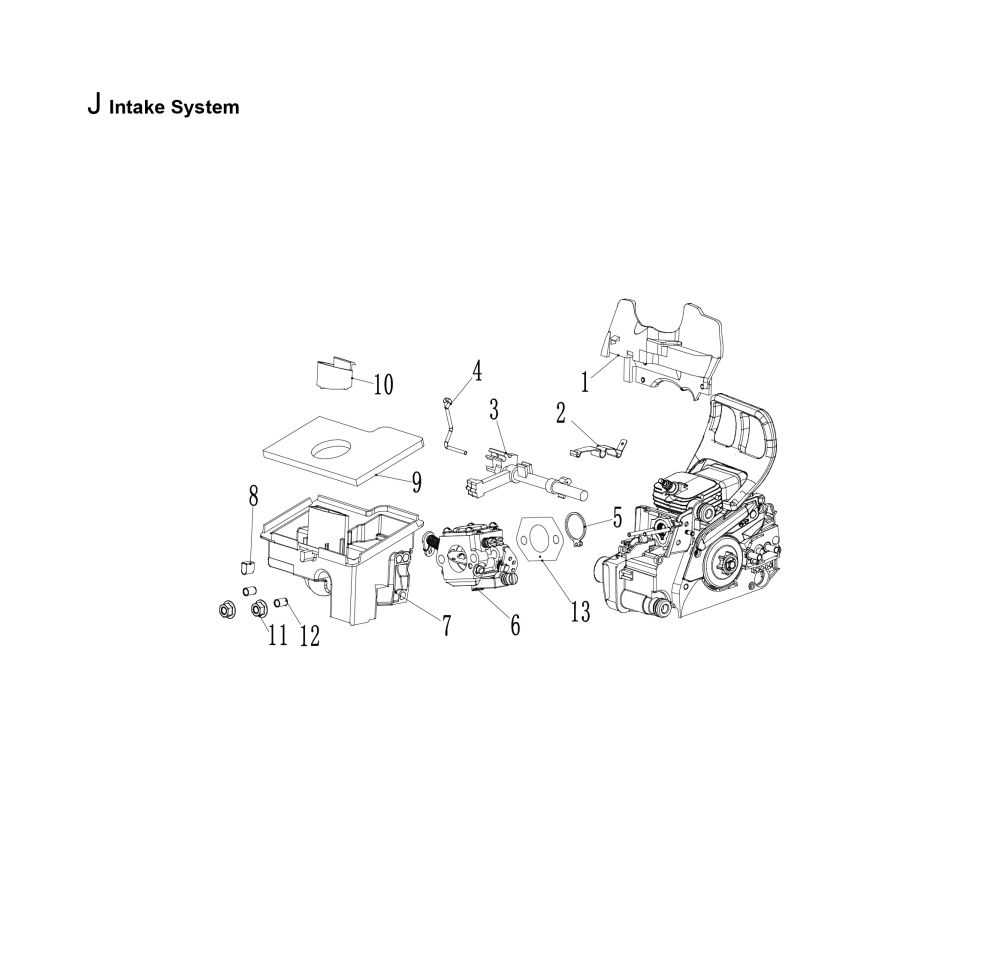

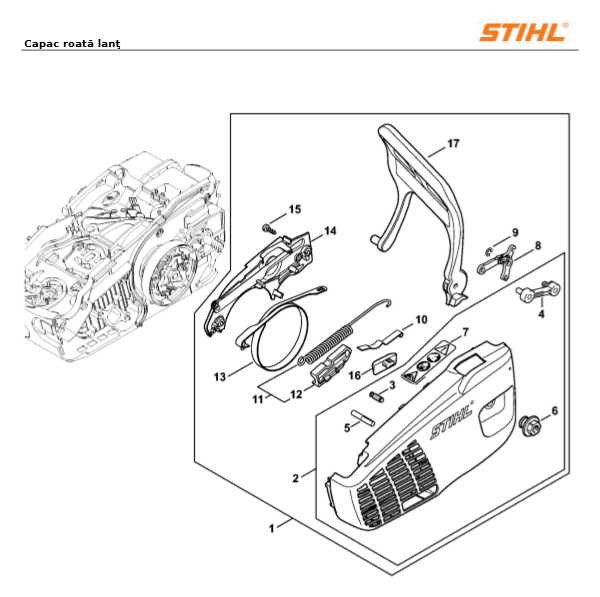

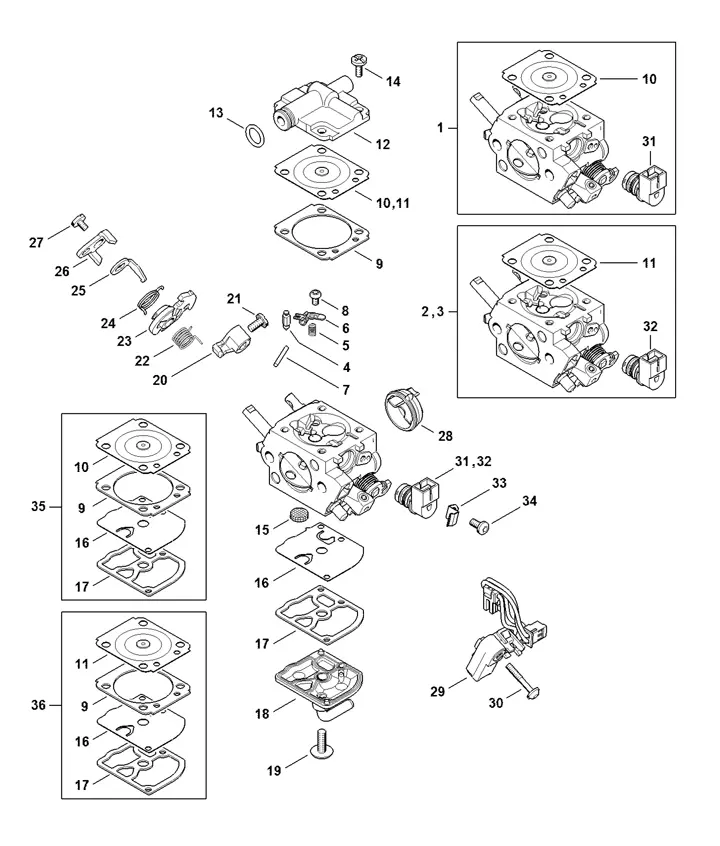

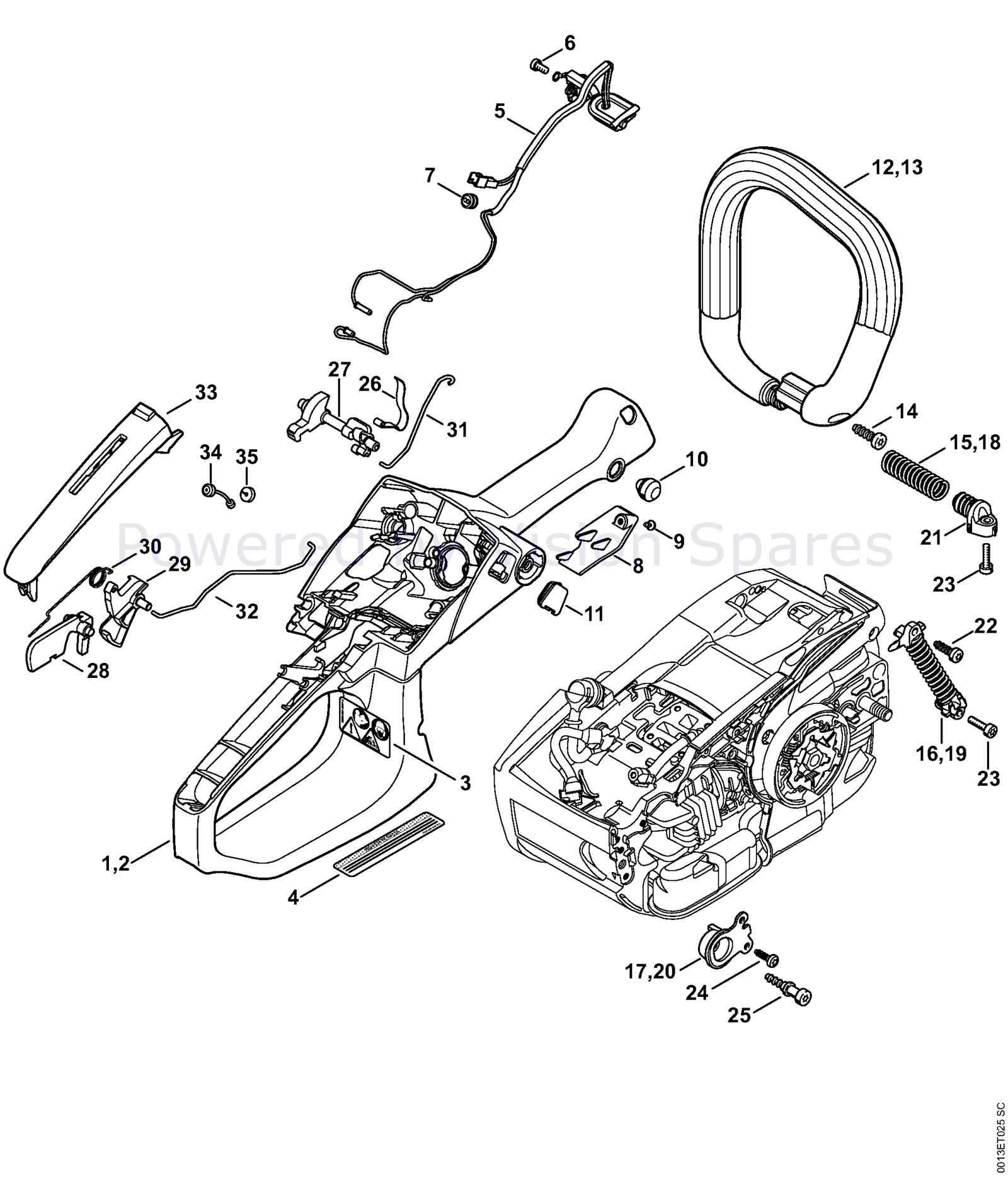

