Ens

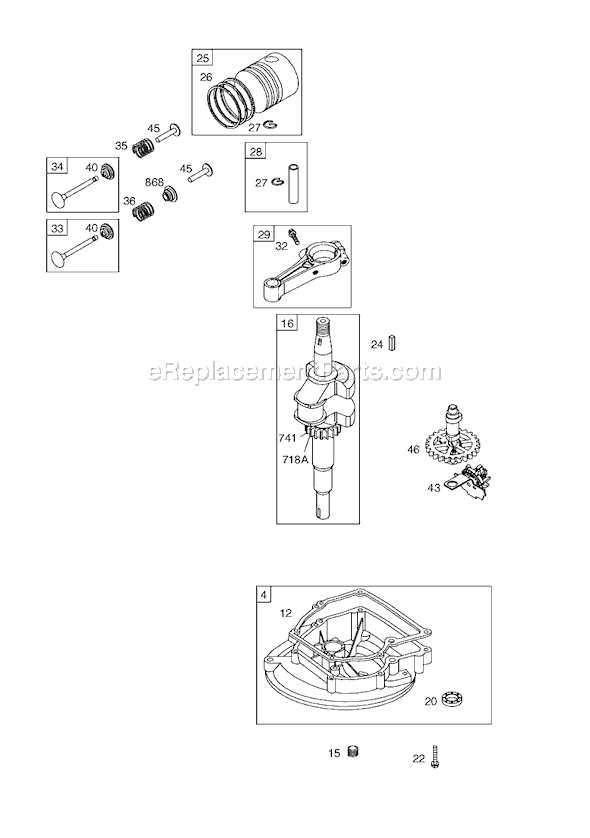

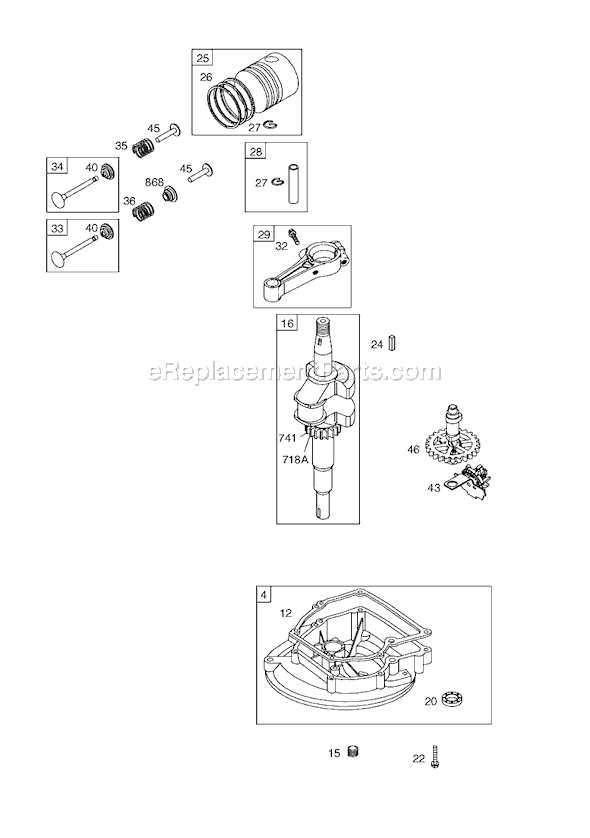

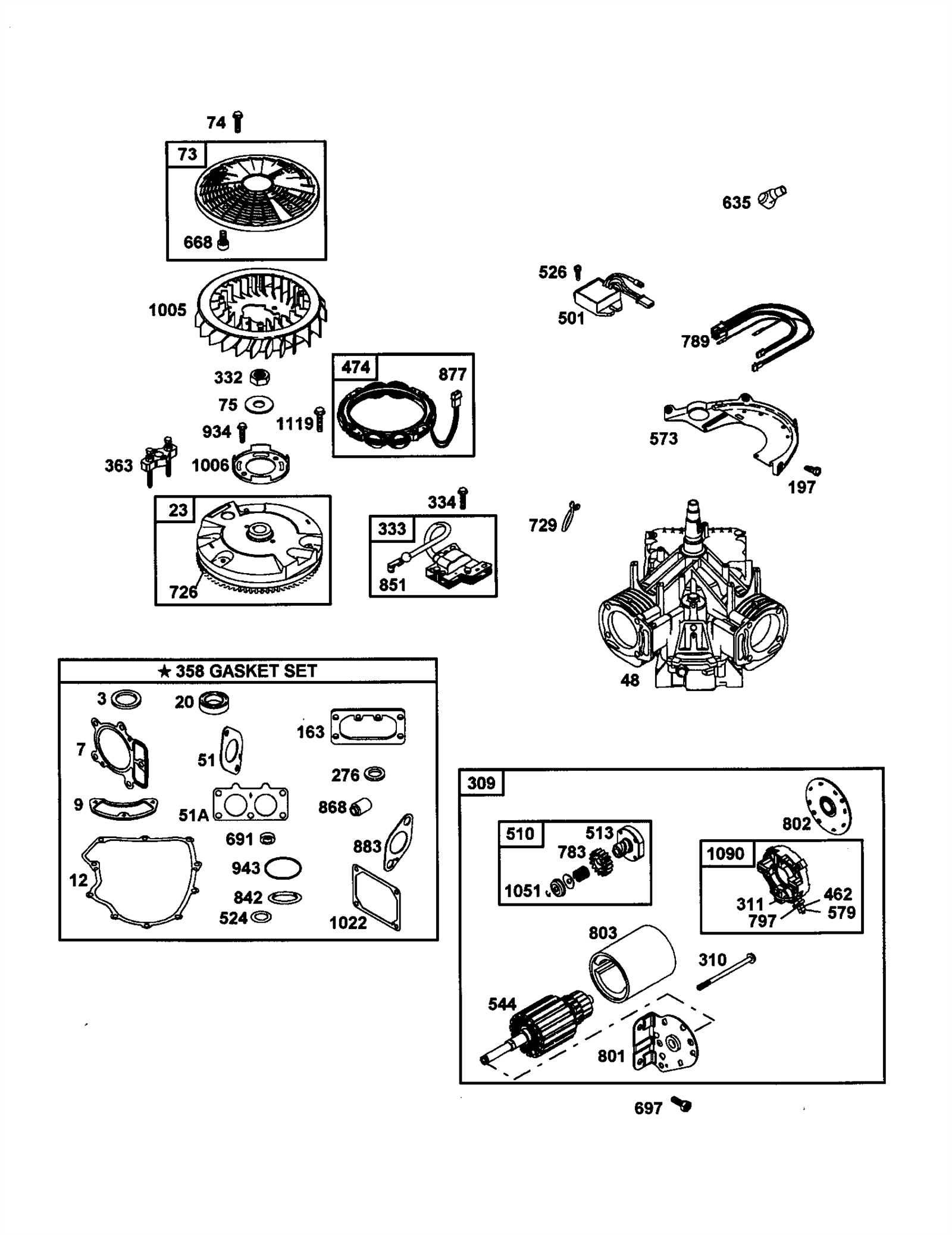

Key Parts to Monitor for Wear

Over time, certain components in mechanical systems are prone to natural degradation due to friction, heat, and extended use. Regular inspection of these elements is essential to maintain optimal performance and prevent costly failures. Identifying early signs of wear can significantly extend the lifespan of the machine.

Critical Moving Components

Moving elements such as belts, pulleys, and shafts are particularly susceptible to wear. Friction and repetitive motion can lead to gradual deterioration, causing reduced efficiency. It’s crucial to inspect these items periodically, looking for cracks, frays, or any unusual vibrations that may indicate a problem.

