Understanding the Stihl MS251C Parts Diagram for Efficient Maintenance

When working with a cutting tool, having a clear grasp of its internal structure and essential elements is crucial for maintenance and effective operation. Familiarizing oneself with the various components ensures longevity and efficiency in performance.

Knowledge of each piece enhances troubleshooting and repair processes, allowing users to identify issues quickly. With a comprehensive breakdown, one can easily navigate the intricate network of parts that make up this powerful machine.

Moreover, understanding how each element interacts contributes to better handling and operational safety. By delving into the specifics, operators can achieve the ultimate balance between performance and reliability, maximizing their investment in the tool.

Understanding Stihl MS251C Components

Every power tool is a marvel of engineering, composed of various essential elements that work in harmony to achieve optimal performance. Familiarizing oneself with these individual components can greatly enhance the user experience and maintenance practices, ensuring longevity and efficiency.

Among the critical segments of this machine are the engine, which serves as the heart, providing the necessary power for operation. The fuel system is equally vital, delivering the mixture required for combustion and sustaining the engine’s functionality. Additionally, the cutting mechanism, designed for precision, allows for clean and effective operation, making it indispensable for any task.

Moreover, the safety features incorporated into the design play a crucial role in protecting the user. These elements not only enhance usability but also ensure that the tool can be handled with confidence. Understanding these components and their interrelations empowers users to make informed decisions regarding maintenance and repairs, ultimately leading to a more satisfying experience.

In conclusion, gaining insights into the various parts of this tool helps users appreciate its sophisticated design and functionality. By recognizing how each component contributes to the overall performance, one can ensure effective operation and care.

