Understanding the Briggs and Stratton 92902 Parts Diagram

In the realm of small machinery, grasping the intricacies of individual components is crucial for maintenance and efficiency. Familiarity with these elements not only enhances performance but also extends the longevity of your equipment.

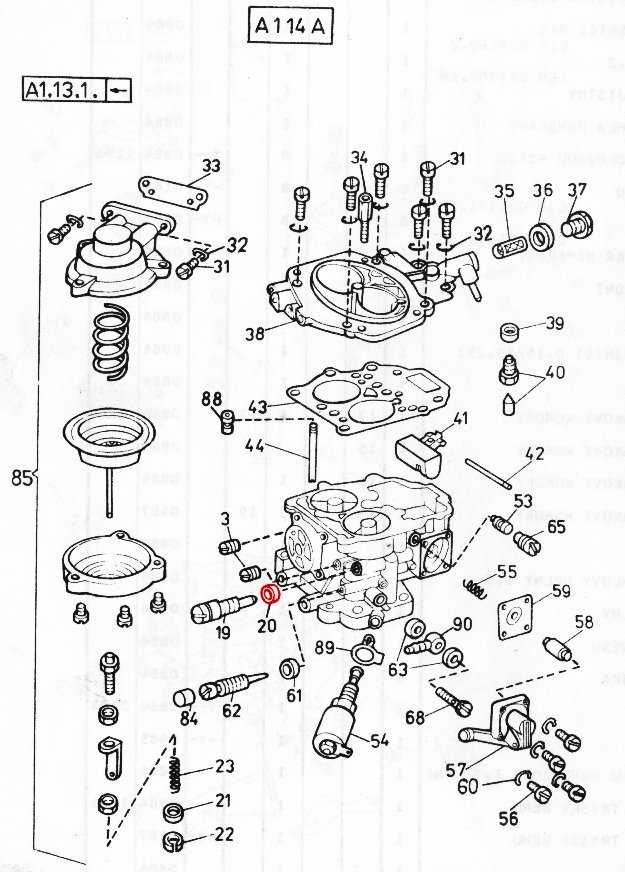

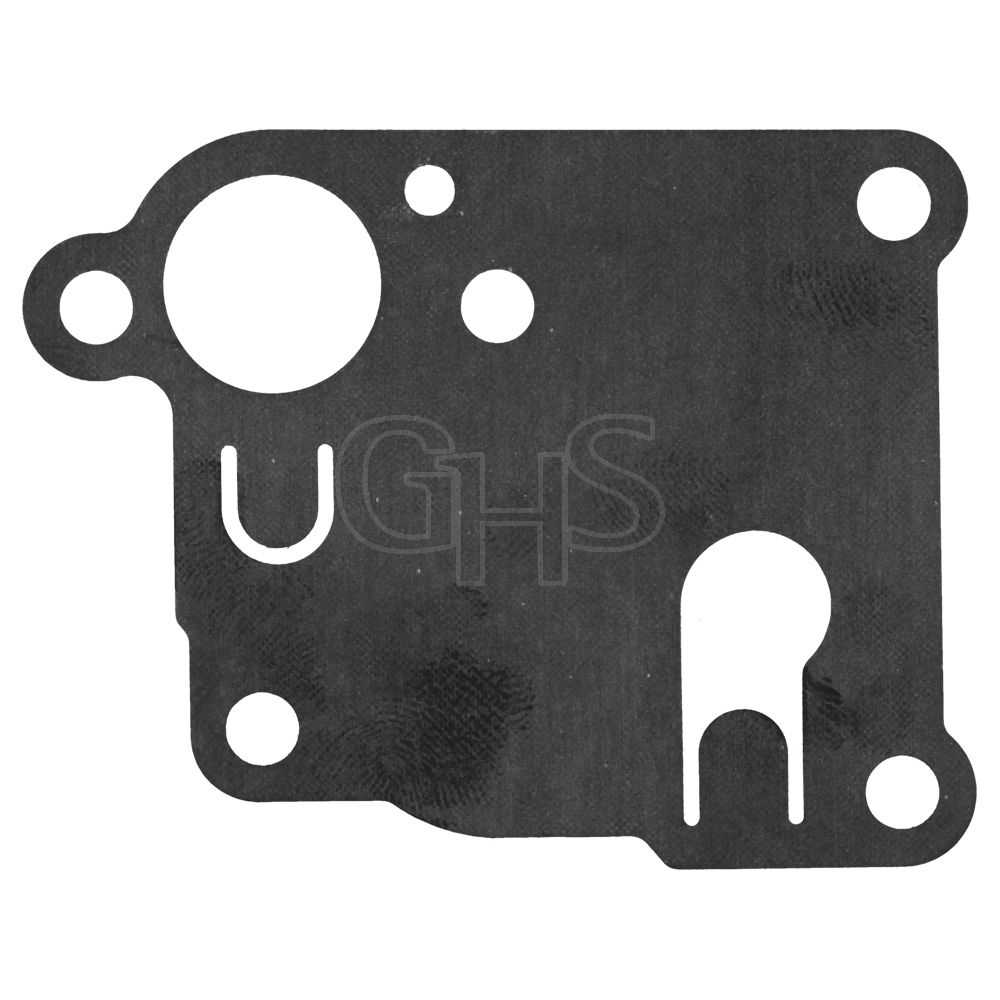

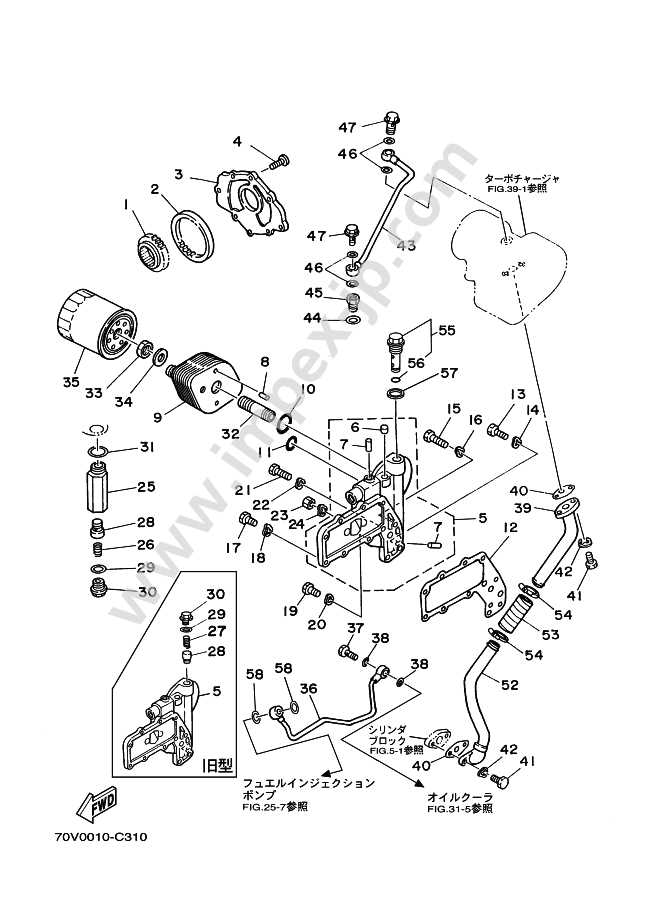

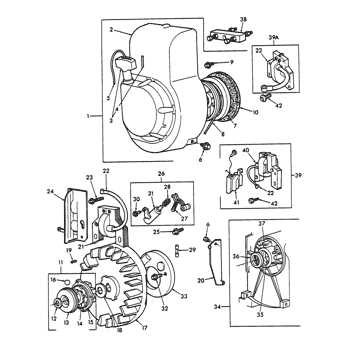

Visual representation of each piece can significantly aid in identifying issues and making informed repairs. Such illustrations serve as an ultimate reference point for enthusiasts and professionals alike.

By delving into the specifics of these critical elements, users can ensure their machinery operates smoothly. A comprehensive overview enables better troubleshooting and a deeper appreciation for the engineering behind these machines.

Understanding Briggs and Stratton 92902

This section explores the intricate workings of a well-known engine model, emphasizing its components and functionality. Gaining insight into its design can significantly enhance maintenance and repair efforts.

Key Features

- Durability: Built to withstand rigorous conditions.

- Efficiency: Optimized for performance and fuel consumption.

- Versatility: Suitable for various applications.

Maintenance Tips

- Regularly check oil levels to ensure smooth operation.

- Inspect air filters and replace them as needed.

- Keep spark plugs clean for optimal ignition.

