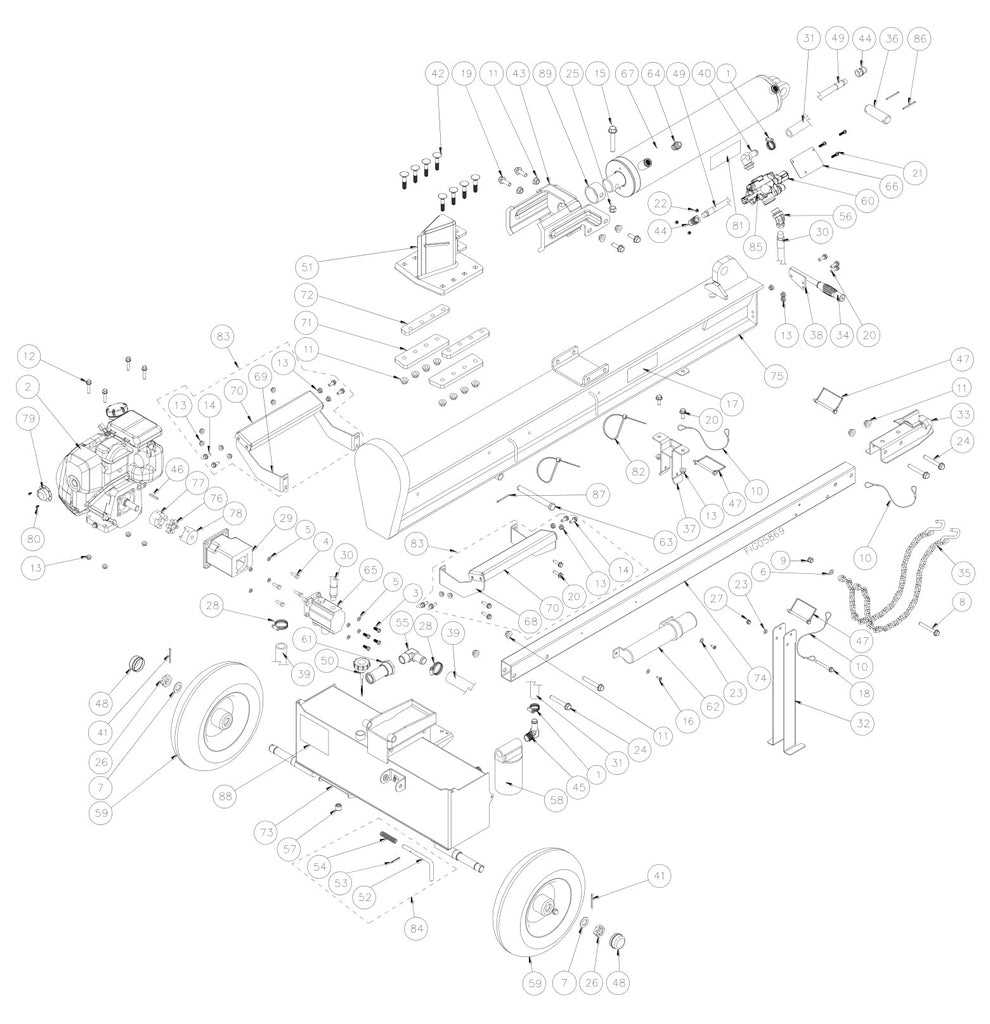

Stihl Power Broom Components Overview

This section provides a detailed look into the essential elements of a specific outdoor maintenance tool. Understanding the arrangement and function of each component is crucial for effective operation and maintenance. Whether you’re a novice or an experienced user, familiarizing yourself with these elements enhances your overall efficiency.

By examining the layout of the various sections, users can gain insights into how the tool functions as a whole. Each component plays a vital role in ensuring optimal performance, and recognizing their individual characteristics can lead to better handling and care.

Additionally, knowing the specifics of each part allows for easier troubleshooting and repairs. This knowledge not only extends the lifespan of the equipment but also enhances safety during use. A well-informed operator can make informed decisions, ensuring that the tool remains in peak condition.

