Comprehensive Guide to Briggs and Stratton 10 HP Parts Diagram

When it comes to maintaining small engines, having a clear overview of their individual elements is crucial. Knowing how various components interact not only aids in troubleshooting but also enhances overall performance. This guide delves into the intricate makeup of a specific engine type, providing valuable insights for enthusiasts and professionals alike.

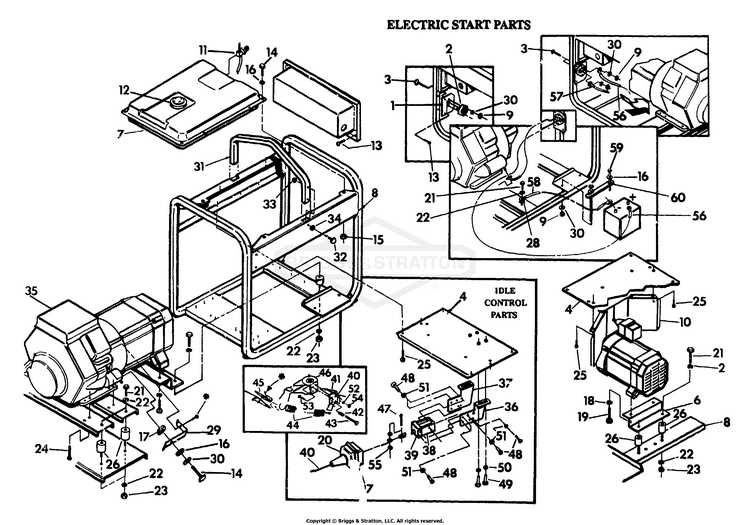

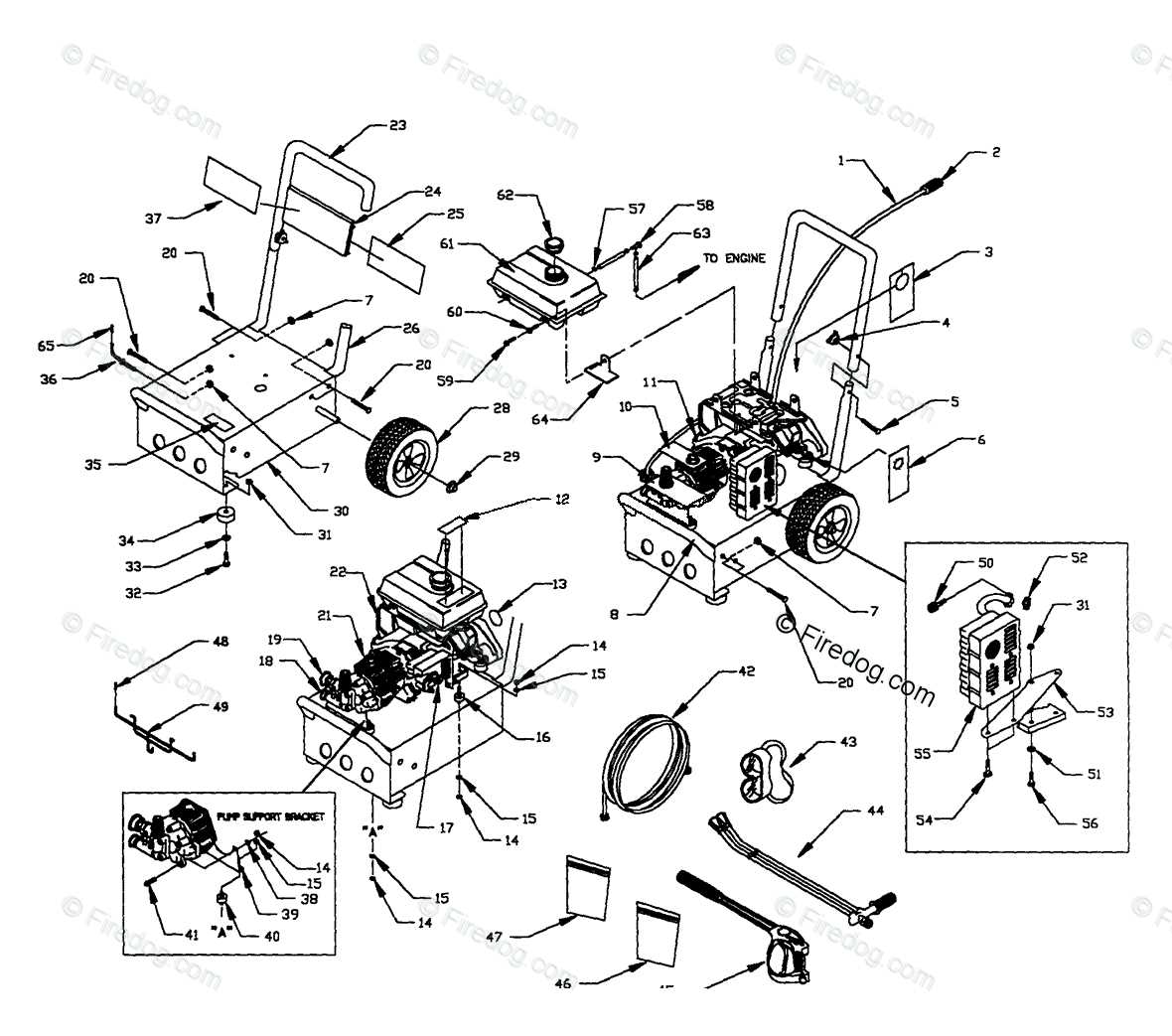

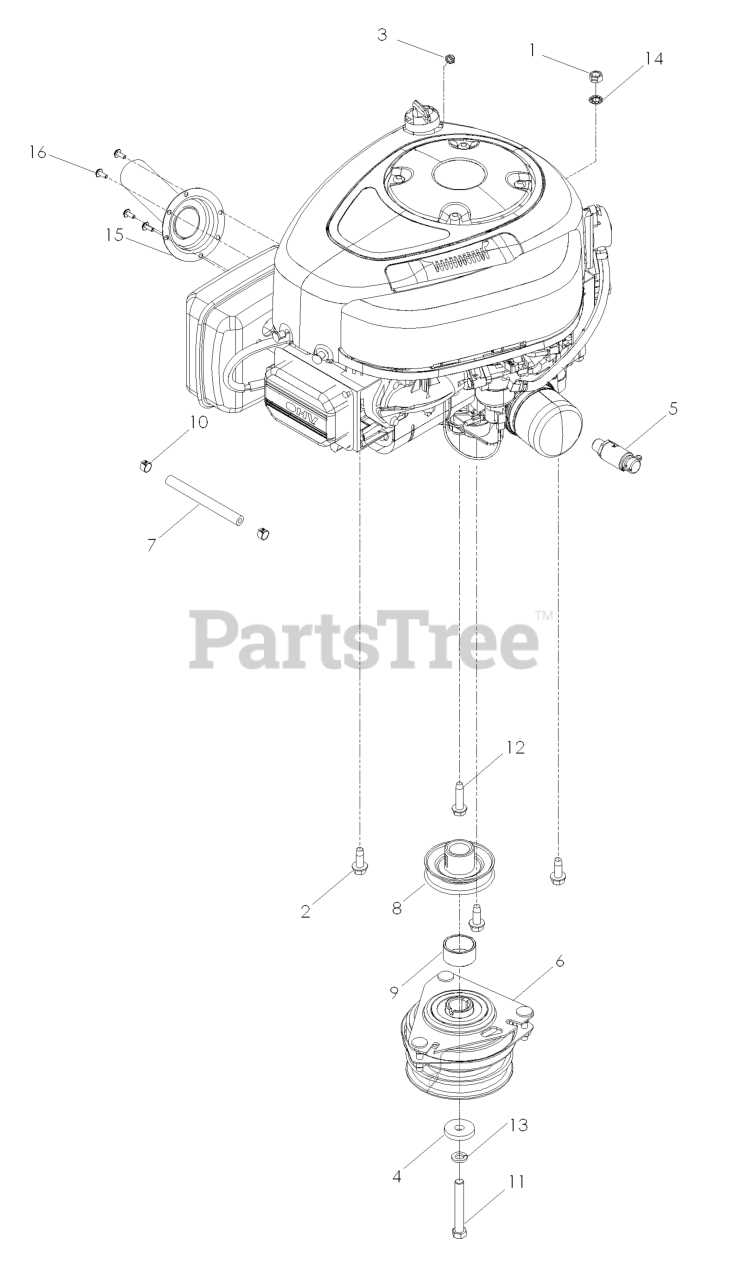

Visual aids play a significant role in grasping the arrangement and function of each piece. By exploring a comprehensive representation, users can easily identify necessary components and understand their placements. This knowledge empowers users to conduct repairs or upgrades with confidence, ensuring optimal engine functionality.

Whether you’re an experienced technician or a novice, familiarizing yourself with the configuration of these essential parts will lead to more efficient maintenance practices. As we break down the details, you’ll discover the importance of each section and how they contribute to the engine’s overall efficiency.

