Understanding the Parts Diagram of Stihl MS250 Chainsaw

In the realm of outdoor equipment, one tool stands out for its efficiency and reliability. This machine is indispensable for both professionals and enthusiasts alike, making it crucial to comprehend its inner workings. A detailed exploration of its components not only aids in effective maintenance but also enhances the overall user experience.

Identifying the individual elements of this powerful instrument is essential for anyone looking to troubleshoot issues or upgrade functionality. By understanding how each section interacts, users can ensure optimal performance and longevity. Moreover, having a visual representation of these components simplifies the process of repairs and modifications.

In this article, we will delve into a comprehensive overview of the key sections, highlighting their roles and importance. Whether you’re a seasoned user or a newcomer, grasping these intricacies will empower you to make informed decisions and enhance your operational capabilities.

Understanding the Stihl MS250 Chainsaw

This section aims to provide an in-depth look at a popular power tool, focusing on its components, functionality, and maintenance. By exploring these aspects, users can enhance their experience and ensure efficient operation.

Key Features and Specifications

This tool is designed for both professional and recreational use, offering a blend of power and user-friendliness. It typically includes a robust engine, a balanced design, and a reliable cutting mechanism. Its lightweight structure contributes to ease of handling, making it suitable for various tasks, from light pruning to heavy-duty cutting.

