Understanding the Stihl MS250 Parts Diagram for Effective Maintenance

In the realm of outdoor power tools, mastering the intricacies of your equipment can significantly enhance its performance and longevity. A thorough comprehension of the various elements that make up a chainsaw is essential for effective maintenance and troubleshooting. This section will guide you through the essential components that play a pivotal role in the functionality of your machine.

Visualizing the Assembly of your tool is crucial. By familiarizing yourself with its layout, you can easily identify each piece, from the engine to the cutting mechanism. This knowledge not only aids in recognizing any issues that may arise but also empowers you to perform basic repairs and replacements with confidence.

Additionally, understanding the interplay between different components allows for better optimization of your tool’s performance. Whether you’re a seasoned user or a newcomer, grasping the relationship between each part will enhance your overall experience and ensure your chainsaw operates at peak efficiency.

Understanding Stihl MS250 Components

Grasping the essential elements of a cutting tool can greatly enhance its performance and longevity. Each component plays a crucial role, contributing to the overall functionality and efficiency. By familiarizing oneself with these parts, users can better maintain their equipment and address issues as they arise.

Key Components Overview

- Engine: The heart of the machine, providing power for cutting.

- Bar: The metal beam that supports the cutting chain.

- Chain: The looped blade that performs the actual cutting.

- Fuel System: Comprising the tank, lines, and filter, crucial for operation.

- Air Filter: Prevents debris from entering the engine, ensuring optimal performance.

Maintenance Tips

- Regularly check the oil levels to ensure proper lubrication.

- Inspect the chain tension frequently to avoid wear.

- Clean the air filter regularly to maintain airflow and engine efficiency.

- Examine the spark plug for signs of wear or damage.

- Keep the exterior clean to prevent dirt accumulation affecting performance.

Essential Parts Overview

Understanding the key components of a chainsaw is crucial for both maintenance and optimal performance. Each element plays a significant role in ensuring the equipment operates smoothly and efficiently. This section provides an overview of the vital elements that contribute to the functionality of the tool, highlighting their importance and interconnectivity.

Key Components

| Component | Description |

|---|---|

| Engine | The powerhouse that drives the entire system, providing the necessary force for cutting. |

| Guide Bar | A metal bar that supports the chain and guides it during operation, crucial for precision. |

| Chain | The cutting element that rotates around the guide bar, equipped with sharp teeth for effective slicing. |

| Air Filter | Filters out debris and contaminants from the air intake, ensuring optimal combustion. |

| Fuel Tank | Stores the fuel necessary for engine operation, influencing the runtime and power output. |

Importance of Maintenance

Regular inspection and upkeep of these essential components are vital for extending the lifespan of the equipment. Proper care not only enhances performance but also ensures safety during use. Familiarity with these elements allows operators to troubleshoot issues effectively and maintain peak operational efficiency.

