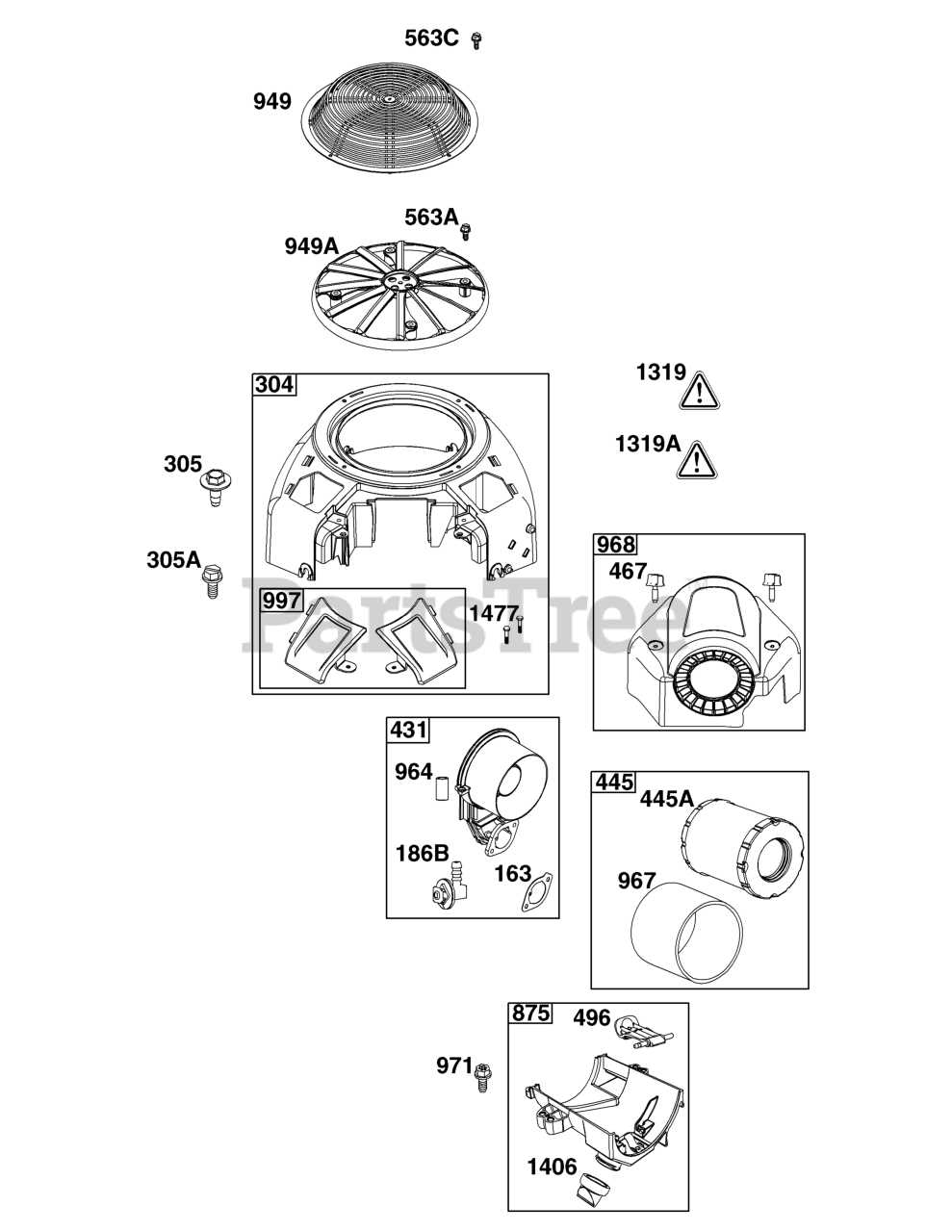

Briggs and Stratton 31C707 Parts Overview

Understanding the layout and function of various mechanical components in an engine is essential for proper maintenance and repairs. Knowing how each element is interconnected allows for a more efficient troubleshooting process, ensuring that your equipment runs smoothly.

This section provides a detailed look into the specific mechanisms that make up the engine’s structure. By following the visual representation and recognizing the key functions of each element, you will be equipped with the knowledge to identify and replace necessary parts with confidence.

Whether you are performing routine maintenance or handling more complex repairs, having a clear picture of how everything fits together will streamline the process, making your work more effective and accurate.

