Exploring the Toro 20018 Parts Diagram for Optimal Maintenance

In the realm of outdoor machinery, having a comprehensive understanding of each element is crucial for optimal performance and maintenance. This knowledge allows users to effectively identify and replace worn or damaged components, ensuring the longevity of their equipment. An organized representation of these elements can significantly enhance the user’s ability to navigate and manage repairs.

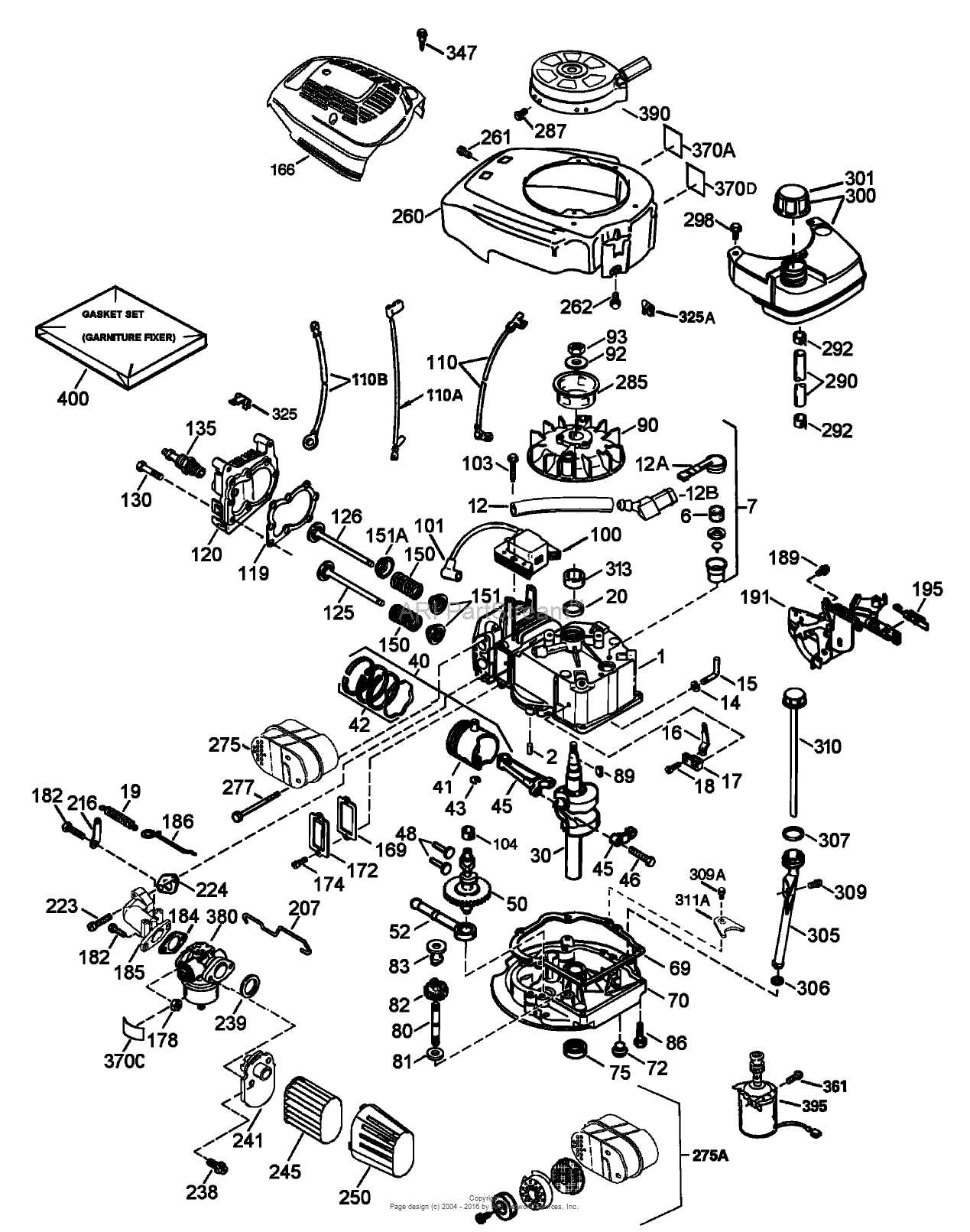

When exploring the intricacies of a specific model, one may find it beneficial to refer to a detailed visual representation. Such illustrations provide clarity regarding the arrangement and functionality of various segments, making it easier to troubleshoot issues. By breaking down the assembly into its individual pieces, users gain insight into the mechanics at play, fostering a deeper connection with their tools.

Whether you are a seasoned operator or a newcomer to the world of outdoor equipment, familiarizing yourself with the structure of these units can lead to more informed decisions. Understanding how each part interacts within the overall system not only streamlines maintenance but also empowers users to perform repairs with confidence and accuracy.

Toro 20018 Overview

This section provides a comprehensive look at a specific model renowned for its efficiency and reliability in outdoor maintenance tasks. Understanding its components is essential for optimal performance and longevity.

The following table outlines key specifications and features:

| Feature | Description |

|---|---|

| Engine Type | Four-stroke, air-cooled |

| Cutting Width | 21 inches |

| Weight | Approximately 60 lbs |

| Drive System | Self-propelled |

| Warranty | 2 years limited |

Exploring these elements can significantly enhance user experience and maintenance routines, ensuring the equipment remains in peak condition.

Understanding Parts Diagrams

Visual representations of components play a crucial role in helping users comprehend the structure and function of various machinery. These illustrations serve as a guide, providing clarity on how individual elements fit together and interact within a larger assembly. By breaking down complex systems into manageable segments, they facilitate maintenance, repair, and assembly processes.

Each illustration typically includes labels and identifiers that correlate with specific items, making it easier to locate and order replacements when necessary. This visual aid not only enhances understanding but also streamlines troubleshooting efforts, allowing users to identify potential issues quickly. Moreover, familiarity with these visual guides can significantly improve efficiency, ensuring that projects are completed accurately and in a timely manner.

