Understanding the Stihl MS 211 Parts Diagram for Efficient Maintenance

When it comes to maintaining outdoor power equipment, having a clear visual representation of its inner workings is essential. Whether you are a seasoned professional or a casual user, comprehending the various elements of a chainsaw can significantly enhance your ability to troubleshoot issues and perform necessary repairs.

In this section, we will explore the intricate network of components that make up these machines. By familiarizing yourself with each part, you will gain insights into how they interact, which can be invaluable when it comes to ensuring optimal performance and longevity.

Additionally, a well-organized schematic serves as a guide for both assembly and disassembly. This resource not only aids in identifying specific elements but also promotes a deeper understanding of how to effectively care for your equipment. With this knowledge, you can tackle maintenance tasks with confidence, ensuring your tool remains in peak condition.

Understanding Stihl MS 211 Components

Every tool comprises various elements that contribute to its overall functionality. Recognizing and comprehending these individual components is crucial for effective maintenance and optimal performance. This knowledge empowers users to address issues, perform repairs, and enhance the lifespan of their equipment.

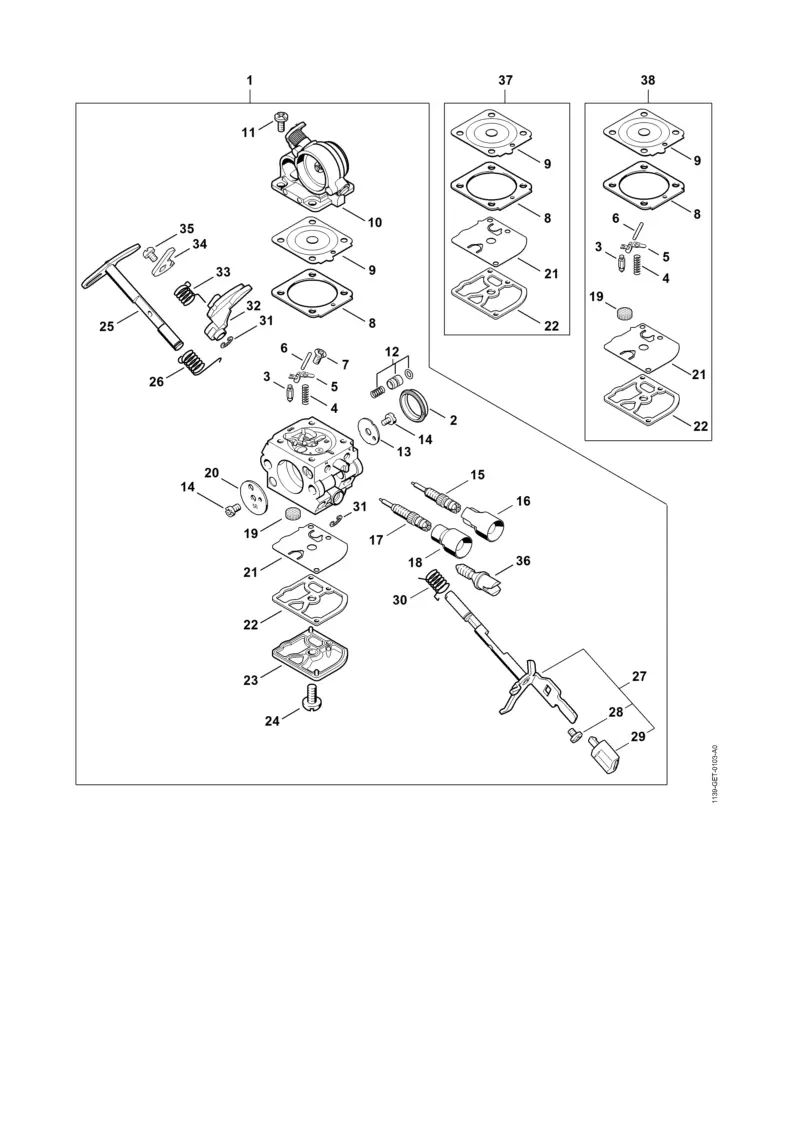

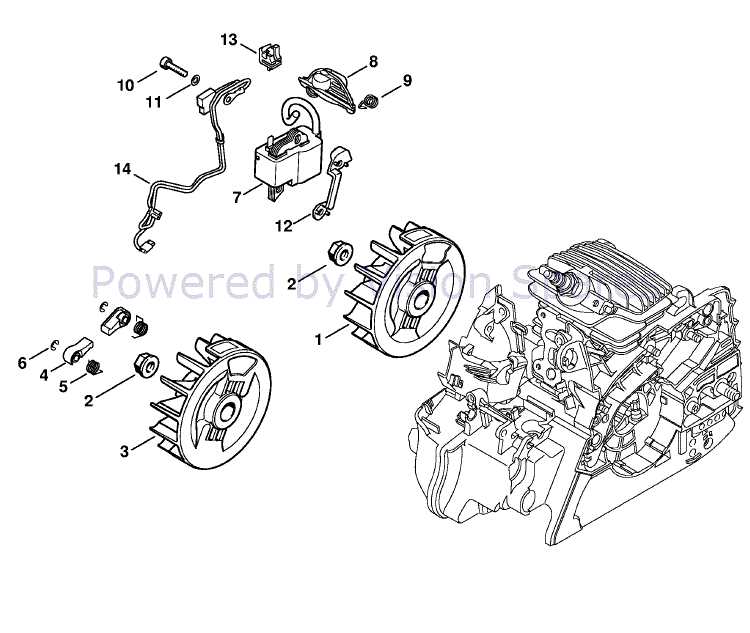

Among the primary parts, the engine serves as the powerhouse, converting fuel into mechanical energy. Coupled with the ignition system, it ensures reliable starts and consistent operation. The cutting mechanism, which includes the chain and bar, is essential for executing precise cuts, making their upkeep vital for safety and efficiency.

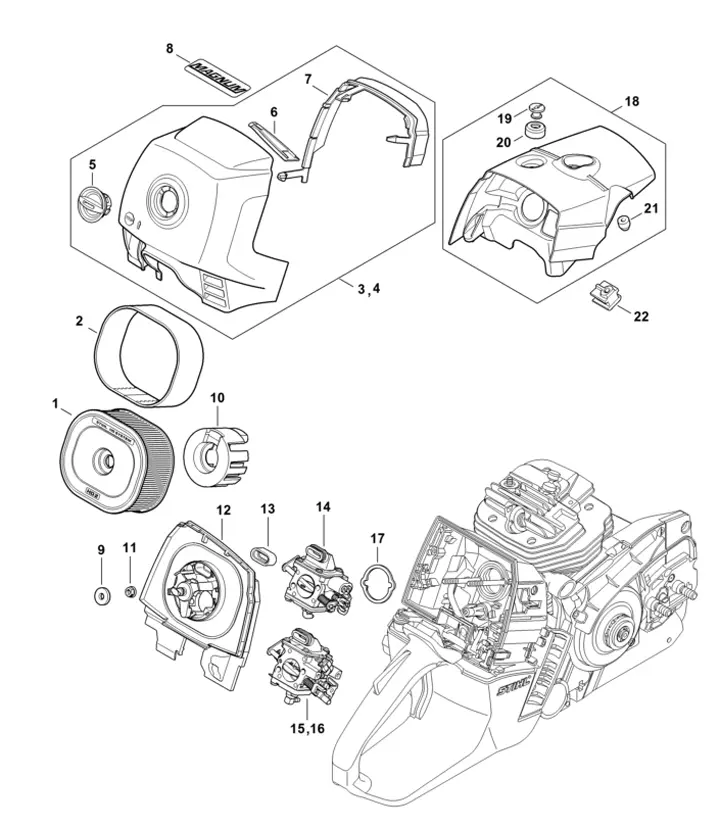

Additionally, various support elements like the fuel system, which comprises the tank and lines, play a significant role in delivering the necessary energy to the engine. Air filters and exhaust components also contribute to the overall performance by maintaining cleanliness and reducing emissions. Understanding how these parts interact can lead to better care and troubleshooting strategies.

In conclusion, familiarizing oneself with the various elements of this tool not only aids in effective management but also enhances the overall user experience. Each component is integral to achieving optimal performance and reliability.

Importance of Parts Diagrams

Understanding the intricate assembly of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools for technicians and enthusiasts alike, allowing for a clearer grasp of component relationships and functionalities.