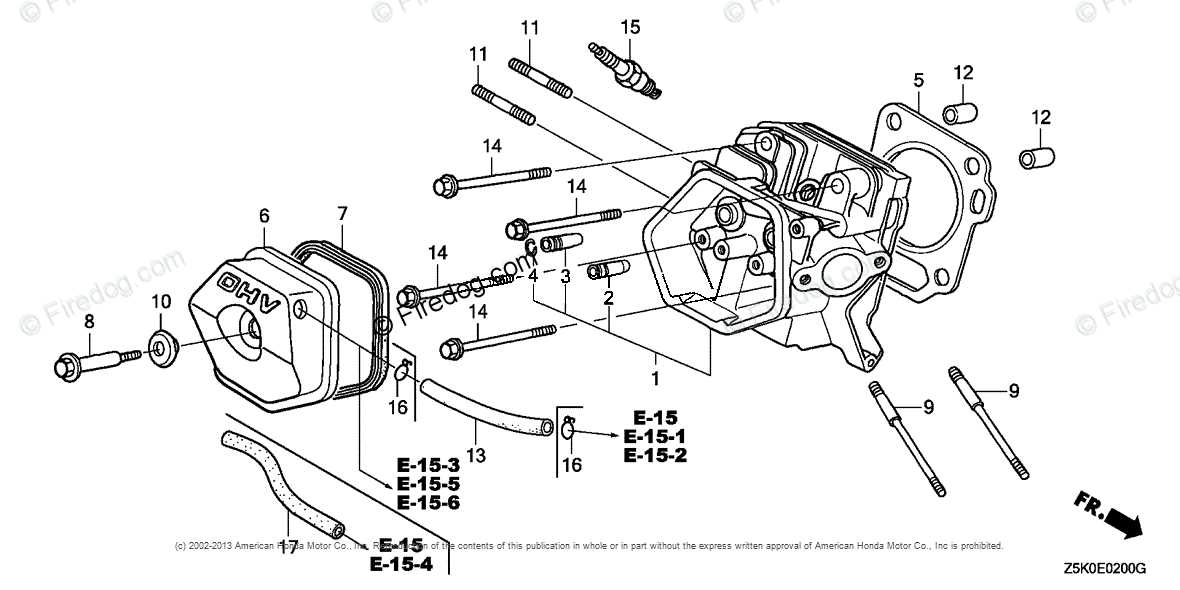

Seals and Gaskets

Seals and gaskets play an essential role in preventing fluid leaks and maintaining pressure. Over time, they can become brittle or develop cracks, which may lead to leaks or reduced efficiency. Regular checks and timely replacement of worn seals ensure a reliable performance.

Conclusion: Monitoring the wear of

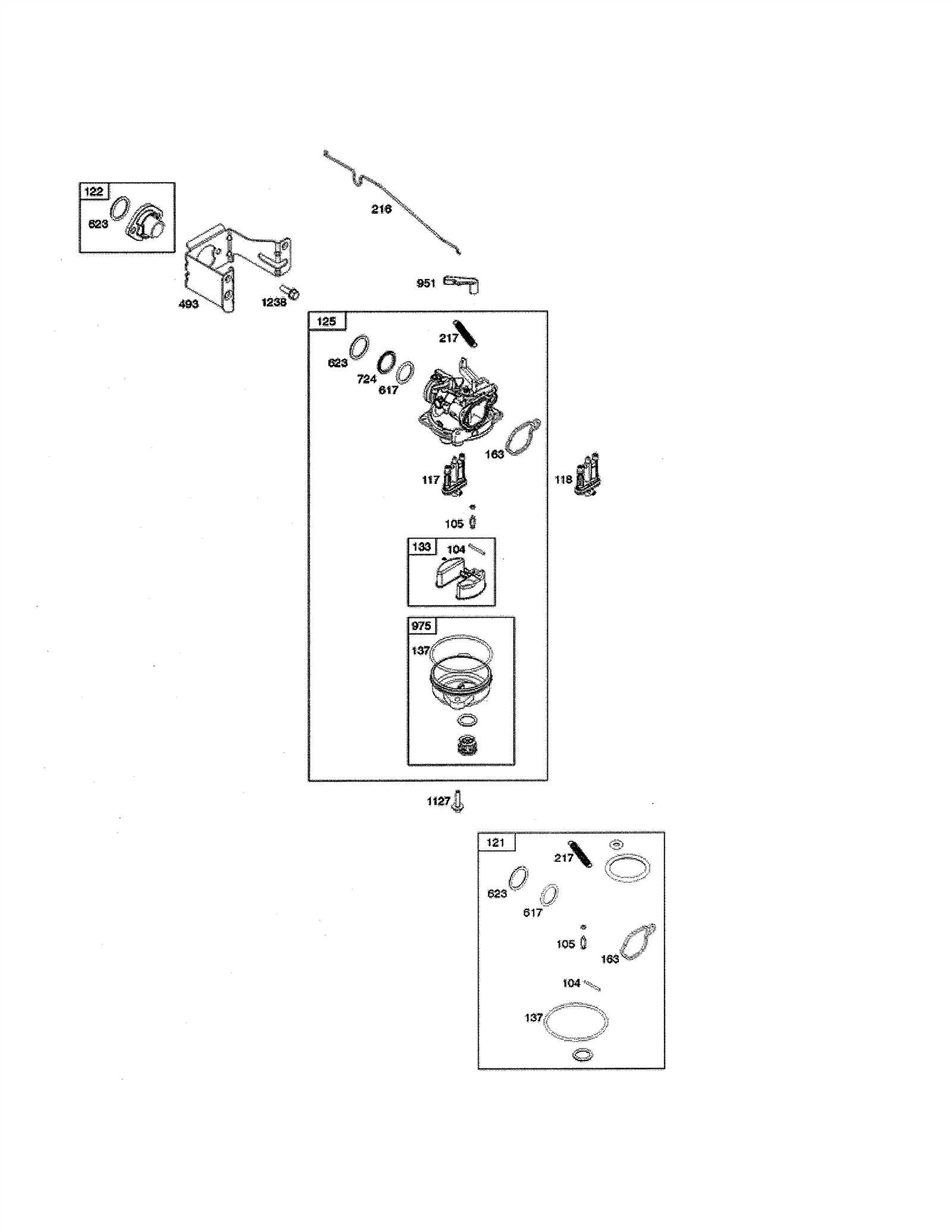

The Role of Air Filters in Engine Performance

Air filters play a critical role in maintaining the performance and longevity of mechanical systems by ensuring that the air entering the combustion chamber is free from dirt, dust, and other contaminants. Their presence helps optimize fuel efficiency, protect internal components, and maintain smooth operation.

How Air Filters Protect the System

The primary function of the air filter is to block harmful particles from reaching sensitive internal parts, which could lead to wear and tear or even damage. By filtering out debris, the system can operate under ideal conditions, reducing the risk of performance issues.

Improving Fuel Efficiency with Clean Air

A clean air filter ensures that the system receives an optimal air-fuel mixture, which is essential for efficient combustion. When properly maintained, it helps the mechanism consume fuel more efficiently