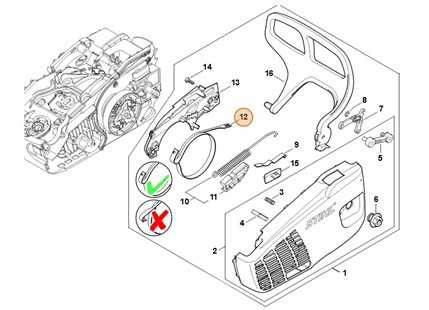

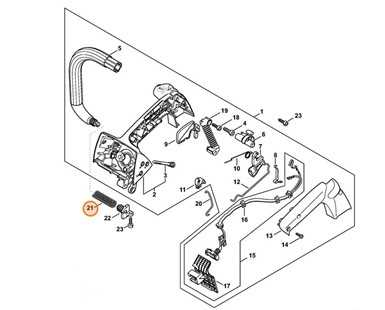

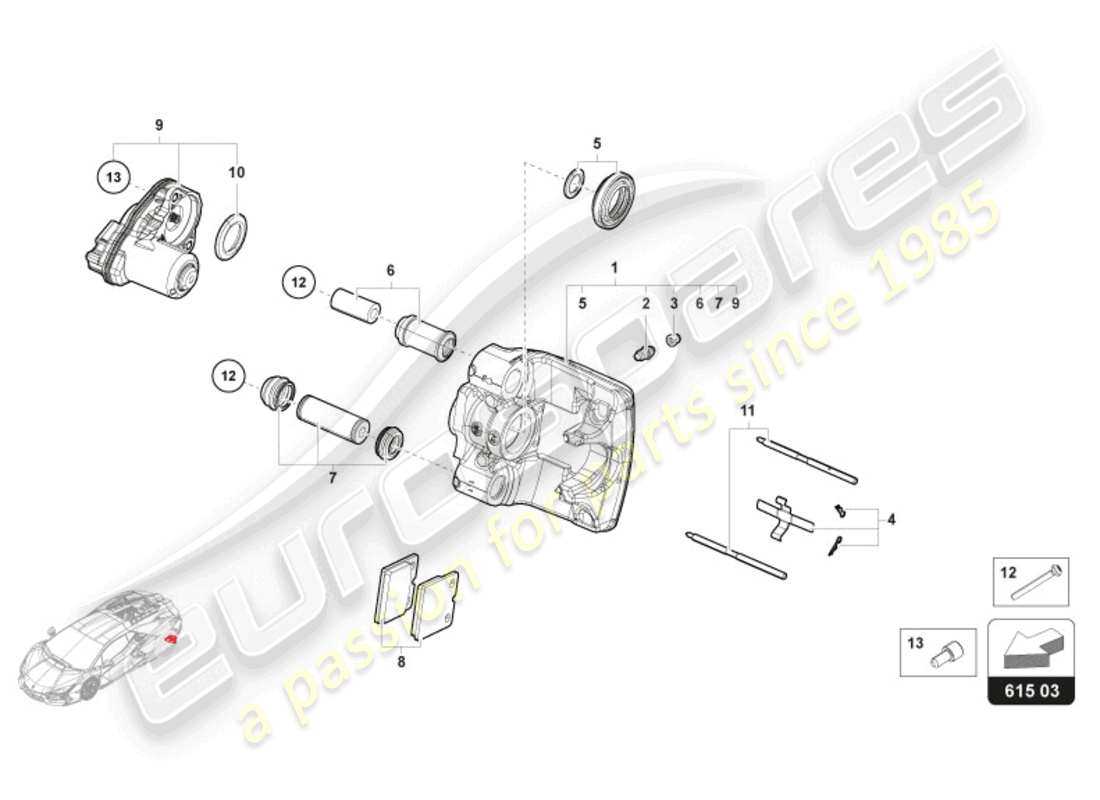

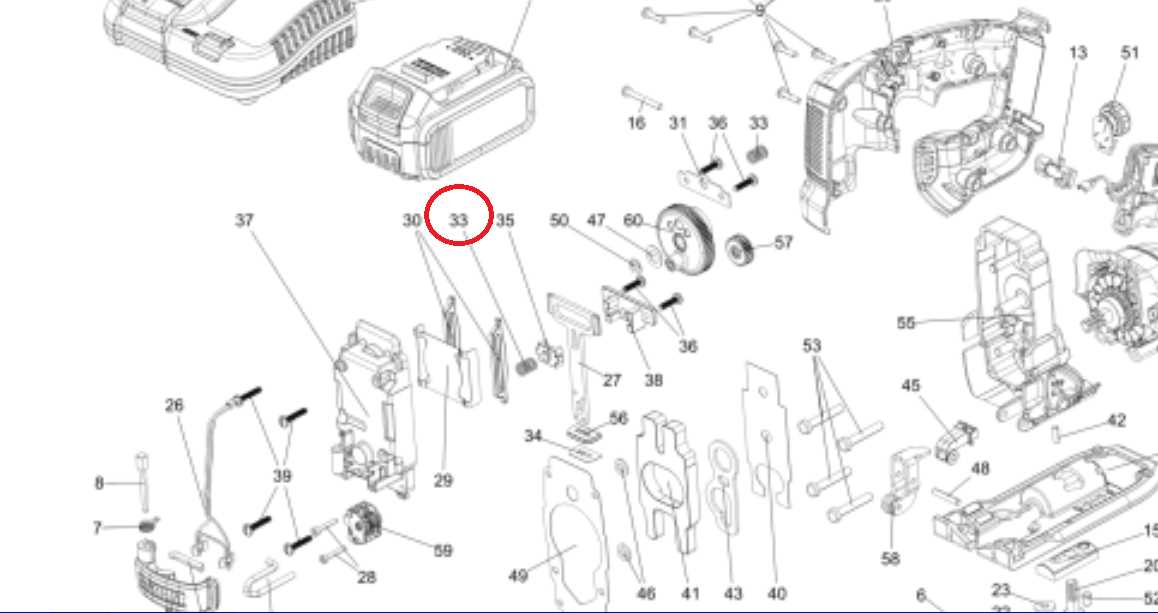

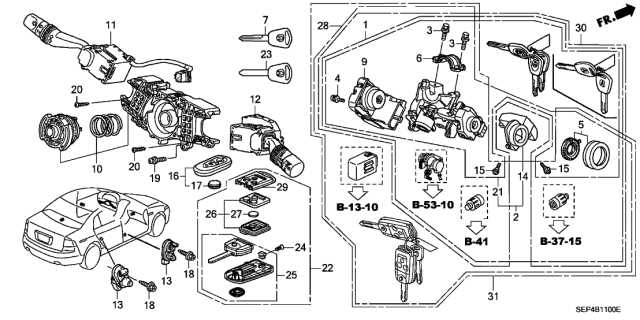

Moreover, visual representations of these assemblies can be invaluable resources. They serve as guides, helping to identify and locate specific elements, ensuring that anyone can navigate the complexities of their equipment. This knowledge not only fosters a deeper appreciation for the craftsmanship involved but also equips users to tackle maintenance tasks with assurance.