Importance of Parts Diagrams

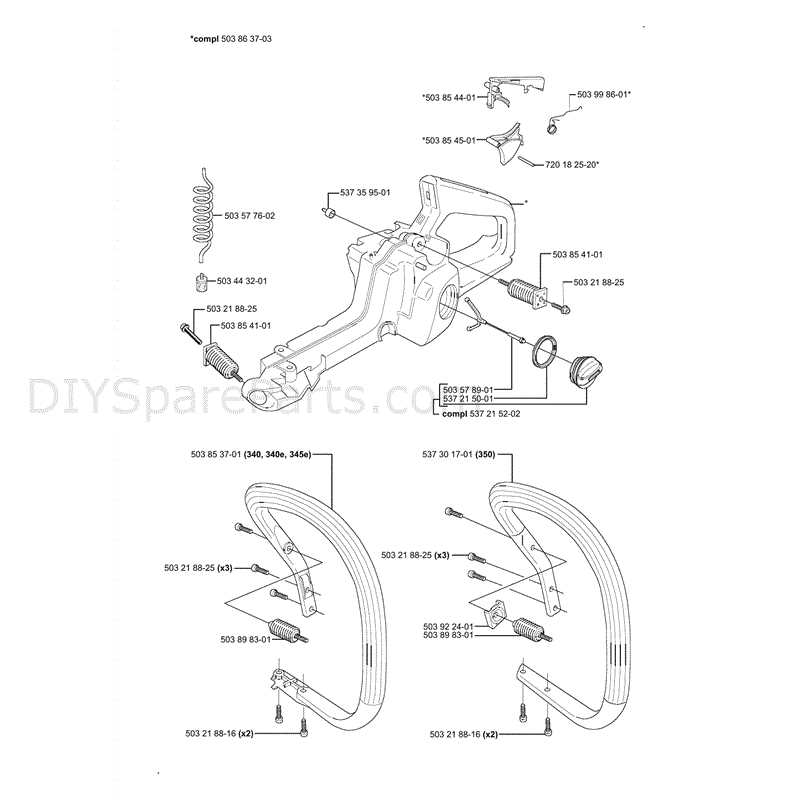

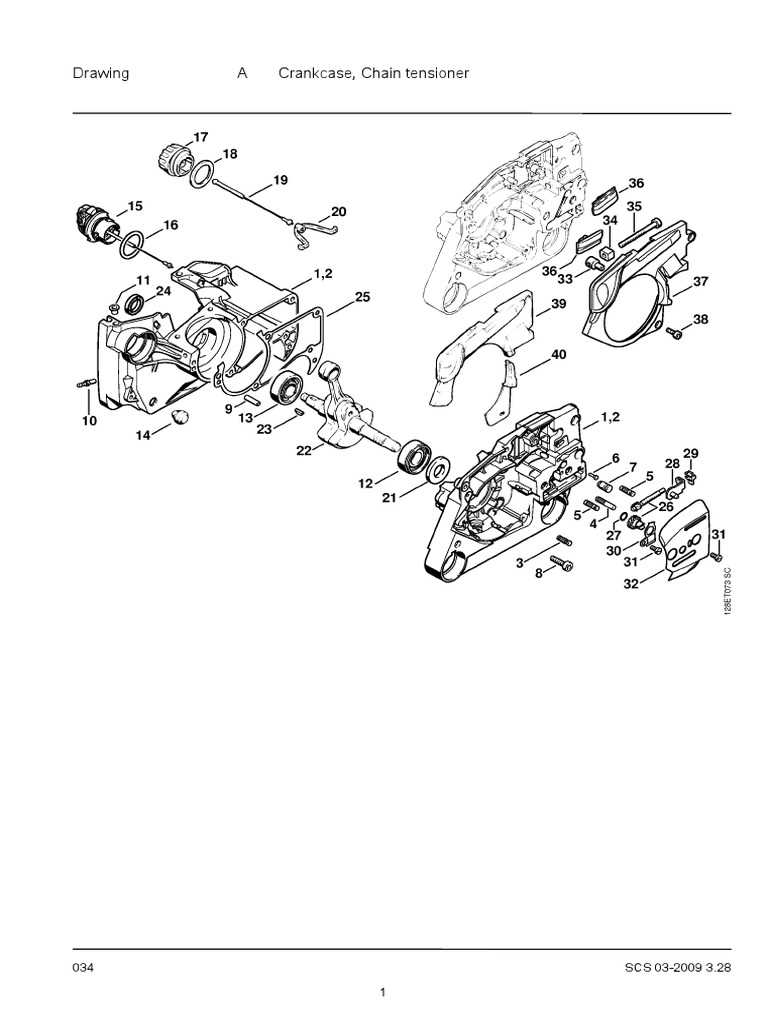

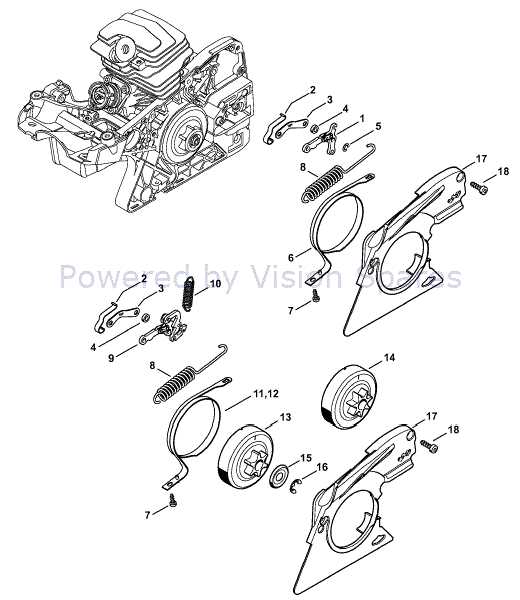

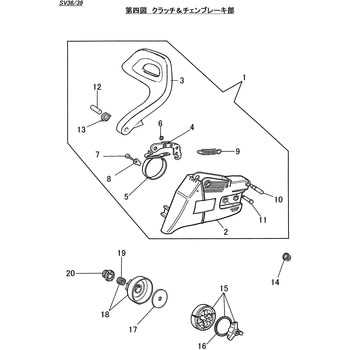

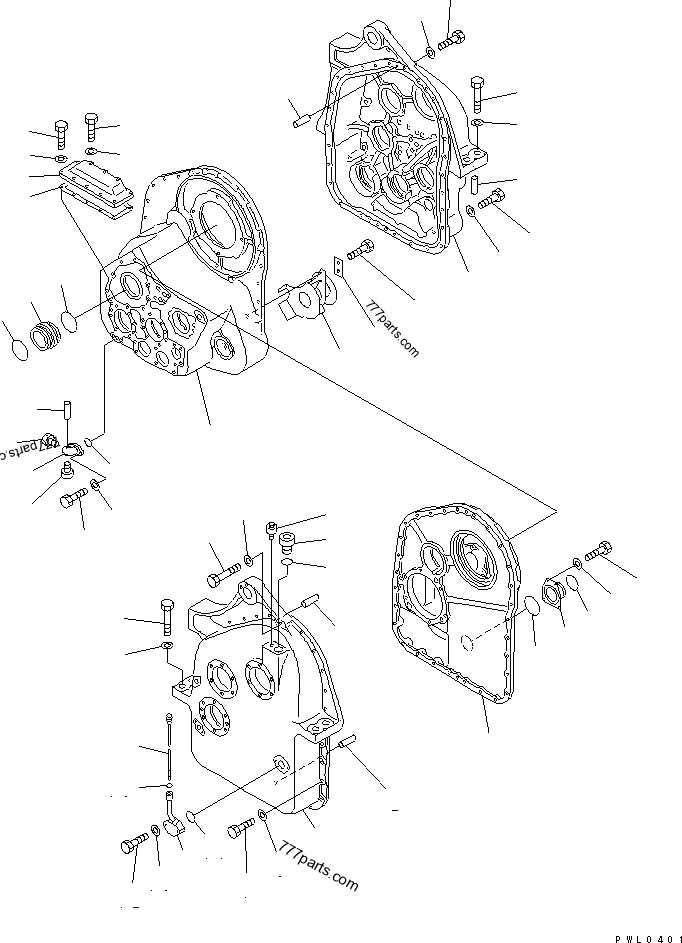

Visual representations of components play a crucial role in understanding and maintaining machinery. They provide a clear overview of the individual elements, aiding both technicians and users in various tasks, from assembly to repairs.

Utilizing these visual guides offers several advantages:

- Enhanced Understanding: Visual aids simplify complex systems, allowing users to grasp the function and placement of each component more easily.

- Efficient Troubleshooting: Identifying issues becomes more straightforward, as users can quickly locate parts that may be malfunctioning.

- Streamlined Maintenance: Regular upkeep is facilitated by knowing which elements require attention and when.

- Time-Saving: Having a visual reference can significantly reduce the time spent searching for specific components during repairs.

Moreover, these illustrations can serve as valuable training tools, helping newcomers learn the intricacies of the equipment. Overall, they enhance the overall user experience and contribute to the longevity of the machinery.

Key Features of Stihl MS251C

This powerful tool is designed for efficiency and ease of use, making it ideal for various tasks. Its standout characteristics ensure optimal performance and user satisfaction.

- Engine Performance: Equipped with a robust engine that delivers reliable power for cutting and trimming.

- Weight Efficiency: Lightweight design enhances maneuverability and reduces user fatigue.

- Ergonomic Handle: Comfort-focused grip allows for extended use without strain.

- Easy Start Technology: Simplifies the starting process, making it accessible for all users.

- Fuel Efficiency: Designed for reduced fuel consumption, promoting sustainability.

These features combine to create a tool that meets the demands of both professional and casual users, enhancing productivity and effectiveness.

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair. These visual representations provide crucial information about the components of a machine, helping users identify, order, and replace items accurately. Familiarizing yourself with how to interpret these visuals can enhance your overall experience with the equipment.