Key benefits of using such illustrations include:

- Facilitating precise identification of components.

- Streamlining the repair process by highlighting assembly sequences.

- Reducing the likelihood of errors during maintenance.

- Enhancing communication between users and service providers.

By utilizing these visual aids, individuals can delve deeper into the workings of their equipment, ultimately improving longevity and performance.

Overview of Stihl MS 211 Features

This section explores the standout characteristics of a well-regarded chainsaw model, highlighting its design and operational efficiency. Known for blending power with user-friendly features, this tool is ideal for both professionals and enthusiasts.

Key Specifications

| Feature | Description |

|---|---|

| Engine Power | Robust engine that delivers impressive cutting capabilities. |

| Weight | Lightweight design that enhances maneuverability. |

| Chain Tensioning | Easy-adjust system for quick chain modifications. |

| Vibration Reduction | Advanced technology to minimize user fatigue. |

Additional Features

Beyond essential specifications, this model incorporates safety mechanisms and fuel efficiency, ensuring a seamless experience for various cutting tasks. Its durable construction also promises longevity and reliability, making it a top choice in its category.

Key Parts of the Chainsaw

Understanding the essential components of a cutting tool enhances efficiency and maintenance. Each element plays a crucial role in performance, safety, and durability, making it vital for users to be familiar with their functions and interconnections.

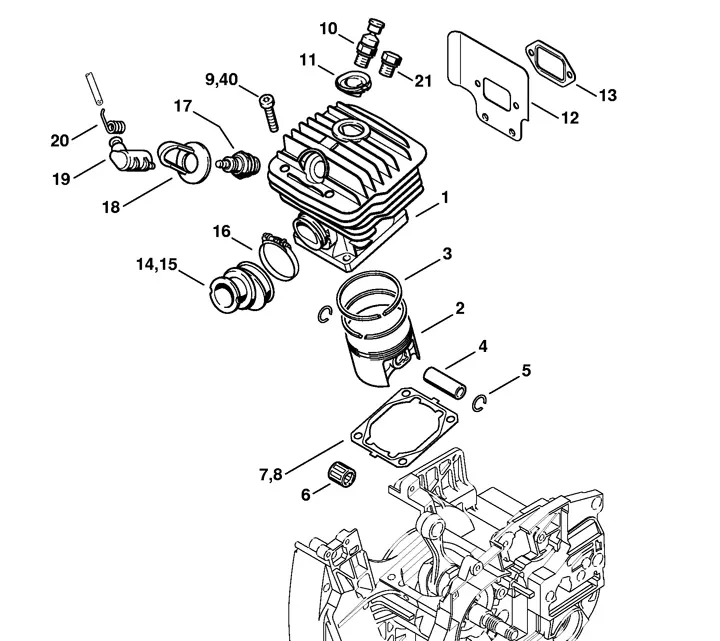

Engine and Power System

The heart of the machine is its engine, which converts fuel into power. This system includes various parts like the carburetor, spark plug, and ignition coil, all working together to ensure smooth operation.

Cutting Mechanism

The cutting mechanism is primarily composed of the guide bar and the chain. The guide bar provides stability while the chain, with its sharp teeth, efficiently slices through wood. Proper tension and lubrication are key for optimal performance.