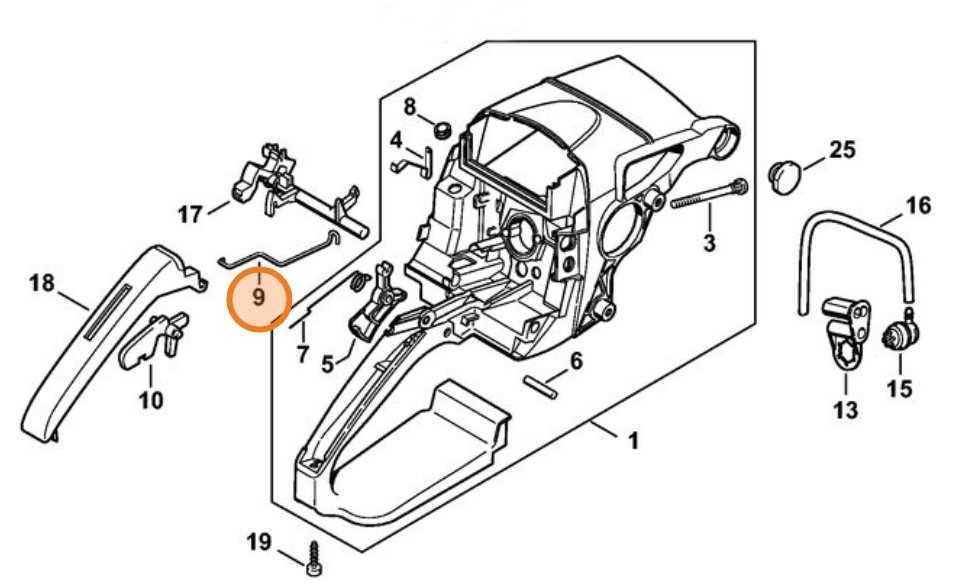

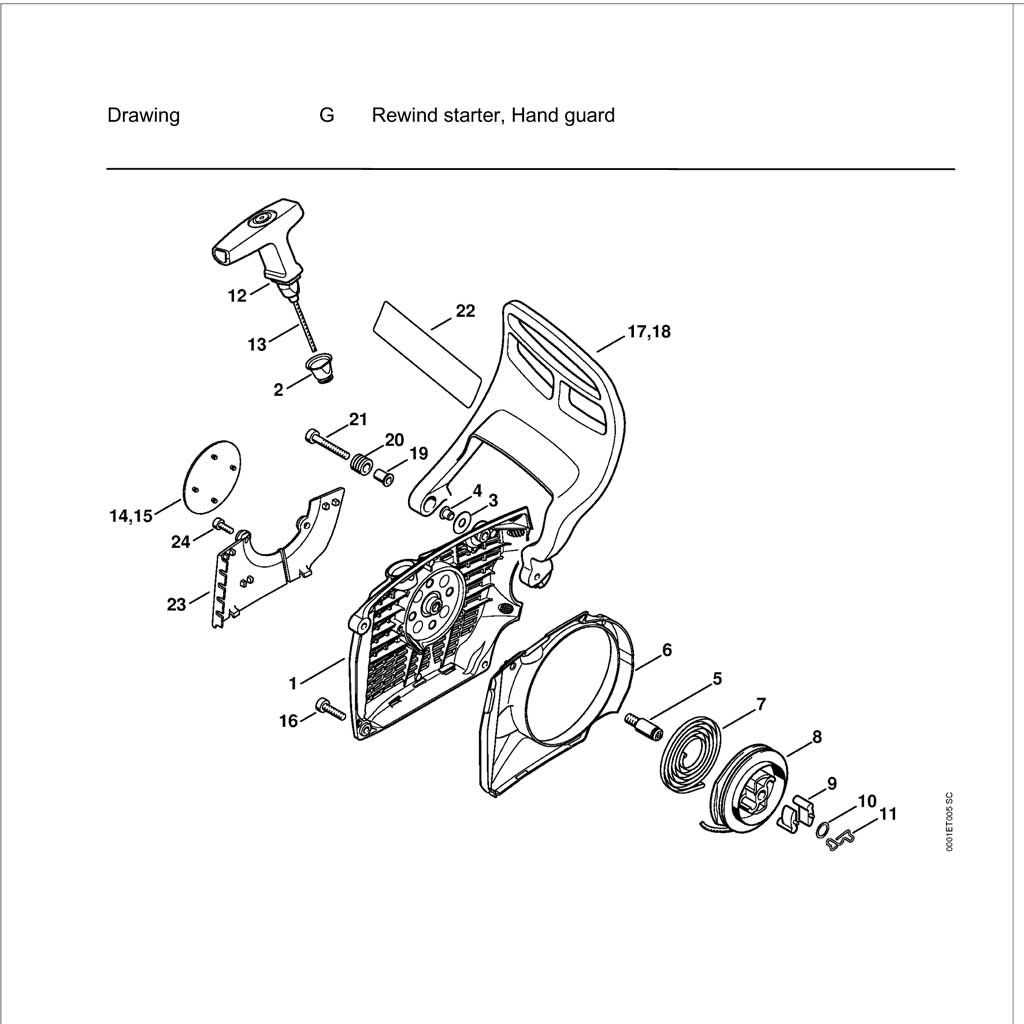

How to Read the Parts Diagram

Understanding an assembly illustration is essential for effective maintenance and repair of any machinery. These visuals provide a comprehensive view of the components and their arrangement, aiding users in identifying specific items needed for service or replacement.

Here are some key steps to help you interpret the assembly illustration:

- Familiarize Yourself with Symbols: Different shapes and icons represent various parts. Knowing what each symbol means is crucial.

- Identify the Main Components: Start by locating the primary sections of the machinery. This will give you context for the smaller components.

- Follow the Numbering System: Components are often numbered sequentially. Refer to the corresponding list for detailed descriptions and specifications.

- Examine the Connections: Pay attention to how parts fit together. This can help you understand their function and how to disassemble or reassemble them.

By mastering these steps, you can efficiently navigate assembly illustrations, ensuring you have the right components for your needs.

Common Issues with MS250 Parts

When it comes to maintaining outdoor power tools, various components can encounter challenges that affect performance and longevity. Understanding these frequent problems can help users troubleshoot effectively and ensure smooth operation.