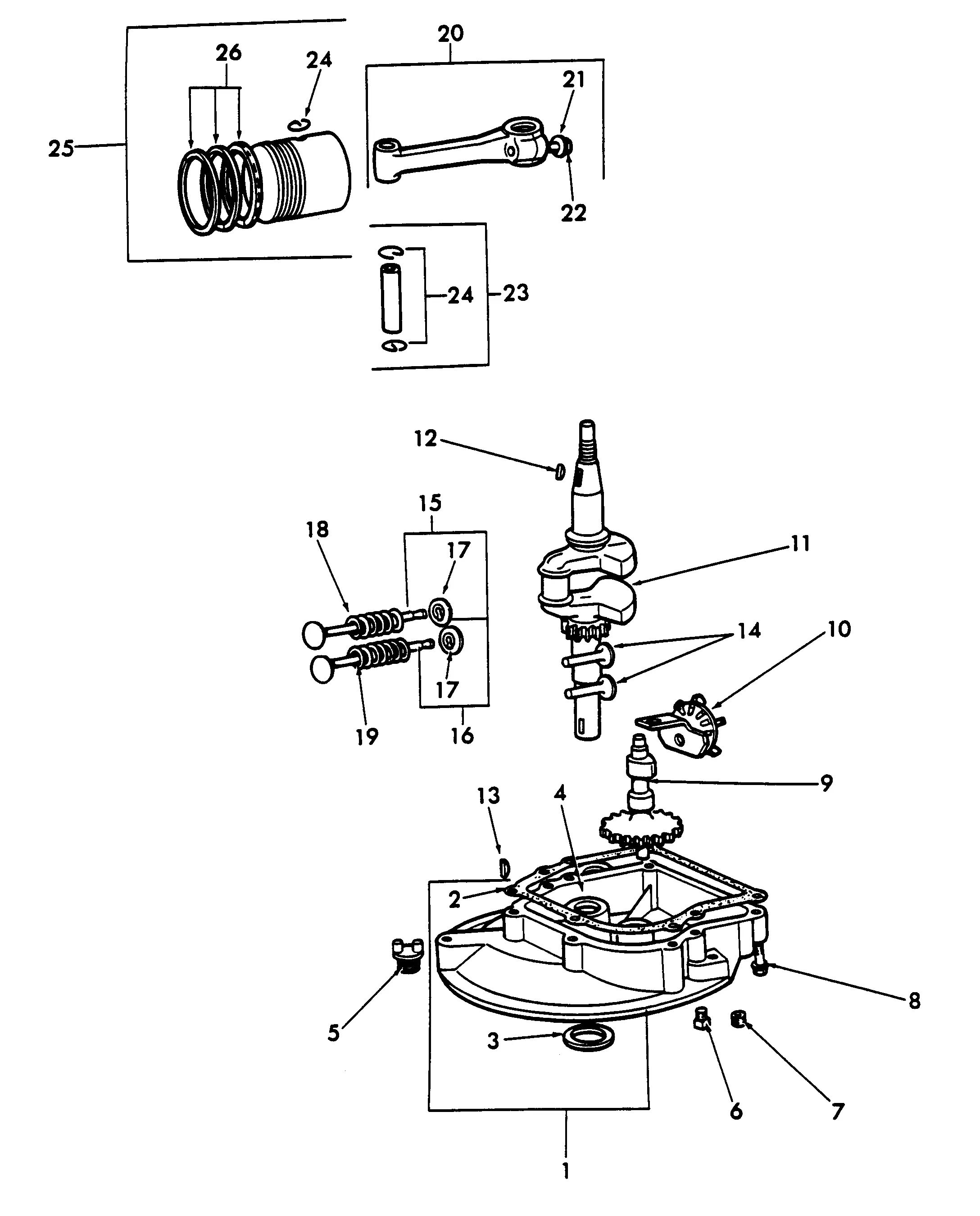

Key Components Explained

This section focuses on essential elements that contribute to the efficient functioning of various outdoor power equipment. Understanding these fundamental parts can enhance maintenance and repair efforts, ensuring optimal performance over time.

Engine Assembly

The engine assembly serves as the powerhouse, converting fuel into mechanical energy. Key elements include the cylinder, piston, and crankshaft, all working together to facilitate combustion and generate motion.

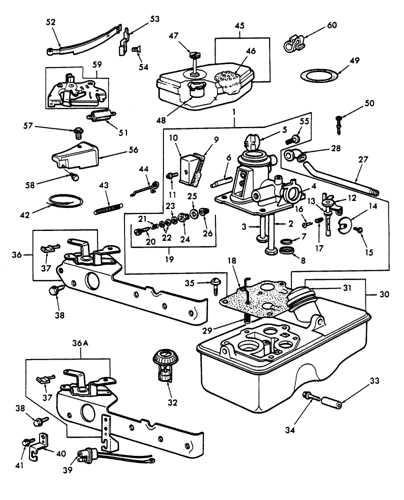

Fuel System

The fuel system is crucial for delivering the right amount of fuel to the engine. It comprises components such as the carburetor and fuel lines, which regulate flow and maintain efficiency, ensuring smooth operation during use.