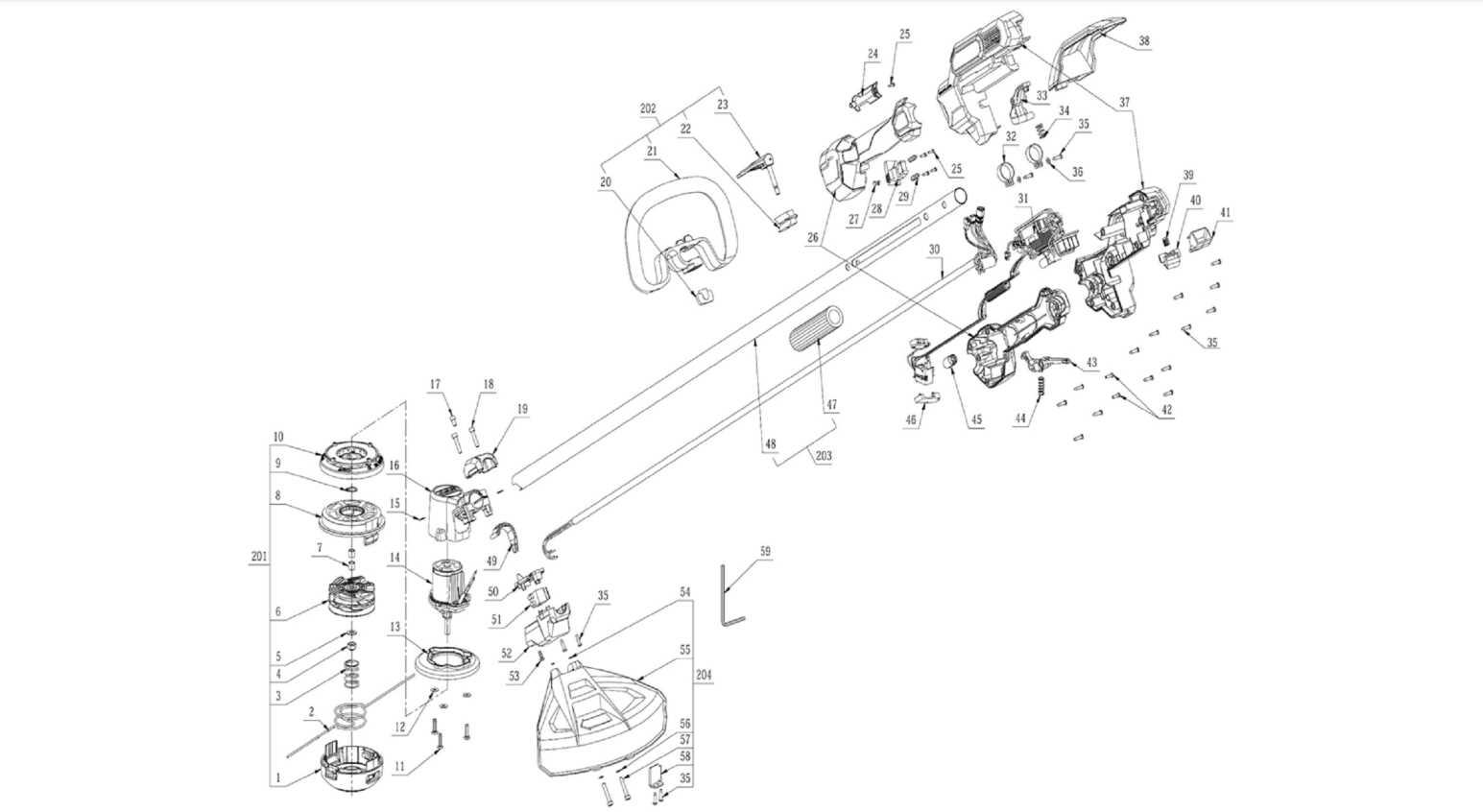

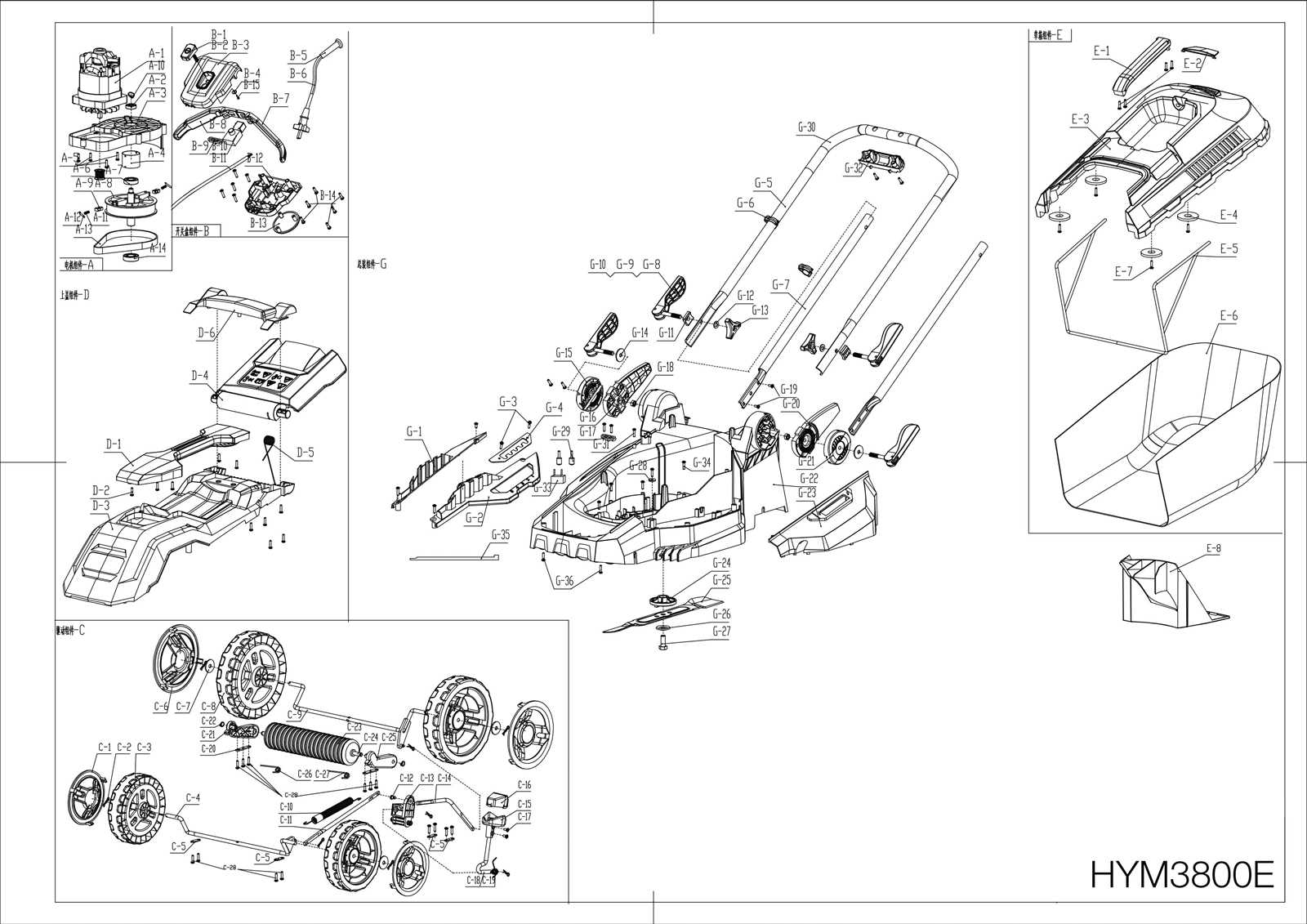

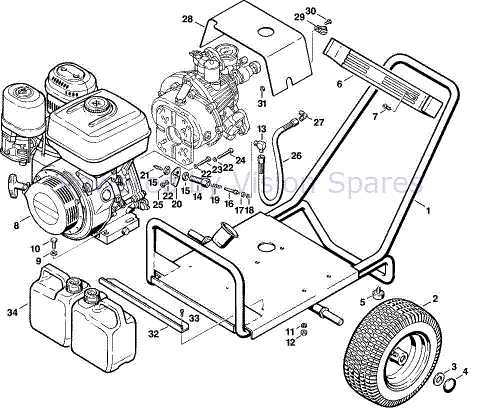

Overview of Power Broom Components

This section provides an insight into the various elements that make up the sweeping device. Understanding these components is essential for effective maintenance and operation.