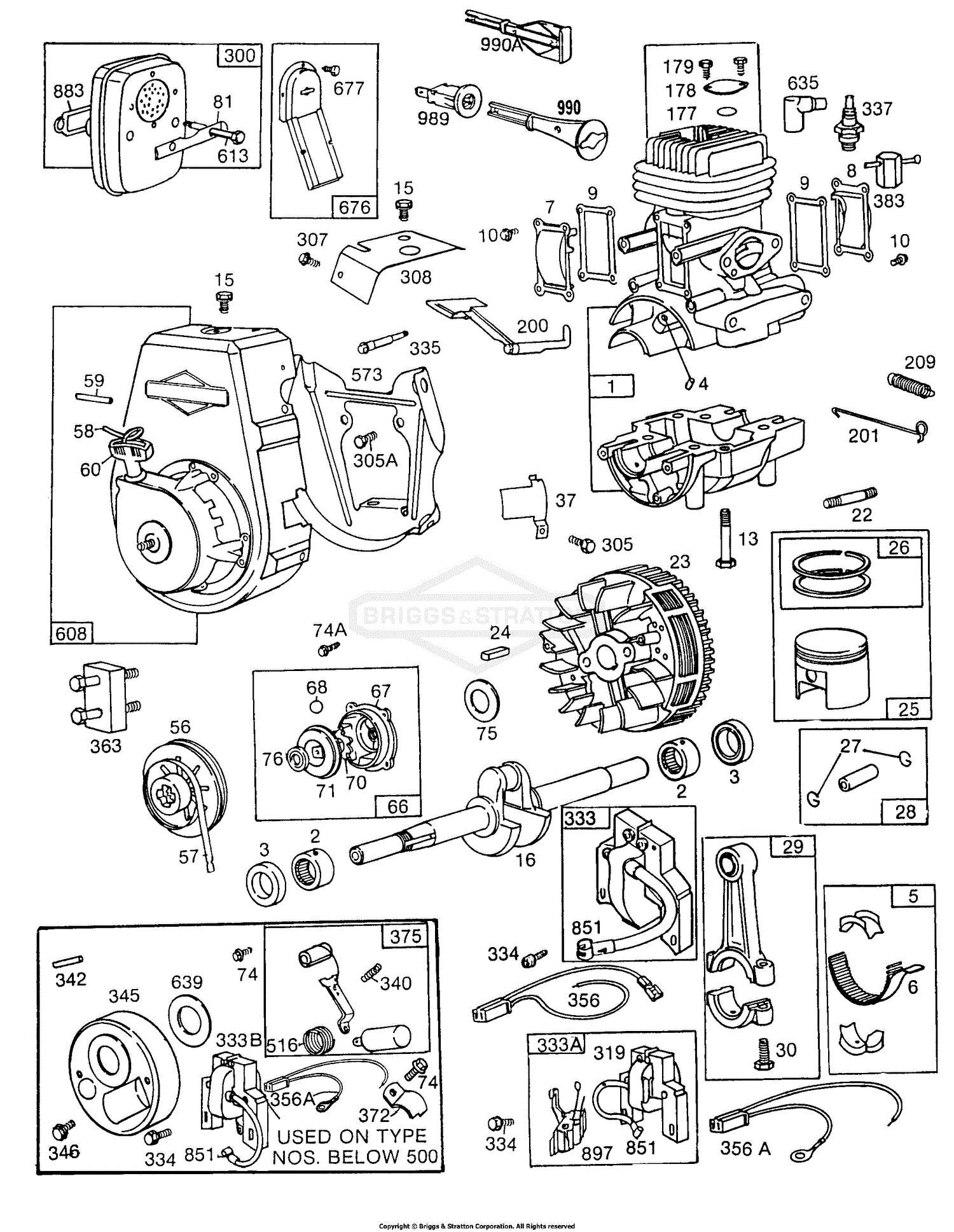

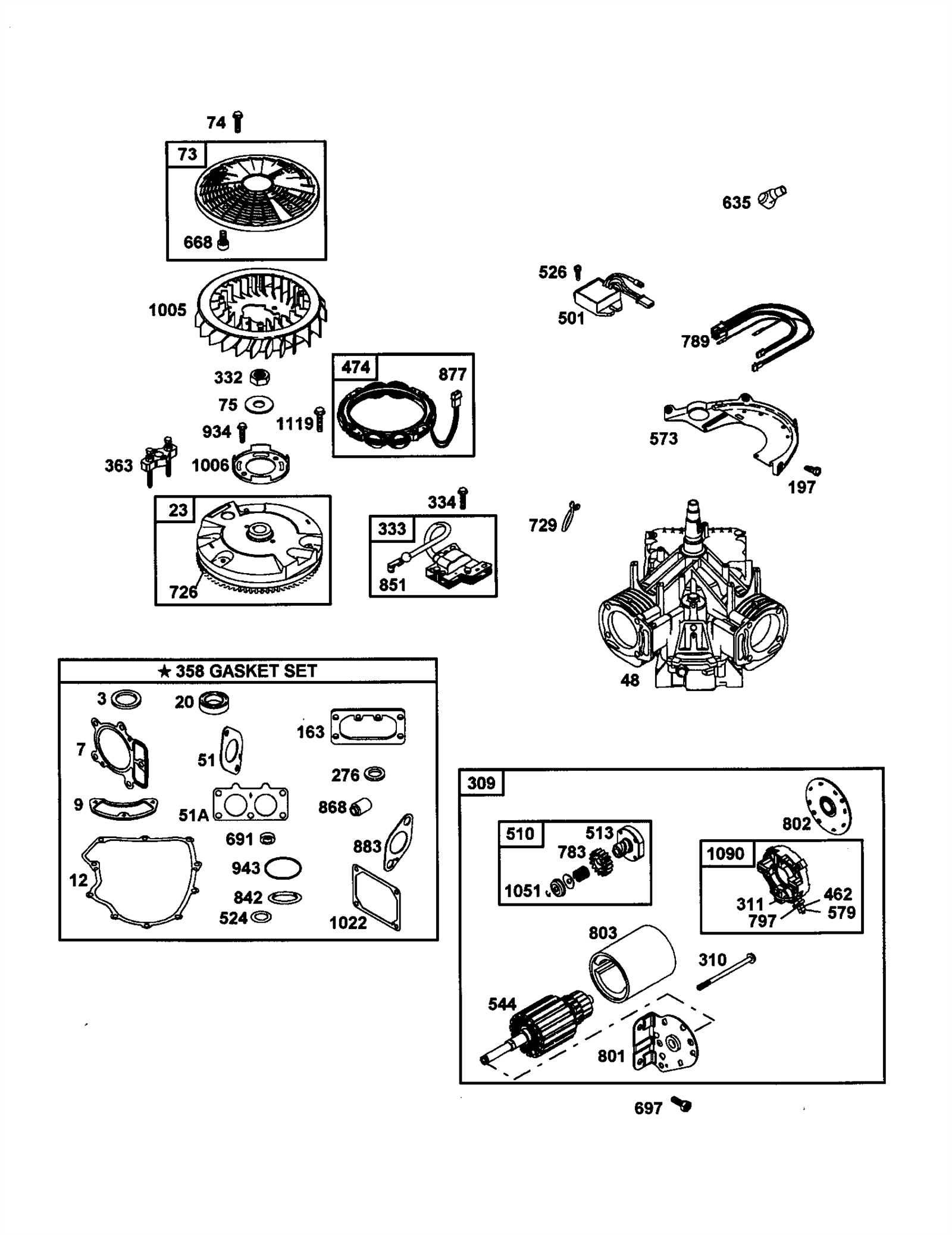

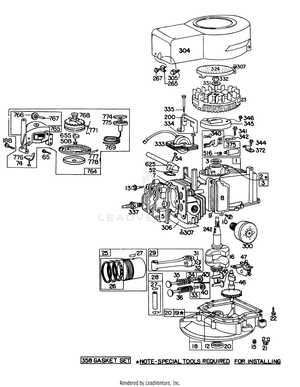

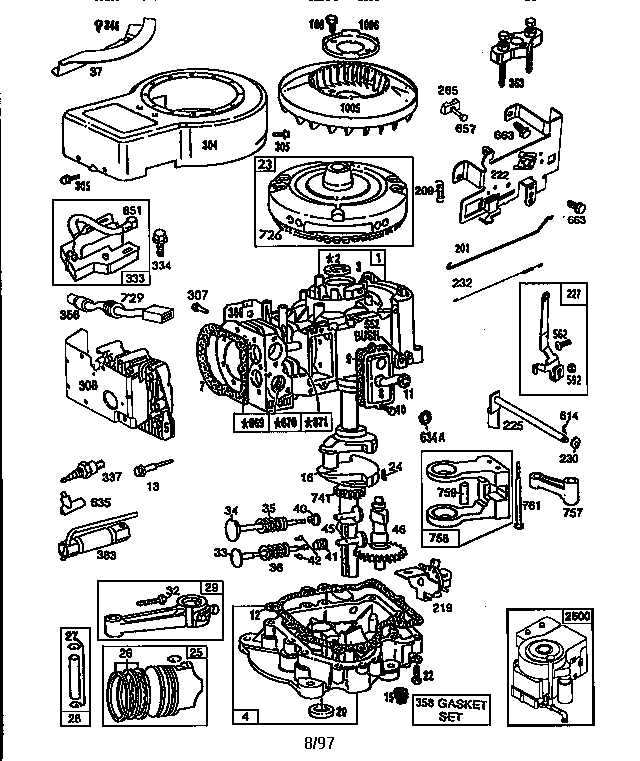

Ignition System Breakdown for Beginners

The ignition system is essential for ensuring proper operation by delivering the necessary spark to ignite fuel. Understanding how this system functions can help you troubleshoot common issues and maintain smooth performance. Whether you’re new to engine mechanics or simply want to learn the basics, this guide provides a clear overview of the components involved.

Spark Plug: This component generates the spark that ignites the fuel. It is crucial to inspect and replace the spark plug regularly to maintain reliable operation.

Flywheel: The flywheel plays a key role in generating the energy needed to create the spark. As it rotates, magnets on the flywheel pass by a coil, which triggers a spark at the right time.