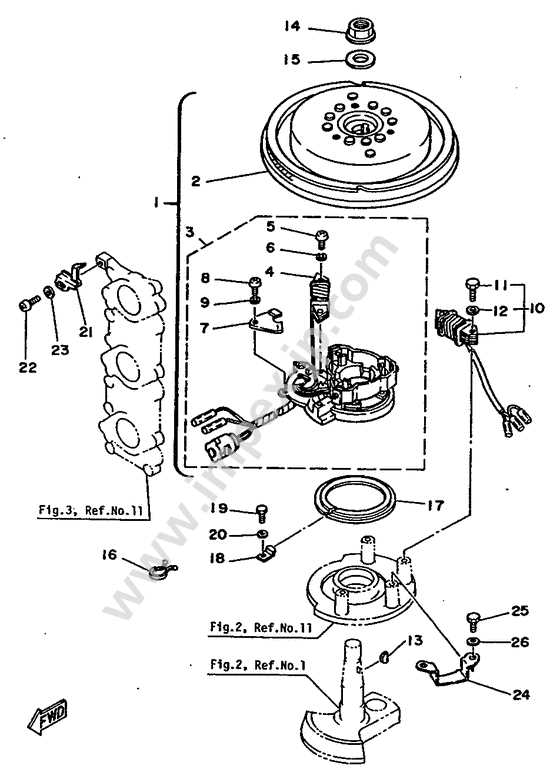

Importance of Diagrams in Maintenance

Visual representations are essential tools in the upkeep of machinery. They provide clear guidance, enabling users to understand complex systems at a glance. By illustrating components and their relationships, these visuals facilitate efficient troubleshooting and repair processes.

Clarity is one of the primary benefits of these illustrations. When dealing with intricate mechanisms, having a visual aid can significantly reduce confusion. Users can quickly identify parts and their functions, ensuring that maintenance tasks are performed accurately.

Moreover, these visual guides enhance communication among technicians. When multiple individuals are involved in servicing equipment, having a common reference point fosters collaboration and reduces errors. This is particularly important in team settings where clarity of instructions is vital.

Additionally, the use of these aids promotes efficiency. Technicians can follow step-by-step procedures without unnecessary delays. This streamlined approach not only saves time but also minimizes the risk of overlooking crucial steps, ultimately extending the lifespan of the equipment.

In summary, visual representations play a pivotal role in maintenance activities. They provide clarity, enhance communication, and improve overall efficiency, making them invaluable resources for anyone involved in the care of machinery.

Common Issues and Solutions

When operating small engines, users often encounter a range of challenges that can hinder performance. Identifying these problems promptly can help in implementing effective solutions, ensuring longevity and reliability of the equipment. This section outlines frequent issues along with practical fixes.

1. Engine Won’t Start

This is a prevalent issue faced by many users. A non-starting engine can result from various factors, such as fuel supply problems, battery issues, or faulty ignition components.

| Possible Cause | Solution |

|---|---|

| No Fuel | Check fuel level and refill if necessary. |

| Clogged Fuel Line | Inspect and clear any blockages in the fuel line. |

| Defective Spark Plug | Replace the spark plug with a new one. |

2. Overheating Issues

Engines may overheat due to inadequate cooling or obstructions. Addressing this problem quickly is crucial to prevent severe damage.

| Possible Cause | Solution |

|---|---|

| Low Oil Level | Check and replenish oil to the recommended level. |

| Blocked Air Vents | Clear any debris or obstructions from the air intake. |

| Worn Out Cooling System | Inspect the cooling components and replace if necessary. |

Where to Find Replacement Parts

Locating suitable components for your equipment can greatly enhance its performance and longevity. Whether you are conducting repairs or performing maintenance, knowing where to source these items is essential. Here are some effective avenues to explore.

| Source | Description |

|---|---|

| Manufacturer’s Website | Direct access to official resources, including detailed specifications and purchasing options. |

| Authorized Dealers | Local retailers often carry certified replacements, ensuring compatibility and quality. |

| Online Marketplaces | Platforms like eBay and Amazon offer a wide selection, often at competitive prices. |

| Specialty Repair Shops | These establishments frequently stock niche items and can provide expert advice. |

| Local Classifieds | A viable option for finding used or discounted items from other users in your area. |

Using the Diagram Effectively

Understanding a schematic can significantly enhance your ability to troubleshoot and repair machinery. By visualizing the various components and their relationships, you can approach maintenance tasks with greater confidence. This approach not only saves time but also helps in preventing common mistakes.

To maximize the utility of the schematic, start by familiarizing yourself with its layout. Identify key sections and components, taking note of how they interact with each other. This will provide a clearer picture of the overall system. Make sure to highlight areas that seem complex or critical, as these are often the focal points during repairs.

