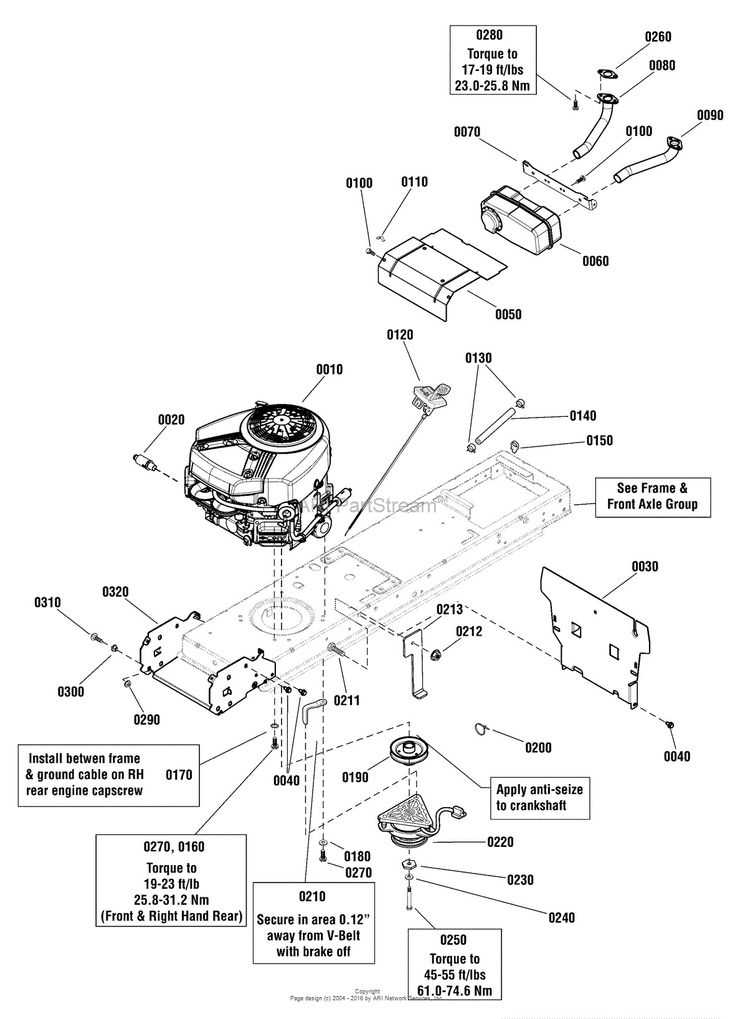

Briggs and Stratton 20 HP V Twin Parts Diagram Explained

Exploring the intricacies of a powerful 20 horsepower V-engine reveals a complex arrangement of components, each playing a vital role in the overall functionality. This overview serves to enhance your understanding of how these elements interact to deliver optimal performance.

