Suzuki King Quad Parts Diagram Overview

In the realm of off-road machinery, comprehending the intricate elements that contribute to optimal performance is paramount. Enthusiasts and operators alike benefit from a thorough exploration of the various segments that form the backbone of their vehicles. This knowledge not only enhances maintenance practices but also elevates the overall riding experience.

Each segment of an all-terrain vehicle plays a vital role in ensuring functionality and longevity. By gaining insights into these crucial components, users can make informed decisions about repairs, upgrades, and modifications. Furthermore, understanding how these elements interact can lead to a deeper appreciation of the engineering involved.

As we delve into the specifics, you’ll uncover the ultimate guide to identifying and locating these essential features. Whether you’re a seasoned rider or a newcomer, mastering this knowledge is key to unlocking your vehicle’s full potential.

Understanding Suzuki King Quad Parts

When it comes to maintaining your all-terrain vehicle, it’s crucial to have a solid understanding of its individual components. Each element plays a vital role in ensuring the vehicle performs optimally and is safe for any terrain. Recognizing the different mechanisms allows for better decision-making during repairs or upgrades, leading to improved functionality and longevity.

Mechanical systems within the vehicle are designed to work in harmony, ensuring smooth operation across various surfaces. These systems, from the propulsion units to the control elements, must be checked regularly to prevent wear and tear. Proper knowledge of the core elements helps enhance the vehicle’s durability and performance.

Upkeep of the propulsion, suspension, and steering units is essential to avoid malfunctions during use. Addressing these components proactively not only extends the vehicle’s lifespan but also reduces the likelihood of unexpected breakdowns. Being familiar with the essential mechanisms simplifies routine checks and major repairs alike.

Overview of King Quad Models

When it comes to off-road vehicles, these models have long been recognized for their versatility and dependability. Offering a range of features tailored to both utility and adventure, they are designed to meet diverse needs, from heavy-duty work to recreational exploration.

Performance and Features

- Equipped with robust single-cylinder engines, these vehicles ensure efficient power delivery suitable for challenging terrains.

- Many models come with a continuously variable transmission (CVT), allowing smooth transitions in different riding conditions.

- Advanced fuel injection systems enhance fuel efficiency and reliability, ensuring consistent performance regardless of the environment.

Comfort and Usability

To enhance user experience, these vehicles are designed with rider comfort in mind. Adjustable power steering options are available on select models, making maneuvering easier even in tough conditions. The ergonomic design, combined with features like electric starters and customizable suspension, caters to riders seeking a smooth and controlled ride.

- Electric starter systems offer ease of use.

- Adjustable suspension ensures adaptability across different terrains.

- Integrated digital displays provide essential information at a glance, enhancing operational convenience.

These models also stand out for their rugged durability, designed to endure harsh environments while maintaining a high level of performance.

