Toro 20353 Parts Diagram Overview

For anyone working with outdoor machines, knowing the layout and connections of different elements is essential. By having a clear overview, maintenance and repairs become significantly easier. This section focuses on exploring the various mechanisms involved in a specific model, providing a helpful reference to navigate through the individual elements.

Each section of this model has unique features, designed to work seamlessly together. Whether it’s the engine or the cutting mechanism, understanding the interaction between these parts can help in troubleshooting and ensuring smooth operation. A detailed breakdown of each component’s function is essential for proper upkeep.

In this guide, we will take a closer look at the structure, offering insights that will aid in better handling and maintenance of the machine. This will serve as a practical resource for identifying the right elements and understanding their role in the overall system.

Components Overview

This section provides a detailed look at the various elements that make up this outdoor equipment. Each component plays a crucial role in ensuring smooth operation and long-term durability. Understanding these key elements will help in maintaining and optimizing performance, ensuring efficient functionality for extended periods.

Engine and Cutting Mechanism

The heart of the machine is its engine, responsible for driving the entire system. Coupled with a highly effective cutting mechanism, it ensures precise trimming with minimal effort. The combination of power and sharpness allows for a clean, even finish on various terrains.

Wheels and Drive System

The wheels and drive system work in tandem to provide mobility and control. With sturdy construction and

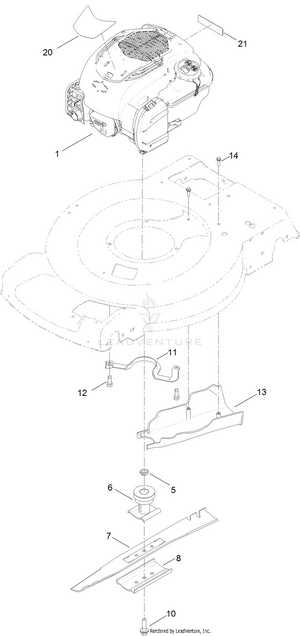

Engine Assembly Breakdown

The engine assembly comprises multiple interconnected components, each playing a critical role in the overall operation. Understanding how these elements interact provides valuable insight into maintaining and repairing the system effectively.

- Crankshaft – Responsible for converting the linear motion of the pistons into rotational force.

- Piston and Cylinder – Work together to create compression, enabling the combustion process to generate power.

- Valves – Regulate the flow of air and fuel mixture into the chamber and allow exhaust gases to exit.

- Camshaft – Controls the timing of valve movements, ensuring optimal engine performance.

- Flywheel – Helps maintain engine stability by storing rotational energy.

Each of these sections is interconnected, requiring precise coordination to ensure smooth operation and prevent wear. Regular inspection of these elements can prolong engine life and prevent costly repairs.