Understanding Briggs and Stratton Engines

This section explores the fundamental aspects of small combustion units commonly used in various outdoor equipment. Recognizing the components and their functions can enhance maintenance and performance, ensuring longevity and efficiency.

| Component | Function |

|---|---|

| Cylinder | Houses the piston, creating compression for ignition. |

| Piston | Moves up and down to convert fuel energy into mechanical work. |

| Crankshaft | Transfers the piston motion to rotational energy for operation. |

| Carburetor | Mixes air with fuel for optimal combustion. |

| Ignition System | Generates a spark to ignite the fuel-air mixture. |

Overview of 10 HP Models

The 10 HP engine category encompasses a variety of robust designs, renowned for their reliability and efficiency. These power units are commonly utilized in numerous applications, ranging from lawn maintenance to industrial machinery. Each model showcases unique features that cater to specific operational needs, ensuring optimal performance across different environments.

| Model | Type | Key Features |

|---|---|---|

| Model A | Air-Cooled | Compact design, easy maintenance |

| Model B | Vertical Shaft | High torque, fuel-efficient |

| Model C | Horizontal Shaft | Versatile mounting options |

Key Components of 10 HP Engines

Understanding the essential elements of 10 HP power units is crucial for effective maintenance and optimal performance. These engines comprise various integral parts, each playing a vital role in ensuring smooth operation and reliability. Familiarity with these components can greatly aid in troubleshooting and enhancing engine longevity.

Major Elements

Among the primary components are the cylinder block, which houses the pistons and facilitates combustion, and the crankshaft, responsible for converting linear motion into rotational force. The carburetor is another critical part, mixing air and fuel in the correct proportions for efficient combustion. The ignition system ensures timely spark generation, essential for starting and running the engine.

Supporting Systems

Additionally, lubrication systems are vital for minimizing friction between moving parts, while the cooling system prevents overheating. The exhaust system directs gases away from the engine, maintaining optimal performance and reducing emissions. Each of these elements works harmoniously to provide reliable power and efficiency in various applications.

Parts Identification for Maintenance

Proper upkeep of your engine requires a clear understanding of its components. Recognizing each element not only aids in troubleshooting but also ensures that any necessary replacements are accurate and effective. Familiarity with the various sections can lead to a smoother maintenance experience and extend the life of your machinery.

Understanding Component Roles

Each segment of the engine plays a vital role in its overall functionality. For instance, the ignition system is crucial for starting, while the fuel system ensures optimal performance. Regular checks and knowing where each part fits within the assembly can help in diagnosing potential issues early.

Tips for Effective Identification

To efficiently locate and recognize individual elements, consider keeping a detailed list of components and their functions. Utilizing labeled diagrams can also be beneficial. When inspecting, take note of any signs of wear or damage. Maintaining a proactive approach will not only simplify the process but also enhance the reliability of your equipment.

How to Read a Parts Diagram

Understanding a visual representation of components can greatly enhance your ability to identify and replace essential elements in machinery. These illustrations often provide a clear overview of each piece, its function, and its placement. Mastering this skill allows you to effectively navigate repairs and maintenance tasks.

Start by familiarizing yourself with the various symbols and labels used within the visual aid. Each element is typically numbered or coded to correspond with a list, facilitating easy reference. This can help you locate the specific item you need to address.

Pay attention to the layout, as it often reflects the assembly sequence. Understanding how components fit together can inform you of the order in which to disassemble or reassemble them, preventing confusion during your project.

Lastly, consult the accompanying documentation for detailed descriptions and specifications. This additional information can provide insight into compatibility and functionality, ensuring that you select the correct replacement for your needs.

Common Replacement Parts Needed

Regular maintenance of outdoor engines often requires replacing certain components to ensure optimal performance and longevity. Familiarity with these essential items can help in keeping your machinery running smoothly, minimizing downtime and repair costs.

One frequently needed component is the air filter, which plays a crucial role in maintaining engine efficiency by preventing dirt and debris from entering. Spark plugs are also vital for ensuring reliable ignition; replacing them at regular intervals can enhance engine performance.

Fuel filters are essential for keeping the fuel system clean and preventing clogs that could lead to operational issues. Additionally, oil filters should be replaced regularly to maintain proper lubrication and engine health.

Another common replacement item is the carburetor gasket, which ensures a proper seal and prevents leaks. Belts and hoses, subject to wear over time, may also need replacement to maintain the functionality of various systems within the engine.

Ordering Genuine Parts Online

Acquiring authentic components online is crucial for maintaining the efficiency and longevity of your equipment. This process not only ensures quality but also supports optimal performance. Understanding how to navigate the online marketplace effectively can save time and resources.

Steps to Follow

- Identify the exact component needed.

- Visit reputable online retailers or manufacturer websites.

- Use the search function to find the desired item.

- Verify the authenticity through customer reviews and ratings.

- Add the item to your cart and proceed to checkout.

Benefits of Genuine Components

- Enhanced durability and reliability.

- Improved performance of your machinery.

- Access to warranty and support services.