Key Elements to Note

- Labels: Each component is typically labeled with a reference number or letter, corresponding to a list of parts.

- Groupings: Components are often grouped by function or assembly, making it easier to locate parts related to a specific task.

- Orientation: Pay attention to the orientation of the illustration, as it may depict the assembly from a particular angle.

Steps for Effective Interpretation

- Start by identifying the main components outlined in the visual.

- Cross-reference the labels with the accompanying list to find specific details.

- Take note of the arrangement of parts, as this can indicate how they fit together.

- If available, consult additional documentation for assembly instructions or troubleshooting tips.

Common Replacement Parts Explained

When it comes to maintaining outdoor power equipment, understanding the various components that may require replacement is essential. This knowledge helps ensure optimal performance and longevity of the machinery. In this section, we will explore some frequently replaced items that play a critical role in the functionality of these devices.

Engine Components

The engine is the heart of any power tool, and several key elements may need attention over time. Spark plugs are crucial for ignition and may degrade, leading to starting issues. Additionally, air filters prevent debris from entering the engine, and regular replacement is necessary to maintain efficiency. Fuel filters also require periodic changes to ensure that the fuel system remains clean and unobstructed.

Cutting Accessories

Cutting tools, such as chains and blades, are essential for effective operation. Chains may wear out due to constant friction and should be replaced when they show signs of damage. Similarly, blades can become dull or nicked, impacting cutting performance. Regular inspection and timely replacement of these components are vital to achieving the best results during operation.

Maintenance Tips for Longevity

Ensuring the longevity of your equipment requires consistent care and attention. Regular maintenance not only enhances performance but also prevents unexpected breakdowns. By following a few essential practices, you can significantly extend the lifespan of your tools.