The combination of these components ensures that the process of combustion occurs efficiently. A solid understanding of how each part works together will allow for better maintenance and quicker

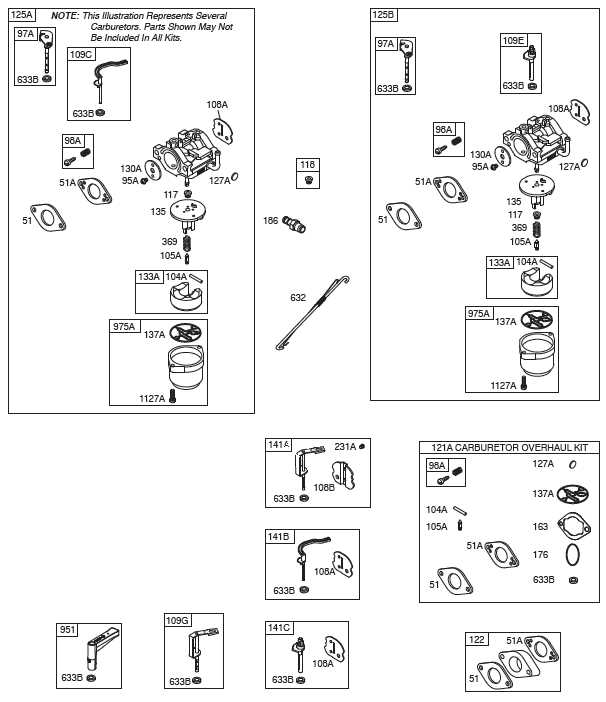

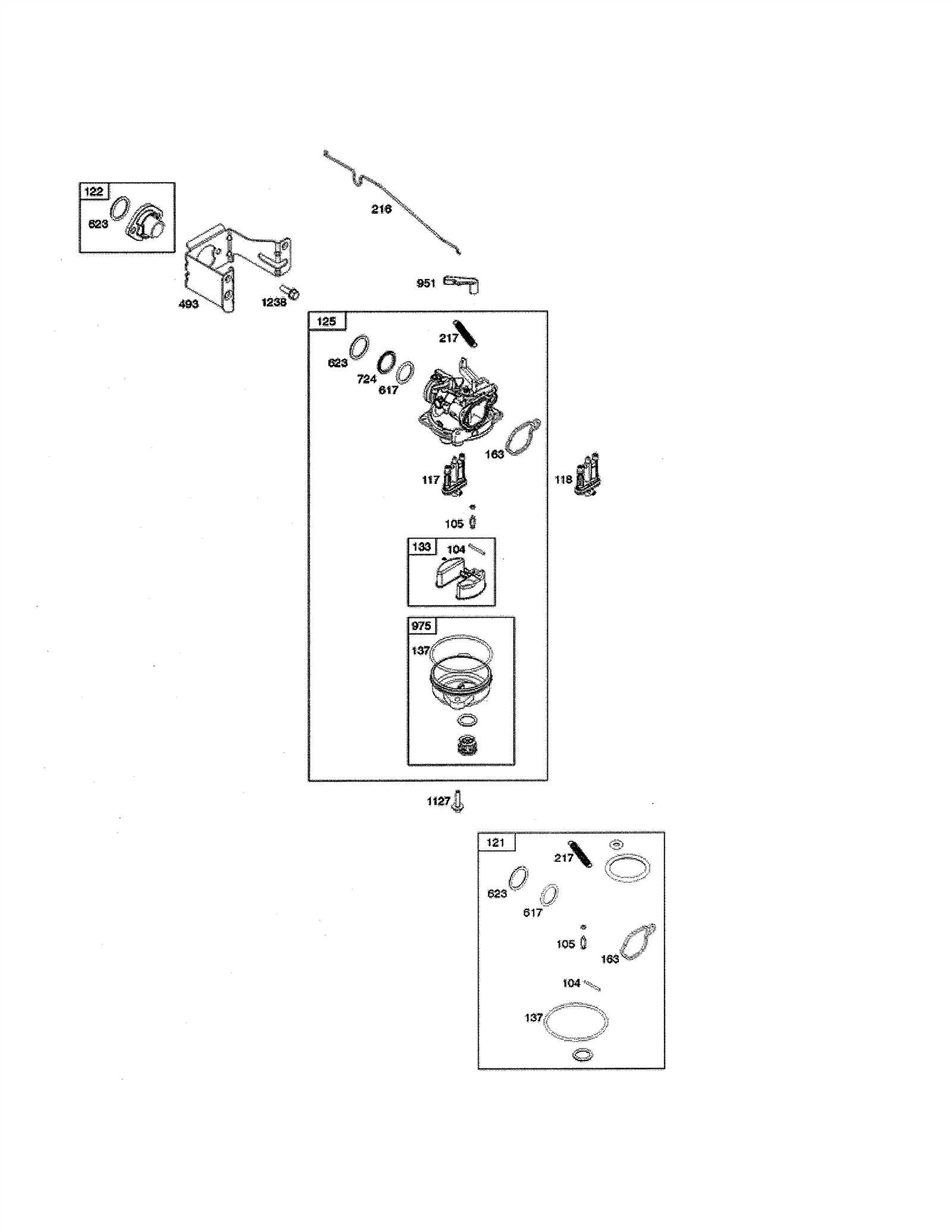

Common Issues with Carburetors

Carburetors are vital components in fuel delivery systems, playing a key role in the proper functioning of various machinery. Despite their importance, these units often encounter several challenges that can affect performance and efficiency. Understanding these common problems is essential for effective maintenance and troubleshooting.

Frequent Problems

- Clogged Jets: Accumulation of dirt and debris can obstruct fuel flow, leading to poor engine performance.

- Fuel Leaks: Wear and tear on gaskets and seals can result in leaks, compromising the system’s efficiency.

- Imbalanced Fuel Mixture: An incorrect air-to-fuel ratio can cause starting issues and erratic operation.

- Sticking Floats: Float malfunctions can prevent proper fuel levels, leading to flooding or starvation.

Troubleshooting Steps

- Inspect the carburetor for visible signs of wear or damage.

- Clean the jets and passages thoroughly to ensure unobstructed fuel flow.

- Check for fuel leaks and replace any damaged gaskets or seals.

- Adjust the air-fuel mixture as necessary to achieve optimal performance.

Exhaust Systems and Their Importance

The exhaust system plays a crucial role in the overall performance and efficiency of any machinery. Its primary function is to direct harmful gases produced during operation away from the combustion chamber, ensuring a safer and cleaner working environment. Proper management of these emissions not only enhances performance but also contributes to the longevity of the unit.

Moreover, an effective exhaust system helps in maintaining optimal temperature levels within the machinery. By facilitating the release of hot gases, it prevents overheating, which can lead to severe damage. Additionally, it minimizes noise pollution, providing a more pleasant experience during use.

Regular maintenance of the exhaust components is essential for sustained functionality. Any blockages or leaks can significantly hinder performance and increase emissions. Thus, understanding the significance of this system allows operators to make informed decisions regarding upkeep and replacement, ultimately improving efficiency and reliability.