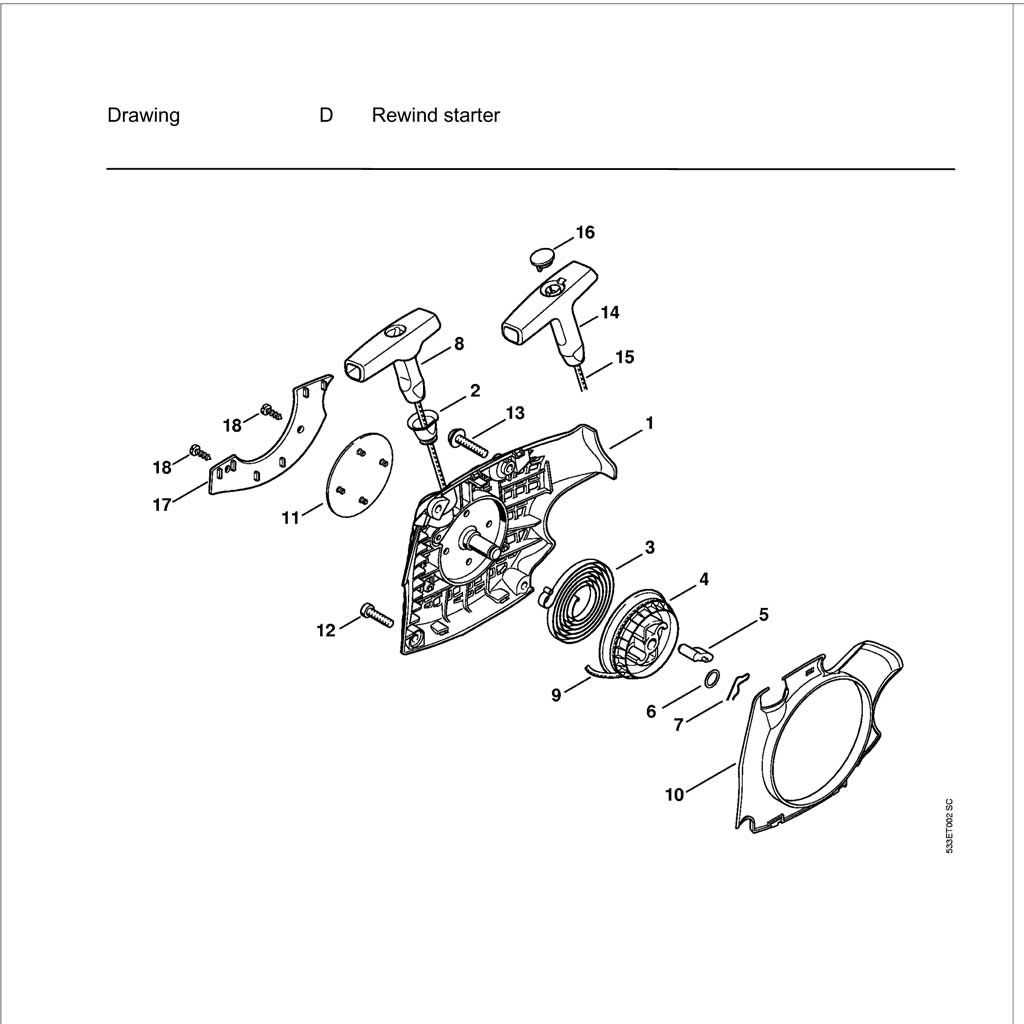

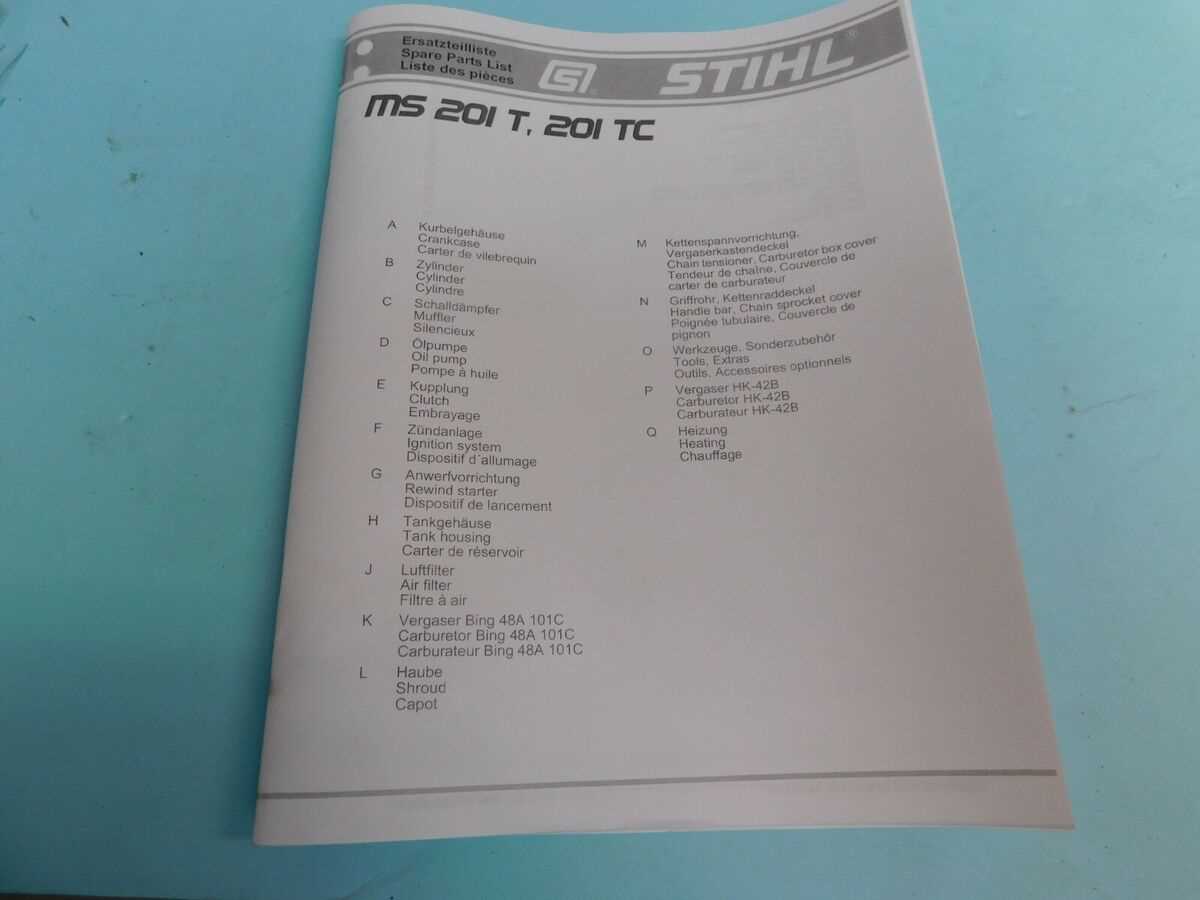

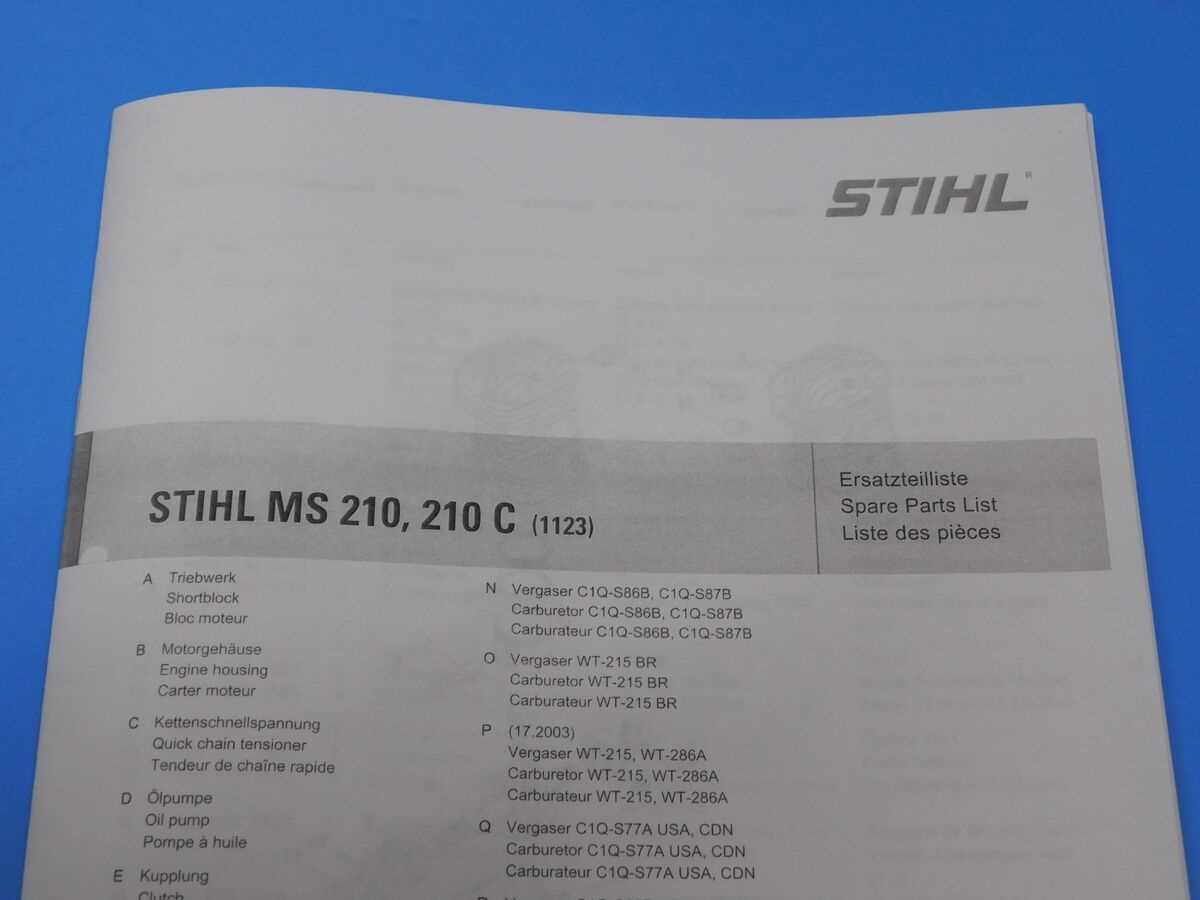

How to Read the Diagram

Understanding technical illustrations can be a valuable skill when maintaining or repairing equipment. These visuals provide essential information about various components, their arrangement, and their interconnections. By learning how to interpret these representations, you can simplify troubleshooting and ensure effective repairs.

Key Elements to Identify

- Labels: Each component is usually marked with a specific identifier or number. Familiarizing yourself with these labels is crucial for accurate reference.

- Connections: Arrows or lines indicate how parts are linked. Pay attention to these to understand the flow and functionality of the assembly.

- Legend: Many illustrations include a legend or key that explains symbols used throughout. This can clarify meanings that might not be immediately obvious.

Steps to Effectively Interpret the Visual

- Begin by reviewing the legend to familiarize yourself with the symbols and labels.

- Identify major components first, such as the engine, housing, and any attachments.

- Trace the connections between parts, noting how they interact within the overall assembly.