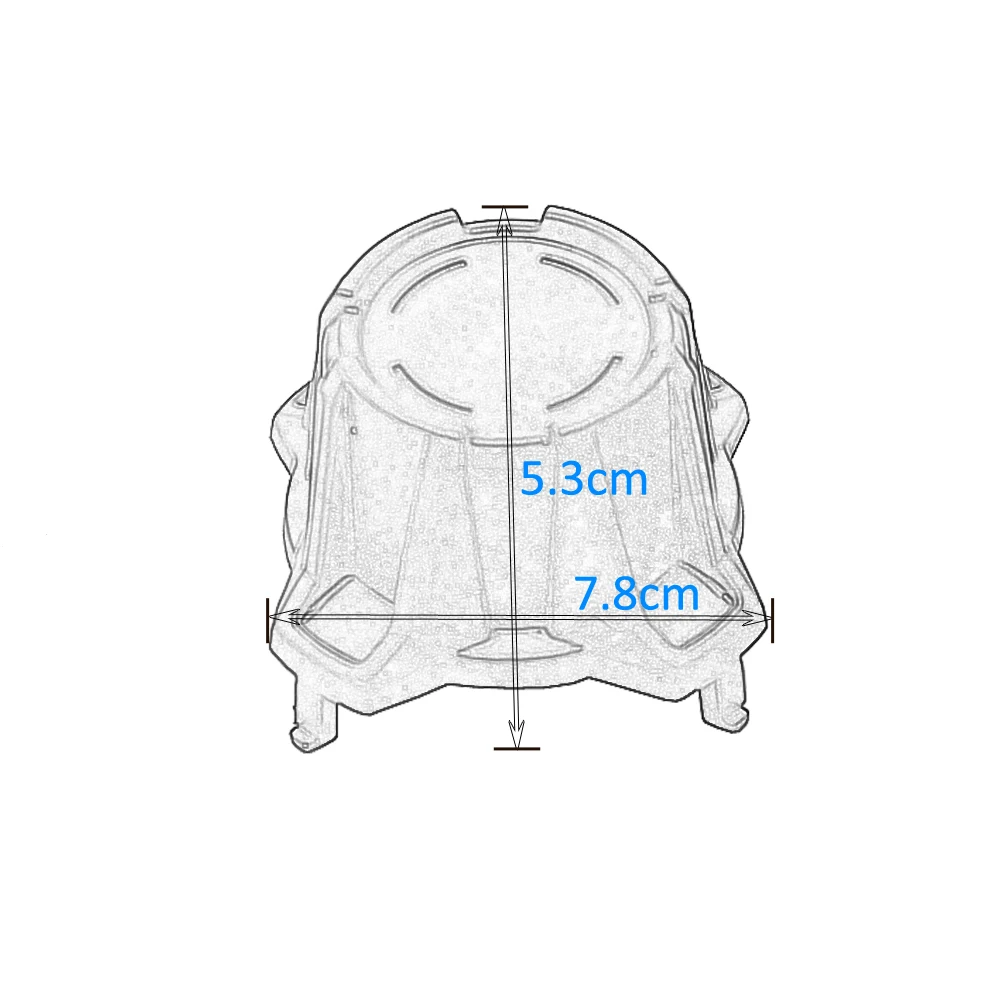

Identification of individual components is crucial for maintenance and repair, enabling enthusiasts and professionals alike to ensure the longevity and efficiency of their machinery. A detailed examination can provide insight into the assembly and operation of this robust engine.

With a focus on visual representation, a schematic layout offers clarity, allowing users to easily pinpoint specific parts. This facilitates not only troubleshooting but also enhances the overall knowledge base surrounding engine mechanics.

Overview of Briggs and Stratton Engines

Engines from this renowned manufacturer are recognized for their durability and efficiency. They serve a variety of applications, powering everything from lawn mowers to generators. With a commitment to innovation, these machines are engineered to meet the demands of users, delivering reliable performance in various conditions.

Key Features

These power units are designed with advanced technology, ensuring optimal fuel consumption and reduced emissions. Features like easy starting mechanisms and robust construction contribute to their popularity among both consumers and professionals. Additionally, maintenance is simplified, making it accessible for users to keep their engines in top condition.

Applications

From residential gardening tasks to commercial landscaping projects, these engines are versatile. They are often found in outdoor equipment, contributing to efficiency and productivity. Their adaptability allows them to excel in diverse environments, making them a preferred choice for many users.

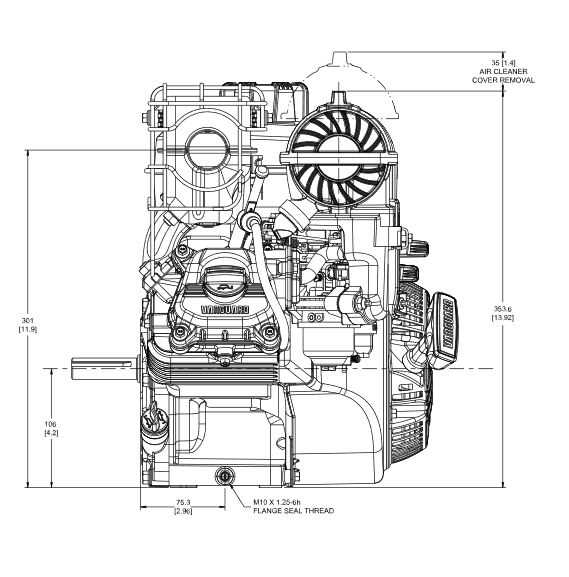

Understanding the V-Twin Engine Design

The V-engine configuration represents a unique approach to internal combustion, providing a harmonious balance between power output and compactness. This design features two cylinders arranged in a V-shape, allowing for efficient fuel combustion and smoother operation.