Maintenance and Care

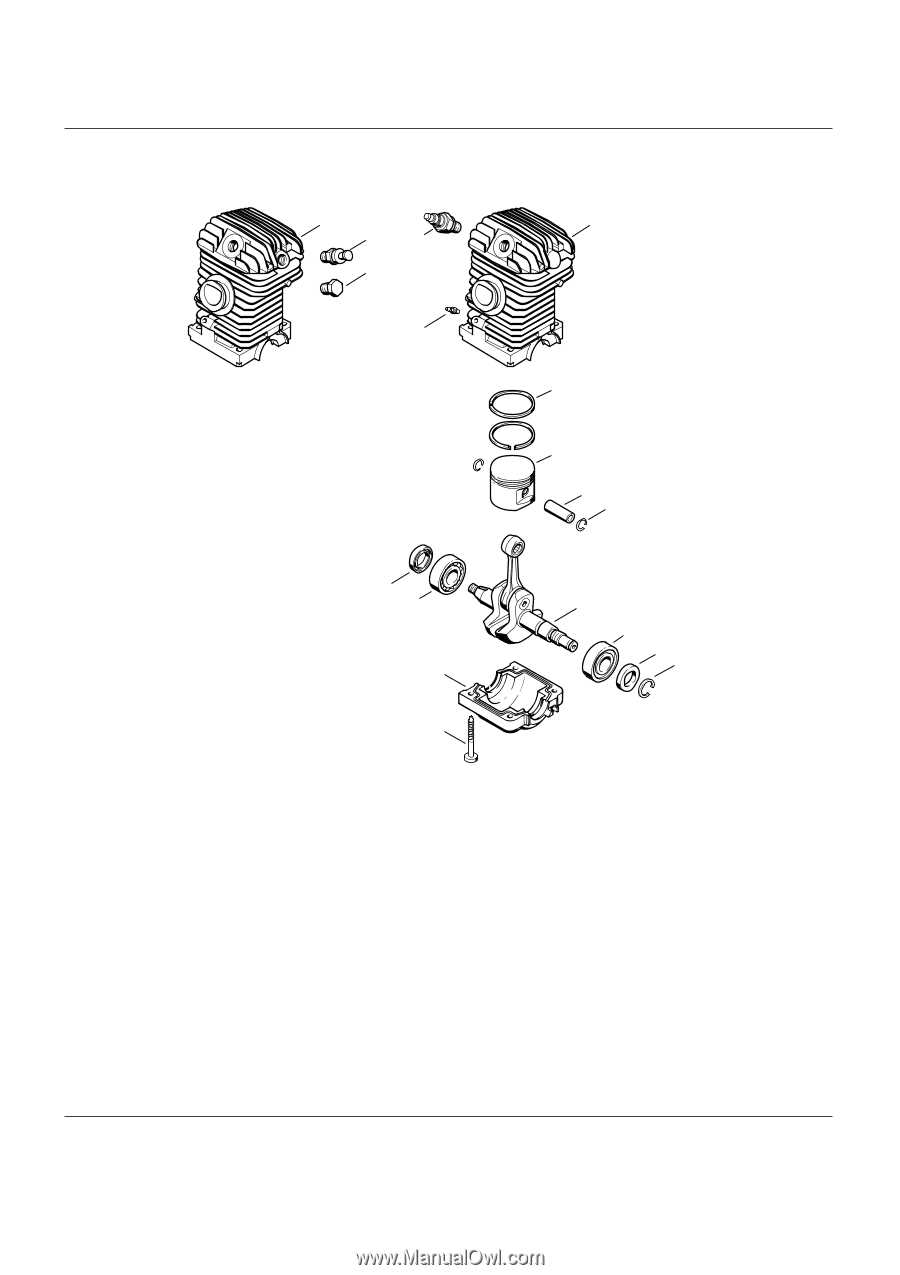

Key Components of the Chainsaw

Understanding the essential elements of a cutting tool enhances its effective use and maintenance. Each component plays a significant role in the overall functionality, contributing to performance, safety, and durability. Familiarity with these parts can lead to better operation and troubleshooting.