| Component | Description |

|---|---|

| Engine | Powers the unit, providing the necessary force for operation. |

| Handle | Offers control and maneuverability during use. |

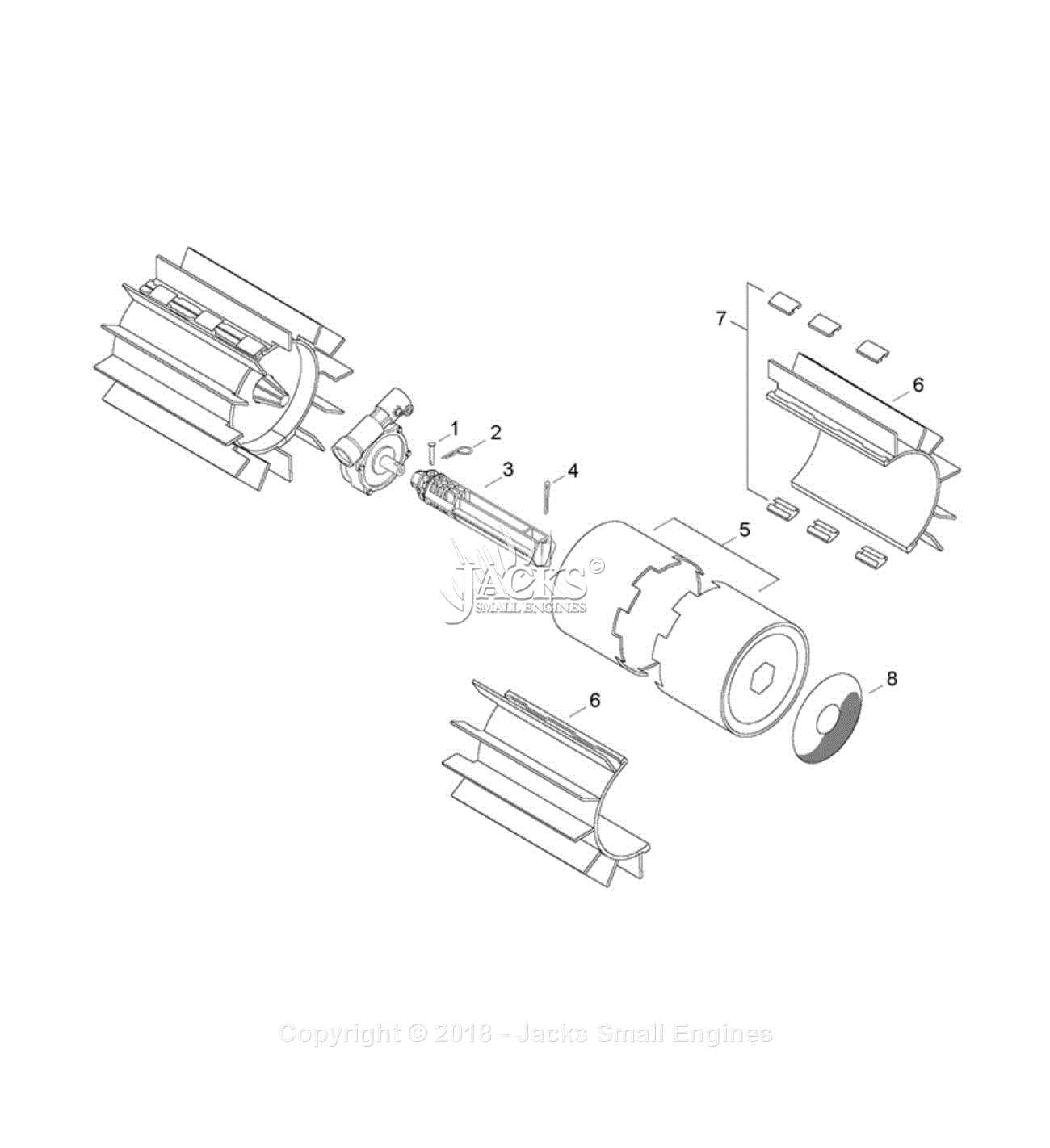

| Brush Assembly | Engages with the surface to collect debris effectively. |

| Frame | Holds all components together, ensuring stability and durability. |

| Transmission | Transmits power from the engine to the brush assembly. |

| Wheels | Facilitates movement across different terrains. |

Key Features of Power Broom

This section explores the essential attributes that enhance the functionality of a sweeping machine designed for efficient outdoor cleaning. These characteristics contribute to its effectiveness in various tasks, making it a valuable tool for both professionals and homeowners.

Versatility in Application

Adaptability to different surfaces allows the machine to be used on various terrains, from driveways to sidewalks. This flexibility makes it suitable for a wide range of cleaning needs, ensuring optimal performance in diverse environments.

Ergonomic Design

The user-friendly design promotes ease of use, reducing strain during operation. Features such as adjustable handles and lightweight construction contribute to a more comfortable experience, making it accessible for extended periods.