- Compatibility with existing equipment.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring optimal performance and extending the lifespan of your engine. Implementing simple practices can make a significant difference in efficiency and reliability over time.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Oil Change | Every 50 hours | Improves lubrication and reduces wear |

| Air Filter Cleaning | Every 25 hours | Enhances airflow and engine efficiency |

| Spark Plug Inspection | Every 100 hours | Ensures proper ignition and fuel combustion |

| Fuel Stabilizer Use | Before storage | Prevents fuel degradation and engine issues |

Typical Issues with 10 HP Engines

Engines of this power rating often encounter a variety of common problems that can affect performance and longevity. Understanding these issues is essential for maintenance and troubleshooting.

Fuel System Problems: Clogged filters or degraded fuel can lead to poor combustion, causing difficulty in starting or erratic operation.

Ignition Failures: Worn spark plugs or faulty ignition coils may result in misfires, impacting engine efficiency and power output.

Overheating: Insufficient cooling due to low oil levels or blocked cooling fins can lead to severe damage, necessitating immediate attention.

Mechanical Wear: Components such as pistons and rings can wear out over time, leading to decreased compression and overall performance.

Vibration Issues: Unbalanced parts or loose fittings can cause excessive vibrations, which not only affect operation but may also lead to further mechanical failures.

Addressing these concerns promptly can enhance the reliability and functionality of these engines, ensuring they perform at their ultimate best.

Tools Required for Repair

When undertaking maintenance or fixing machinery, having the right tools is crucial for a successful outcome. This section outlines essential instruments that will facilitate repairs effectively and efficiently.

- Wrenches: Various sizes are necessary for loosening or tightening bolts.

- Screwdrivers: Both flathead and Phillips types are needed to address different screw heads.

- Socket Set: A comprehensive set will help with various fastening tasks.

- Pliers: Useful for gripping, twisting, and cutting wires or small components.

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

- Oil Filter Wrench: Helps in removing and installing oil filters without damage.

- Multimeter: Essential for diagnosing electrical issues within the system.

Having these tools at your disposal will not only simplify the repair process but also enhance the overall effectiveness of your work. Make sure to gather them before starting any project for a smooth experience.

DIY Repair vs. Professional Service

When it comes to fixing machinery, there are two main approaches: tackling the issue yourself or enlisting the help of an expert. Each method has its own advantages and drawbacks, which can influence the decision based on individual skills, time constraints, and budget considerations.

Choosing the DIY route can be rewarding, as it allows for personal involvement and potential cost savings. However, it requires a solid understanding of the equipment and access to the necessary tools.

- Pros of DIY:

- Cost-effective solutions.

- Opportunity to learn and develop skills.

- Control over the repair process.

- Cons of DIY:

- Risk of mistakes leading to further damage.

- Time-consuming, especially without experience.

- Need for specialized tools and parts.

On the other hand, opting for professional assistance brings its own set of benefits. Experts possess extensive knowledge and experience, which often results in quicker and more reliable repairs.

- Pros of Professional Service:

- Expertise ensures accurate diagnosis and repair.

- Time-saving for busy individuals.

- Warranty or guarantee on the work performed.

- Cons of Professional Service:

- Higher costs compared to DIY methods.

- Less personal involvement in the repair process.

- Potential for longer wait times if busy.

Ultimately, the choice between self-repair and hiring a professional will depend on personal preferences, the complexity of the issue, and overall confidence in one’s ability to resolve the problem effectively.

Safety Precautions During Repairs

Ensuring safety while performing maintenance is crucial for preventing accidents and injuries. Adhering to specific guidelines can significantly reduce risks associated with mechanical work. Proper preparation and awareness of potential hazards are key components of a secure repair environment.

First, always wear appropriate personal protective equipment, such as gloves and safety glasses. This minimizes exposure to sharp objects and harmful substances. Additionally, make sure your workspace is clean and organized to avoid tripping or misplacing tools.

Second, disconnect any power sources before beginning work. This step prevents unintended starts and electrical shocks. Furthermore, use tools correctly and according to manufacturer instructions to ensure safe handling.

Lastly, if you encounter unfamiliar components, consult manuals or seek expert advice. Delving into proper knowledge enhances not only your safety but also the effectiveness of the repair process.

Where to Find Repair Manuals

Locating comprehensive guides for maintenance and troubleshooting is essential for ensuring optimal performance of equipment. These resources offer detailed instructions, diagrams, and specifications that can assist in various repair tasks.

Online Resources: Numerous websites specialize in providing downloadable manuals for different models. Manufacturer sites often have a dedicated section for customer support, where users can access technical documentation.

Local Retailers: Many hardware stores and authorized dealers carry printed manuals for the products they sell. Visiting these locations can yield valuable information directly from knowledgeable staff.

Community Forums: Engaging with online communities can lead to shared resources and advice from experienced users. Many enthusiasts upload and discuss manuals, making it easier to find what you need.

Library Archives: Public libraries often maintain collections of repair manuals and related materials. This option provides access to a wealth of information without any cost.