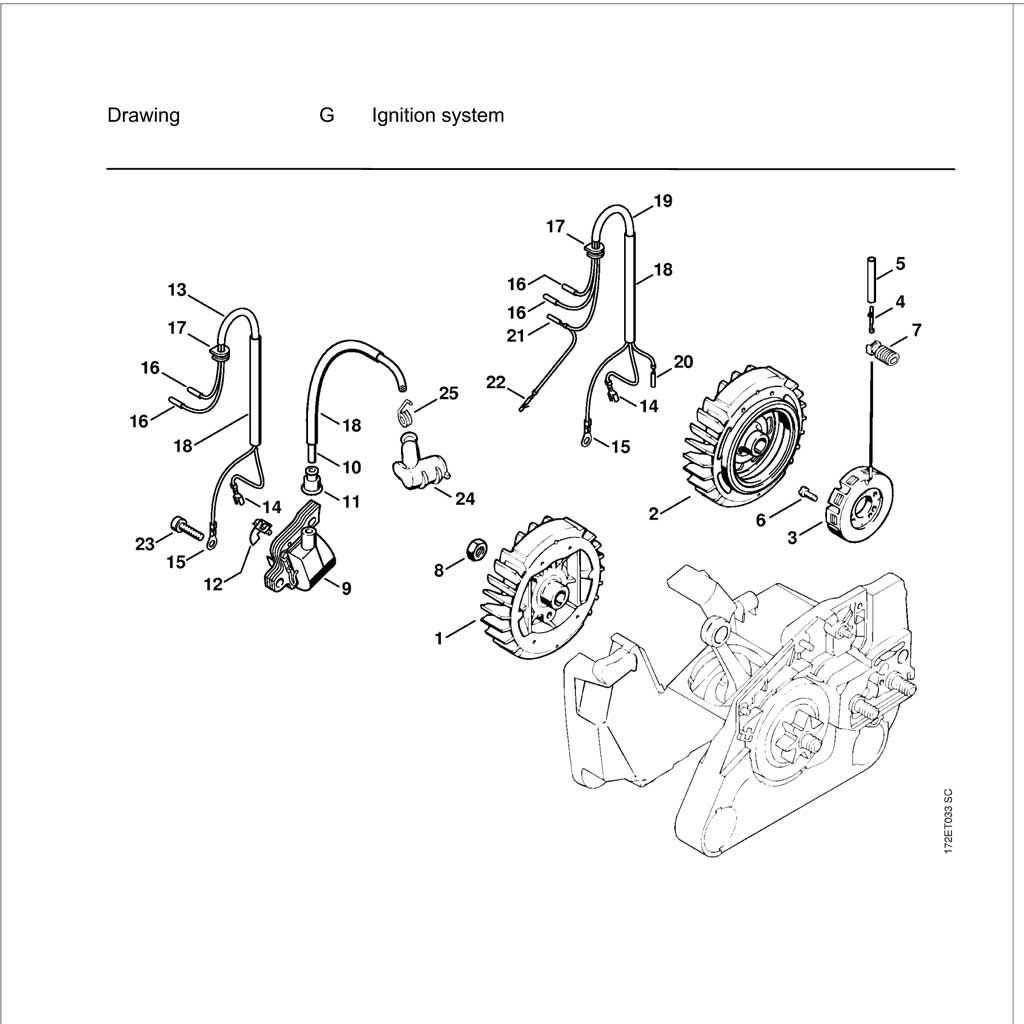

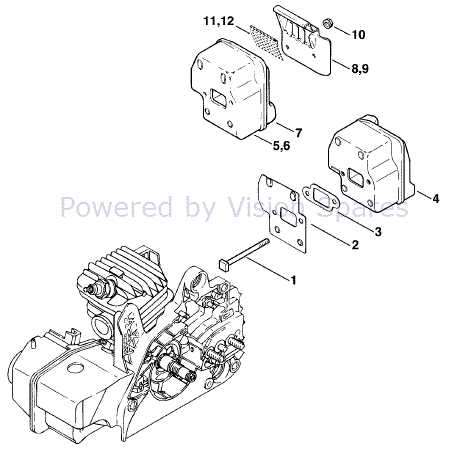

Power Source

The engine is the heart of the device, providing the necessary energy to operate. Whether gas-powered or electric, its efficiency and power output directly influence cutting performance.

Cutting Mechanism

The cutting system comprises the guide bar and the chain. These elements work together to achieve precise cuts. The design and sharpness of the chain are crucial for ensuring smooth operation and optimal results.

