Understanding the Stihl MS290 Chainsaw Parts Diagram

The intricate design of a power saw encompasses various elements that work in harmony to ensure optimal performance. Each component plays a crucial role in the overall functionality, making it essential for users to comprehend how these parts interact. This knowledge not only aids in effective operation but also empowers individuals to troubleshoot issues when they arise.

For those looking to maintain or repair their equipment, having a clear visual representation of the various sections can be invaluable. This guide delves into the specifics of each component, outlining their positions and functions within the machinery. Understanding these details fosters a deeper appreciation for the engineering behind these powerful tools.

By familiarizing oneself with the assembly and layout of the equipment, users can enhance their skills and confidence when tackling maintenance tasks. Whether you are a seasoned professional or a hobbyist, grasping the organization of these crucial elements can significantly improve your experience and outcomes.

Understanding Stihl MS290 Chainsaw Parts

Grasping the components of this powerful cutting tool is essential for effective maintenance and operation. Each segment plays a vital role in ensuring optimal performance and longevity.

- Engine: The heart of the device, responsible for power generation.

- Bar: The elongated metal piece that guides the cutting chain.

- Chain: A series of sharp links designed for cutting through wood.

- Clutch: Engages and disengages the chain from the engine.

- Handle: Provides grip and control during operation.

Understanding how these components interact is crucial for troubleshooting and enhancing functionality.

- Regular inspections can prevent unexpected failures.

- Knowing each element helps in identifying wear and tear.

- Replacement of worn components ensures safety and efficiency.

By delving into these features, users can achieve the ultimate performance from their equipment.

Overview of Chainsaw Components

This section explores the essential elements that make up a cutting tool designed for efficient wood processing. Understanding these components is crucial for optimal performance and maintenance.

Key Elements

The main components include the engine, cutting mechanism, and safety features. Each part plays a vital role in the overall functionality, ensuring smooth operation and user safety.

Maintenance Considerations

Regular upkeep of these elements enhances durability and efficiency. Attention to details, such as lubrication and wear, can significantly impact the longevity of the equipment.

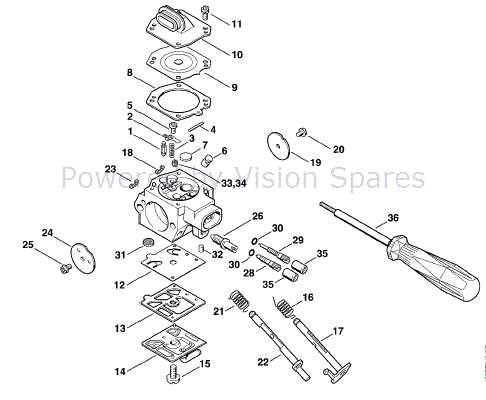

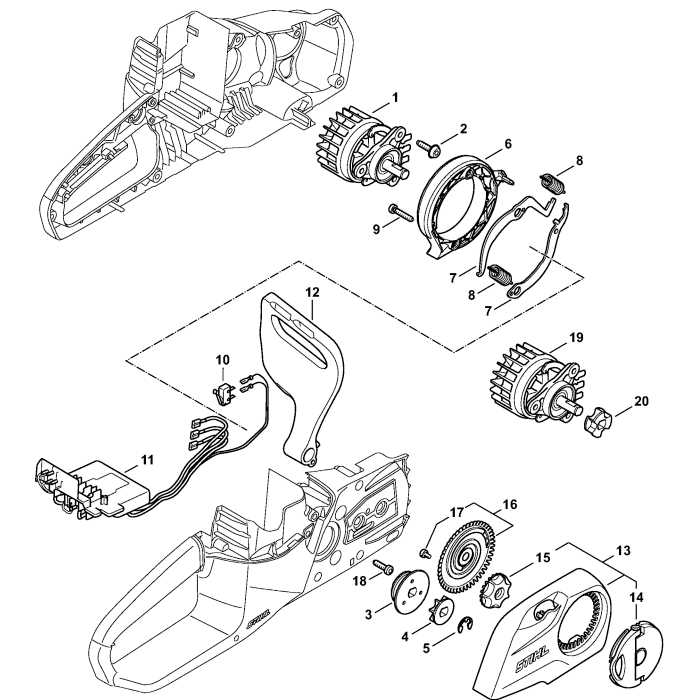

Importance of a Parts Diagram

An effective illustration of components is crucial for anyone looking to maintain or repair equipment. It provides a visual representation that enhances understanding of how individual pieces fit together and function within the larger system. This clarity aids both novice and experienced users in troubleshooting and ensuring proper assembly.

Moreover, having access to such an illustration can save time and reduce frustration when addressing issues. Users can quickly identify necessary replacements and understand the relationships between different elements. This not only streamlines the repair process but also promotes the longevity of the equipment.