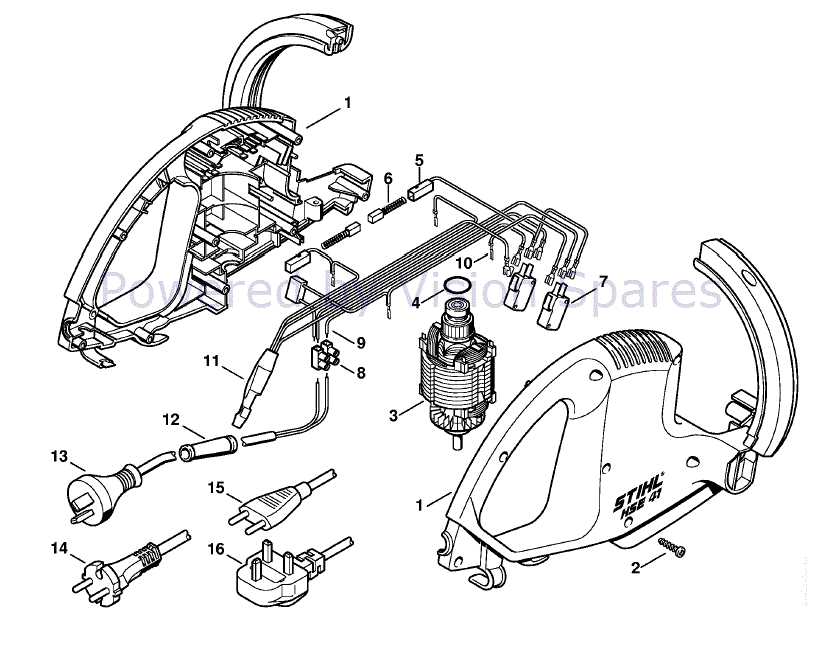

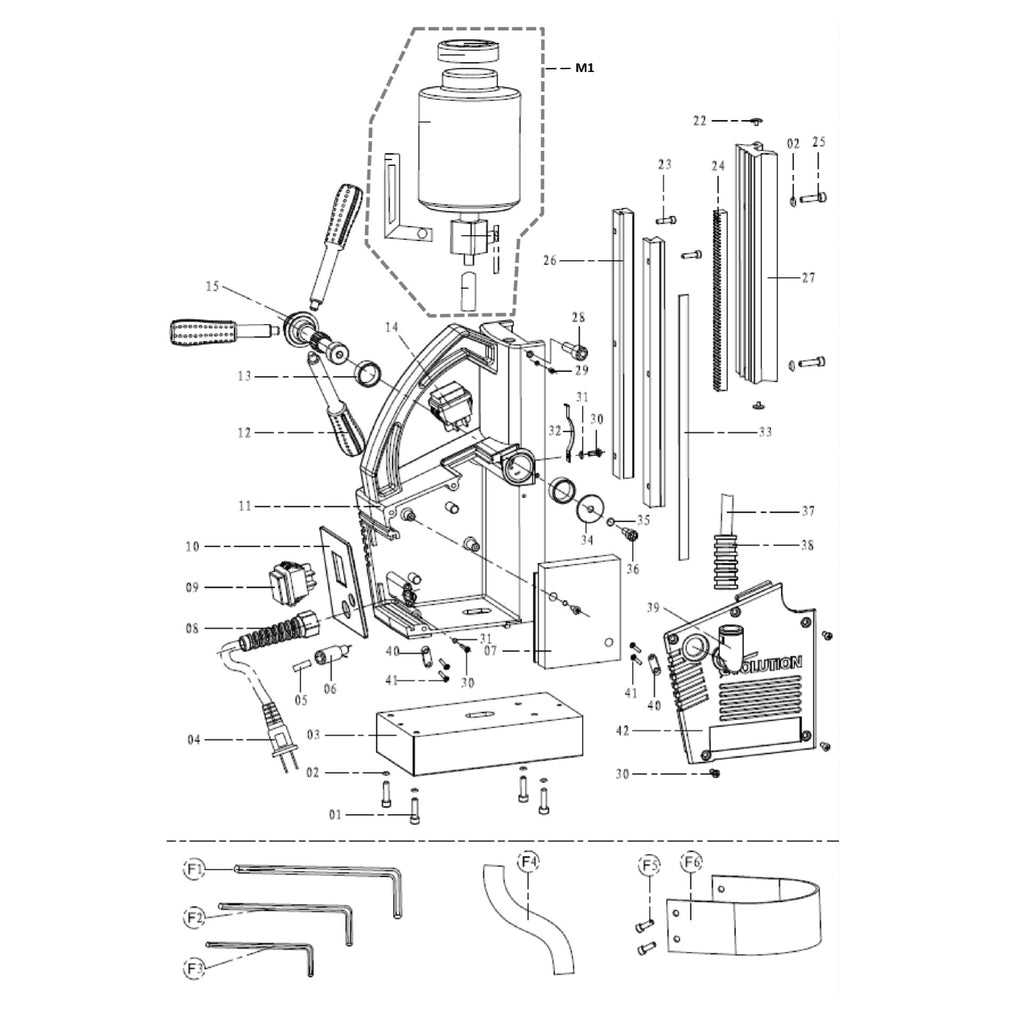

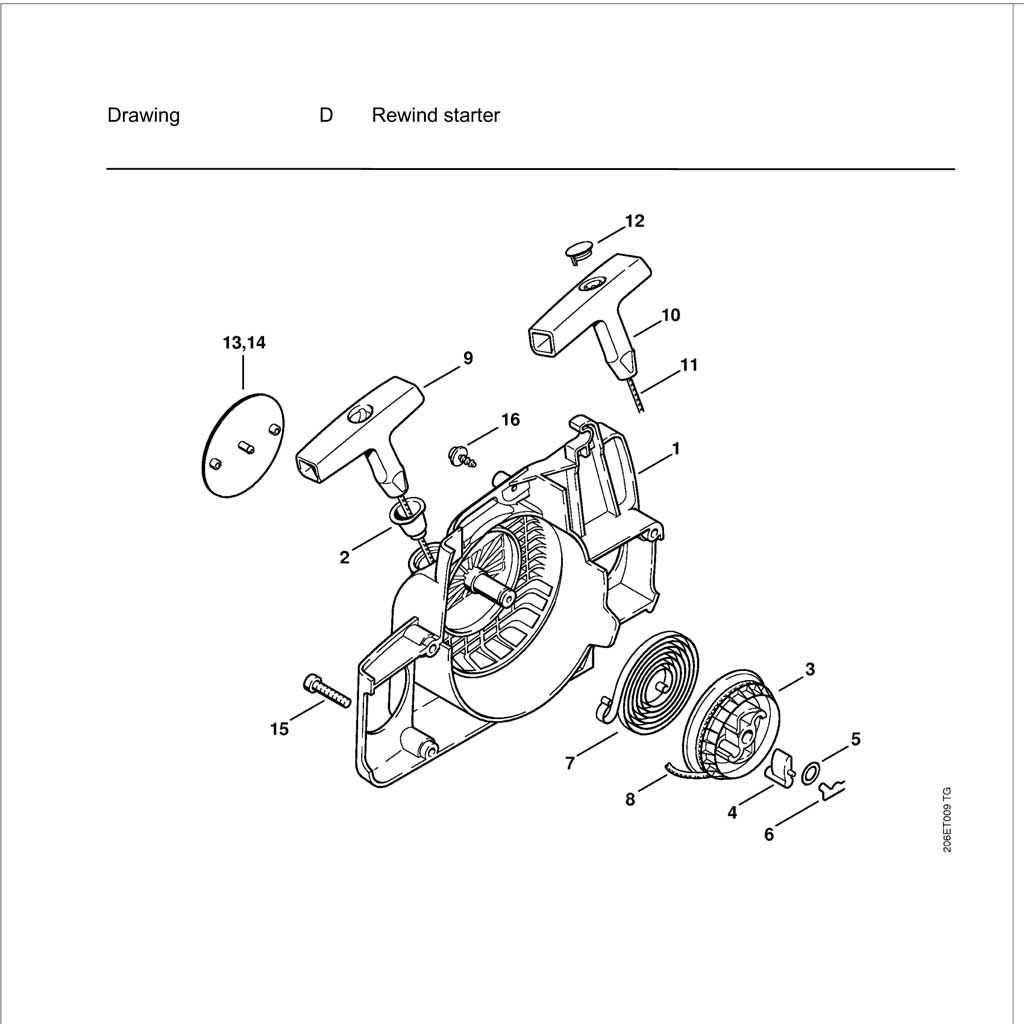

Understanding the Parts Diagram

A comprehensive visual representation of components is essential for effective maintenance and troubleshooting. This guide focuses on interpreting the layout that illustrates the various elements of the equipment.

Key benefits of familiarizing oneself with this visual representation include:

- Enhancing understanding of individual components and their functions.

- Facilitating easier identification of specific parts when performing repairs.

- Improving overall efficiency in maintenance tasks.

When analyzing the layout, consider the following:

- Each section corresponds to a specific area of the machinery.

- Connections between elements often indicate how they interact with one another.

- Color coding may be used to differentiate between various categories of components.

By grasping these aspects, users can better navigate the complexities of the equipment, leading to more effective and informed use.

Common Issues with Power Broom Parts

