Briggs and Stratton Vanguard 16 HP Parts Diagram Explained

In the world of small engines, comprehending the various components and their functions is essential for maintenance and repair. This section aims to provide a clear overview of the essential elements that contribute to the operation of a powerful 16 HP engine. Whether you are a seasoned mechanic or a novice enthusiast, having access to detailed information about these crucial parts can enhance your ability to troubleshoot and service the machinery effectively.

From the ignition system to the fuel delivery mechanisms, each element plays a significant role in ensuring optimal performance. Familiarity with these components not only aids in identifying potential issues but also empowers users to carry out repairs confidently. Understanding how everything fits together is the key to achieving longevity and efficiency in engine operation.

In this guide, we will explore the intricate details of each segment, providing insights into their interconnections and functionalities. By equipping yourself with this knowledge, you can enhance your technical skills and ensure that your engine remains in peak condition for years to come.

Understanding Briggs and Stratton Engines

This section explores the intricacies of small engines commonly used in various outdoor equipment. These power units are renowned for their reliability and efficiency, making them a preferred choice for both professionals and hobbyists alike. Understanding their components and functionality is essential for maintenance and optimal performance.

Key Components

Every engine comprises vital parts that work harmoniously to produce power. Key elements include the carburetor, ignition system, and fuel tank, each playing a crucial role in the overall operation. Familiarity with these components enables better troubleshooting and enhances longevity.

Maintenance Tips

Regular upkeep is necessary to ensure peak performance. Simple practices such as checking oil levels, cleaning air filters, and inspecting spark plugs can significantly impact the engine’s efficiency. Implementing these tips leads to enhanced durability and reduced downtime.

Importance of Vanguard Engine Models

Engine models play a crucial role in various applications, providing reliability and performance that meet industry standards. These specific designs are tailored for heavy-duty use, ensuring longevity and efficiency in demanding environments.

Key Benefits

- Enhanced durability for prolonged use.

- High power output suitable for challenging tasks.

- Innovative technology for improved fuel efficiency.

Applications

- Construction machinery.

- Agricultural equipment.

- Lawn care tools.

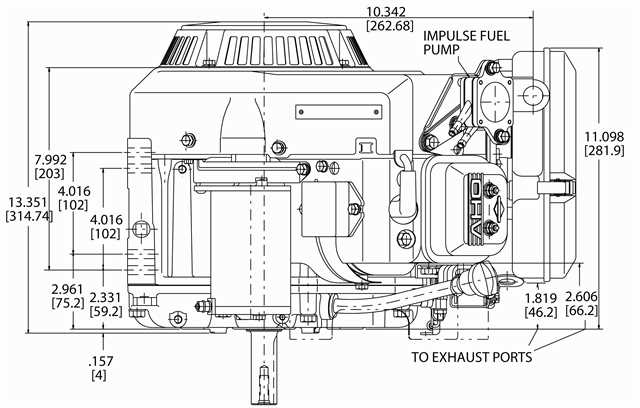

Key Features of the 16 HP Engine

The 16 horsepower engine is designed to provide exceptional performance and reliability, making it a popular choice for various applications. Its robust construction and advanced technology ensure efficient operation, catering to both professional and recreational needs.

Power and Efficiency

This engine boasts impressive power output, delivering strong torque for demanding tasks. Its engineering maximizes fuel efficiency, allowing longer operation between refueling, which is essential for extended projects.