Ultimately, a well-organized visual guide serves as an invaluable resource, empowering users to take control of their maintenance tasks with confidence.

How to Read the Diagram

Understanding an assembly illustration is crucial for anyone looking to maintain or repair their equipment effectively. This visual representation simplifies complex mechanisms, allowing users to identify various components and their relationships. By familiarizing yourself with the layout and symbols, you can enhance your repair skills and ensure that each part is correctly reassembled.

Identifying Components

Each item in the illustration is labeled, usually with numbers or letters that correspond to a parts list. Begin by locating the main components, such as the engine and housing, then follow the lines and arrows that indicate how parts connect. This will provide clarity on how everything fits together, making it easier to spot any missing or damaged pieces.

Understanding the Connections

Pay attention to the lines and notations that describe how components interact. Solid lines typically indicate direct connections, while dotted lines may suggest additional pathways or optional elements. Familiarizing yourself with these conventions will help you comprehend the overall functionality, enabling more efficient repairs or upgrades.

Common Parts in Stihl MS290

This section explores the essential components found in a popular cutting tool, highlighting their functions and significance. Understanding these elements is crucial for maintenance and effective operation.

| Component | Description |

|---|---|

| Engine | The heart of the tool, providing the necessary power for operation. |

| Guide Bar | Serves as a track for the cutting chain, enabling precise cuts. |

| Chain | Designed for cutting through wood, it moves around the guide bar during operation. |

| Air Filter | Prevents debris from entering the engine, ensuring efficient performance. |

| Fuel Tank | Holds the mixture of fuel and oil necessary for operation. |

| Oil Pump | Distributes oil to the chain for lubrication, enhancing durability. |

| Starter Mechanism | Facilitates the ignition process, allowing for easy starting of the device. |

Where to Find Replacement Parts

Finding the right components for your outdoor equipment can significantly enhance its performance and longevity. Knowing where to look ensures you get quality items that fit your specific model.

Online Retailers

- Specialized e-commerce platforms

- Manufacturer’s official websites

- General marketplaces with a wide selection

Local Stores

- Authorized dealers and service centers

- Hardware stores with dedicated sections

- Second-hand shops for budget-friendly options

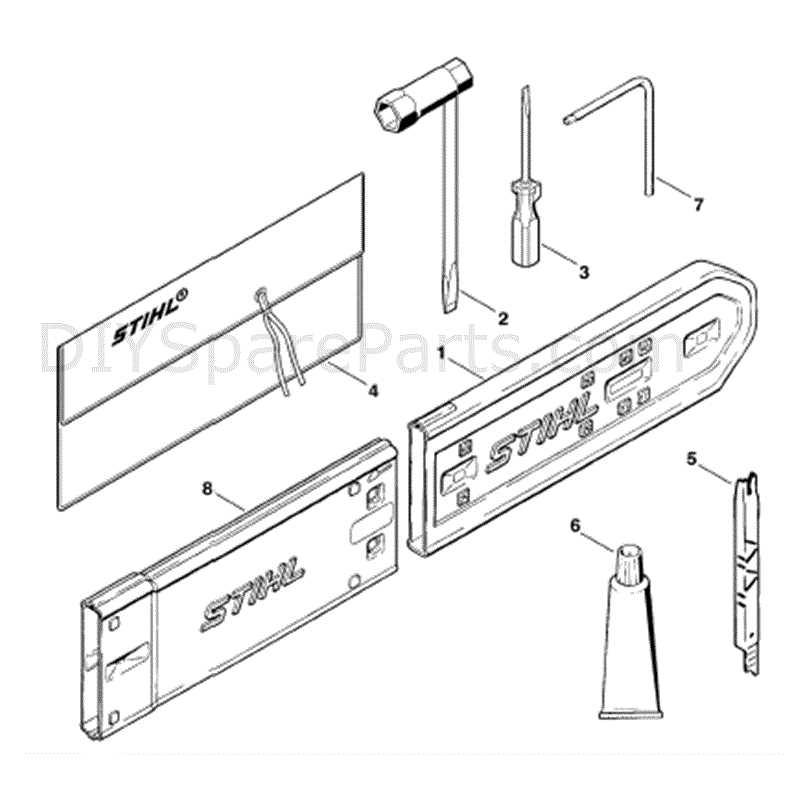

Tools Needed for Maintenance

Regular upkeep of your equipment ensures optimal performance and longevity. Having the right tools is essential for effective maintenance, allowing you to address issues promptly and efficiently.

- Wrench Set: For tightening or loosening various components.

- Screwdriver Set: Necessary for adjusting screws and fittings.

- Cleaning Brushes: To remove debris and keep surfaces clear.

- Fuel Mix Container: For preparing the appropriate fuel blend.

- Protective Gear: Including gloves and goggles for safety during maintenance.