Frequent Challenges

- Fuel System Problems: Clogged filters and fuel lines can lead to poor engine performance.

- Ineffective Ignition: Worn spark plugs or faulty ignition coils may result in difficulty starting.

- Chain Issues: Dull chains or improper tension can lead to inefficient cutting and increased wear.

- Vibration and Noise: Loose components can cause excessive vibration, leading to operator discomfort and potential damage.

Maintenance Tips

- Regularly inspect and replace filters to ensure optimal fuel flow.

- Check spark plugs periodically and replace them as needed.

- Sharpen or replace chains regularly for efficient cutting.

- Ensure all screws and bolts are properly tightened to minimize vibration.

By being aware of these common challenges and following maintenance recommendations, users can extend the life of their equipment and maintain high performance levels.

Replacement Parts and Their Functions

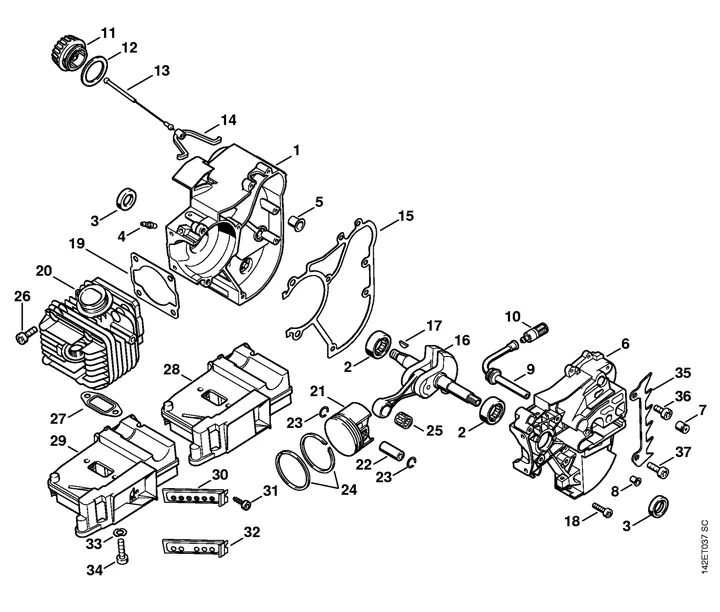

Understanding the various components of a chainsaw is essential for effective maintenance and optimal performance. Each element plays a specific role in ensuring the tool operates smoothly and efficiently. Familiarizing oneself with these components can aid in identifying potential issues and making informed decisions during repairs or replacements.

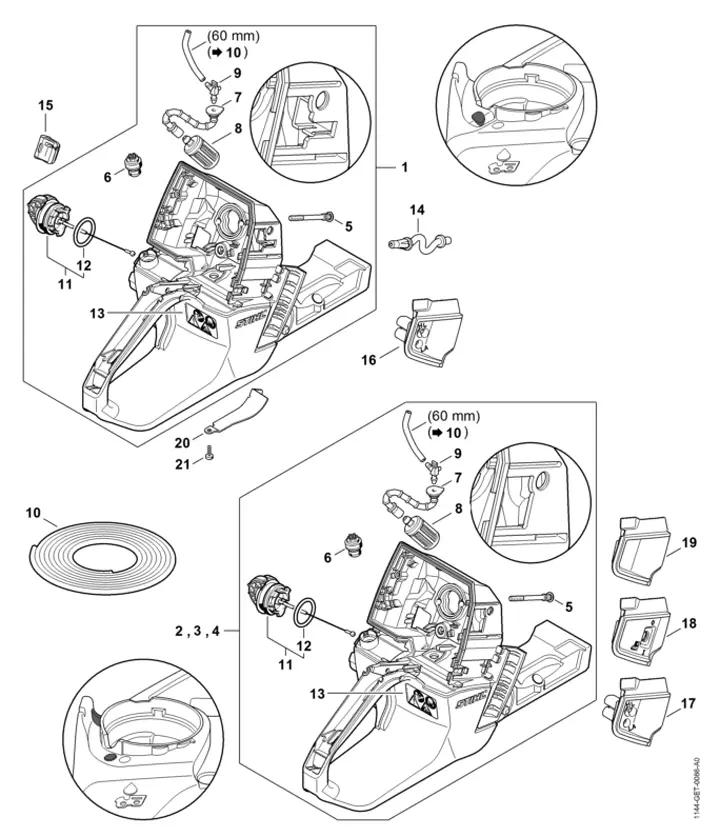

The engine serves as the heart of the device, providing the necessary power for cutting tasks. The fuel system, including the carburetor and fuel lines, is crucial for delivering the right mixture of air and fuel to the engine, which influences its performance and efficiency. A clean and functioning air filter is vital, as it prevents debris from entering the engine, ensuring proper airflow and combustion.

