Toro 20332 Parts Diagram Overview

Maintaining outdoor machinery can often seem daunting, especially when it comes to identifying the various elements that make up the equipment. A comprehensive overview of these components is essential for ensuring optimal performance and longevity. Knowledge of each part’s function and placement plays a crucial role in effective maintenance and repair.

For anyone looking to enhance their understanding, visual aids can be invaluable. These resources provide clarity by illustrating how each piece interacts within the larger system. By familiarizing yourself with the layout, you can tackle issues more efficiently and ensure that your machine operates at its best.

Delving into the specifics of each component allows users to make informed decisions, whether it’s for routine upkeep or addressing potential malfunctions. This knowledge not only empowers users but also fosters a deeper connection to their equipment, transforming maintenance into a more manageable task.

Parts Overview

This section provides a comprehensive examination of the components associated with the specified model. Understanding the various elements is essential for maintenance, repair, and overall functionality, ensuring that users can efficiently manage their equipment.

Key Components

Each element plays a vital role in the performance and longevity of the equipment. Familiarity with these items enhances troubleshooting and enables optimal operation.

Component Specifications

| Component Name | Description | Function |

|---|---|---|

| Engine | Power source for operation | Drives all functionalities |

| Chassis | Main frame structure | Supports all other components |

| Blades | Cutting elements | Ensures efficient trimming |

| Control Panel | User interface for operations | Manages settings and controls |