- Refer to the illustration while disassembling or reassembling, ensuring accuracy in your work.

Common Issues and Solutions

When using a particular brand of outdoor power tools, users may encounter various challenges that can affect performance and efficiency. Understanding these common problems and their solutions can enhance the overall experience and prolong the life of the equipment.

- Engine Won’t Start

- Check the fuel level and ensure it’s fresh.

- Inspect the spark plug for damage or wear.

- Examine the air filter for clogs.

- Excessive Vibration

- Ensure all bolts and screws are tightened.

- Inspect the cutting chain for proper tension.

- Check for damaged or worn components.

- Overheating

- Verify that the cooling fins are clean.

- Check the fuel mixture for correct ratio.

- Monitor operating conditions to avoid prolonged use.

By addressing these issues proactively, users can ensure their equipment runs smoothly and efficiently.

Replacing Worn-Out Components

Over time, various elements of your equipment may experience wear and tear, impacting performance and efficiency. Identifying and replacing these aged components is crucial to maintain optimal functionality. Regular maintenance not only extends the lifespan of your tool but also ensures safety during operation.

Identifying Signs of Wear

Common indicators that components need attention include unusual noises, reduced power, or difficulty starting. Inspecting parts regularly can help you spot these issues early. Pay close attention to any visible damage, such as cracks or corrosion, which may compromise performance.

Steps for Replacement

Once you have determined which components require replacement, gather the necessary tools and a suitable replacement. Follow the manufacturer’s guidelines for safe disassembly and reassembly. Ensure that all connections are secure and that new parts are compatible with existing equipment. Regular checks after replacement can help you monitor the effectiveness of the new components.

Maintenance Tips for Longevity

Proper upkeep of your outdoor power equipment is essential for ensuring its efficiency and extending its lifespan. Regular maintenance not only enhances performance but also prevents costly repairs down the line. Here are some effective strategies to help keep your tools in optimal condition.

Regular Cleaning

After each use, it is crucial to clean your equipment thoroughly. Remove any debris, dirt, or residue that may accumulate on the exterior and within the engine components. A clean machine runs more efficiently and reduces the risk of overheating.