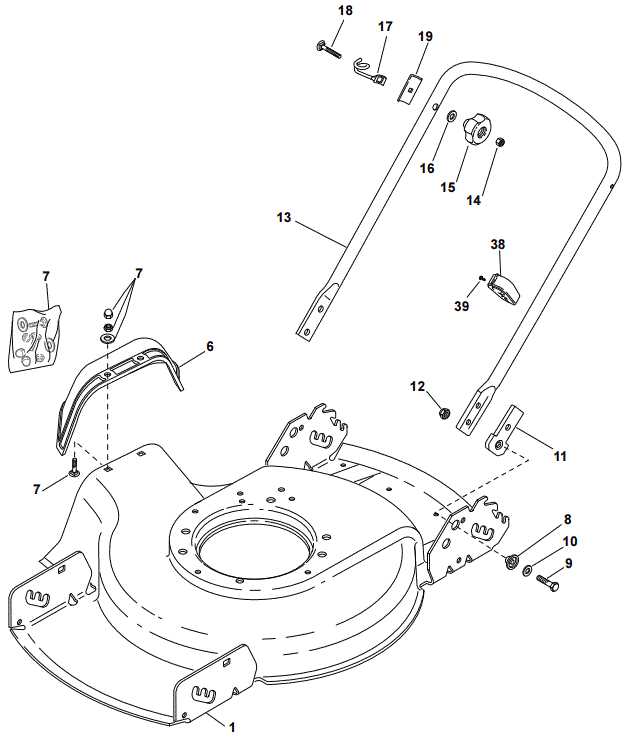

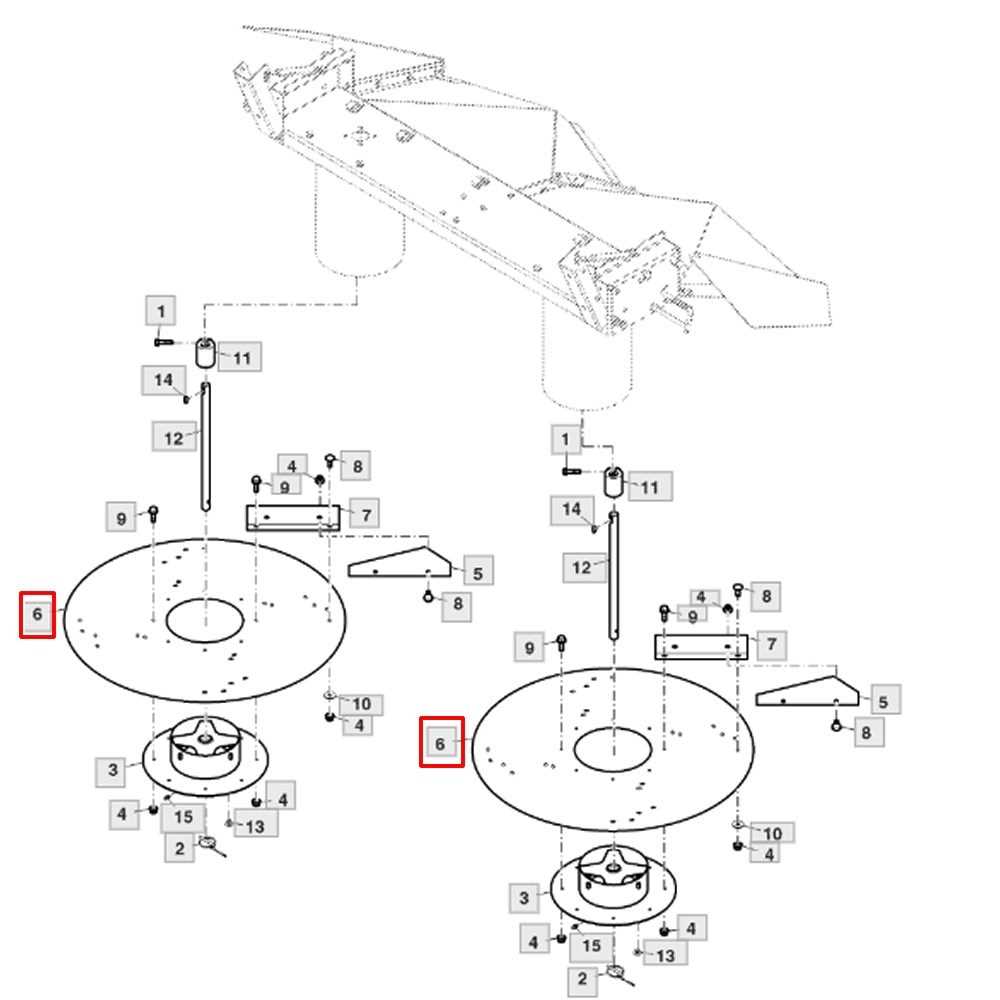

Blade and Deck Structure

The cutting mechanism and platform design play a critical role in ensuring effective and efficient operation. These components are carefully engineered to work together, providing a smooth, clean cut while maintaining stability and control during use. Understanding how these elements interact can help in optimizing performance and prolonging the lifespan of the equipment.

Cutting Mechanism

The sharp cutting edge is designed to slice through various materials with precision. Its shape and construction are vital for maintaining efficiency, while proper maintenance ensures long-lasting functionality. The alignment and balance of this element are also key factors in achieving consistent results.