Key Advantages

The V-engine setup enhances performance by reducing vibrations and increasing torque. Its ability to deliver substantial power at lower RPMs makes it a favorite for various applications, from lawn equipment to larger machinery.

Innovative Cooling

With cylinders positioned at an angle, airflow is optimized, contributing to effective heat dissipation. This design promotes longevity and reliability, making it suitable for demanding tasks.

Conclusion

Overall, the V-engine design combines innovation and efficiency, providing an ultimate solution for those seeking robust performance in compact machinery.

Key Features of 20 HP Model

The 20 HP engine variant boasts a range of impressive characteristics designed to enhance performance and efficiency. These attributes make it suitable for various applications, ensuring reliability and power when needed most.

| Feature | Description |

|---|---|

| Power Output | Delivers robust performance with reliable horsepower. |

| Engine Design | Features a durable construction for long-lasting use. |

| Fuel Efficiency | Optimized for minimal fuel consumption while maintaining high output. |

| Maintenance | Easy access to components for straightforward servicing and upkeep. |

| Vibration Control | Equipped with systems to reduce vibration, enhancing operator comfort. |

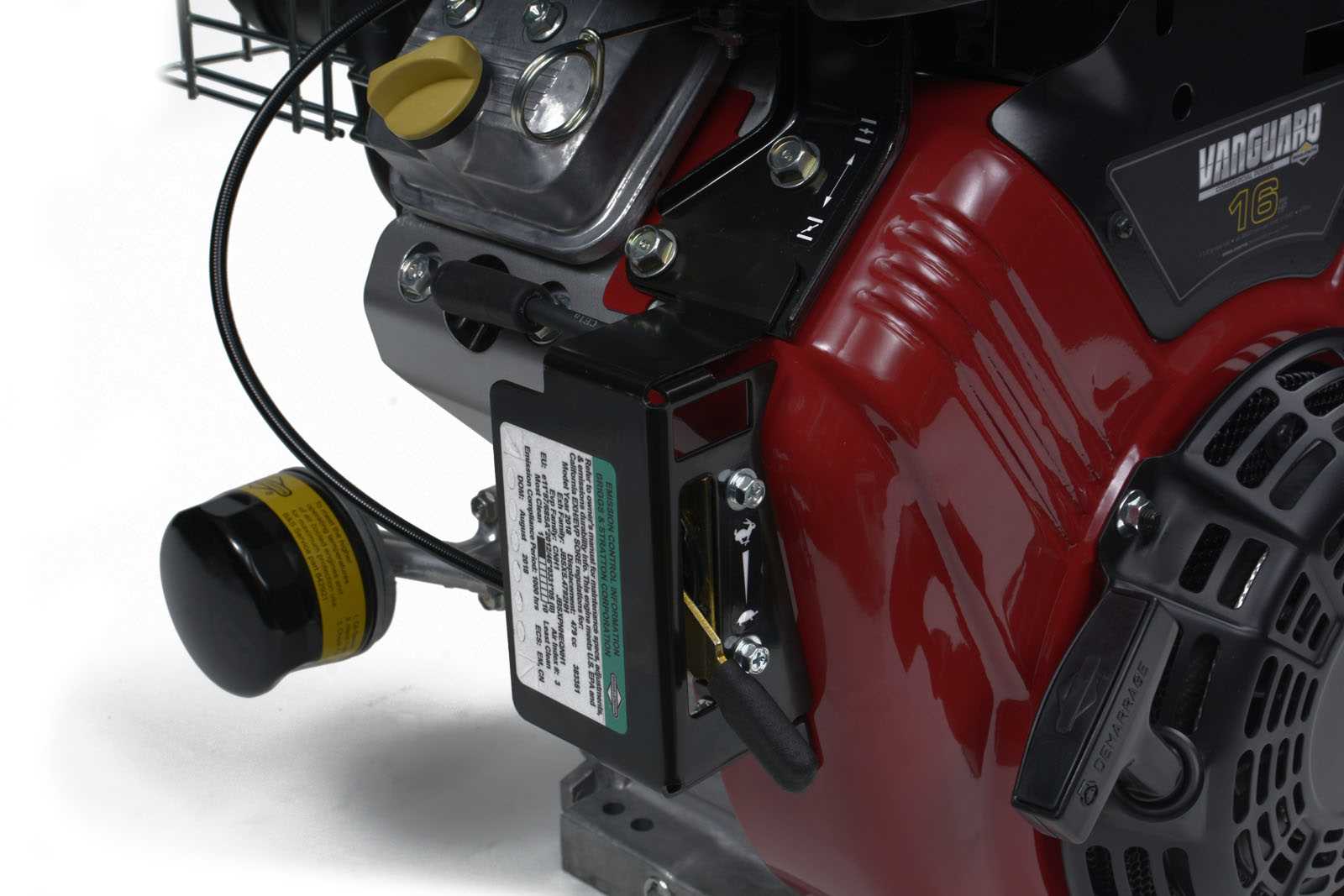

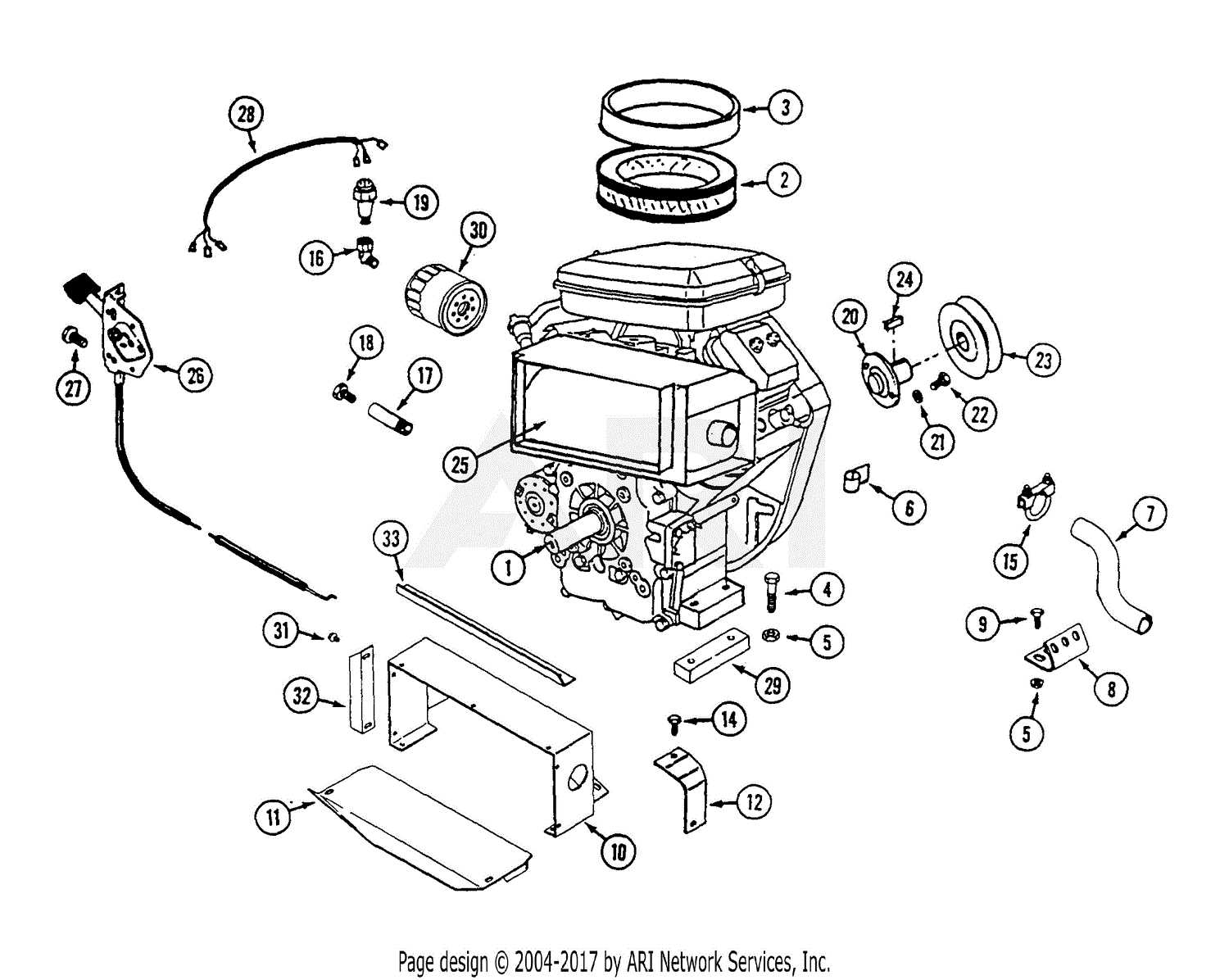

Essential Components of the Engine

Understanding the fundamental elements that make up a powerful machine is crucial for maintenance and performance enhancement. Each component plays a vital role in the overall functionality, contributing to efficiency and durability.