Scheduled Inspections

Implement a routine inspection schedule to identify potential issues before they escalate. Check for wear and tear on essential components such as the chain, air filter, and spark plug. Replacing worn parts promptly can prevent further damage and maintain peak performance. Additionally, keep the fuel system clean and ensure proper oil levels are maintained.

By following these guidelines, you can significantly enhance the durability of your equipment and enjoy reliable performance for years to come.

Tools Needed for Repairs

When embarking on maintenance tasks, having the right instruments is crucial for achieving optimal results. Proper tools not only streamline the repair process but also enhance safety and efficiency.

- Screwdrivers: Essential for loosening and tightening various components.

- Wrenches: Useful for securing nuts and bolts.

- Pliers: Ideal for gripping and manipulating small parts.

- Fuel Mixing Container: Necessary for preparing the correct fuel ratio.

- Protective Gear: Gloves and goggles ensure safety during repairs.

By gathering these fundamental tools, you can ensure a smoother repair process and tackle any issues that may arise with confidence.

Where to Find Genuine Parts

Finding authentic components for your equipment is crucial for maintaining its performance and longevity. Reliable sources ensure that you receive high-quality replacements that fit perfectly and uphold safety standards.

Authorized Dealers

One of the best options is to visit authorized dealers, who provide certified replacements. These locations often have knowledgeable staff to assist you in selecting the right items for your needs.

Online Retailers

Many reputable online platforms specialize in selling genuine components. Make sure to check for customer reviews and ratings to ensure you’re purchasing from a trustworthy source.

| Source | Advantages |

|---|---|

| Authorized Dealers | Certified quality, expert advice |

| Online Retailers | Convenience, often competitive pricing |

Upgrades for Enhanced Performance

Improving the functionality and efficiency of your equipment can lead to a more enjoyable and productive experience. By considering various enhancements, you can boost power, reduce wear, and increase overall longevity. This section will explore some effective modifications that can transform your tool into a high-performance machine.

Power Enhancements

One of the most sought-after upgrades involves enhancing the engine’s output. This can be achieved through high-performance air filters that improve airflow, allowing the engine to breathe better. Additionally, upgrading to a premium spark plug can optimize ignition, ensuring smoother starts and better fuel efficiency. Together, these modifications can significantly increase cutting power and overall performance.

Durability Improvements

Incorporating more robust materials and components can greatly extend the lifespan of your tool. Consider replacing standard chains with reinforced options designed for heavy-duty use. Additionally, installing a protective guard can minimize damage from debris, while quality lubricants can reduce friction and wear. These adjustments not only enhance durability but also contribute to smoother operation over time.

Safety Precautions When Repairing

Ensuring safety during maintenance activities is essential to prevent injuries and accidents. Familiarizing yourself with the proper procedures and using protective gear can significantly reduce risks while working with machinery. Below are some key precautions to consider when undertaking repair tasks.

Personal Protective Equipment

- Always wear safety goggles to protect your eyes from debris.

- Use gloves to avoid cuts and abrasions.

- Employ sturdy footwear to shield your feet from heavy objects.

- Consider ear protection if working with loud equipment.

Work Environment

- Ensure the workspace is well-lit and organized to minimize hazards.

- Keep the area free of clutter to avoid tripping hazards.

- Verify that all tools are in good condition before use.

- Maintain a safe distance from flammable materials.

By following these guidelines, you can create a safer environment for yourself while performing necessary repairs. Always prioritize safety to enhance both your efficiency and well-being.

FAQs About Stihl MS 211 Parts

This section addresses common inquiries related to components and their maintenance for a specific chainsaw model. Understanding these elements can enhance user experience and extend the lifespan of the equipment.

- What are the most common issues with the device?

- Difficulty starting the engine

- Inconsistent cutting performance

- Excessive vibration

- How can I identify which component needs replacement?

- Listen for unusual sounds during operation

- Inspect for physical wear and tear

- Check for leaks or fuel issues

- Where can I find replacement components?

- Authorized dealers

- Online retailers

- Local hardware stores

- What is the best way to maintain these components?

- Regular cleaning after use

- Scheduled inspections for wear

- Proper storage when not in use

- Are there any specific tools required for replacement?

- Wrenches and screwdrivers

- Specialty tools for certain components

- Safety gear for protection