The cutting mechanism, comprising the bar and chain, is responsible for the actual cutting action. The bar guides the chain, while the teeth on the chain engage with the wood. Regular inspection and maintenance of these components are necessary to achieve clean cuts and prolong their lifespan. Additionally, the tensioning system allows for adjustments to the chain’s tightness, ensuring safe and effective operation.

The ignition system is another critical element, as it ignites the fuel-air mixture to start the engine. Components such as the spark plug and ignition coil must be in good condition to ensure reliable starting and operation. Lastly, the safety features, including the chain brake and throttle lock, play a significant role in preventing accidents and enhancing user control.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of your equipment. Regular attention to maintenance not only enhances performance but also extends the lifespan of your machinery. Following a few key practices can help you achieve optimal results.

- Regular Cleaning: Keep the exterior and internal components clean to prevent the accumulation of debris. Use compressed air and brushes to remove dirt and grime.

- Lubrication: Apply appropriate lubricants to moving parts. This reduces friction and wear, contributing to smoother operation.

- Inspect Components: Frequently check vital parts for signs of wear or damage. Look for cracks, corrosion, or other issues that may require replacement.

- Replace Filters: Change air and fuel filters as recommended. This ensures optimal airflow and fuel flow, improving efficiency.

- Sharpen Blades: Regularly sharpen cutting blades to maintain cutting performance. Dull blades can cause unnecessary strain on the engine.

- Check Fuel Quality: Use fresh fuel and consider adding a stabilizer if the equipment will not be used for an extended period. This prevents fuel degradation.

- Store Properly: When not in use, store the equipment in a dry and clean environment. Protect it from extreme temperatures and moisture.

By following these maintenance tips, you can ensure that your equipment remains reliable and performs at its best for years to come.

Where to Buy Stihl Parts

Finding the right components for your equipment can enhance its performance and longevity. Whether you need replacement items or accessories, it’s essential to know where to look for high-quality options. Here are some reliable sources to consider when searching for the necessary items for your machinery.

Authorized Dealers

Visiting authorized dealers is one of the best ways to ensure you get genuine components. These retailers typically offer:

- Expert advice from knowledgeable staff

- A wide selection of original equipment

- Warranty and support services

Online Marketplaces

Online shopping has become increasingly popular for purchasing machinery components. Here are some platforms to explore:

- Amazon: Offers a vast range of items, often with customer reviews to guide your choice.

- eBay: A great option for both new and used components, often at competitive prices.

- Ace Hardware: Features a selection of tools and accessories, along with helpful customer service.

By exploring these avenues, you can find the right items to keep your equipment running smoothly.

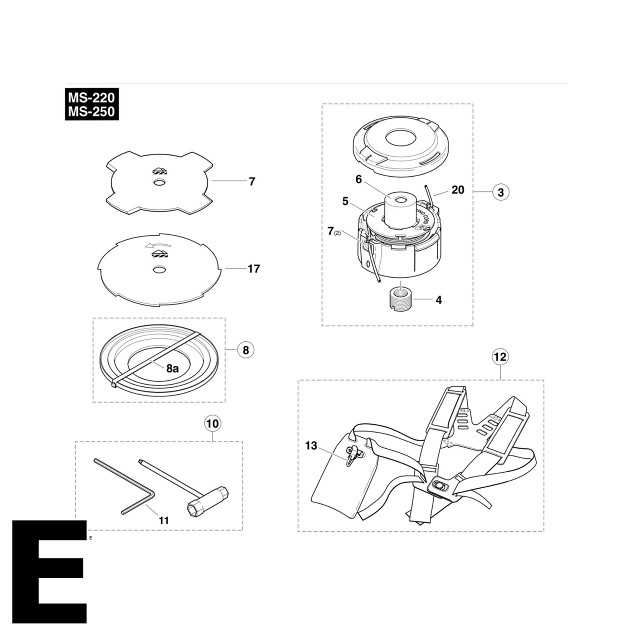

Tools Needed for Repairs

When it comes to maintaining and fixing outdoor power equipment, having the right tools is essential. A well-equipped toolkit not only makes the process smoother but also ensures that repairs are performed efficiently and effectively. Proper tools help in diagnosing issues, replacing worn components, and fine-tuning machinery for optimal performance.