Platform Design

The underlying support structure offers a sturdy base for the operation. It is constructed to manage vibrations and impact, allowing for smoother movement. Its design also aids in directing the materials efficiently to ensure optimal performance during each use.

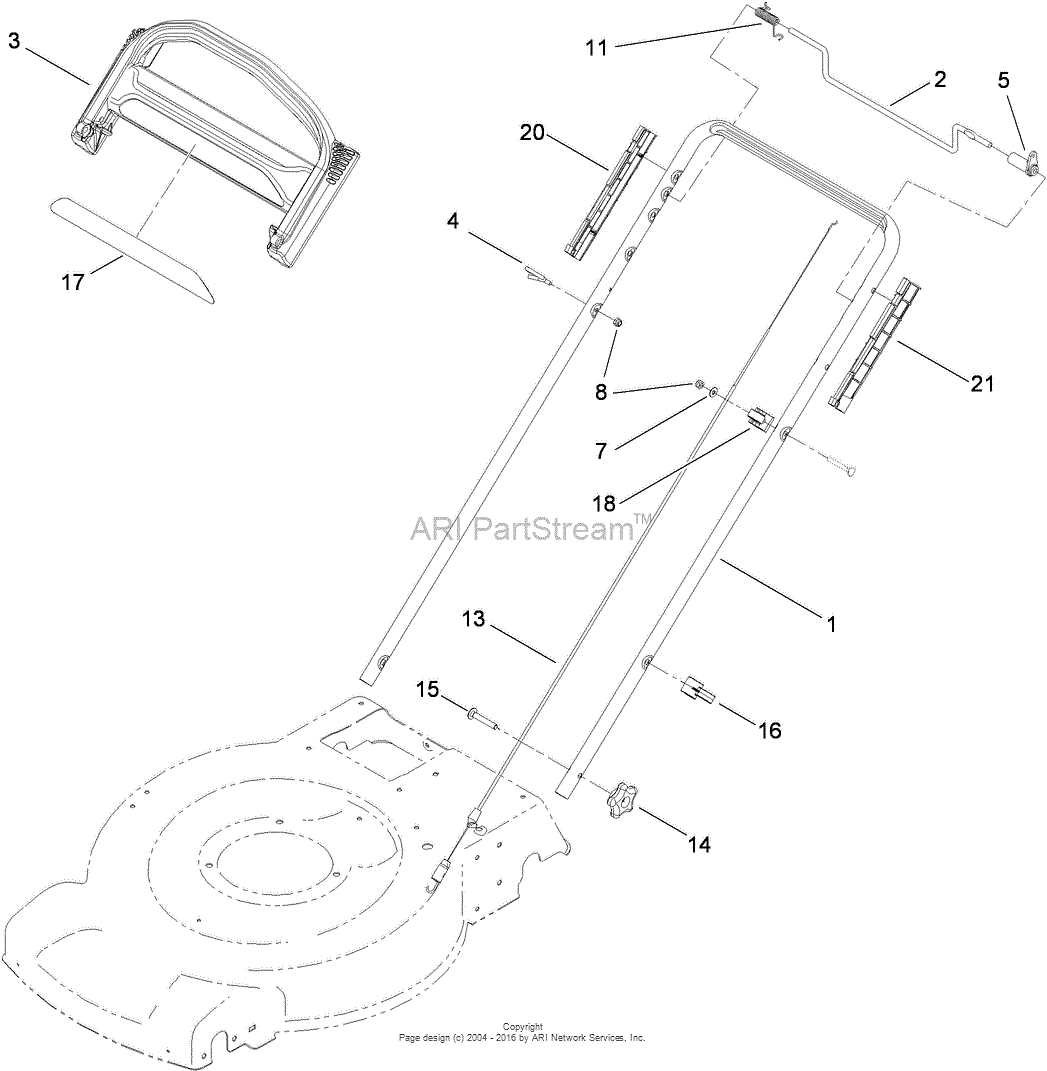

Handle Mechanism and Adjustments

The handle system is a key component designed to provide comfort and control during operation. Understanding its structure and making necessary modifications can enhance both usability and overall performance. This section explains the essential aspects of the handle’s configuration and the process for fine-tuning it to suit individual preferences.