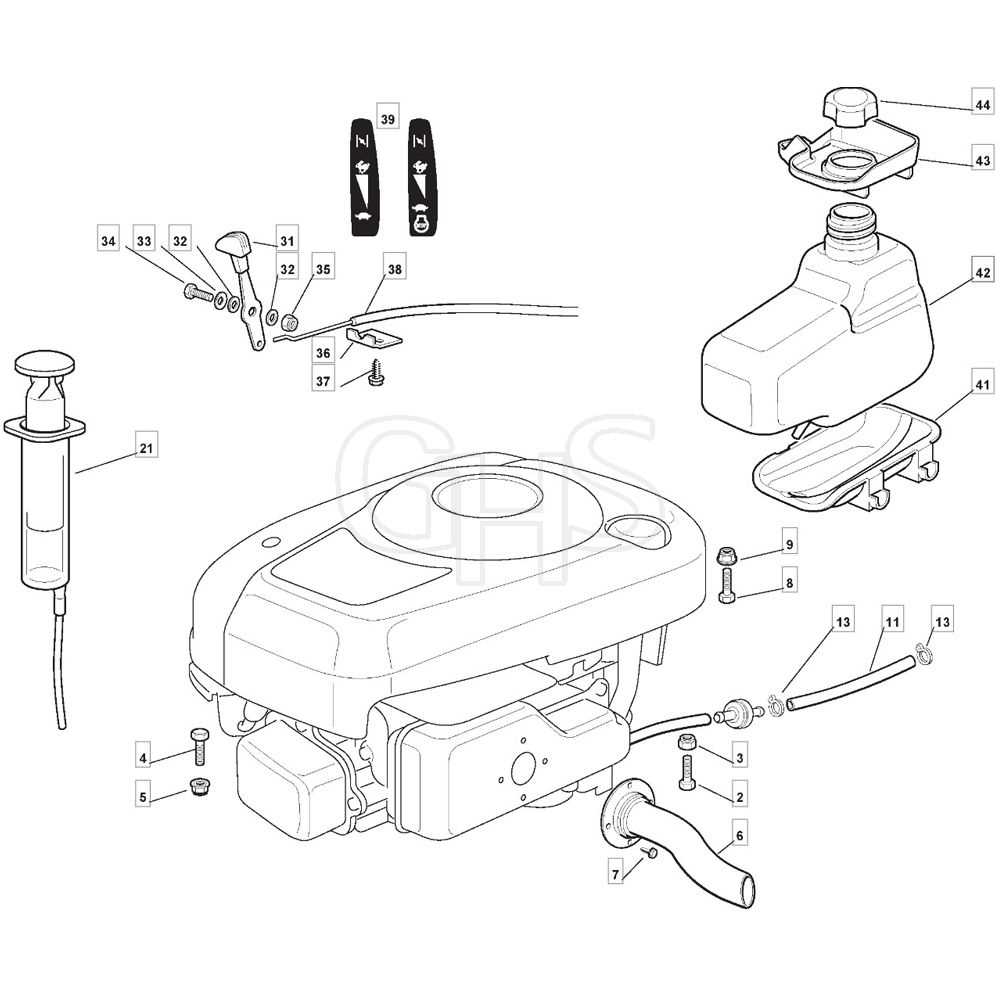

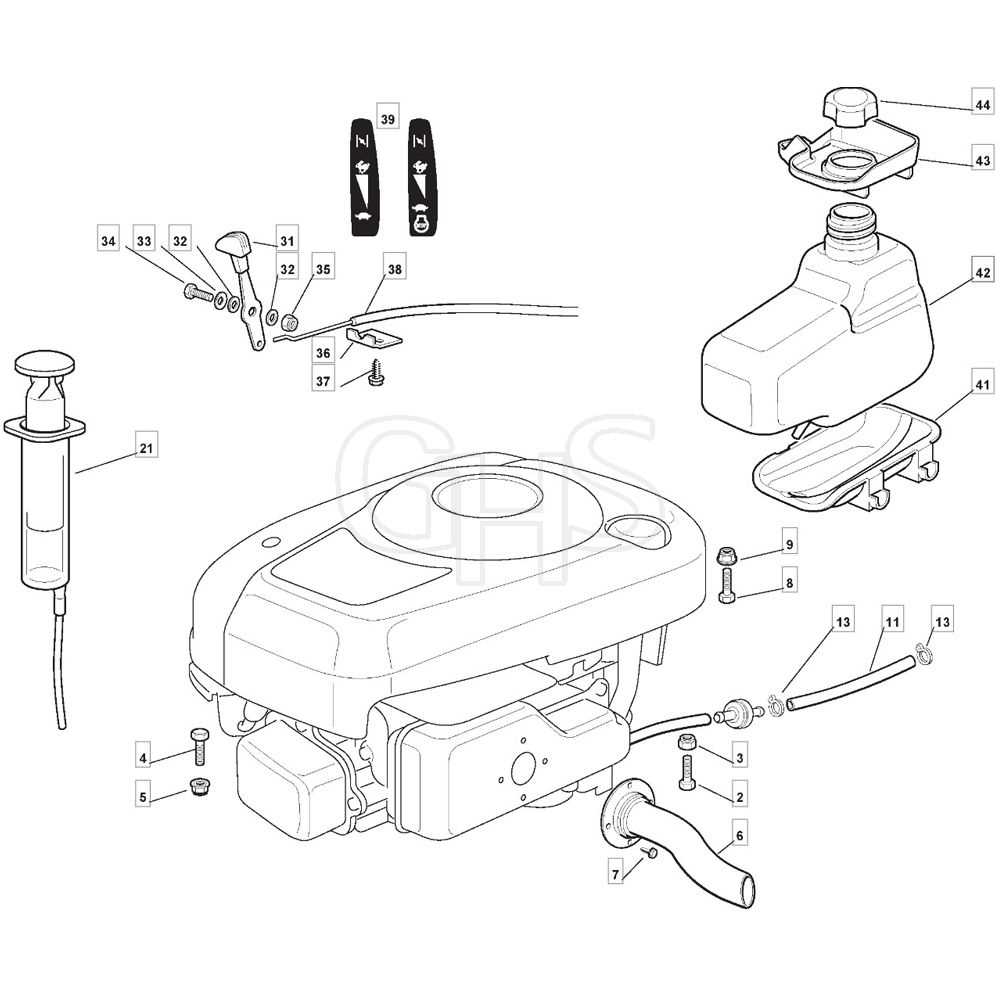

Fuel System Components Explained

The fuel system is a vital aspect of any power machinery, ensuring the efficient delivery of fuel to the combustion chamber. Each element plays a crucial role in maintaining optimal performance, from storage to ignition. Understanding these components helps in troubleshooting and enhancing the overall functionality of the equipment.

The following table outlines the main components of the fuel delivery system and their respective functions:

| Component |

Function |

| Fuel Tank |

Stores the fuel until it is needed for combustion. |

| Fuel Pump |

Moves fuel from the tank to the carburetor or fuel injection system. |

| Carburetor |

Mixes air and fuel in the correct ratio for efficient combustion. |

| Fuel Filter |

Removes impurities from the fuel before it reaches the combustion chamber. |

| Fuel Lines |

Transport fuel from the tank to the engine components. |

| Injector (in fuel-injected systems) |

Delivers precise amounts of fuel directly into the combustion chamber. |

Each of these elements contributes to the smooth operation of the machinery. Regular maintenance and inspection of the fuel system are essential for ensuring longevity and efficiency.

Proper Maintenance for Engine Longevity

Ensuring the extended life of your machinery involves consistent care and attention to detail. By implementing effective maintenance practices, you can significantly enhance performance and durability. Regular upkeep not only prevents unexpected breakdowns but also optimizes functionality and efficiency.

Here are key practices to consider for optimal care:

- Regular Cleaning: Keep the exterior and interior components free from dirt and debris to prevent corrosion and wear.

- Fluid Checks: Frequently inspect oil, fuel, and other necessary fluids to ensure they are at appropriate levels and free from contaminants.

- Filter Replacement: Replace air and fuel filters according to the manufacturer’s recommendations to maintain proper airflow and fuel efficiency.

- Inspection of Belts and Cables: Regularly check for wear and tear on belts and cables, replacing them as needed to prevent failures.

- Sharpening Blades: For machinery with cutting components, ensure that blades are sharp and properly aligned to improve cutting efficiency.

By following these guidelines, you will contribute to the longevity and reliability of your equipment, ensuring it operates smoothly for years to come.

