Suzuki DF20A Parts Diagram Guide

When it comes to maintaining and repairing marine engines, having a clear understanding of their individual components is essential. This knowledge not only enhances the efficiency of the engine but also ensures its longevity. A comprehensive overview of the various elements involved allows for more effective troubleshooting and timely repairs.

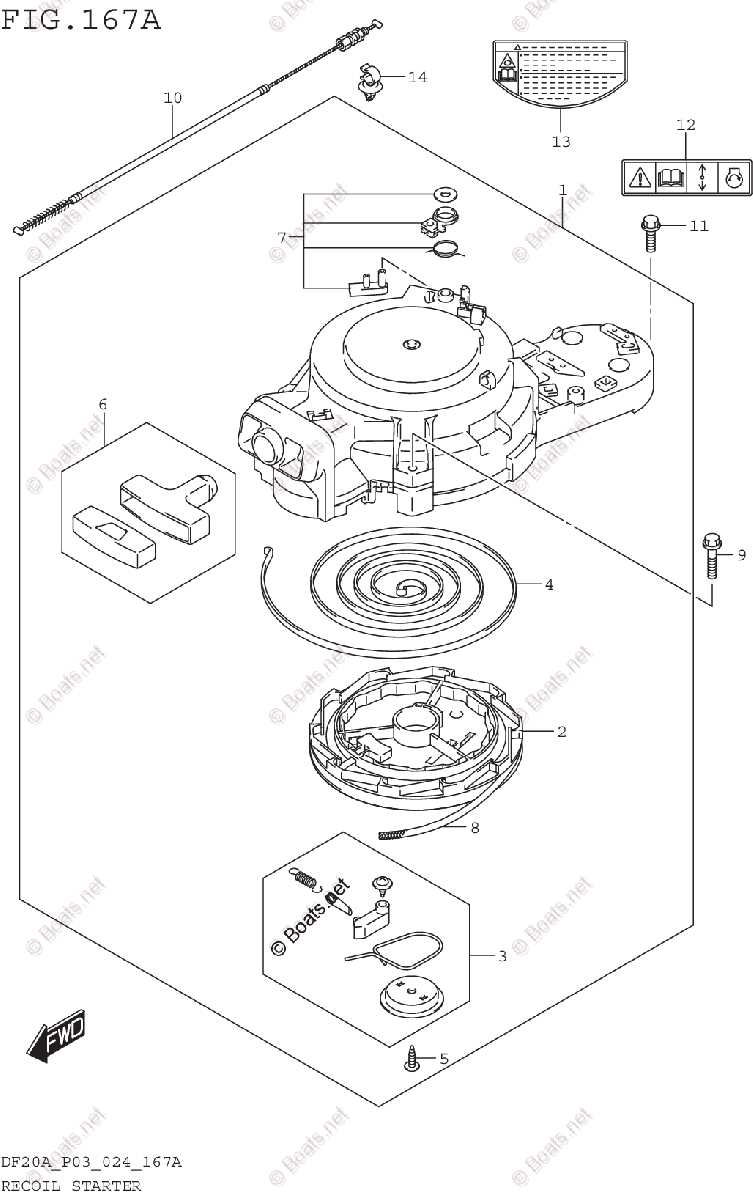

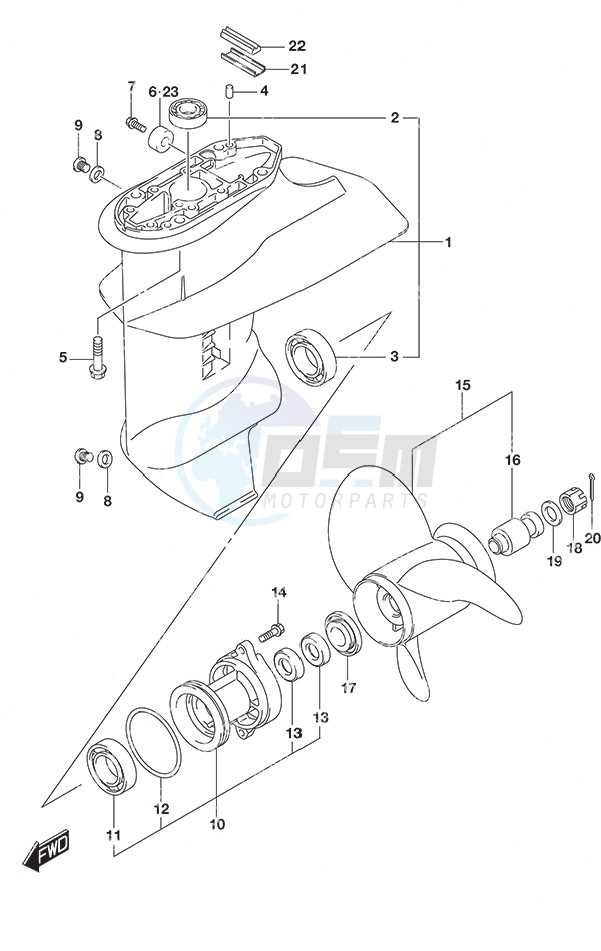

Visual representations of engine components serve as valuable tools for both seasoned technicians and enthusiastic boat owners. These illustrations provide insight into the intricate relationships between parts, making it easier to identify issues and understand assembly processes. By familiarizing oneself with these detailed visuals, one can gain a greater appreciation for the engineering that goes into marine propulsion systems.

In this article, we will delve into the specific components of a popular outboard engine model, highlighting their functions and interconnections. Whether you are looking to replace a faulty piece or simply enhance your understanding of the system, this exploration will equip you with the knowledge necessary to tackle any maintenance challenge.

Understanding the Suzuki DF20A Engine

The compact marine engine is designed to offer reliable performance and efficiency, making it a popular choice among boating enthusiasts. With its advanced engineering, this power unit delivers a blend of power and precision, suitable for various watercraft. Understanding the key components and functionality of this engine can significantly enhance maintenance and performance optimization.

Core Features

One of the standout characteristics of this engine is its lightweight design, which facilitates easy handling and installation. The incorporation of modern technology ensures that it operates smoothly under various conditions. Additionally, the fuel efficiency of this unit allows for extended journeys without the constant need for refueling, appealing to both casual users and avid adventurers.

Maintenance and Care

Regular upkeep is essential to keep this marine engine in top shape. Familiarizing oneself with its individual components can aid in identifying potential issues before they escalate. A proactive approach to maintenance, including routine checks and timely replacements, not only extends the lifespan of the engine but also enhances its overall performance.