Understanding the Handle Structure

The handle assembly is composed of several interconnected elements that work together to ensure stability and ease of use. These elements include the main bar, adjustment points, and locking mechanisms, all designed for effortless customization. Familiarizing yourself with the layout helps in maintaining optimal control and reducing fatigue during extended use.

Making Adjustments for Comfort

Adjusting the handle to the desired height and angle is crucial for comfortable and efficient operation. The adjustment points allow you to raise or lower the handle, while ensuring it remains securely locked in place. It’s important to test different positions until you find the setting that offers maximum comfort and control.

Transmission and Drive Belt System

The transmission and belt system play a critical role in ensuring smooth movement and proper functionality. These components work together to transfer power efficiently, enabling the machine to operate effectively across various terrains and conditions.

Main Components

- Drive Belt: Responsible for transmitting power from the engine to the wheels, ensuring motion.

- Transmission Assembly: Controls the speed and torque, allowing for smooth changes in direction and pace.

- Pulleys: Guide the belt, maintaining tension and ensuring consistent performance.

Maintenance Tips

- Regularly inspect the belt for signs of wear or fraying.

- Ensure pulleys are free from debris to prevent obstructions.

- Check the transmission fluid levels and replace them as necessary for optimal function.

Fuel System Components

The fuel system is a critical aspect of any engine, responsible for delivering the necessary energy to ensure optimal performance. It comprises various elements that work together to store, transport, and manage fuel effectively, allowing for smooth operation and reliability.

Key Elements of the Fuel System

At the heart of the fuel system are several essential components, including the fuel tank, pump, and injectors. The fuel tank serves as a reservoir, holding the fuel until needed. The pump is vital for transferring fuel from the tank to the engine, while injectors atomize the fuel for efficient combustion. Together, these elements ensure that the engine receives a consistent and adequate fuel supply.

Maintenance and Care

Regular maintenance of the fuel system is crucial for preventing issues that may affect engine performance. Checking for leaks, ensuring proper fuel flow, and cleaning or replacing filters can significantly enhance the longevity of these components. By taking care of the fuel system, users can ensure that their equipment operates efficiently and reliably.

Wheels and Axle Construction

The wheels and axle assembly plays a crucial role in the overall functionality and performance of a vehicle. This section delves into the various components that contribute to this vital structure, emphasizing their significance in ensuring smooth movement and stability.

Key elements of wheel and axle construction include:

- Wheels: These are the circular components that facilitate motion. Their design can affect traction and maneuverability.

- Axles: Serving as the central shaft, axles connect the wheels and allow them to rotate. They are critical in transferring power from the engine to the wheels.

- Bearings: These reduce friction between the axle and the wheel, enabling smooth rotation and enhancing efficiency.

- Hubs: The hub is the central part of the wheel that connects to the axle, providing support and stability.

- Fasteners: These secure the wheels to the axles, ensuring they remain intact during operation.

Understanding the construction and interaction of these components is essential for maintaining optimal performance. Proper alignment and quality materials are vital in prolonging the lifespan of the assembly.

In summary, the relationship between wheels and axles is foundational in the mechanics of mobility, influencing both the effectiveness and safety of the vehicle.

Cutting Height Adjustment Parts

The ability to modify the cutting height is essential for achieving optimal results in lawn maintenance. This mechanism allows users to select the desired grass length, contributing to the overall health and aesthetics of the landscape.

Key components involved in the height adjustment system include:

- Adjustment Lever: A pivotal element that enables the user to easily modify the cutting height.

- Height Adjustment Pins: These pins secure the cutting deck at various heights, ensuring stability during operation.

- Spring Mechanism: Provides tension to maintain the desired height settings and absorb shocks during use.