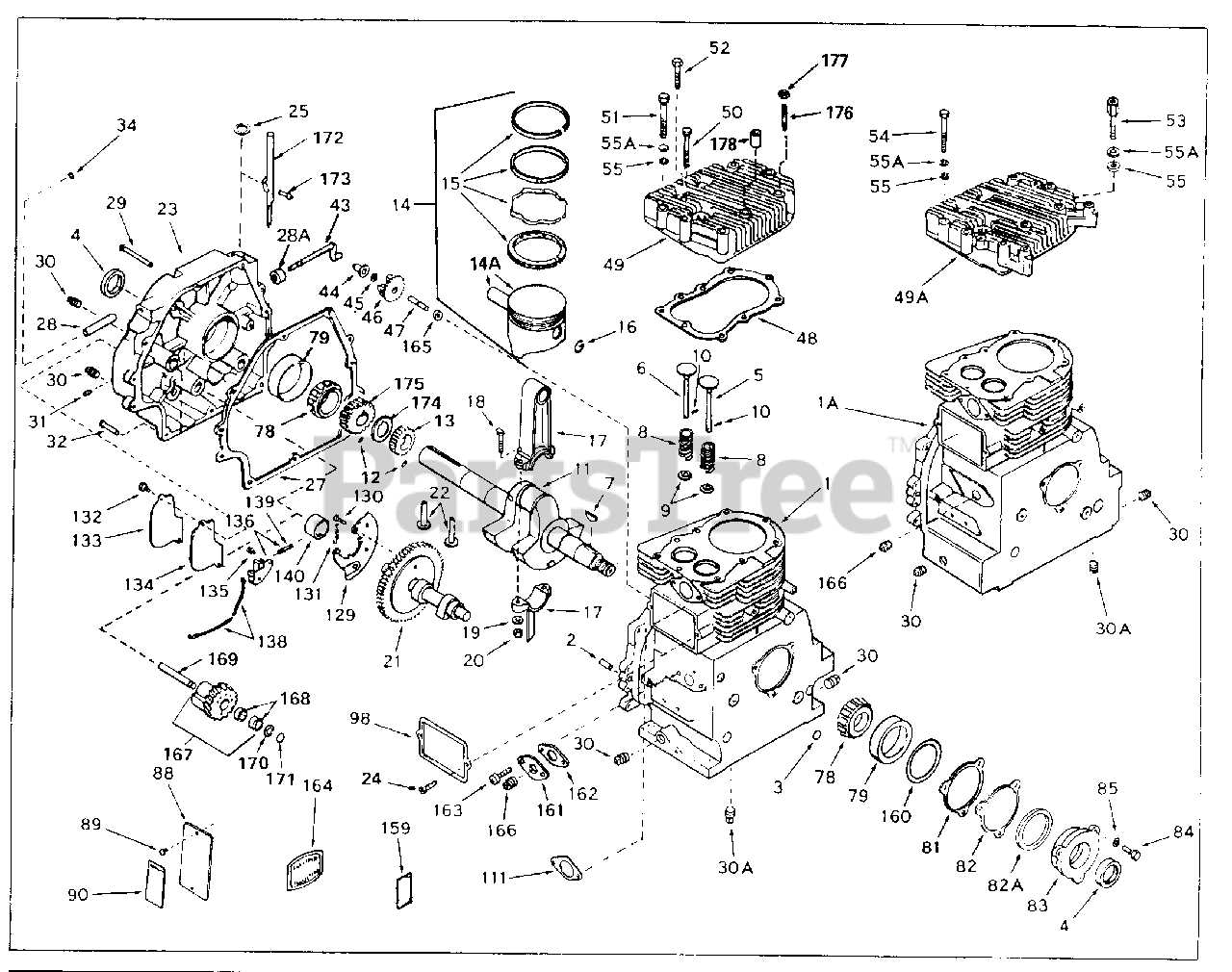

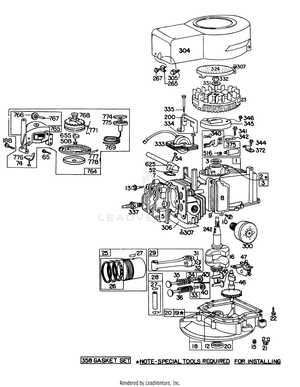

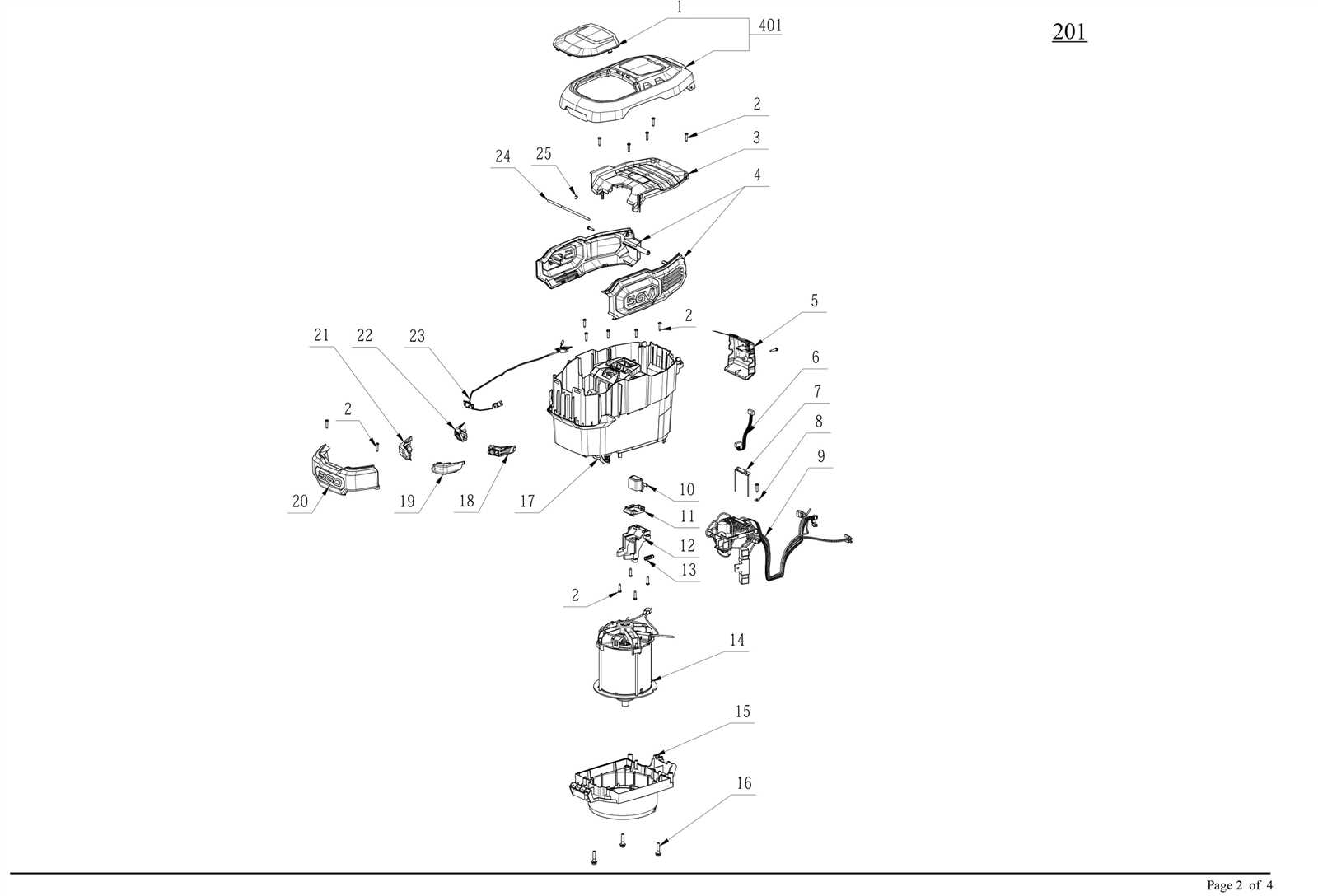

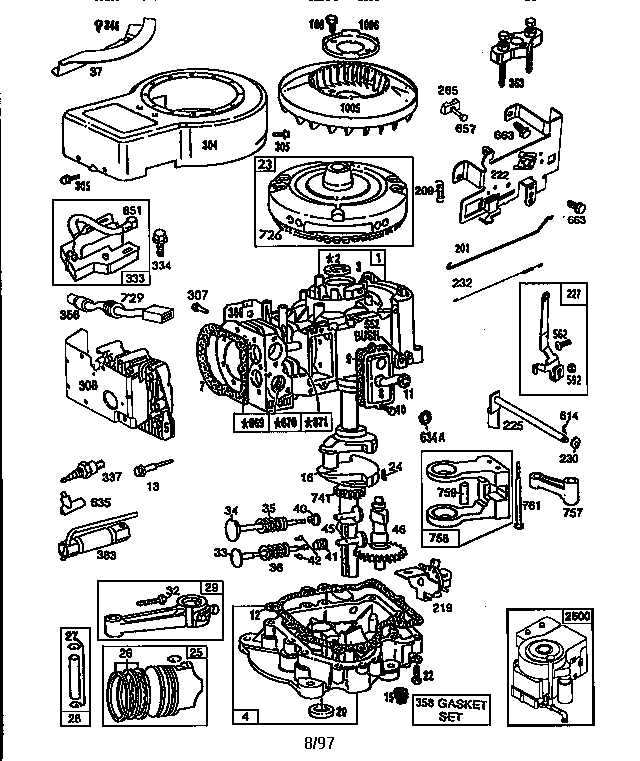

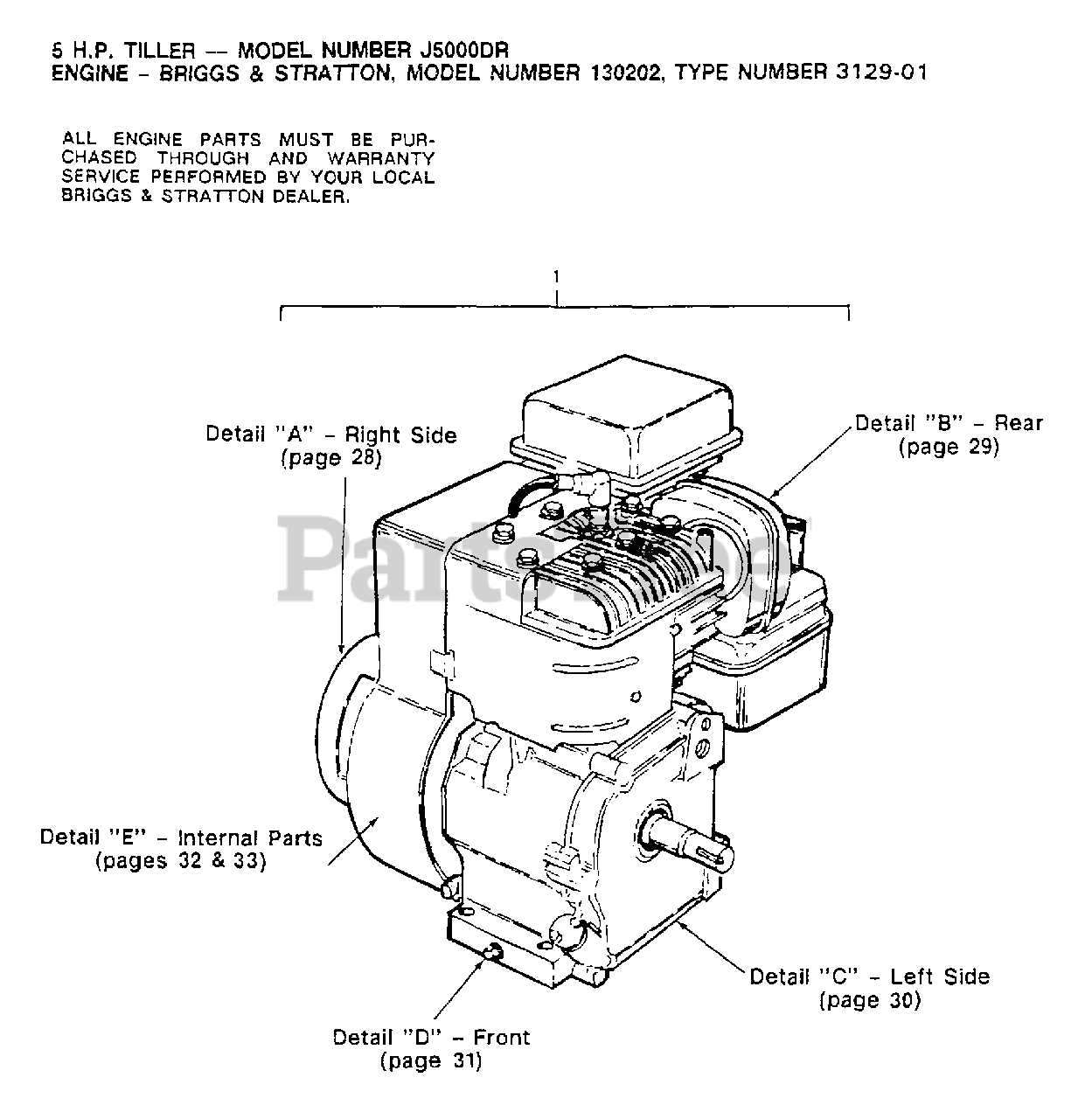

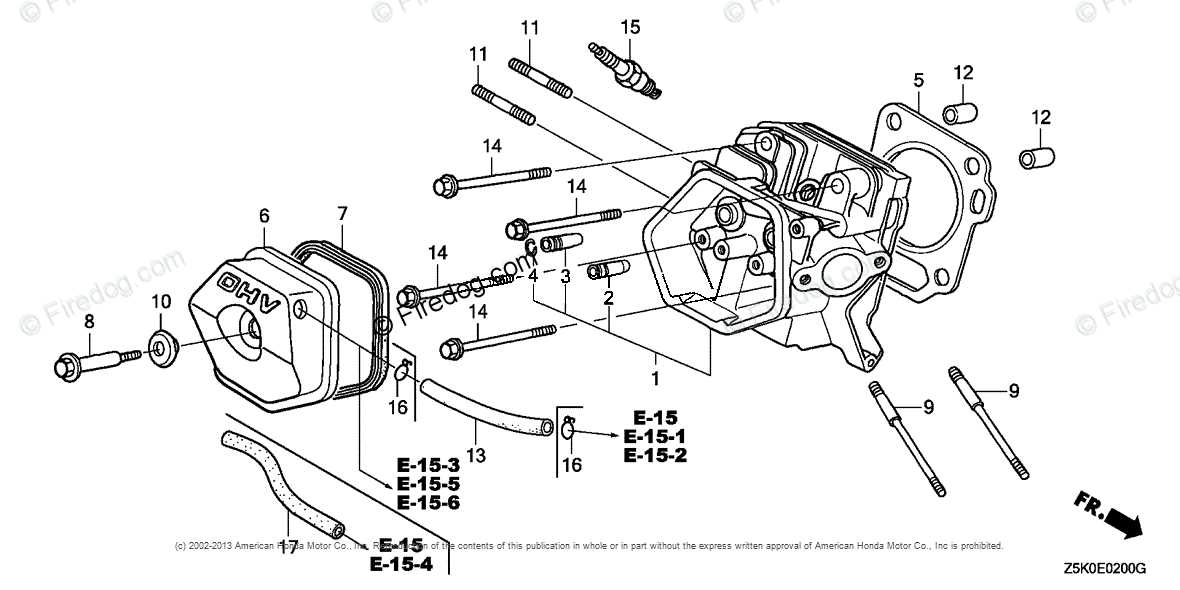

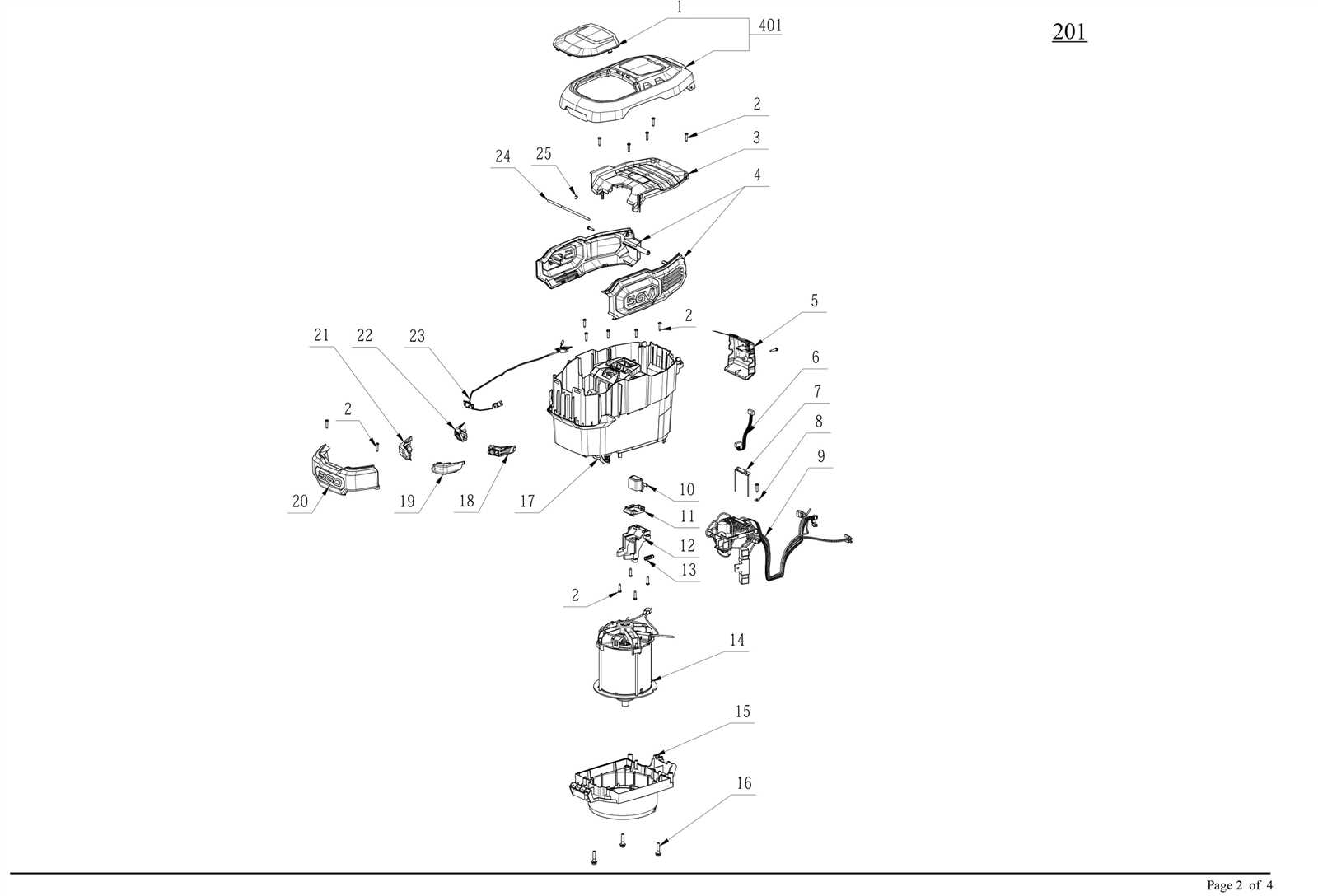

Using Diagrams for Troubleshooting

Visual representations can significantly enhance the process of diagnosing issues in mechanical systems. By providing a clear layout of components and their interconnections, these illustrations allow users to identify potential problems more efficiently. Utilizing these visual aids simplifies complex information, making it accessible for individuals at all skill levels.