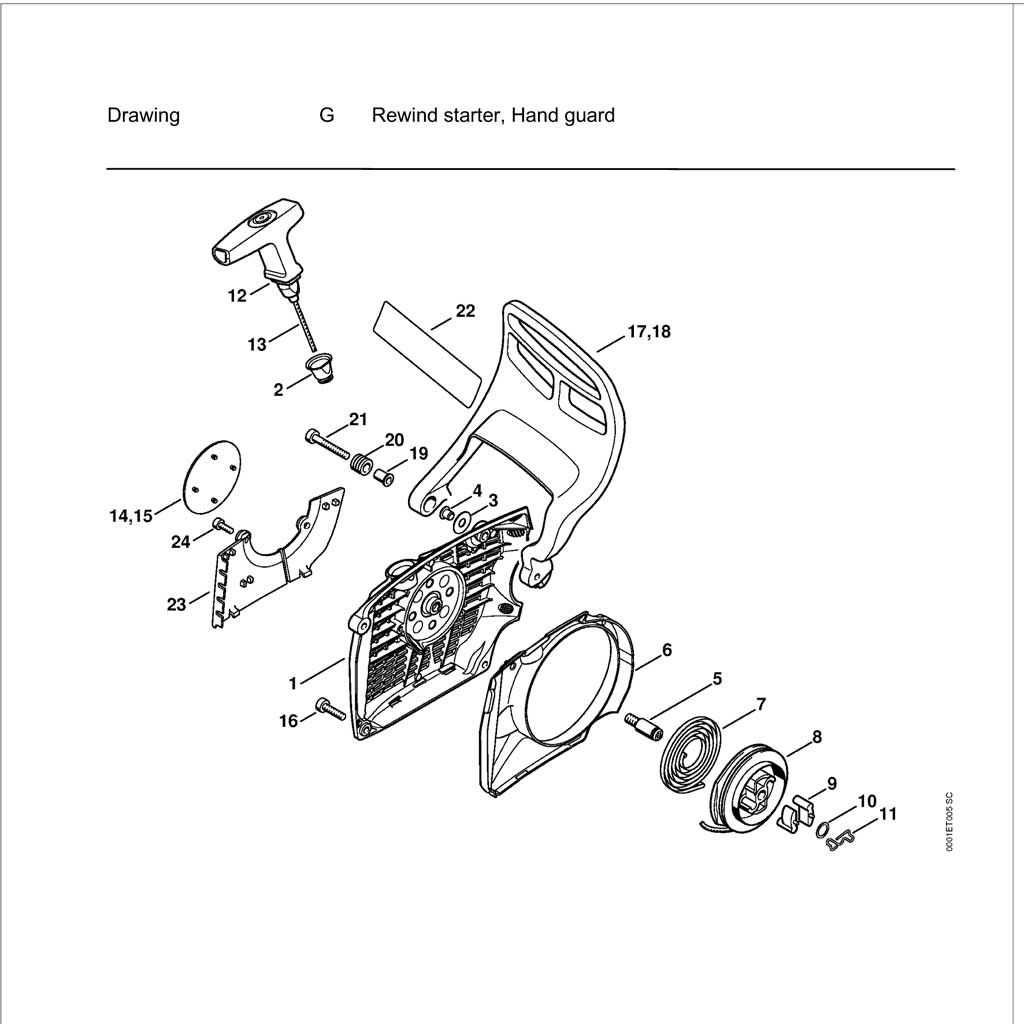

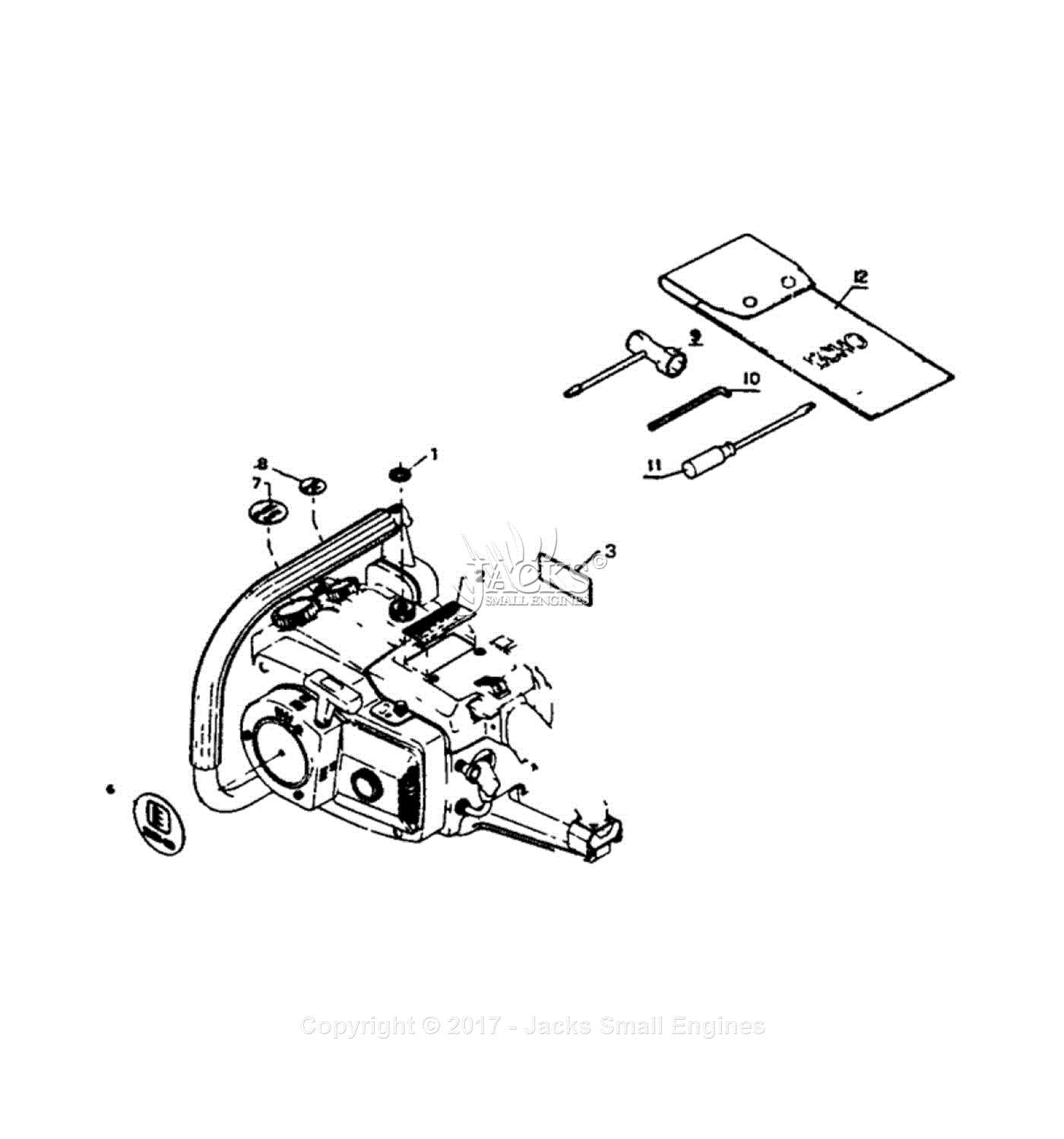

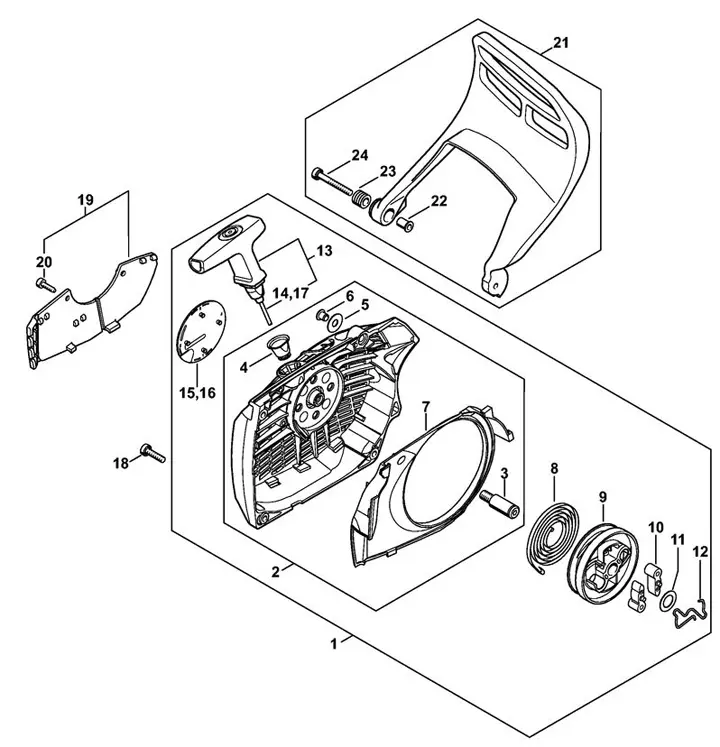

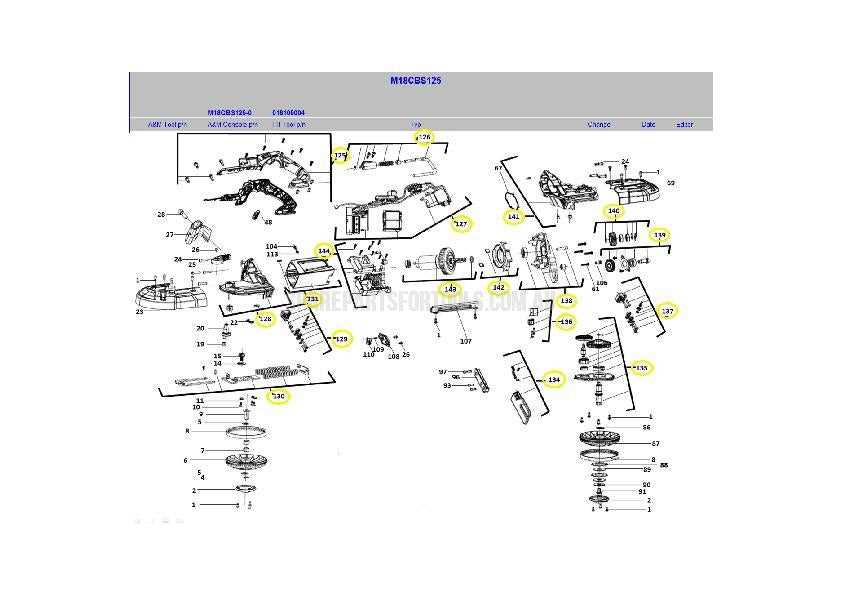

Importance of a Parts Diagram

Understanding the components of a mechanical device is essential for effective maintenance and repair. A visual representation serves as a crucial tool for both novice and experienced users, enabling them to identify each element and its function within the system.