Key Features of the DF20A

This remarkable outboard motor stands out due to its impressive combination of performance, efficiency, and user-friendly design. Engineered for versatility, it caters to a wide range of aquatic activities, making it a popular choice among enthusiasts and professionals alike.

One of the standout characteristics is its lightweight construction, which enhances portability without sacrificing power. The innovative engineering ensures a smooth and quiet operation, allowing for a more enjoyable experience on the water. Additionally, the advanced fuel efficiency contributes to longer outings, minimizing the need for frequent refueling.

The motor is equipped with easy-to-use controls, providing a seamless experience for both novices and seasoned users. Its reliable starting mechanism ensures that users can quickly get on the water, while the robust design offers durability in various conditions. Furthermore, the integration of modern technology enhances overall performance, making it an excellent investment for any boating enthusiast.

Importance of Parts Diagrams

Understanding the various components of a machine is crucial for effective maintenance and repair. Visual representations of these elements provide valuable insights into the assembly and functionality of the equipment. By utilizing such illustrations, users can identify specific pieces, understand their relationships, and ensure proper handling during servicing.

These visual aids serve multiple purposes, including facilitating the ordering of replacement items, simplifying troubleshooting processes, and enhancing the overall efficiency of repairs. Clarity in visual information significantly reduces the risk of errors and speeds up the workflow.

| Benefits | Description |

|---|---|

| Enhanced Understanding | Visual aids allow users to grasp complex structures quickly. |

| Efficient Repairs | Identifying components easily leads to faster service and maintenance. |

| Accurate Ordering | Clear illustrations help in correctly identifying needed replacements. |

| Reduced Errors | Visual references minimize mistakes during assembly or disassembly. |

In conclusion, leveraging visual representations is essential for anyone involved in the upkeep of machinery. They provide a roadmap for understanding, maintaining, and restoring equipment to optimal working condition.