Overview of the Briggs and Stratton 31C707 Engine

This type of engine represents a well-designed and highly functional internal combustion system, recognized for its reliability and efficiency. Built for various applications, it combines advanced features with user-friendly design to ensure smooth operation and optimal performance in a range of power equipment.

- Efficient fuel consumption, reducing overall operational costs

- Durable construction, ensuring longevity even in demanding conditions

- Easy maintenance, with accessible components for quick repairs

- Compact design, allowing for flexible use in different machinery

The engine’s structure is optimized to provide consistent power, making it suitable for both residential and professional environments. It integrates modern technology to enhance functionality, while still being straightforward to use and maintain.

Main Components of the 31C707 Model

The internal structure of this engine includes key elements that work together to ensure smooth and efficient performance. Understanding the core components helps in maintaining and troubleshooting the machine effectively.

Cylinder and Piston Assembly

The heart of the system is the cylinder, where the piston moves up and down to generate power. This movement is driven by the combustion of fuel, with the piston transferring energy through the crankshaft to other mechanical systems.

Fuel and Air System

This system manages the intake of air and fuel, ensuring the proper mixture for combustion. It includes essential elements like the carburetor and air filter, which play a crucial role in optimizing engine efficiency and maintaining clean air flow.

Understanding the Fuel System Components

The fuel system is an essential part of any engine, ensuring a consistent and efficient supply of fuel to maintain optimal performance. In this section, we will explore the key elements of this system, highlighting their roles and functions within the engine’s operation.

Main Elements of the Fuel System

- Fuel Tank: Stores the fuel required for the engine to run. It must be durable and resistant to corrosion.

- Fuel Line: Connects the tank to other system components, allowing the fuel to flow smoothly towards the engine.

- Carburetor: Mixes fuel with air in the proper ratio to achieve combustion. A critical part for maintaining engine efficiency.

Additional Components

- Fuel Filter: Removes impurities from the fuel to prevent clogging in the carburetor and ensure clean fuel

Key Features of the Ignition System

The ignition system plays a crucial role in ensuring reliable engine performance by facilitating the process that powers the engine. It is designed to generate the necessary spark that ignites the fuel-air mixture, enabling the engine to run smoothly and efficiently. Understanding the essential elements of this system can help in maintaining its optimal function.

Efficient Spark Generation

A primary feature of the ignition mechanism is its ability to produce a strong and consistent spark. This is achieved through precise coordination between the electrical components, ensuring that the timing of the spark aligns perfectly with the engine’s cycles. A well-functioning system contributes to better fuel combustion and enhanced engine performance.

Durable Components

The reliability of the ignition system depends on the durability of its components, including the coil, spark plug, and related wiring. These parts are designed to withstand high temperatures and mechanical stress, ensuring that the engine remains operational even under demanding conditions. Regular maintenance of these elements is essential for the longevity of the system.

Air Filter and Intake System Explanation

The air filtration and intake system are essential components that ensure a clean flow of air into the engine. They prevent harmful particles from entering the internal mechanisms, allowing for efficient and safe operation. Proper maintenance of these systems is crucial for sustaining the engine’s performance and longevity.

- The air filter blocks dust, dirt, and debris, keeping the engine clean and functioning smoothly.

- In the intake system, air passes through a series of channels, allowing the engine to receive the necessary oxygen for combustion.

- A well-maintained intake pathway improves fuel efficiency and overall engine output.

Regularly checking and replacing the filter ensures that the engine can breathe freely, leading to optimized operation under various conditions.

Detailed View of the Carburetor Assembly

The carburetor assembly is a critical component in the engine’s operation, responsible for mixing air and fuel in the correct proportions. A thorough understanding of its structure and function is essential for effective maintenance and troubleshooting.

This assembly typically comprises several key elements, including the float chamber, jets, and throttle plate. Each part plays a vital role in ensuring optimal performance by regulating fuel delivery and airflow. Understanding how these components interact can help in identifying issues such as poor fuel efficiency or engine misfires.

Regular inspection of the carburetor assembly can prevent potential problems. Cleaning the jets and ensuring the float operates correctly are crucial tasks that can enhance engine reliability. Familiarity with the assembly’s layout facilitates efficient repairs and contributes to the overall longevity of the equipment.

Maintenance of the Exhaust System

Regular upkeep of the exhaust assembly is crucial for ensuring optimal performance and longevity of the engine. A well-maintained exhaust system not only enhances efficiency but also minimizes harmful emissions, contributing to a cleaner environment.