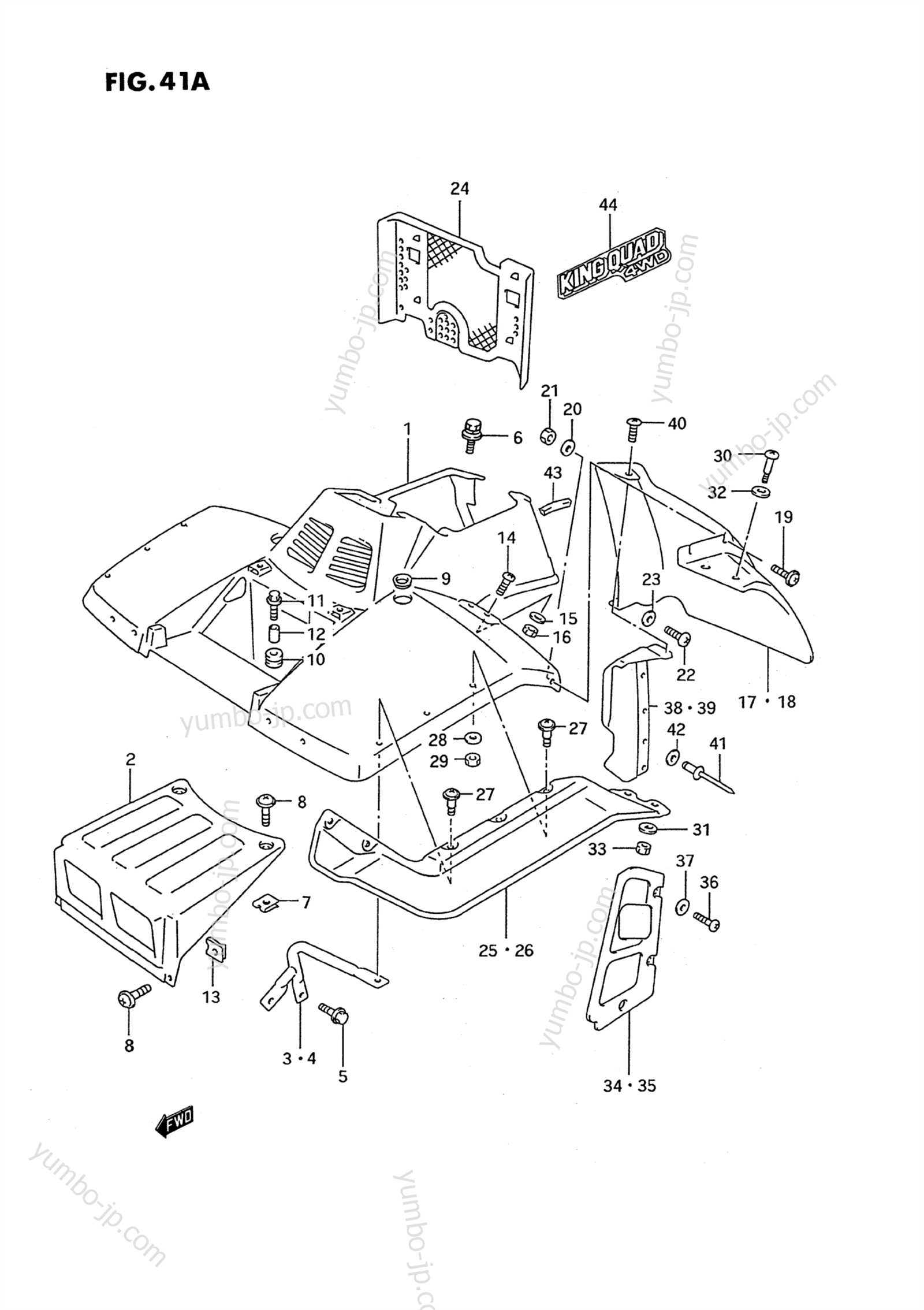

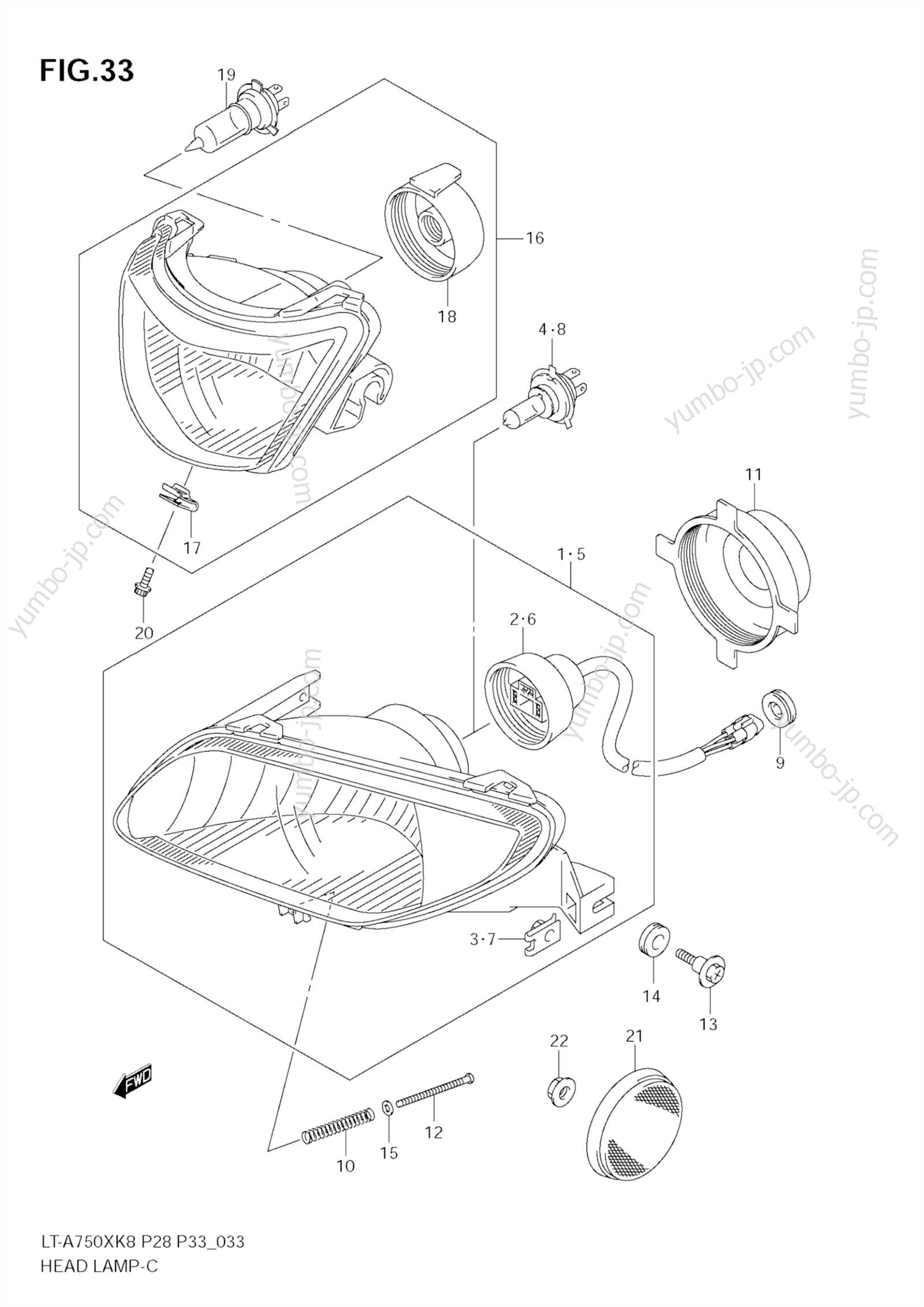

Importance of Parts Diagrams

Understanding the structure of any mechanical system is crucial for effective maintenance and repair. Detailed illustrations that show the arrangement of components serve as essential references for professionals and enthusiasts alike. These visual aids make it easier to identify individual elements, ensuring that repairs are performed accurately and efficiently.

Why Visual References Matter

When working with complex machinery, having a visual guide can significantly reduce the chances of errors. Such guides highlight the relationship between different elements, helping users find the right connections and placements. This reduces the likelihood of mistakes, which could lead to costly damage.

Enhanced Efficiency and Precision

Accurate visual guides not only save time but also promote precision. By following these resources, users can ensure that each component is placed correctly, resulting in smoother operation and longer-lasting performance. These tools are invaluable in maintaining the integrity of any mechanical system.

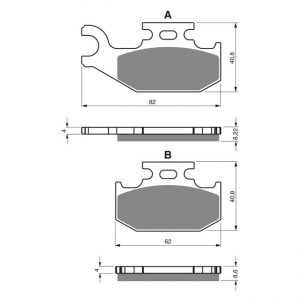

Common Replacement Parts Explained

When maintaining all-terrain vehicles, certain components are more prone to wear and tear due to the challenging environments they navigate. Replacing these elements regularly ensures optimal performance and prevents larger mechanical failures. In this section, we will explore frequently swapped-out items that help keep your vehicle functioning efficiently.