| Component | Description |

|---|---|

| Cylinder | The chamber where fuel combustion occurs, providing the necessary power for operation. |

| Piston | A moving element within the cylinder that converts combustion energy into mechanical motion. |

| Crankshaft | A rotating shaft that transforms the linear motion of the piston into rotational energy. |

| Valves | Control the intake of air-fuel mixture and the expulsion of exhaust gases. |

| Camshaft | Operates the valves in synchrony with the piston movements to ensure efficient engine cycles. |

| Fuel System | Delivers the necessary fuel to the combustion chamber for optimal engine performance. |

| Ignition System | Generates a spark to ignite the air-fuel mixture, initiating the combustion process. |

Common Parts and Their Functions

Understanding the essential components of a 20 hp V-engine is crucial for effective maintenance and performance optimization. Each element plays a specific role, contributing to the overall functionality and efficiency of the machine.

The crankshaft is pivotal for converting linear motion into rotational force, driving the engine’s power output. The cylinder houses the combustion process, where fuel and air mix for energy generation. Valves regulate the intake and exhaust flow, ensuring optimal engine performance.

The ignition system initiates combustion, while the carburetor mixes fuel and air in the right proportions. The cooling system prevents overheating, maintaining safe operating temperatures. Lastly, the oil pump circulates lubricant, reducing friction and wear on moving parts.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular attention and care. By following a structured maintenance routine, you can significantly extend the life of your engine and enhance its performance. Here are some essential practices to keep in mind.

| Tip | Description |

|---|---|

| Regular Oil Changes | Changing the oil at recommended intervals prevents sludge buildup and maintains optimal lubrication. |

| Air Filter Maintenance | Keep the air filter clean to ensure proper airflow and efficient combustion. |

| Spark Plug Inspection | Check and replace spark plugs as needed to ensure smooth ignition and operation. |

| Fuel Quality | Use fresh, high-quality fuel to avoid engine problems and improve performance. |

| Check for Leaks | Regularly inspect for fuel or oil leaks to address issues before they become serious. |

Diagnosing Engine Issues Effectively

Identifying problems in an engine requires a systematic approach to ensure accurate resolution. By following a structured method, you can minimize downtime and enhance performance.

Start with the following steps:

- Visual Inspection: Check for leaks, worn belts, and loose connections.

- Listen for Unusual Noises: Pay attention to any irregular sounds during operation.

- Test Performance: Observe how the engine starts, accelerates, and idles.

Utilize diagnostic tools:

- Multimeter: Measure electrical components and battery health.

- Compression Tester: Assess cylinder compression levels.

- Scan Tool: Read error codes from the engine control unit.

Finally, consult the manufacturer’s guidelines to delve deeper into specific issues. This comprehensive approach leads to the ultimate diagnosis and repair of engine problems.

Finding Replacement Parts Easily

Locating suitable components for your engine can be a straightforward task with the right approach. Understanding where to search and which resources to utilize can save both time and frustration, ensuring you maintain optimal performance.

Utilizing Online Resources

Websites dedicated to machinery often provide extensive catalogs, enabling users to filter by model or specifications. Utilizing these resources allows for quick identification of necessary components. Many sites also feature user reviews, which can aid in making informed decisions.

Consulting Local Experts

Visiting local repair shops or dealerships can offer valuable insights. Experts in these establishments can recommend quality alternatives and may even have spare components readily available. Establishing a good rapport with local professionals can lead to better service and potential discounts.

Benefits of Genuine Parts

Using authentic components in your machinery ensures optimal performance and longevity. Genuine items are designed specifically for your engine, providing the best fit and functionality. This leads to improved efficiency, reduced wear, and ultimately, a longer lifespan for your equipment.