Understanding the Stihl MS 201 TC

This section explores the essential features and functionalities of a specific type of high-performance chainsaw. Designed for arborists and professionals, it combines power and precision, making it ideal for various cutting tasks.

Key Features

The equipment is engineered with advanced technology to enhance performance and durability. Its lightweight design allows for easy maneuverability, while the ergonomic handle ensures comfort during prolonged use. The engine delivers impressive power, making it suitable for demanding applications.

Maintenance Considerations

| Component | Function |

|---|---|

| Engine | Power source |

| Bar | Guides the chain |

| Chain | Cutting mechanism |

| Air filter | Prevents debris entry |

| Oil tank | Lubricates the chain |

Key Features of the Chainsaw

Chainsaws are essential tools designed for a variety of cutting tasks, known for their efficiency and power. They incorporate advanced technology to deliver optimal performance while ensuring user safety and comfort. Understanding the key attributes of these machines can significantly enhance their usability and effectiveness in different applications.

One prominent feature is the lightweight design, which allows for easier maneuverability during operation. This is particularly beneficial for users who need to work for extended periods. Additionally, many models come equipped with a powerful engine that provides ample cutting speed, making quick work of even the toughest materials.

Safety mechanisms are another crucial aspect, with features such as chain brakes and low kickback chains that minimize the risk of accidents. Ergonomically designed handles improve grip and reduce fatigue, contributing to a more comfortable experience. Furthermore, easy-access air filters and tool-less chain tensioning systems simplify maintenance, ensuring the equipment remains in top condition.

Lastly, versatility is a significant advantage, as various attachments and configurations allow users to tackle diverse tasks, from pruning branches to felling trees. These characteristics make chainsaws indispensable tools for both professionals and enthusiasts alike.

Importance of Parts Diagrams

Understanding the components of any mechanical device is crucial for effective maintenance and repair. Visual representations of these elements serve as invaluable tools, enabling users to identify, locate, and comprehend the relationships between various parts. This clarity not only simplifies the repair process but also enhances overall functionality and longevity of the equipment.

Benefits of Visual Guides

Utilizing visual guides provides several advantages, including:

| Advantage | Description |

|---|---|

| Enhanced Understanding | Illustrations help in grasping the structure and layout of components. |

| Efficient Repairs | Quickly locating specific elements streamlines the repair process. |

| Reduced Errors | Visual aids minimize mistakes during reassembly by providing clear guidance. |

Facilitating Maintenance

Regular upkeep becomes more manageable when users have access to comprehensive visual resources. They allow for proper inspection of individual components, ensuring that any worn or damaged parts are promptly addressed. By fostering a deeper understanding of how each element interacts, these resources promote proactive maintenance, ultimately leading to improved performance and durability.

Common Components in the Diagram

Understanding the key elements of a machine’s structure is essential for effective maintenance and repair. Various parts work together to ensure optimal functionality and performance. Familiarity with these components not only aids in troubleshooting but also enhances the overall longevity of the equipment.

Engine: The heart of the machinery, responsible for converting fuel into mechanical energy. Its condition significantly impacts the efficiency of the entire system.

Chain brake: A critical safety feature that halts the chain’s movement when activated. This component is vital for preventing accidents during operation.

Guide bar: The elongated metal piece that supports the cutting chain. Its length and design influence cutting capabilities and maneuverability.

Fuel system: Comprising the fuel tank, lines, and filter, this system ensures a steady flow of fuel to the engine, essential for maintaining performance.

Air filter: This component protects the engine by trapping dirt and debris from the air, promoting cleaner combustion and preventing damage.

Clutch: Engages and disengages the power from the engine to the chain, allowing for smoother operation and control during use.

Recognizing these components and their functions is crucial for anyone looking to maintain or repair their equipment effectively. A well-informed approach leads to better performance and safer operation.

How to Read the Diagram

Understanding an assembly illustration is crucial for anyone looking to maintain or repair equipment. This type of visual guide provides a comprehensive overview of the components, their arrangement, and how they interact. Mastering this resource can greatly enhance your troubleshooting and repair skills.