- Enhanced Understanding: A visual guide clarifies the relationships between components, making it easier to comprehend their roles.

- Efficient Repairs: Knowing where each element is located speeds up troubleshooting and repair processes.

- Informed Replacements: Users can identify which components need replacing, ensuring they acquire the correct items.

- Reduced Errors: Visual aids minimize the risk of mistakes during assembly or disassembly, leading to more successful repairs.

Incorporating such resources into maintenance routines can lead to increased longevity and performance of the equipment. Ultimately, familiarity with the arrangement of parts empowers users to manage their devices more effectively.

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair tasks. These visual representations provide a clear overview of components and their relationships, making it easier to identify and replace items as needed.

To effectively interpret these visuals, follow these key steps:

| Step | Description |

|---|---|

| 1 | Familiarize yourself with the legend or key, which explains symbols and numbers used in the illustration. |

| 2 | Identify the main assembly or section you are working on, as these images often show multiple components. |

| 3 | Trace connections and positions carefully to understand how each piece fits within the whole. |

| 4 | Cross-reference the visual with a list of required elements to ensure accuracy during repairs. |

By following these steps, you can confidently navigate and utilize technical illustrations for your repair needs.

Common Replacement Parts Overview

Maintaining optimal performance in your outdoor power equipment often requires periodic replacements of essential components. Understanding which elements commonly need attention can help ensure your machine operates efficiently and effectively. This section highlights frequently replaced items that contribute to the longevity of your equipment.

Essential Components

Key elements such as the fuel filter, spark plug, and air filter are vital for maintaining proper functionality. Regularly replacing these components not only enhances performance but also minimizes wear and tear on the engine. Ensuring clean air and fuel flow is crucial for optimal operation.

Maintenance Accessories

Accessories like chain lubrication and guide bars play a significant role in the longevity of your machinery. Utilizing quality lubricants and regularly checking the condition of the guide bar can prevent unnecessary damage and extend the lifespan of your equipment. Investing time in these details yields ultimate benefits.