Essential Hand Tools

Basic hand tools are the foundation of any repair job. Items such as screwdrivers, wrenches, and pliers are crucial for loosening and tightening various parts. A set of metric and imperial sizes will ensure compatibility with different fasteners. Additionally, a reliable torque wrench is important for achieving the correct tension on screws and bolts.

Specialized Equipment

In addition to standard hand tools, some specialized equipment may be necessary for more intricate repairs. A chain brake tool and a spark plug wrench are often required for engine maintenance. Furthermore, having a workbench with a vise can provide stability when working on larger components, making tasks more manageable and precise.

Assembly Instructions for Beginners

Assembling tools and equipment can be a rewarding experience, especially for those new to the process. Understanding the various components and their functions is crucial to ensure proper setup and operation. This guide will provide step-by-step instructions to help beginners navigate the assembly process with confidence.

Before starting, gather all necessary materials and tools. This preparation will help streamline the process and prevent any interruptions.

- Check the inventory: Ensure that all components are present.

- Read the manual: Familiarize yourself with the instructions and safety precautions.

- Gather tools: Have the required tools ready, such as screwdrivers, wrenches, and pliers.

Follow these steps for a smooth assembly:

- Identify Components: Lay out all parts and identify their functions.

- Start with the Base: Begin by assembling the base or main body as specified in the manual.

- Attach Additional Parts: Gradually add components, ensuring each is securely fastened.

- Double-Check Connections: Review all connections for tightness and accuracy.

- Final Inspection: Conduct a thorough inspection to ensure everything is in place.

Following these simple instructions will help ensure a successful assembly. Remember to take your time and refer back to the manual as needed. Happy assembling!

Identifying Genuine Stihl Parts

When it comes to maintaining outdoor power equipment, ensuring the use of authentic components is crucial for optimal performance and longevity. Recognizing the differences between original and counterfeit items can significantly impact the efficiency and reliability of your machine.

One of the primary indicators of authenticity is the packaging. Genuine components are typically packaged in a branded box with clear labeling, including part numbers and manufacturer information. Always examine the quality of the packaging for signs of tampering or poor craftsmanship.

Another important aspect is the appearance of the item itself. Authentic components usually have a superior finish, precise dimensions, and fit perfectly without requiring modifications. In contrast, imitation parts may have rough edges, uneven surfaces, or discrepancies in size.

Moreover, purchasing from reputable dealers is essential. Authorized retailers often provide warranties or guarantees, ensuring that you are getting genuine products. If you encounter significantly lower prices from unfamiliar sources, it’s a red flag.

Lastly, consult the manufacturer’s resources for verification. Many brands offer online tools to help identify original items, allowing you to cross-reference part numbers and specifications. By taking these precautions, you can safeguard your equipment and maintain its performance effectively.

User Manual Insights

This section offers valuable perspectives on the operational guide for a popular model of power equipment. Understanding the nuances of the manual can enhance the user experience, ensuring safe and efficient use. Key insights will focus on maintenance recommendations, operational tips, and troubleshooting advice that every owner should be familiar with.

Maintenance Recommendations

Regular upkeep is essential for optimal performance. The manual emphasizes the importance of routine inspections and cleaning to prevent wear and tear. Oil levels, filter cleanliness, and chain tension are critical aspects to monitor frequently. Following these guidelines can extend the lifespan of the machine significantly.

Operational Tips

To maximize efficiency, the guide provides instructions on proper handling techniques and safety measures. Correct posture and gripping methods can greatly influence user safety and equipment control. Additionally, understanding the ideal conditions for use, such as temperature and material types, can improve results and reduce strain on the device.

FAQs About MS250 Parts Replacement

Replacing components in your equipment can be a daunting task, especially for those unfamiliar with the process. This section addresses common inquiries related to the replacement of various elements, providing clarity and guidance to ensure a smooth experience for users.

| Question | Answer |

|---|---|

| How do I know when to replace a component? | Look for signs of wear, such as decreased performance, unusual noises, or visible damage. Regular maintenance checks can help identify issues early. |

| Can I use aftermarket components? | Aftermarket options can be viable, but ensure they meet quality standards to avoid compromising performance or safety. |

| What tools do I need for replacement? | Basic tools include screwdrivers, wrenches, and pliers. Specific replacements may require specialized tools, so consult the manual for guidance. |

| Is it difficult to replace components myself? | With proper instructions and some mechanical aptitude, many users find replacements manageable. Detailed guides and tutorials are widely available. |

| How can I ensure the replacement lasts? | Follow maintenance guidelines, use quality components, and ensure proper installation to extend the life of the new parts. |