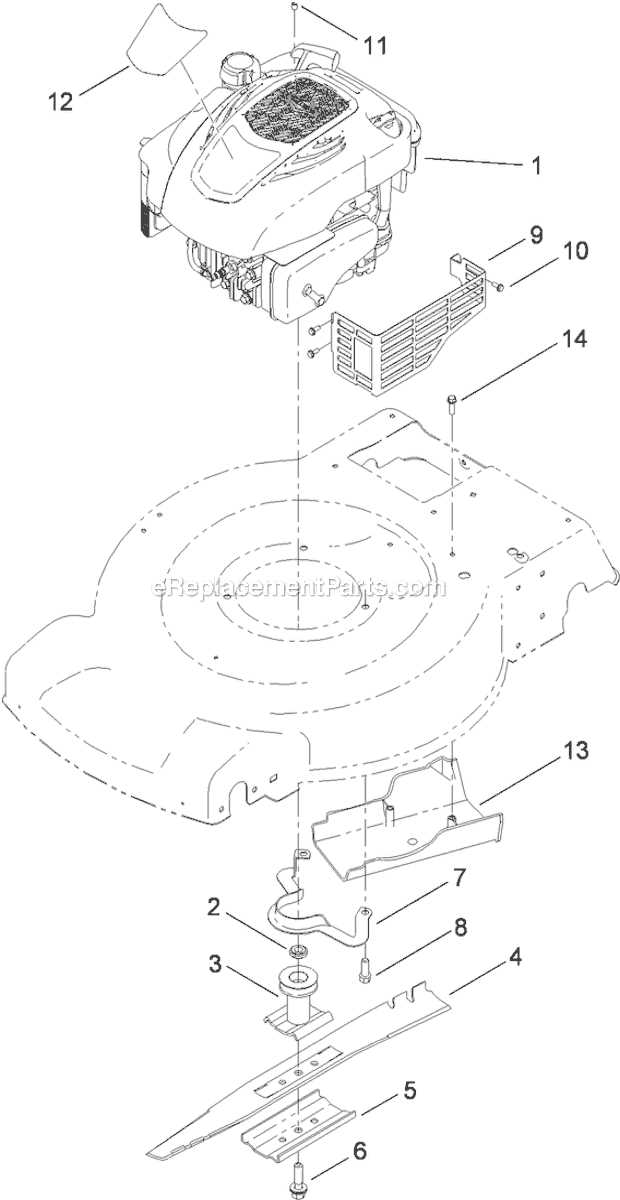

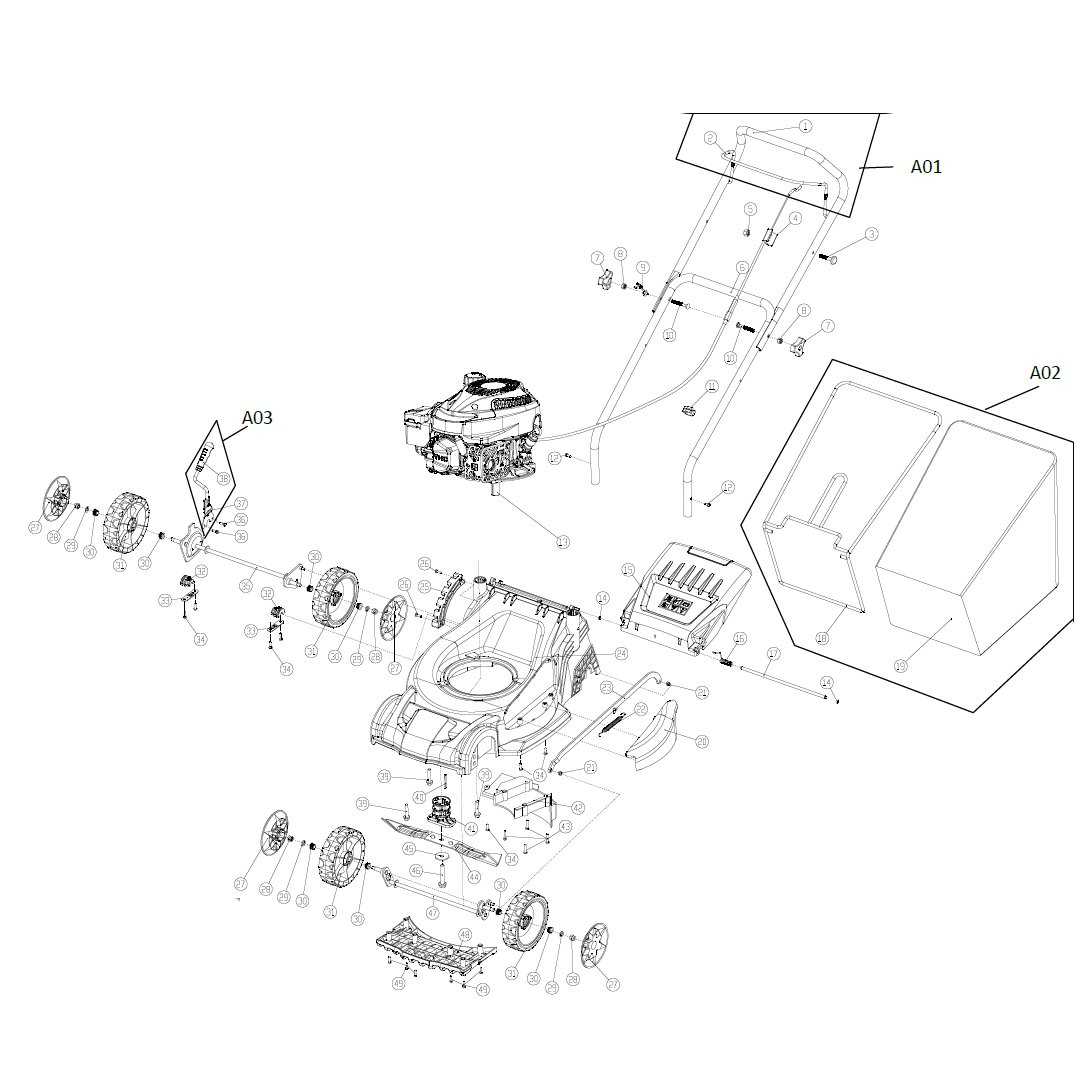

Understanding the Parts Diagram

Grasping the visual representation of components is essential for effective maintenance and repairs. This guide provides insights into how these illustrations convey crucial information, allowing users to identify individual elements and their functions within a system.

Clarity is paramount; each part is often labeled with unique identifiers, enabling quick reference. Understanding the layout facilitates efficient troubleshooting, helping to pinpoint issues without extensive disassembly.

Moreover, familiarizing oneself with these visuals can ultimately enhance one’s confidence in handling equipment. Knowledge of the arrangement fosters a deeper appreciation for the machinery’s design, leading to more informed decisions during servicing.

Key Components of Toro 20332

The understanding of essential elements in this machinery is crucial for efficient operation and maintenance. Each component plays a significant role, contributing to the overall functionality and performance.

Power Source: The engine serves as the heart of the system, providing the necessary energy to drive various functions.

Cutting Mechanism: This element is responsible for achieving precise trimming and shaping, ensuring a clean finish during operation.

Transmission System: The gears and belts facilitate the transfer of power, allowing for smooth movement and control across different terrains.

Chassis: A robust frame supports all components, providing stability and durability, essential for long-term usage.

Controls: User interfaces are designed to allow easy adjustments and settings, enhancing the operator’s experience.

Understanding these fundamental parts can help users delve into maintenance practices, ensuring the ultimate performance of their equipment.

Benefits of Using Genuine Parts

Utilizing authentic components for machinery maintenance offers numerous advantages that enhance performance and longevity. These original elements are specifically designed to work seamlessly with the equipment, ensuring optimal functionality.

Reliability is one of the primary benefits of selecting genuine components. They undergo rigorous testing and adhere to strict quality standards, minimizing the risk of failures and unexpected repairs. Performance is also significantly improved, as original parts are engineered to match the exact specifications needed for efficient operation.

Furthermore, using authentic replacements can lead to cost savings in the long run. While they may have a higher initial price, their durability and reliability reduce the frequency of replacements and repairs, ultimately proving more economical. Additionally, warranty coverage is often more comprehensive when genuine components are used, providing peace of mind and protecting your investment.