Understanding how to read and interpret these illustrations is an essential skill for anyone working with mechanical systems. With practice, users can become adept at navigating these visuals, empowering them to tackle repairs or enhancements with confidence and precision.

Common Components of Toro 20018

This section explores the essential elements that contribute to the functionality and efficiency of a specific model. Understanding these components is crucial for maintenance and performance optimization.

- Engine: Provides the necessary power for operation.

- Chassis: Supports the structure and houses vital systems.

- Transmission: Facilitates movement and speed regulation.

- Deck: Engages with the ground for cutting and trimming.

- Wheels: Ensure mobility and stability during use.

Each of these parts plays a significant role in the overall performance, and familiarity with them can help users in troubleshooting and repairs.

Importance of Replacement Parts

Maintaining the functionality of any machine is crucial for its longevity and performance. Regularly updating components ensures that devices operate at their best and reduces the risk of unexpected failures.

Key benefits of utilizing new components include:

- Enhanced performance and efficiency

- Prolonged lifespan of the equipment

- Improved safety during operation

- Reduced repair costs over time

Choosing high-quality replacements is essential for achieving the ultimate performance. Neglecting this aspect can lead to subpar results and increased downtime.

Investing in quality components not only protects your investment but also optimizes the overall functionality of the machinery.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repairs. These illustrations provide a detailed view of how various elements fit together, making it easier to identify and locate specific pieces. Familiarizing yourself with these visuals can enhance your troubleshooting skills and improve your overall efficiency.

Here are some key steps to effectively interpret these visuals:

- Familiarize Yourself with the Legend: Most illustrations include a legend or key that explains symbols and numbers. Review this section to understand what each symbol represents.

- Identify Major Sections: Typically, these visuals are divided into sections that correspond to different assemblies or systems. Start by identifying these larger categories.