Start with the Legend: Most visuals include a legend that identifies each component. Familiarize yourself with this section, as it will help you decode the symbols and numbers used throughout the illustration.

Follow the Flow: Pay attention to the layout. Components are often arranged in a logical sequence that mirrors the assembly process. Following this order can assist in understanding how each piece fits into the overall mechanism.

Focus on Connections: Look for lines or arrows that indicate relationships between parts. These connections are essential for grasping how various elements work together. Understanding these links can also aid in identifying potential issues.

Take Notes: As you study the illustration, jot down any important details or questions. This practice will help reinforce your understanding and prepare you for practical applications.

By becoming proficient at reading these types of guides, you can improve your ability to maintain equipment efficiently and effectively.

Identifying Wear and Tear Parts

Understanding the components that experience degradation over time is crucial for maintaining optimal performance. Regular inspections can help pinpoint which elements require replacement or servicing, ensuring efficient operation and longevity of your equipment.

Common Signs of Degradation

Look for visible damage such as cracks, fraying, or excessive wear. Decreased performance, such as reduced power or efficiency, can also indicate that certain elements have reached the end of their lifecycle.

Preventive Measures

Implementing a routine check-up schedule can help you identify problematic components before they lead to significant issues. Keeping an eye on lubrication and cleanliness will further prolong the lifespan of critical parts.

Replacing Damaged Components

Addressing worn or broken elements in your equipment is crucial for maintaining its performance and longevity. Timely replacement not only ensures optimal functioning but also enhances safety during operation. Understanding how to identify and replace these components effectively can save time and resources in the long run.

Identifying Worn Parts

Recognizing which elements require attention is the first step. Look for signs of wear, such as cracks, excessive rust, or malfunctioning mechanisms. Regular inspections can help catch issues early, allowing for more manageable repairs.

Replacement Process

Once damaged parts are identified, follow the manufacturer’s guidelines for removal and installation. Ensure you have the correct tools and replacement pieces ready. Taking care to follow each step carefully will facilitate a smooth and efficient replacement process.

Where to Find Replacement Parts

When seeking components for your equipment, it’s essential to explore various reliable sources to ensure quality and compatibility. The right suppliers can make a significant difference in maintaining performance and longevity.

| Source | Description |

|---|---|

| Authorized Dealers | These outlets provide original components, ensuring compatibility and quality. |

| Online Retailers | Websites specializing in equipment offer a wide range of components, often at competitive prices. |

| Local Hardware Stores | Many local shops carry essential items, providing immediate access without shipping delays. |

| Manufacturer Websites | Visiting the official site can help locate specific items and find recommendations for authorized sellers. |

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for ensuring the long-term performance of your equipment. By adhering to a few simple practices, you can significantly extend its lifespan and maintain optimal functionality. Consistent attention to maintenance not only enhances reliability but also contributes to safety and efficiency during use.

Firstly, always ensure that the engine is clean and free from debris. Regularly inspect the air filter and replace it as needed to prevent dust and particles from entering the system. This simple step can greatly improve air flow and performance.

Additionally, keeping the cutting components sharp is crucial. Dull blades require more power and can lead to increased wear on the engine. Regularly sharpening and aligning these parts will ensure smooth operation and reduce the strain on your machine.

Next, check and change the lubrication fluids as recommended by the manufacturer. Fresh oil minimizes friction and wear, while also preventing overheating. Keeping the lubrication system in good condition is vital for the overall health of your equipment.

Lastly, store your device in a dry, protected area when not in use. Exposure to moisture and extreme temperatures can cause corrosion and damage. By taking these preventive measures, you can ensure that your machinery remains in excellent condition for many years to come.

Benefits of Regular Inspections

Conducting routine evaluations of equipment is essential for maintaining optimal performance and longevity. Regular inspections help identify potential issues before they escalate, ensuring reliability and safety during operation.

Enhanced Safety

Regular checks can significantly reduce the risk of accidents by identifying wear and tear or malfunctioning components early. This proactive approach safeguards users and promotes a secure working environment.

Cost Efficiency

By addressing minor repairs promptly, you can avoid costly breakdowns and extensive repairs. Investing time in inspections ultimately leads to financial savings in the long run.

| Inspection Frequency | Benefits |

|---|---|

| Weekly | Immediate identification of issues |

| Monthly | Prevention of major failures |

| Yearly | Comprehensive assessment of performance |