Gathering these items will equip you for thorough inspections and repairs, ultimately enhancing the performance of your equipment.

Step-by-Step Disassembly Guide

This section aims to provide a comprehensive procedure for dismantling the equipment safely and efficiently. Following these steps will ensure that each component is handled with care, facilitating an effective reassembly process later.

Required Tools

| Tool | Purpose |

|---|---|

| Screwdriver Set | To remove screws and fasteners |

| Wrench | For loosening nuts and bolts |

| Pliers | To grip and pull components |

| Safety Goggles | To protect eyes during disassembly |

Disassembly Steps

Begin by ensuring the machine is powered off and unplugged. Remove any outer casing, followed by detaching the fuel and oil tanks. Carefully unscrew and extract internal components, taking note of their arrangement for easier reassembly. Document each step with notes or photos to aid the process later.

Reassembling Your Chainsaw Correctly

Putting your equipment back together can be a meticulous process, requiring attention to detail to ensure optimal performance and safety. Following a structured approach can make this task easier and more efficient.

- Gather all components and tools needed for assembly.

- Refer to the original manual or schematic for guidance.

- Begin with the base unit, securing any necessary brackets or supports.

- Carefully position and attach the engine parts, ensuring proper alignment.

- Install the cutting mechanism, checking for smooth movement.

- Reattach any housing or protective covers, making sure they fit snugly.

After reassembly, perform a thorough inspection and run a preliminary test to confirm everything is functioning as intended. Regular maintenance checks will help prolong the lifespan of your equipment.

Troubleshooting Common Issues

When operating power tools, occasional problems may arise that can hinder performance. Identifying and resolving these issues promptly can ensure the longevity of the equipment and maintain its efficiency. This section will guide you through typical challenges encountered during usage, along with practical solutions to restore optimal functionality.

One prevalent issue is difficulty starting the machine. This can often be attributed to fuel-related problems, such as old or contaminated fuel. Checking and replacing the fuel with a fresh mixture can often resolve this. Additionally, inspect the spark plug for wear or damage, as this component plays a critical role in ignition.

If the device starts but runs inconsistently, it may be suffering from air or fuel flow obstructions. Ensuring that the air filter is clean and unobstructed can help maintain proper airflow. Likewise, examining the fuel filter for clogs can prevent fuel starvation, leading to smoother operation.

Excessive vibration during use may indicate loose components or an unbalanced cutting attachment. Regularly tightening screws and bolts can help mitigate this issue. If the cutting tool is damaged or dull, replacing it can enhance performance and reduce vibrations.

Finally, if the equipment is emitting excessive smoke, it might be a sign of improper fuel mixing or overheating. Checking the oil-to-fuel ratio is essential, as is allowing the engine to cool down periodically during extended use. Addressing these problems promptly can significantly improve overall performance and safety.

Tips for Regular Maintenance

Maintaining your cutting tool is essential for optimal performance and longevity. Regular upkeep not only ensures safety but also enhances efficiency during use. By incorporating simple practices into your routine, you can keep your equipment in prime condition.

1. Clean After Each Use: Always remove debris and residue after operation. This prevents buildup and corrosion, which can affect functionality.

2. Check and Replace the Blade: Regularly inspect the cutting element for dullness or damage. A sharp blade makes work easier and safer.

3. Lubricate Moving Parts: Ensure that all moving components are adequately lubricated to reduce friction and wear over time.

4. Inspect Fuel System: Regularly check the fuel mixture and filters. A clean fuel system helps maintain performance and reduces the risk of clogging.

5. Store Properly: Always store your equipment in a dry, cool place. Proper storage helps prevent rust and other forms of deterioration.

6. Follow Manufacturer Guidelines: Always refer to the user manual for specific maintenance instructions tailored to your tool.

Implementing these practices will ensure your equipment remains reliable and effective for years to come.

Resources for Further Learning

Expanding your knowledge about maintenance and repair techniques is essential for anyone looking to enhance their skills in handling outdoor power equipment. Numerous resources are available that offer insights into the intricacies of various models, troubleshooting methods, and best practices for ensuring longevity and optimal performance.

Books and Manuals

Printed materials can provide in-depth guidance and are invaluable for both beginners and seasoned users. Consider the following resources:

| Title | Author | Publication Year |

|---|---|---|

| The Outdoor Equipment Handbook | John Smith | 2019 |

| Maintenance Basics for Power Tools | Jane Doe | 2021 |

| Advanced Repair Techniques | Emily Johnson | 2020 |

Online Resources

Websites and forums dedicated to outdoor equipment are great places to find tutorials, videos, and community advice. Some reputable sites include:

- Outdoor Equipment Forums

- Video Tutorial Platforms

- Manufacturer’s Official Websites

Utilizing these resources will enhance your understanding and skills, leading to more efficient and effective equipment handling.