When performing a task, refer to the visual guide regularly to ensure that you are following the correct sequence. This will help avoid confusion and ensure that each piece is correctly installed. Additionally, it can serve as a checklist to verify that no essential elements are overlooked during the reassembly process.

Lastly, consider documenting any modifications or observations you make while working. Keeping notes alongside the visual reference can enhance your understanding and provide valuable insights for future projects. This practice not only aids in your current task but also builds a solid foundation for any future maintenance endeavors.

Step-by-Step Assembly Guide

This guide provides a detailed approach to assembling the engine components efficiently and accurately. By following each step, you will ensure that every part is correctly positioned and secured, resulting in optimal performance.

Begin by organizing all components and tools in a clean workspace. Identify each element according to your reference material, which will aid in recognizing the sequence of assembly. Lay out the parts systematically to avoid confusion during the process.

Start with the base structure, securing it firmly to create a solid foundation. Follow with the installation of the essential mechanical components, ensuring that all connections are tight and well-aligned. Utilize appropriate fasteners and check for any missing pieces as you proceed.

As you advance, integrate the electrical elements, making certain that wires are routed correctly to prevent damage. Ensure that all connections are secure and insulated where necessary. Double-check your work before moving on to the final assembly stages.

Finally, attach the exterior covers and any additional accessories. Make sure all parts are aligned and fastened securely. After completing the assembly, perform a thorough inspection to confirm everything is in place and functioning as intended.

Tools Needed for Repairs

Effective maintenance requires the right equipment to ensure proper functioning and longevity. Having the necessary instruments on hand can significantly streamline the repair process, making it more efficient and less frustrating.

Essential Instruments

Key tools typically include wrenches, screwdrivers, and pliers. These basic items are vital for disassembling components and securing them back in place after repairs are completed.

Advanced Gear

For more complex tasks, specialized tools such as torque wrenches and diagnostic equipment may be required. These instruments allow for precise adjustments and in-depth troubleshooting, enhancing the overall repair experience.

Safety Precautions to Consider

When engaging with mechanical equipment, it is essential to prioritize safety to prevent accidents and ensure a smooth operation. Understanding the inherent risks associated with machinery can help in mitigating potential hazards.

Always wear appropriate protective gear, such as gloves and goggles, to shield against debris and sharp edges. Ensure the work area is clear of obstacles to maintain a safe environment. Familiarize yourself with the equipment’s operating instructions and follow them closely to avoid misuse.

Regularly inspect components for wear or damage before use. Disconnect the power source during maintenance to prevent accidental activation. Additionally, keep children and pets away from the workspace to eliminate distractions and potential risks.

By adopting these safety measures, users can significantly reduce the likelihood of injuries and enhance the overall effectiveness of their tasks.

Comparing OEM and Aftermarket Parts

When maintaining or repairing equipment, one of the key decisions revolves around choosing between original components and those from third-party manufacturers. Each option carries its own set of advantages and disadvantages, making it essential to understand the implications of your choice.

Benefits of Original Components

- Quality Assurance: Original items are typically manufactured to meet specific standards, ensuring reliability.

- Compatibility: These components are designed to fit seamlessly with the original machinery, reducing the risk of malfunction.

- Warranty Protection: Using original parts often keeps the warranty intact, providing additional peace of mind.

Advantages of Third-Party Components

- Cost-Effectiveness: Aftermarket options are often more affordable, making them appealing for budget-conscious consumers.

- Variety: There is a wider selection available, allowing for customization and unique solutions.

- Availability: These components may be easier to find, especially for older or discontinued models.

Ultimately, the choice between original and third-party components depends on individual needs, preferences, and the specific application. Evaluating the pros and cons will help make an informed decision.

Customer Reviews and Feedback

This section delves into the experiences and insights shared by users regarding their equipment. Gathering opinions from individuals who have utilized specific components can provide valuable information for potential buyers. Understanding their satisfaction levels, performance assessments, and any challenges faced helps in making informed decisions.

User Experiences

Many customers have expressed their views based on practical usage. These insights highlight aspects such as durability, efficiency, and ease of installation. Positive reviews often emphasize reliability and cost-effectiveness, while constructive feedback points to areas needing improvement.

To further illustrate user sentiments, the following table summarizes key feedback points collected from various reviews:

| Feedback Aspect | Positive Comments | Areas for Improvement |

|---|---|---|

| Durability | Long-lasting, withstands heavy use | Occasional wear noted over time |

| Performance | Highly efficient, performs well under load | Minor issues with specific tasks |

| Installation | Simple and straightforward process | Instructions could be clearer |