- Trace Connections: Follow the lines and arrows that indicate how components are interconnected. This will help you grasp the assembly order and function of each part.

- Note the Item Numbers: Pay attention to the numbers associated with each component. These identifiers are crucial for ordering replacements or discussing specifics with a supplier.

By mastering these steps, you’ll enhance your ability to navigate component illustrations, ultimately streamlining your repair process and ensuring successful maintenance outcomes.

Identifying Specific Components

Understanding the various elements of a machine is essential for effective maintenance and repair. By recognizing the unique features and functions of each component, users can ensure optimal performance and longevity of the equipment. This section focuses on how to identify specific parts and their roles within the overall system.

To effectively identify components, consider the following approaches:

- Visual Inspection: Carefully examine the exterior for labels or markings that indicate the part number or function.

- Consulting Manuals: Refer to user manuals or technical guides that provide detailed descriptions and diagrams of the elements.

- Utilizing Online Resources: Search for online databases or forums where other users share information about their experiences and findings.

When identifying specific components, it can be helpful to categorize them based on their functions:

- Power System: Elements responsible for energy generation and distribution.

- Operational Parts: Components that facilitate the primary functions of the equipment.

- Support Structures: Parts that provide stability and housing for the operational elements.

By systematically approaching the identification of each part, users can better understand how to maintain and troubleshoot their machinery effectively.

Tools Needed for Repairs

When undertaking maintenance or restoration tasks, having the right tools at your disposal is crucial for achieving optimal results. The appropriate equipment not only facilitates the repair process but also enhances efficiency and safety. Each project may require a unique set of implements, tailored to the specific components involved.

Basic Hand Tools: A set of essential hand tools should always be on hand. These include wrenches, screwdrivers, and pliers, which are fundamental for loosening and tightening various fittings. Ensure you have a variety of sizes to accommodate different applications.

Power Tools: For more demanding tasks, power tools can significantly reduce the time and effort required. Drills and saws are invaluable for cutting through materials or driving fasteners, making them indispensable for many repair projects.

Specialized Equipment: Depending on the specific task, specialized tools may be necessary. Items such as torque wrenches, impact drivers, or alignment tools can provide the precision needed for intricate repairs, ensuring everything functions correctly.

Safety Gear: Never overlook the importance of safety equipment. Protective eyewear, gloves, and ear protection are vital to safeguarding yourself from potential hazards while working.

In summary, assembling the right toolkit not only streamlines the repair process but also promotes a safer working environment. Investing in quality tools will pay off in the long run, making future maintenance tasks easier and more effective.

Where to Purchase Parts

Finding the right components for your equipment can significantly enhance its performance and longevity. Numerous avenues exist for acquiring these essential elements, catering to various preferences and needs.

Online Retailers: The internet hosts a plethora of platforms where you can easily browse and order the necessary components from the comfort of your home. Sites often provide detailed descriptions and customer reviews, ensuring informed choices.

Local Dealers: Visiting nearby distributors can offer personalized service and immediate access to the items you require. These establishments may also provide expert advice and support.

Second-Hand Markets: Exploring used goods platforms can yield valuable finds at reduced prices. Just ensure to check the condition and compatibility of the components before purchasing.

In summary, whether you opt for online shopping, local dealers, or second-hand marketplaces, the key is to delve into your options to secure the ultimate components for your needs.

Maintenance Tips for Toro 20018

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. Implementing a few straightforward practices can greatly enhance performance and minimize the risk of unexpected failures. This guide outlines key strategies to maintain optimal functionality.

1. Routine Cleaning: Keeping the exterior and interior of your machinery clean is vital. Remove any debris, grass clippings, or dirt that may accumulate. This prevents blockages and reduces wear on components.

2. Check Fluids: Regularly inspect and replace oils and other fluids as needed. Clean, high-quality lubricants help maintain smooth operation and protect against corrosion.