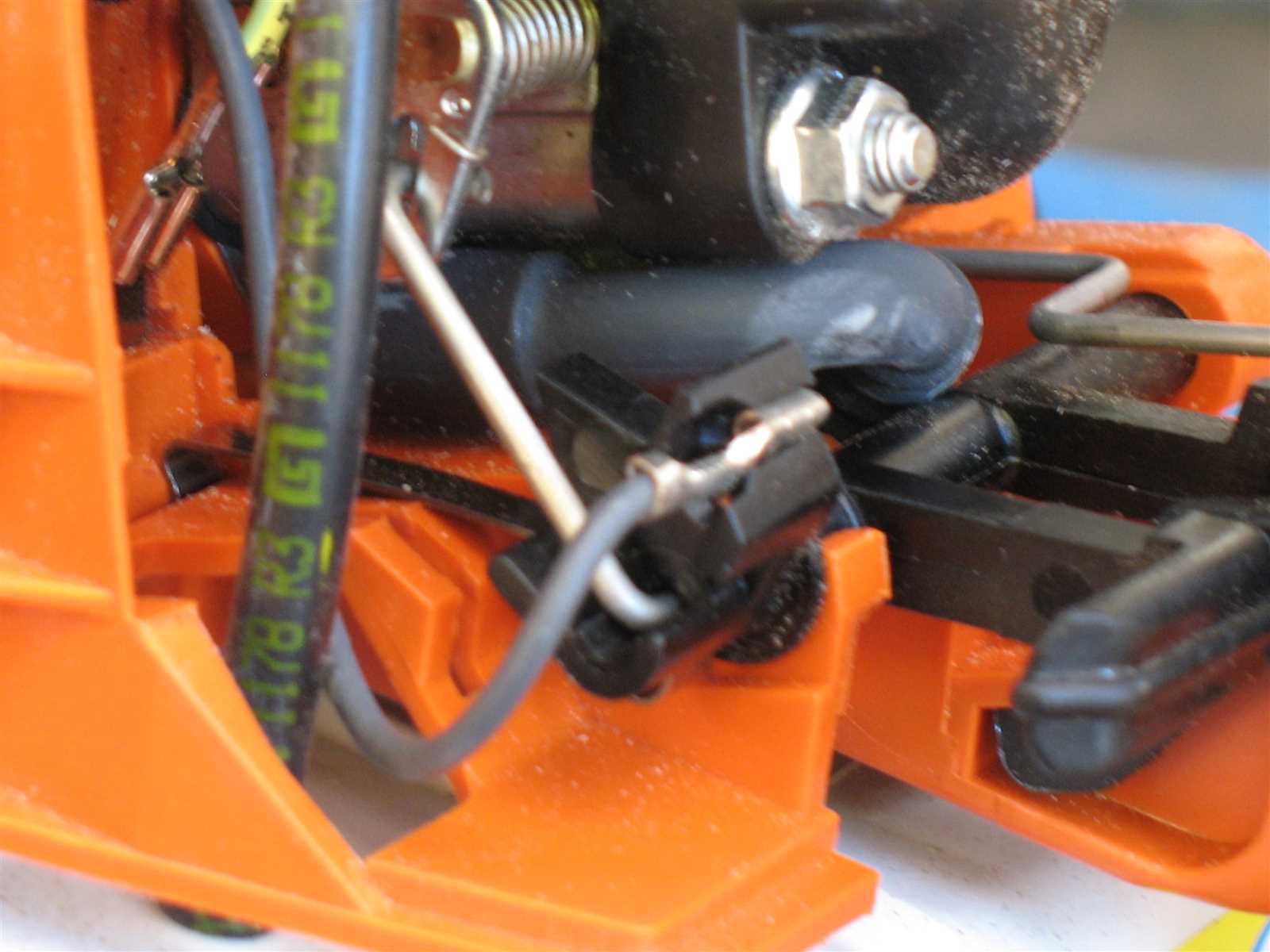

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your power tool requires consistent care and attention. Regular maintenance not only extends the life of the equipment but also enhances its performance, making your tasks smoother and safer. Adopting simple practices can make a significant difference in reliability over time.

Regular Cleaning

After each use, clean the exterior and internal components to prevent buildup of debris and sap. This practice helps maintain optimal functioning and prevents potential damage from accumulated grime.

Proper Lubrication

Keep moving parts well-lubricated to reduce friction and wear. Regularly check and replenish oil levels, ensuring that all mechanisms operate seamlessly and efficiently.

Identifying Wear and Tear Signs

Recognizing the indicators of deterioration in your equipment is crucial for maintaining its performance and longevity. Regular inspection can help identify issues before they escalate, ensuring efficient operation and safety.

| Sign | Description |

|---|---|

| Cracks | Visible fractures in the body or components that compromise structural integrity. |

| Rust | Corrosion forming on metal parts, indicating exposure to moisture. |

| Worn Edges | Blades or cutting surfaces that appear dull or have rounded edges, affecting cutting efficiency. |

| Loose Fasteners | Nuts and bolts that are not securely fastened, potentially leading to component failure. |

| Excessive Vibration | Unusual shaking during operation, suggesting misalignment or wear in moving parts. |

Where to Purchase Genuine Parts

When it comes to maintaining your outdoor equipment, sourcing authentic components is essential for optimal performance and longevity. Ensuring that you acquire high-quality replacements can significantly impact the efficiency and safety of your tools.

Here are several reliable options for obtaining genuine components:

- Authorized Dealers: Visiting certified retailers is one of the best ways to find authentic items. These locations often have knowledgeable staff who can assist you in selecting the correct replacements.

- Manufacturer’s Website: The official website typically offers a dedicated section for purchasing components. This ensures that you receive genuine items directly from the source.

- Local Repair Shops: Many repair specialists carry a selection of authentic components. They can also provide valuable advice based on their experience with various models.