Inspecting for Damage: Frequent checks for cracks, rust, or other forms of wear are essential. Any signs of deterioration can lead to leaks, which may compromise the overall function. Addressing these issues promptly can prevent further damage.

Cleaning the Components: Keeping the exhaust parts clean is vital. Accumulation of soot and debris can hinder airflow, affecting engine efficiency. Utilize appropriate cleaning solutions and tools to maintain clear passages.

Checking Fasteners: Ensure all bolts and connections are secure. Loose fasteners can create vibrations that lead to misalignment and potential failures. Periodic tightening of these components can prolong the lifespan of the system.

Monitoring Performance: Regularly observe the engine’s operation for any unusual sounds or changes in performance. Such symptoms may indicate exhaust problems that require immediate attention to avoid more severe complications.

Oil and Lubrication System Overview

The oil and lubrication system is a vital component in ensuring the smooth operation and longevity of small engines. This system plays a crucial role in minimizing friction between moving parts, thereby enhancing performance and reducing wear. Proper maintenance and understanding of this system are essential for optimal functionality.

Key Functions

- Reduces friction between engine components.

- Cools the engine by dissipating heat.

- Prevents corrosion and contamination of internal parts.

- Facilitates the efficient movement of components.

Maintenance Tips

- Regularly check and change the oil according to the manufacturer’s recommendations.

- Use the appropriate type of lubricant suitable for your engine.

- Inspect the oil filter and replace it as needed to ensure cleanliness.

- Monitor oil levels and top up when necessary to maintain optimal performance.

Starter Mechanism and Parts Breakdown

The starting assembly of small engines plays a crucial role in initiating the combustion process. This section explores the key components involved in the mechanism, highlighting their functions and interactions within the system.

Key Components of the Starting Assembly

The primary elements of the starting assembly include the recoil starter, flywheel, and ignition system. The recoil starter is designed to engage the engine, providing the initial pull necessary for operation. The flywheel stores kinetic energy, aiding in the engine’s rotation, while the ignition system ensures the timely spark required for combustion.

Functionality and Interaction

Each component of the starting mechanism is meticulously engineered to function in harmony. The recoil starter engages the flywheel through a series of pawls, allowing for a smooth initiation of the engine cycle. As the flywheel rotates, it triggers the ignition system, which activates the spark plug, igniting the fuel-air mixture within the combustion chamber.

Connecting Rod and Crankshaft Analysis

This section delves into the essential relationship between the connecting rod and the crankshaft in small engine mechanics. These components work together to convert linear motion into rotational energy, playing a crucial role in the engine’s overall performance and efficiency. Understanding their interaction is vital for diagnosing issues and ensuring optimal functionality.

Functionality of the Connecting Rod

The connecting rod serves as a pivotal link between the piston and the crankshaft. Its primary function is to transmit the force generated by the piston during combustion to the crankshaft, facilitating movement. A well-designed connecting rod minimizes friction and maximizes efficiency, enabling smooth operation within the engine.

Crankshaft Dynamics

The crankshaft, on the other hand, is responsible for converting the linear motion of the piston into rotational movement. This component’s design influences the engine’s balance and stability. Analyzing the crankshaft’s construction and its relationship with the connecting rod can reveal insights into performance characteristics and potential areas for improvement.

Troubleshooting Common Issues with 31C707

Addressing frequent complications encountered with small engines is crucial for maintaining optimal performance. Understanding these common concerns can significantly enhance the reliability and efficiency of your machinery. This section will provide insights into typical challenges and practical solutions to ensure seamless operation.

Identifying Engine Performance Issues

When an engine fails to operate smoothly, it may exhibit several symptoms. Here are some signs to watch for:

- Difficulty starting or cranking

- Irregular idling or stalling

- Reduced power output during operation

- Unusual noises while running

If any of these issues arise, consider the following troubleshooting steps:

- Check the fuel supply to ensure it is clean and adequately filled.

- Inspect the air filter for blockages and replace if necessary.

- Examine the spark plug for wear or damage; replace if needed.

Resolving Starting Problems

Starting difficulties are a common concern for users. To address these issues:

- Ensure that the throttle is set to the correct position.

- Verify the battery charge and connections for any faults.

- Check for fuel leaks or obstructions in the fuel line.

By following these guidelines, you can troubleshoot and resolve many of the prevalent challenges associated with small engines, leading to improved performance and longevity.