- Cutting Deck Assembly: The platform that houses the cutting blades, designed to work in conjunction with the height adjustment features.

Proper maintenance of these components is vital for ensuring smooth operation and extending the lifespan of the equipment. Regular checks for wear and tear can help maintain effective height adjustment capabilities.

Ignition System and Wiring

The ignition system plays a crucial role in the operation of small engines, ensuring they start smoothly and run efficiently. This system is responsible for generating the spark necessary to ignite the fuel-air mixture in the combustion chamber. Understanding the components and their interconnections is essential for effective troubleshooting and maintenance.

Components Overview

The primary elements of the ignition system include the spark plug, ignition coil, and various wiring connections. The spark plug acts as the final point where the electric spark is generated, while the ignition coil transforms the battery’s low voltage into a high voltage required to create that spark. Proper wiring ensures that electrical signals flow smoothly between these components, allowing the engine to start without issues.

Troubleshooting Common Issues

When problems arise in the ignition system, it often manifests as starting difficulties or erratic engine performance. Common issues may include worn spark plugs, faulty ignition coils, or damaged wiring. Regular inspection of these components, along with ensuring secure connections, can help prevent significant operational problems and prolong the life of the engine.

Air Filter and Intake Setup

The air filtration and intake configuration plays a crucial role in maintaining optimal engine performance. Proper airflow is essential for efficient combustion, ensuring the machine operates smoothly and reliably. In this section, we will explore the components involved in this setup, highlighting their functions and maintenance practices.

Components of the Air Filtration System

The primary elements of an air filtration system include the air filter and intake manifold. The air filter is responsible for trapping dust, debris, and other contaminants, preventing them from entering the engine. A clean filter enhances airflow and boosts performance. Regular inspections and replacements are vital to ensure the filter functions effectively.

Maintaining Optimal Airflow

Proper intake alignment is equally important for maximizing engine efficiency. The intake manifold directs air into the engine cylinders, and any obstruction or damage can hinder performance. Ensure that all connections are secure and free from leaks. Regular maintenance and cleaning of these components will promote a healthy engine environment, contributing to longevity and reliability.

Brake and Control Mechanisms

The functionality of any machine heavily relies on its braking and control systems, which ensure safe operation and precision in movement. These systems are designed to provide users with the ability to regulate speed, maintain stability, and halt the machinery effectively when needed.

Control mechanisms play a crucial role in managing the overall operation, allowing for smooth transitions and adjustments during use. This includes the integration of levers, pedals, and electronic components that enhance user interaction and responsiveness. Proper maintenance of these components is essential to avoid malfunctions that could compromise performance.

Braking systems are equally vital, providing the necessary force to stop or slow down machinery safely. Various types of braking methods, including friction and hydraulic systems, can be employed depending on the specific application. Regular inspections and timely replacements of worn-out parts are fundamental to ensuring reliability and safety during operation.

Maintenance Tips for Toro 20353 Parts

Proper upkeep of your equipment is essential for ensuring longevity and optimal performance. Regular attention to various components can prevent potential issues and enhance efficiency. By following a few straightforward guidelines, you can keep your machinery running smoothly and reduce the likelihood of costly repairs.

1. Regular Inspection: Schedule routine checks of all critical components to identify signs of wear or damage early. This proactive approach can save time and resources in the long run.

2. Cleanliness: Keeping parts free from dirt and debris is vital. Accumulated grime can hinder functionality, so ensure regular cleaning using appropriate methods and products.

3. Lubrication: Apply suitable lubricants to moving parts to minimize friction. Proper lubrication can extend the lifespan of these components and enhance overall performance.

4. Replacement of Worn Components: Be vigilant for signs of fatigue in individual parts. Replacing worn or damaged items promptly will help maintain the effectiveness of your equipment.

5. Storage Practices: When not in use, store your machinery in a dry and protected area. This practice will shield it from the elements and help prevent deterioration over time.

By following these maintenance tips, you can ensure that your machinery operates efficiently, allowing you to tackle tasks effectively and avoid unnecessary disruptions.