Regular Cleaning

After each use, it’s crucial to clean the exterior and interior components. Remove debris and buildup to maintain optimal function. This simple step can prevent wear and tear and promote smoother operation.

Lubrication and Inspection

Frequent lubrication of moving parts is essential for reducing friction and enhancing efficiency. Additionally, inspect components regularly for signs of damage or wear. Timely replacements can prevent more extensive issues down the line.

Where to Find Genuine Parts

Locating authentic components for your equipment is crucial for maintaining its performance and longevity. Ensuring you use original replacements helps avoid compatibility issues and enhances reliability. There are several trusted sources where you can acquire these essential items.

One of the best options is the official retailer, where you can browse a comprehensive selection of verified items. Online marketplaces also offer a variety of choices, but it’s important to verify the seller’s reputation and the authenticity of the products. Local authorized dealers can provide personalized assistance and advice on the right components for your machinery. Additionally, manufacturers often have dedicated websites that list approved distributors.

Identifying Troublesome Components

Understanding the common issues that arise within machinery can significantly enhance maintenance and performance. Identifying the components that frequently cause trouble allows users to address problems before they escalate, ensuring smoother operation and longevity of the equipment.

Common Indicators of Failure

Many users may notice certain signs indicating that specific elements are not functioning optimally. These may include unusual noises, decreased efficiency, or difficulty in starting the machine. By paying attention to these symptoms, one can pinpoint which parts might require inspection or replacement.

Critical Areas to Inspect

Focus should be directed towards key areas that are often susceptible to wear and tear. Filters, spark plugs, and fuel lines are examples of components that can significantly affect performance if not regularly maintained. Regular checks in these areas can prevent minor issues from developing into major failures.

Tools Needed for Repairs

When undertaking maintenance or restoration tasks on outdoor power equipment, having the right instruments is crucial for efficiency and effectiveness. Each repair job may demand a specific set of tools that can help ensure precision and safety throughout the process.

Basic Hand Tools are essential for any repair work. These typically include screwdrivers, wrenches, and pliers. A good set of these tools will allow you to easily remove and secure components.

Specialized Equipment may also be necessary, depending on the complexity of the repair. For instance, torque wrenches and compression gauges can assist in making sure that parts are fitted correctly and function optimally.

Additionally, protective gear such as gloves and safety goggles should not be overlooked. Working with machinery can pose risks, so it’s important to prioritize personal safety while handling tools and components.

Lastly, having a reliable work surface and proper lighting will enhance your repair experience, making it easier to focus and ensuring that all tasks are performed efficiently.

Comparing MS251C with Other Models

This section explores the differences and similarities between a specific model and other comparable units in the same category. Understanding these variations can help users make informed choices based on their needs, whether for professional use or casual tasks. Key aspects such as power, weight, features, and ergonomics will be evaluated to provide a comprehensive overview.

Power and Performance

When assessing the performance of different chainsaws, engine capacity and power output are critical factors. The highlighted model typically features a robust engine that delivers ample power for various cutting tasks. In contrast, some alternative models may offer lighter engines, prioritizing ease of handling over sheer power, which can be advantageous for users who require extended operation without fatigue.

Weight and Design

Weight and design play significant roles in user experience, particularly for those using the equipment for prolonged periods. The model in question strikes a balance between durability and manageability, making it suitable for a wide range of users. Comparatively, some other options might lean towards being heavier and more robust, designed for heavy-duty applications, while others may focus on being lightweight and compact, enhancing portability for occasional use.

FAQs About Parts Diagrams

Understanding the intricacies of machinery can often feel daunting, especially when it comes to identifying components and their functions. This section aims to clarify common inquiries regarding visual representations that illustrate various elements of equipment, aiding users in effective maintenance and repair.

What is the purpose of these visual representations?

These illustrations serve as essential guides, helping users locate and identify individual components, facilitating troubleshooting and repairs.

How can I find the correct illustration for my equipment?

Most manufacturers provide resources online, allowing users to access specific visuals by entering the model number or type of machinery.

Are these guides helpful for beginners?

Absolutely! They simplify the understanding of complex machinery, making it easier for novice users to engage in maintenance tasks.

What if I can’t find a specific part in the illustration?

If a particular component is not listed, consulting customer service or local dealers can provide additional support and information.

Can I use these resources for older models?

Many manufacturers archive past models, so it’s often possible to find illustrations for older equipment, although availability may vary.

How do I interpret the information in these visuals?

Familiarizing yourself with the symbols and numbering conventions used in these guides will enhance your understanding, allowing for efficient identification and replacement of parts.