Durability and Maintenance

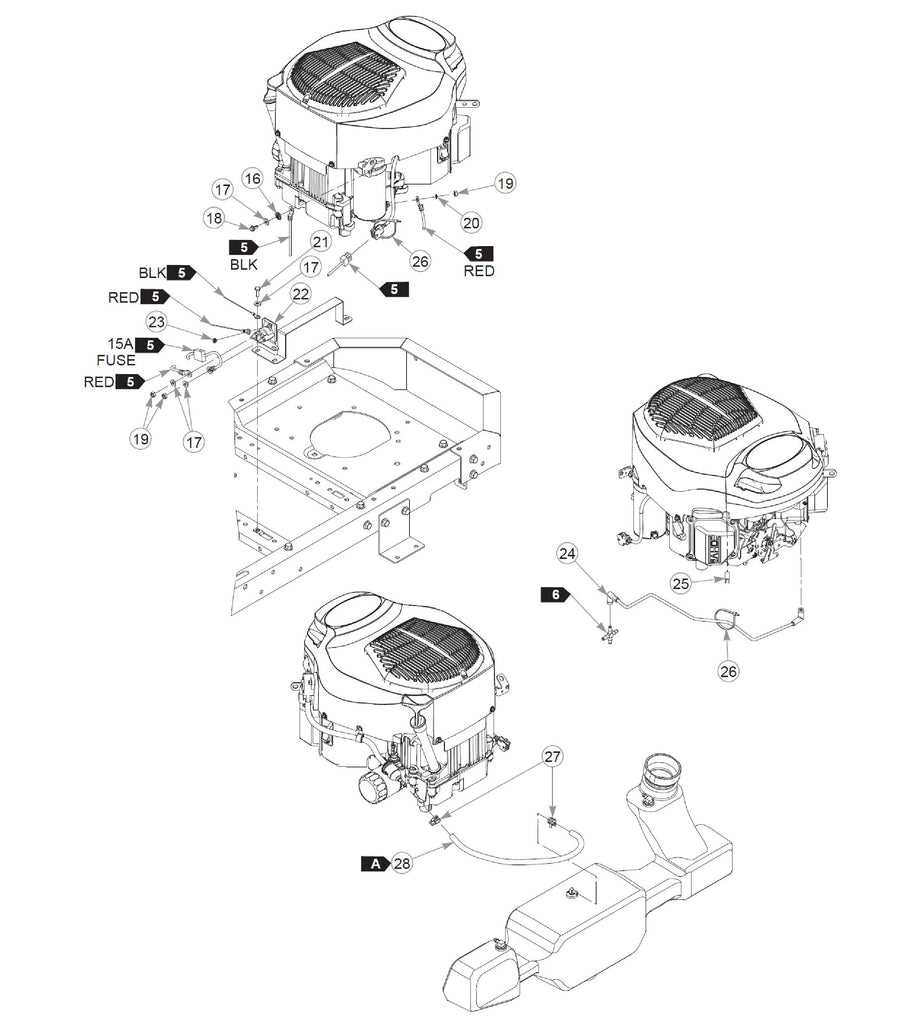

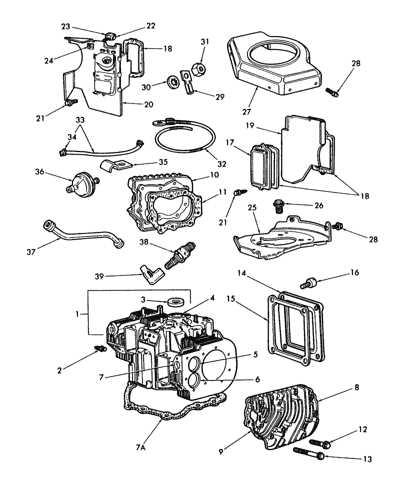

Identifying Component Functions

Understanding the roles of various elements within a power unit is crucial for effective maintenance and repair. Each component plays a unique role in the overall functionality, contributing to performance and reliability.

Main Components

- Engine Block: The core structure housing critical elements.

- Piston: Converts pressure from combustion into mechanical energy.

- Cylinder Head: Contains valves and is vital for the combustion process.

Supporting Elements

- Crankshaft: Transforms linear motion into rotational movement.

- Fuel System: Delivers the necessary fuel for combustion.

- Cooling System: Prevents overheating, ensuring optimal operation.

Common Issues with Vanguard Engines

Engines of this type are widely utilized in various applications, yet they can encounter several prevalent challenges. Understanding these issues can aid in effective maintenance and timely repairs, ensuring optimal performance and longevity.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Hard Starting | Engine fails to start or requires multiple attempts | Check fuel supply, battery condition, and ignition system |

| Overheating | Engine runs hotter than normal, steam or smoke | Inspect cooling system, clean air filters, and check for blockages |

| Excessive Vibration | Unusual shaking during operation | Ensure proper mounting, inspect flywheel, and check balance |

| Oil Leaks | Visible oil on engine surface or ground | Examine seals and gaskets, replace as necessary |

| Poor Performance | Loss of power or rough running | Clean or replace air filters, check fuel quality, and inspect spark plugs |

Parts Replacement Guide

Maintaining small engines requires a keen understanding of components and their functions. Regularly replacing worn-out elements not only enhances performance but also extends the lifespan of your equipment. This guide provides essential insights into the various components, helping you identify when a replacement is necessary and how to proceed with it.