Key Mechanical Components

| Component | Purpose |

|---|---|

| Axles | Facilitate power transfer from the engine to the wheels, crucial for maneuverability over rough terrain. |

| Brakes | Ensure reliable stopping power, essential for safety in high-speed or downhill scenarios. |

| Ball Joints | Allow flexible movement of suspension, maint

Where to Find Diagrams OnlineLocating detailed visual references for mechanical components and assemblies online can significantly simplify the repair or maintenance process. These resources offer a clear breakdown of the necessary parts and how they fit together, making it easier to understand complex systems. Here are several options to explore when searching for such resources:

How to Use a Parts DiagramUnderstanding the visual breakdown of mechanical components is crucial when it comes to maintaining or repairing your vehicle. By following a well-structured schematic, you can easily identify each element and its place within the assembly, ensuring accurate reassembly and replacement. This approach minimizes errors and streamlines the process of locating what needs attention. Locating Key Components

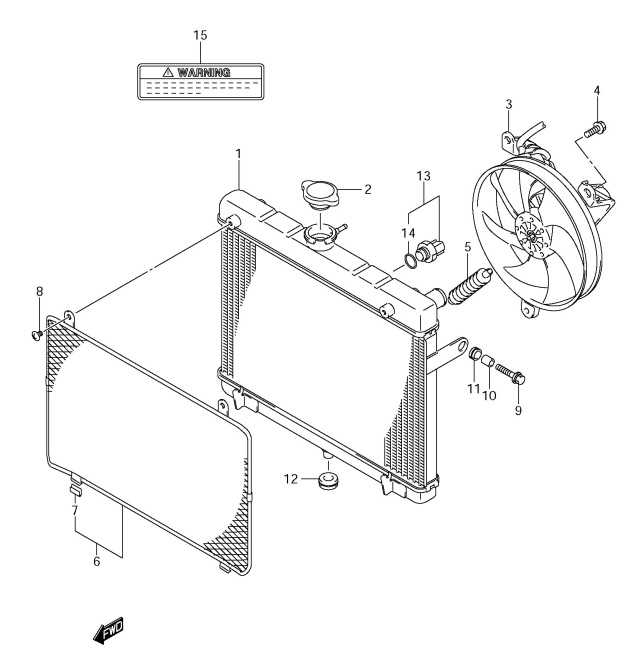

The first step in utilizing a schematic is identifying the specific section you need to examine. Whether you’re looking at the engine, transmission, or any other system, detailed illustrations will guide you to the exact area. Each part is typically labeled with a unique reference number, helping you to cross-reference with lists for better clarity. Ensuring Proper Fit and CompatibilityAnother benefit of these diagrams is that they help ensure you’re selecting the correct replacement item. By comparing the identified component in the diagram with the list provided, you can verify its specifications such as size, model, and compatibility. This reduces the chance of errors during repairs and ensures that the selected items match perfectly with your equipment. Identifying OEM vs. Aftermarket PartsWhen maintaining or upgrading your vehicle, understanding the difference between factory-made components and third-party alternatives is essential. Original Equipment Manufacturer (OEM) items are produced by the same company that made the original components, ensuring a precise fit and consistent performance. In contrast, aftermarket parts come from independent companies, offering a wide range of options at varying price points and quality levels. Both choices have their advantages. OEM parts guarantee compatibility and reliability but often come at a premium. Aftermarket options, on the other hand, can be more affordable and offer specialized features, although they might not always provide the same level of consistency in performance. Evaluating your specific needs, including cost, durability, and availability, will help guide you toward the best decision. Maintenance Tips for King QuadEnsuring the longevity of your all-terrain vehicle requires attention to both routine upkeep and proactive care. Regular inspections of essential components, such as the engine, transmission, and fuel systems, play a vital role in preventing potential issues. Taking the time to perform simple maintenance tasks can greatly enhance the reliability of your vehicle. Keep Fluids in CheckChecking and replenishing fluids is one of the most critical maintenance tasks. This includes engine oil, coolant, and brake fluid, which should be at optimal levels to prevent overheating and ensure smooth operation.

|