In conclusion, opting for original elements enhances your machinery’s overall efficiency and lifespan while ensuring reliability and potential cost-effectiveness.

How to Access the Parts Diagram

Finding the necessary illustrations for your equipment can streamline maintenance and repairs. This section will guide you through the process of locating these visual aids effectively.

Steps to Locate the Visual Aids

- Visit the official website of the manufacturer.

- Navigate to the support or resources section.

- Enter your model number in the search bar provided.

- Look for a link to manuals or technical resources.

- Select the appropriate document that contains the illustrations you need.

Alternative Sources

- Check online forums and community groups dedicated to your equipment.

- Consult authorized dealers or repair shops for assistance.

- Explore third-party websites that specialize in equipment resources.

By following these guidelines, you can efficiently find the necessary illustrations to aid in your maintenance tasks.

Common Issues and Solutions

When maintaining outdoor equipment, users often encounter various challenges that can hinder performance. Identifying these issues and implementing effective solutions can significantly enhance the longevity and efficiency of the machinery.

Frequent Problems

- Starting difficulties

- Uneven cutting performance

- Unusual noises during operation

- Fuel leaks

Effective Solutions

- Check and replace the spark plug if necessary.

- Ensure blades are sharp and properly aligned.

- Inspect and tighten any loose components.

- Examine fuel lines for wear and replace them if leaks are found.

Maintenance Tips for Toro 20332

Proper upkeep of your equipment ensures optimal performance and longevity. Regular attention to key components can prevent breakdowns and enhance efficiency.

Routine Checks

- Inspect the oil levels and change as needed.

- Examine air filters for cleanliness; replace if clogged.

- Check spark plugs for wear and replace them regularly.

Seasonal Maintenance

- Sharpen blades at the beginning of each season.

- Clean the undercarriage to prevent rust and buildup.

- Store in a dry place during off-season to avoid moisture damage.

Ordering Replacement Parts Effectively

Ensuring a seamless experience when acquiring necessary components is crucial for maintaining equipment functionality. By following a systematic approach, one can simplify the ordering process and minimize downtime.

- Identify the Component: Clearly determine the specific item required for replacement.

- Check Compatibility: Ensure that the selected item is suitable for your model to avoid issues.

- Gather Information: Collect model numbers and specifications to facilitate accurate searches.

- Compare Suppliers: Research various vendors to find the best price and availability.

- Read Reviews: Assess feedback from other customers to gauge reliability and quality.

- Place Your Order: Choose a secure payment method and confirm your order details before finalizing.

By implementing these steps, one can delve into a more efficient ordering process and achieve the ultimate satisfaction with each acquisition.

Exploring Aftermarket Options

In the realm of equipment maintenance, considering alternatives to original components can be a strategic choice for many users. These aftermarket solutions often present an enticing balance of affordability and performance, appealing to those who seek to enhance their machinery without incurring excessive costs.

One significant advantage of these options lies in the variety they offer. Users can delve into a wide array of products designed to meet or even exceed the specifications of factory-made items. This diversity not only allows for tailored solutions but also encourages innovation among manufacturers, ultimately benefiting the end user.

However, it is crucial to exercise caution when exploring these alternatives. Quality can vary greatly, so it is advisable to research reputable brands and reviews. Ensuring compatibility with existing equipment is essential to avoid future complications, making informed decisions vital for optimal performance.

Compatibility with Other Toro Models

Understanding the interchangeability of components among different equipment can significantly enhance maintenance efficiency and cost-effectiveness. Various models within the same brand often share similarities in design and functionality, allowing users to benefit from a wider range of compatible parts. This aspect is crucial for those looking to optimize their machinery without needing to source entirely new components.

In many cases, features from one unit can seamlessly integrate with another, promoting versatility in repair and upkeep. Identifying compatible systems not only simplifies the replacement process but also ensures that the performance of the equipment remains at its peak. Users should explore cross-references to determine which units share parts or components, thereby making informed decisions about upgrades or replacements.

Resources for Toro 20332 Owners

This section provides essential tools and references for owners seeking to maintain and enhance their equipment. With the right information, users can effectively manage repairs, upgrades, and routine maintenance to ensure optimal performance.

Key Resources

Utilizing reliable sources can make a significant difference in the longevity and functionality of your machinery. Below are some valuable links and materials:

| Resource Type | Description |

|---|---|

| Manuals | Access detailed guides for operation and maintenance procedures. |

| Forums | Join communities for advice and shared experiences from fellow owners. |

| Videos | Watch tutorials for step-by-step guidance on repairs and upgrades. |

| Retailers | Find local and online suppliers for necessary components and tools. |

Maintenance Tips

Regular upkeep is crucial for ensuring the longevity of your equipment. Consider these practices: clean filters, check fluid levels, and inspect components for wear. Delve into each task to guarantee ultimate efficiency and performance.