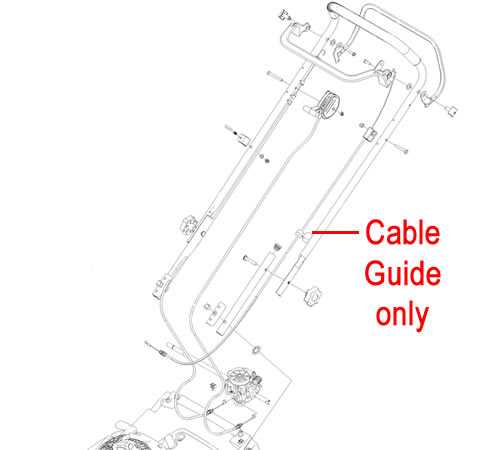

3. Inspect Belts and Cables: Examine belts and cables for signs of wear or fraying. Replacing damaged parts promptly can prevent further complications and ensure reliable performance.

4. Sharpen Blades: Keeping cutting edges sharp enhances efficiency and promotes a clean cut. Dull blades can strain the engine and lead to uneven cutting.

5. Seasonal Maintenance: At the start and end of each season, conduct thorough checks. This includes changing filters, checking spark plugs, and ensuring all components are in proper working order.

6. Store Properly: When not in use, store your equipment in a dry, protected area. Use covers to shield against dust and moisture, which can cause premature deterioration.

By following these simple yet effective maintenance tips, you can ensure your equipment remains in top condition, providing reliable service for years to come.

Common Issues and Solutions

When operating outdoor equipment, various challenges may arise that can affect performance and efficiency. Identifying these common problems and implementing effective solutions is crucial for maintaining optimal functionality.

Frequent Malfunctions

One of the most prevalent issues is engine starting difficulties. This can often stem from fuel quality or ignition system failures. Regularly checking and replacing fuel, as well as inspecting spark plugs, can help resolve these concerns.

Performance Degradation

Another issue involves reduced power output during operation. This may be attributed to air filter blockages or worn-out blades. Cleaning or replacing the air filter and ensuring blades are sharp can significantly enhance performance.

Warranty Information for Parts

When purchasing components for your equipment, understanding the warranty coverage is essential for ensuring long-term satisfaction and protection. This section outlines the key aspects of warranty provisions, including duration, coverage limits, and necessary actions for claims.

Coverage Details

The warranty typically encompasses defects in materials and workmanship, ensuring that any faulty items are repaired or replaced without additional cost. However, it is crucial to review specific terms as some exclusions may apply based on usage or installation methods.

Claim Process

To initiate a warranty claim, retain your purchase receipt and contact the authorized dealer or manufacturer. They will guide you through the necessary steps to address any issues effectively, ensuring a smooth resolution.

Expert Recommendations for Upgrades

Enhancing the performance and functionality of your equipment can significantly improve its efficiency and lifespan. Upgrading certain components not only boosts capabilities but also ensures smoother operation and better reliability. This section outlines key suggestions for optimizing your machinery.

1. Quality Components: Investing in high-quality replacement parts can lead to substantial performance improvements. Look for durable materials that offer better resistance to wear and tear.

2. Engine Enhancements: Consider upgrading to a more powerful engine or enhancing existing engine features. This can provide increased torque and improved fuel efficiency, allowing for more demanding tasks without compromising performance.

3. Advanced Control Systems: Implementing modern control technology can streamline operations. Look for systems that provide better feedback and allow for easier adjustments during use.

4. Improved Accessories: Adding specialized attachments can expand the versatility of your equipment. For instance, enhanced cutting tools or advanced implements can optimize performance for specific tasks.

5. Regular Maintenance: Alongside upgrades, maintaining existing systems is crucial. Regular check-ups and timely replacements will keep your machinery running at its best and extend its operational life.

By following these expert recommendations, you can maximize the potential of your equipment and ensure it meets the demands of your tasks effectively.