When utilizing outdoor cleaning equipment, various complications can arise with the components that facilitate its operation. Understanding these common challenges is essential for maintaining efficiency and prolonging the lifespan of the machine.

Wear and Tear: Over time, components may experience deterioration due to regular use. This can lead to reduced performance and the need for replacements.

Improper Assembly: Incorrect installation of components can result in malfunction or inefficiency. Ensuring that all parts are fitted correctly is crucial for optimal functionality.

Clogging: Accumulation of debris can obstruct movement, affecting the effectiveness of the equipment. Regular cleaning and maintenance can help mitigate this issue.

Noise Levels: Unusual sounds may indicate an underlying problem with components. Identifying the source of the noise is important to address potential mechanical failures.

Fluid Leaks: Leaks from various components can lead to operational issues. Regular inspections can help detect and resolve these leaks promptly.

Maintenance Tips for Power Broom

Regular upkeep is essential for optimal performance and longevity of your equipment. By following a few simple guidelines, you can ensure that it operates efficiently and effectively over time.

Begin by inspecting the components frequently for any signs of wear or damage. Replace any worn parts promptly to prevent further issues. Keep the surface clean and free from debris to avoid blockages that can hinder functionality.

Lubricate moving parts as recommended in the user manual to reduce friction and wear. Additionally, check and change fluids as necessary, ensuring all levels are within specified ranges. Properly store the equipment in a dry, protected area to prevent rust and degradation.

Lastly, refer to the manufacturer’s recommendations for seasonal maintenance tasks. Performing these actions will help maintain high performance and extend the life of your machine.

How to Replace Worn Components

Replacing worn components is essential for maintaining optimal performance and prolonging the lifespan of your equipment. Identifying which elements need attention can enhance functionality and ensure safety during operation.