Quality Assurance: Original components undergo rigorous testing and quality control processes. This guarantees that each piece meets high standards, minimizing the risk of failures or malfunctions.

Performance Optimization: Authentic components are engineered to work seamlessly with your engine. This compatibility enhances overall performance, ensuring that your machinery operates at its best under various conditions.

Warranty Protection: Many manufacturers offer warranties on their equipment when using genuine components. This protection can save you money on repairs and replacements, providing peace of mind.

Support for Maintenance: Genuine parts often come with detailed installation instructions and support from the manufacturer. This can make maintenance easier and more effective, reducing the likelihood of errors during repairs.

Environmental Responsibility: Authentic components are produced with environmental considerations in mind, often leading to lower emissions and a smaller ecological footprint compared to aftermarket alternatives.

Using a Parts Diagram Efficiently

Understanding the layout of components is essential for effective maintenance and repair. A visual representation of machinery helps identify each element’s location and function, streamlining the process of troubleshooting and replacement. This guide provides tips for maximizing the utility of such illustrations.

Identifying Components

Familiarizing yourself with individual elements is crucial. Follow these steps to enhance your comprehension:

- Study the legend or key to grasp the symbols used.

- Locate frequently referenced parts to build a mental map.

- Group similar items to ease identification during repairs.

Organizing Your Workflow

A systematic approach can significantly improve efficiency. Consider these strategies:

- Print or enlarge the visual for easy reference.

- Mark off components as you complete tasks to avoid confusion.

- Keep a list of required items to streamline ordering replacements.

By effectively utilizing these visual resources, you can simplify your repair processes and ensure long-lasting performance of your equipment.

Tools Needed for Repairs

When undertaking maintenance or repairs on small engines, having the right tools is essential for efficiency and accuracy. The proper equipment not only facilitates smoother processes but also ensures that each task is completed safely and effectively.

Essential Tools

- Wrench Set

- Screwdriver Set

- Socket Set

- Pliers

- Torque Wrench

- Feeler Gauge

Additional Equipment

- Fuel Line Clamp

- Oil Filter Wrench

- Multimeter

- Magnetic Tray

- Safety Goggles

- Work Gloves

Equipping yourself with these tools will help streamline your repair tasks, making the process more manageable and less prone to errors.

Safety Precautions During Repairs

When undertaking maintenance on any engine, it is crucial to prioritize safety to prevent accidents and injuries. Proper precautions help ensure that both the individual performing the work and the equipment remain unharmed. By following a few essential guidelines, you can create a safer working environment and effectively manage any potential hazards.

Essential Safety Guidelines

Implementing basic safety measures is key to conducting repairs safely. Consider the following recommendations:

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use safety glasses, gloves, and steel-toed boots to protect against flying debris and sharp objects. |

| Ensure Proper Ventilation | Work in a well-ventilated area to avoid inhaling fumes and to maintain a safe environment. |

| Disconnect Power Source | Before starting any repair, ensure that the engine is off and disconnected from its power supply. |

| Use Correct Tools | Utilize the right tools for the job to prevent accidents and equipment damage. |

| Follow Manufacturer’s Instructions | Refer to the user manual for specific guidelines related to repairs and maintenance. |

Emergency Preparedness

Being prepared for emergencies is equally important. Familiarize yourself with the location of first aid kits and fire extinguishers. Knowing how to respond in case of an accident can significantly reduce risks. Regularly review safety protocols to ensure they are up-to-date and understood by everyone involved in the repair process.

Upgrading Your Engine Components

Enhancing your engine’s performance can lead to a more efficient and powerful machine. By selecting quality components, you can significantly improve reliability and functionality. Whether you’re seeking better acceleration or increased durability, the right upgrades can make a substantial difference.

Understanding Your Options is crucial when considering enhancements. Various components, such as air filters, exhaust systems, and ignition systems, can be tailored to boost performance. Each element plays a role in optimizing overall engine function, so it’s essential to choose wisely.

Research and Compatibility are vital to ensure that the new parts work harmoniously with your existing setup. Upgrading without proper knowledge may lead to inefficiencies or even damage. Delve into reviews and specifications to find the ultimate match for your needs.

In summary, upgrading engine components can unlock new levels of performance and longevity. With careful selection and research, your machine can achieve its full potential.