Common Components of DF20A

This section explores the essential elements found in a specific outboard motor model, highlighting their functions and importance. Understanding these components is crucial for effective maintenance and repair, ensuring optimal performance on the water.

| Component | Description |

|---|---|

| Engine Block | The core structure housing the internal mechanisms, providing strength and durability. |

| Powerhead | Encloses the combustion chamber and associated parts, generating the necessary power for propulsion. |

| Lower Unit | Contains the gear assembly and propeller shaft, responsible for transferring power to the propeller. |

| Fuel System | Comprises components like the fuel pump and injectors, crucial for delivering fuel to the engine. |

| Cooling System | Ensures that the engine operates within safe temperature limits, utilizing water or oil circulation. |

| Ignition System | Generates the spark required to ignite the air-fuel mixture, playing a vital role in engine operation. |

How to Read Parts Diagrams

Understanding technical illustrations is essential for anyone looking to maintain or repair machinery. These visual guides provide a comprehensive view of various components and their relationships, enabling users to identify and locate specific elements efficiently. Mastering the art of interpreting these illustrations can significantly enhance your ability to manage maintenance tasks.

1. Familiarize Yourself with the Layout

Before diving into the details, take a moment to observe the overall structure of the illustration. Typically, these visuals are organized into sections, with each area representing different assemblies or groups of components. Recognizing how the parts are grouped will help you navigate the illustration more effectively.

2. Identify Key Symbols and Labels

Each illustration includes a set of symbols and labels that denote various parts. Commonly, these will be accompanied by a legend or key that explains what each symbol represents. Familiarizing yourself with these identifiers is crucial for accurate interpretation.

3. Use Reference Numbers

Most technical illustrations employ reference numbers to link parts to their descriptions. By locating these numbers on the illustration, you can easily cross-reference them with accompanying documentation to gather more information about each component, including specifications and replacement options.

4. Pay Attention to Orientation

It’s important to note the orientation of the components depicted. Some illustrations may show parts from different angles, which can affect how they fit together. Understanding the perspective will aid in visualizing the assembly process during repairs.

5. Practice Makes Perfect

Finally, like any skill, proficiency in reading technical illustrations comes with practice. The more you familiarize yourself with these guides, the more intuitive they will become. Over time, you will find that your ability to interpret these visuals will streamline your repair and maintenance efforts.

Maintenance Tips for DF20A Parts

Proper upkeep of your outboard motor components is essential for optimal performance and longevity. Regular maintenance not only enhances reliability but also prevents costly repairs down the line. This section outlines key practices to ensure your motor operates smoothly.

Routine Inspections

- Check for any visible wear or damage on components.

- Inspect seals and gaskets for leaks or deterioration.

- Examine electrical connections for corrosion or loose wiring.

Cleaning and Lubrication

- Clean the exterior regularly to prevent salt and grime buildup.

- Lubricate moving parts as per the manufacturer’s recommendations.

- Ensure that fuel filters are clean to maintain optimal fuel flow.

Implementing these maintenance practices will help keep your motor in peak condition, enhancing both performance and reliability for years to come.

Where to Find Genuine Parts

Locating authentic components for your marine engine is crucial for ensuring optimal performance and longevity. Relying on original products helps maintain the reliability and efficiency of your equipment, preventing unnecessary complications and costs down the line.

Authorized Dealers

The most reliable source for genuine components is through authorized dealerships. These establishments offer a comprehensive selection of original products, along with expert advice on installation and maintenance. To find a dealer near you:

- Visit the manufacturer’s official website for a dealer locator tool.

- Contact customer support for recommendations on trusted dealers in your area.

Online Retailers

Numerous online platforms specialize in marine components, often featuring a vast inventory of original products. When shopping online, keep the following tips in mind:

- Check for customer reviews to ensure the retailer’s credibility.