Steps to Identify Worn Parts

Begin by visually inspecting the equipment for any signs of wear or damage. Common indicators include:

- Cracks or breaks in components

- Excessive wear on moving parts

- Unusual noises during operation

Replacement Procedure

Once you’ve identified the worn components, follow these steps for replacement:

| Step | Action |

|---|---|

| 1 | Disconnect the equipment from power sources. |

| 2 | Remove the damaged components using appropriate tools. |

| 3 | Install new parts, ensuring proper alignment. |

| 4 | Reconnect the equipment and test for proper function. |

Identifying Compatible Spare Parts

When it comes to maintaining outdoor cleaning equipment, understanding how to select appropriate replacement components is essential. Ensuring compatibility with your machine can enhance performance and extend its lifespan. This section will guide you through the steps to identify suitable alternatives that meet your needs.

Checking Manufacturer Specifications

Always start by reviewing the specifications provided by the manufacturer. This information typically includes model numbers and compatibility details that are crucial for selecting the correct components. By matching your equipment’s details with the manufacturer’s guidelines, you can make informed decisions.

Consulting User Manuals and Online Resources

Another effective method is to consult user manuals or reliable online platforms. Many manufacturers provide digital resources that outline compatible replacements and installation instructions. Utilizing these resources can save time and reduce the risk of purchasing unsuitable items.

Tools Required for Repairs

When undertaking maintenance or fixing issues with outdoor cleaning equipment, having the right tools is essential for ensuring effective repairs. A well-equipped toolbox not only simplifies the process but also enhances the quality of the work performed.

Essential Hand Tools

Basic hand tools such as wrenches, screwdrivers, and pliers are vital for disassembling components and accessing internal mechanisms. A set of metric and imperial sizes will cover various fasteners, ensuring compatibility with different equipment models.

Specialized Equipment

In addition to standard tools, specialized equipment like torque wrenches and diagnostic testers can greatly aid in the repair process. These tools allow for precise adjustments and accurate troubleshooting, helping to maintain optimal performance.

Safety Precautions During Maintenance

Ensuring safety during upkeep activities is essential to prevent accidents and injuries. Proper preparation and awareness can significantly reduce risks while working with equipment. Adhering to guidelines is crucial for a secure maintenance process.

Preparation Before Maintenance

- Wear appropriate personal protective equipment, including gloves and goggles.

- Ensure the area is well-lit and free of obstacles.

- Read the manufacturer’s manual for specific safety instructions.

During Maintenance Procedures

- Disconnect the power source to avoid accidental activation.

- Keep tools organized and within reach to prevent unnecessary movements.

- Maintain a clean workspace to minimize hazards.

Assembly Instructions for Power Broom

This section provides guidance on the assembly process for the sweeping device. Following these instructions will ensure that all components are correctly fitted, allowing for optimal performance during use.

Begin by laying out all components on a flat surface. Identify each piece and refer to the provided schematic to understand how they interconnect. Start with the main frame, ensuring it is stable and secure.

Next, attach the handle, making sure it is firmly locked in place. Check for any adjustments needed to align it properly. After securing the handle, proceed to install the bristle attachment, ensuring that it is evenly spaced and tightly affixed.

Finally, double-check all connections and fastenings. Conduct a thorough inspection to confirm that everything is assembled according to the outlined specifications, ensuring safety and efficiency in operation.

Where to Buy Replacement Parts

Finding the right components for your equipment can be crucial for maintaining its performance and longevity. Several options are available for sourcing these essential elements, each with its advantages and considerations.

| Source | Description |

|---|---|

| Authorized Dealers | These retailers specialize in genuine components and often provide expert advice on installation and compatibility. |

| Online Retailers | Convenient for comparison shopping, many websites offer a wide selection, often at competitive prices. Ensure to check reviews for reliability. |

| Local Hardware Stores | A good option for immediate needs, many local shops carry a selection of commonly used components and can offer personalized service. |

| Aftermarket Suppliers | These vendors often provide cost-effective alternatives, but ensure quality and compatibility by checking user feedback. |