- Online Marketplaces: Reputable online platforms may offer genuine components. Ensure you verify the seller’s ratings and reviews before making a purchase.

- Trade Shows and Expos: Attending industry events can connect you with vendors who specialize in authentic items, often providing exclusive offers.

Prioritizing genuine replacements not only ensures compatibility but also enhances the overall lifespan of your equipment, allowing you to work efficiently for years to come.

Aftermarket Parts: Pros and Cons

Exploring alternative components can offer both advantages and disadvantages for those seeking to enhance or repair their equipment. Understanding these factors is essential for making informed decisions.

Advantages

- Cost-Effective: Typically more affordable than original options.

- Variety: A wider selection can provide unique features or enhancements.

- Accessibility: Often easier to find in local markets or online.

Disadvantages

- Quality Variability: Not all substitutes meet the same standards as original products.

- Compatibility Issues: Potential for fit and performance discrepancies.

- Warranty Concerns: Using non-original components may void existing guarantees.

Tools Needed for Repairs

When undertaking maintenance or fixing issues with your outdoor power equipment, having the right tools at your disposal is crucial. A well-equipped toolkit not only streamlines the repair process but also ensures that each task is performed safely and effectively. Understanding the essential instruments will prepare you for a variety of common repairs and adjustments.

First and foremost, basic hand tools such as screwdrivers, wrenches, and pliers are indispensable. These items allow you to access and manipulate various components with ease. Additionally, a set of Allen keys can be particularly useful for securing or loosening specific fasteners. A sturdy workbench will provide a stable surface for your projects, enhancing both safety and efficiency.

For more intricate tasks, specialized tools like a torque wrench or a spark plug socket may be necessary. These instruments ensure that components are tightened to the manufacturer’s specifications, which is vital for optimal performance. Having a reliable cleaning brush and lubricant on hand will help maintain the machine’s longevity and functionality.

Lastly, consider investing in safety gear such as gloves and goggles. Protecting yourself during repairs is as important as having the right tools. With a comprehensive toolkit and appropriate safety measures, you can confidently tackle repairs and keep your equipment running smoothly.

Assembly and Disassembly Instructions

This section provides a comprehensive guide on how to correctly assemble and disassemble your equipment for optimal performance. Following precise steps ensures both safety and efficiency during maintenance tasks.

To begin disassembly, ensure the device is powered off and cool to the touch. Remove any covers or shields carefully, using appropriate tools to avoid damage. Take note of the arrangement of components as you progress, making it easier for reassembly.

For assembly, start with the main components, aligning them as indicated in the manufacturer’s guidelines. Secure each part firmly, checking for any misalignment before tightening. Lastly, replace the covers, ensuring they are securely fastened to maintain safety during operation.

Understanding Engine Specifications

Exploring the intricacies of engine specifications is essential for grasping the performance and capabilities of power equipment. These metrics not only determine efficiency but also impact overall functionality, making it crucial for users to familiarize themselves with key details.

Key Components

Several vital elements contribute to an engine’s performance, including displacement, power output, and torque. Understanding these components helps in evaluating how well the machinery will operate under various conditions.

Performance Metrics

| Specification | Description |

|---|---|

| Displacement | The total volume of the engine’s cylinders, influencing power generation. |

| Power Output | The amount of work the engine can perform, typically measured in horsepower. |

| Torque | The rotational force available, crucial for handling challenging tasks. |

Frequently Asked Questions About MS250

This section addresses common inquiries regarding a specific power tool model, offering clarity on its features, maintenance, and troubleshooting. Understanding these elements can enhance the user experience and extend the tool’s lifespan.

What is the fuel mixture ratio for optimal performance? The ideal ratio for this model is typically 50:1, combining high-quality oil with gasoline.

How often should I sharpen the blade? Regular sharpening is recommended after every 5-10 hours of use to maintain efficiency.

What are common signs of wear and tear? Look for reduced cutting speed, excessive vibration, or difficulty starting as indicators of potential issues.

Can I use this tool in wet conditions? It’s advisable to avoid using it in wet environments to ensure safety and prevent damage.

Where can I find replacement components? Replacement parts can typically be sourced from authorized dealers or reputable online retailers.