- Verify that the items come with a warranty and return policy.

- Compare prices across different sites to find the best deals.

Common Issues and Solutions

Understanding frequent challenges and their resolutions can greatly enhance the reliability and performance of your marine engine. Many users encounter similar problems, which can often be addressed with straightforward fixes. Below is a summary of typical issues and their corresponding solutions.

| Issue | Description | Solution |

|---|---|---|

| Overheating | Engine temperature rises beyond normal levels, potentially causing damage. | Check coolant levels, inspect for blockages in the cooling system, and ensure the water pump is functioning properly. |

| Starting Problems | Engine fails to start or experiences difficulty in starting. | Inspect the battery for charge, check the fuel system for blockages, and ensure spark plugs are clean and functional. |

| Vibration | Excessive shaking or rattling during operation, indicating potential misalignment. | Examine mounting points and connections, ensuring everything is secure and properly aligned. |

| Fuel Leaks | Visible fuel escaping from lines or connections, posing safety hazards. | Identify the source of the leak, replace damaged lines or fittings, and ensure all connections are tightened. |

| Unusual Noises | Strange sounds such as knocking or grinding may indicate internal issues. | Conduct a thorough inspection of internal components and lubricate where necessary; consult a technician if problems persist. |

Comparing DF20A with Other Models

This section explores the distinctions between a specific outboard motor and its counterparts in the same category. By examining various features, performance metrics, and user experiences, we can gain insights into how this particular model stands out among its peers.

Key Features

- Power Output

- Fuel Efficiency

- Weight and Portability

- Noise Levels

- Maintenance Requirements

Performance Comparison

- Speed and Acceleration: Assessing how quickly each motor reaches optimal speed.

- Handling and Maneuverability: Evaluating ease of use in various water conditions.

- Durability: Comparing longevity and resilience to wear and tear.

- Environmental Impact: Looking at emissions and eco-friendliness of different models.

Ultimately, understanding these aspects can help potential buyers make informed decisions based on their specific needs and preferences.

DIY Repair vs. Professional Help

When it comes to fixing machinery, individuals often face the choice between tackling repairs themselves or seeking assistance from experts. Each approach has its own advantages and challenges, influencing both the outcome and the overall experience. Understanding these differences can help one make an informed decision that best suits their skills and needs.

DIY repairs can offer a sense of accomplishment and cost savings. By taking matters into your own hands, you gain valuable experience and knowledge about the equipment. Additionally, this method allows for flexibility in scheduling, enabling you to work at your own pace. However, it can also lead to frustration if the task proves too complex or if the right tools and parts are not readily available.

On the other hand, professional assistance ensures that repairs are handled by skilled technicians with expertise in the field. This option often leads to faster and more reliable results, minimizing the risk of further damage. Nevertheless, hiring a professional can come with a higher price tag, and it may require waiting for an appointment, which can be inconvenient.

Ultimately, the choice between repairing independently or engaging a professional hinges on factors such as the severity of the issue, personal experience, and available resources. Weighing these elements can guide you to the best solution for your specific situation.

Upgrading Your DF20A Engine

Enhancing the performance of your marine propulsion system can lead to improved efficiency, power, and longevity. By focusing on specific modifications and upgrades, you can transform your engine’s capabilities, making your water adventures even more enjoyable.

Key Areas for Improvement

- Fuel Efficiency: Upgrading the fuel system can lead to better combustion and reduced consumption.

- Ignition System: A modern ignition system can enhance starting performance and throttle response.

- Exhaust System: Improving the exhaust flow can boost power output and reduce emissions.

- Cooling System: Upgrading the cooling components helps maintain optimal operating temperatures, preventing overheating.

Steps to Consider

- Assess your current setup and identify areas for enhancement.

- Research compatible upgrades that match your performance goals.

- Consult with professionals or enthusiasts for advice on installation and best practices.

- Perform regular maintenance to ensure all components function smoothly post-upgrade.

With the right modifications, you can elevate your engine’s performance and enjoy a more thrilling experience on the water.