Identifying Worn Components: Regular inspection is crucial. Look for signs of wear such as cracks, leaks, or unusual noises. Common items needing attention include filters, spark plugs, and belts. Knowing what to check can save you time and prevent further damage.

Choosing Quality Replacements: Opt for high-quality substitutes to ensure reliability. Authentic components may cost more initially but can provide better performance and longevity. Researching reputable suppliers will help you find the best options available.

Replacement Process: When replacing any element, follow manufacturer guidelines. Gather the necessary tools and take your time to ensure a proper fit. If uncertain, consulting a professional can save you from making costly mistakes.

Maintenance Tips: After replacing any part, routine maintenance is vital. Regularly clean and inspect your equipment, and keep an eye on performance to catch issues early. This proactive approach can significantly enhance operational efficiency.

Where to Find Diagrams

Locating detailed illustrations for engines can enhance your understanding and maintenance of machinery. Several resources provide comprehensive visuals that can assist in identifying components and their arrangements.

- Manufacturer Websites: Official sites often offer downloadable resources.

- Online Retailers: Websites selling engine components frequently include diagrams in their product descriptions.

- Forums and Community Groups: Engaging with enthusiasts can yield shared diagrams and insights.

- Repair Manuals: Investing in a dedicated manual can provide extensive illustrations and instructions.

- YouTube Channels: Video tutorials may include visual guides and breakdowns.

Utilizing these sources can ultimately streamline your repair or maintenance tasks.

Choosing Quality Replacement Parts

When maintaining outdoor machinery, selecting high-quality components is essential for optimal performance and longevity. Ensuring the reliability of your equipment hinges on sourcing reliable items that match or exceed original specifications.

Benefits of Quality Components

Investing in superior replacements can yield numerous advantages:

- Durability: Premium materials enhance the lifespan of the equipment.

- Performance: High-grade items improve efficiency and operation.

- Compatibility: Quality replacements often fit seamlessly, minimizing installation issues.

- Warranty: Reputable manufacturers usually provide guarantees, adding peace of mind.

How to Identify Quality Options

When searching for superior components, consider the following tips:

- Research Brands: Look for manufacturers known for their reliability and customer satisfaction.

- Read Reviews: Check user feedback to gauge the performance of specific items.

- Verify Specifications: Ensure the replacements match the required measurements and functionalities.

- Consult Experts: Seek advice from professionals or experienced users for recommendations.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficiency of your engine. Implementing a few straightforward practices can significantly extend its lifespan and enhance performance.

- Change the oil regularly to prevent buildup and maintain optimal lubrication.

- Inspect air filters frequently; clean or replace them as necessary to ensure proper airflow.

- Check spark plugs for wear; replacing them can improve starting and fuel efficiency.

- Clean the fuel system to prevent clogs and ensure smooth operation.

- Inspect belts and hoses for signs of wear; replace them to avoid breakdowns.

Following these guidelines will help you delve deeper into effective maintenance, leading to the ultimate performance of your machinery.

Upgrading Your Engine Components

Enhancing the performance and longevity of your engine is crucial for achieving optimal efficiency. By focusing on specific components, you can significantly improve power output, fuel efficiency, and overall functionality. This section delves into effective strategies for elevating your engine’s capabilities through targeted upgrades.

Choosing Quality Components

When considering enhancements, prioritize high-quality components that are designed for compatibility with your engine’s specifications. Upgrading elements such as air filters, exhaust systems, and fuel injectors can lead to remarkable improvements. Investing in premium parts not only boosts performance but also ensures reliability and durability.

Performance Modifications

Incorporating performance modifications can yield substantial benefits. For instance, installing a high-performance carburetor can improve air-fuel mixture efficiency, leading to enhanced combustion. Additionally, upgrading ignition systems can result in quicker starts and smoother operation. Assess your engine’s needs to determine the most impactful modifications.