When encountering a malfunction, referring to a visual guide can help pinpoint the source of the issue. For instance, users can trace electrical pathways or fluid lines, ensuring that all elements function correctly. This approach not only aids in identifying failures but also assists in understanding the overall structure and operation of the machinery.

In addition, utilizing these visuals encourages a systematic approach to repairs. By following a structured methodology, individuals can avoid unnecessary disassembly and focus on the components most likely to be causing the malfunction. As a result, troubleshooting becomes more efficient, saving both time and resources.

Ultimately, integrating visual aids into the troubleshooting process fosters a more thorough comprehension of mechanical systems, enabling users to resolve issues confidently and effectively.

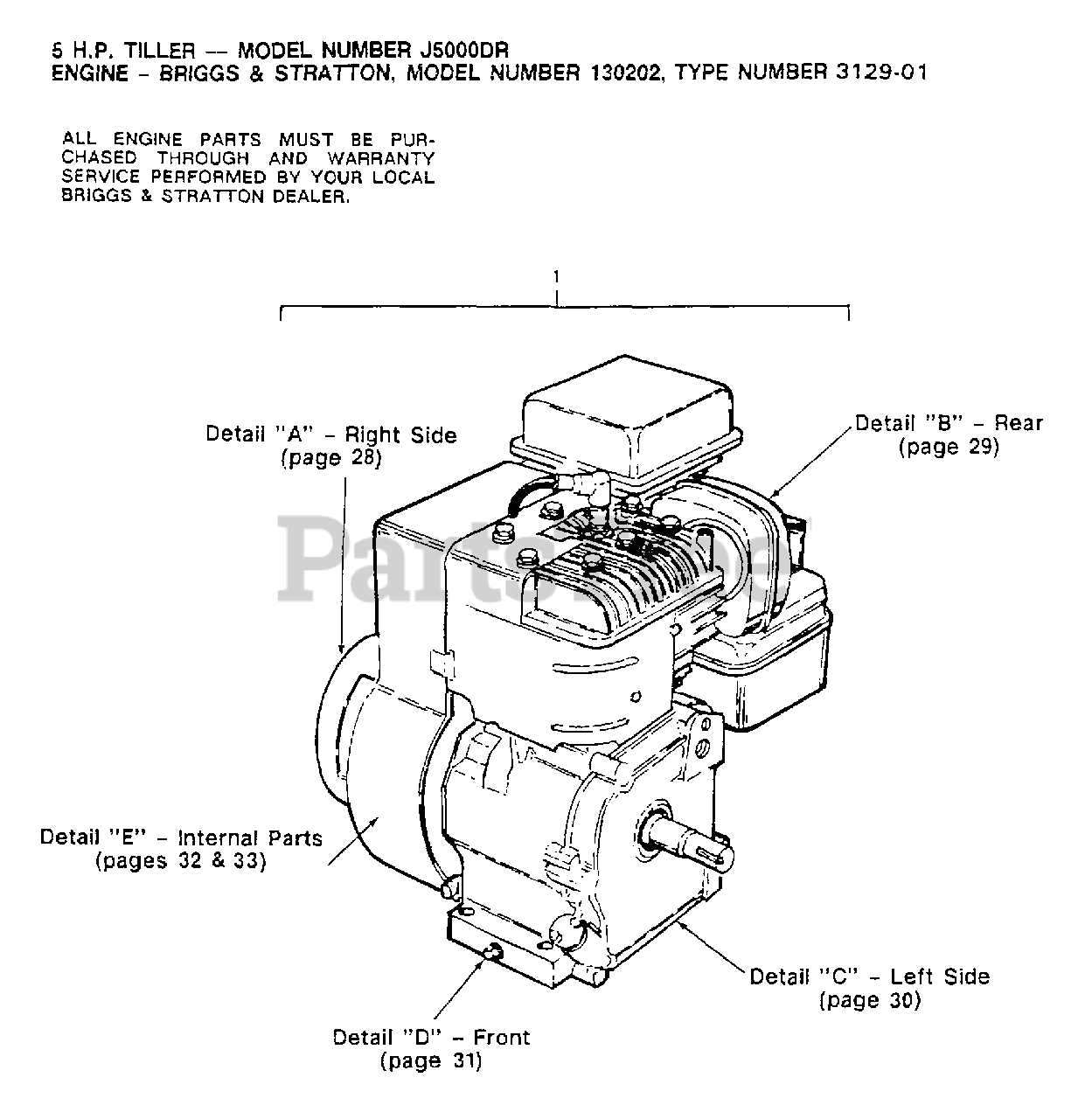

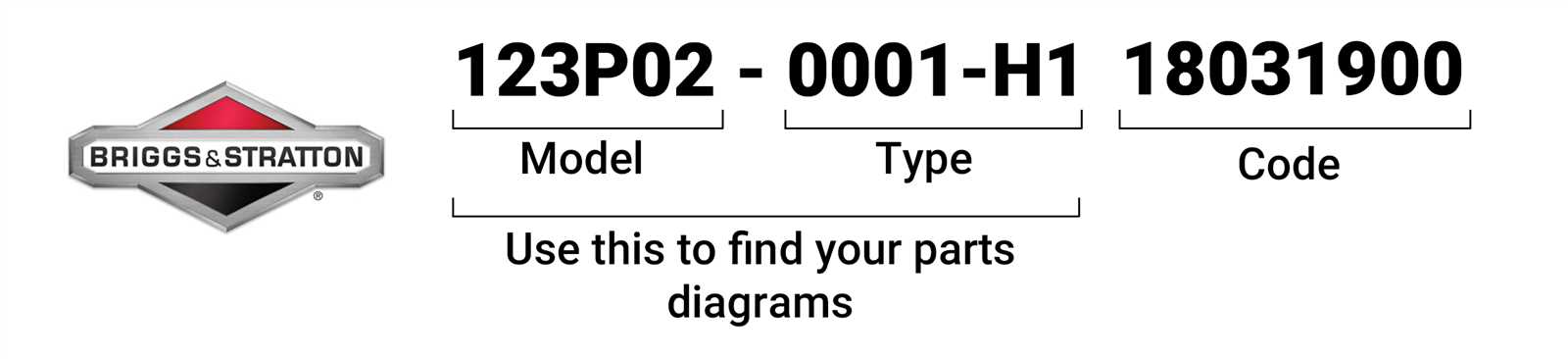

Choosing the Right Replacement Parts

Selecting suitable components for your machinery is crucial for ensuring optimal performance and longevity. Identifying the right substitutes not only enhances functionality but also minimizes potential issues during operation. By understanding the specific requirements of your equipment, you can make informed decisions that lead to successful maintenance and repair tasks.

Understanding Compatibility

When sourcing new components, it’s essential to consider compatibility with your specific model. Each unit has unique specifications that must be matched to avoid operational disruptions. Referencing the manufacturer’s guidelines can help you determine the correct dimensions and functionality of the required substitutes.

Quality vs. Cost

While affordability is an important factor, prioritizing quality over cost can save you money in the long run. High-quality replacements tend to perform better and last longer, ultimately reducing the frequency of replacements. Evaluate various suppliers and their reputations to ensure you are investing in reliable components.

Understanding Belt and Pulley Mechanisms

Belt and pulley systems play a vital role in transmitting motion and power within various machines. These components work together to create an efficient transfer of energy, allowing for the seamless operation of different mechanisms. By understanding their functionality, one can appreciate their significance in optimizing performance.

The mechanism consists of a flexible looped material, known as a belt, that runs over a series of grooved wheels called pulleys. As one pulley rotates, it moves the belt, which, in turn, causes the adjacent pulley to spin. This interaction enables various applications, from simple devices to complex machinery.

Types of Belts

There are several types of belts used in these systems, including flat, V-shaped, and timing belts. Each type serves a specific purpose and is designed for particular operational conditions. For instance, V-belts are commonly utilized for their ability to grip pulleys effectively, reducing slippage and enhancing power transmission.

Importance of Pulleys

Pulleys come in various sizes and configurations, allowing for adjustments in speed and torque. The selection of appropriate pulleys can significantly influence the overall performance and efficiency of the mechanism. Proper alignment and tensioning of belts are crucial to prevent wear and ensure longevity.

Conclusion

In conclusion, belt and pulley systems are fundamental components that facilitate energy transfer in machinery. A comprehensive understanding of these mechanisms aids in maintenance and troubleshooting, ultimately contributing to the reliability and efficiency of the equipment.

|