Toro 824 Parts Diagram Overview

Understanding the intricate assembly of machinery is essential for effective maintenance and repair. A comprehensive overview of the individual elements that make up a specific snow removal unit can greatly assist users in identifying and resolving issues. This section delves into the various components and their arrangement, offering insights that can enhance the user experience.

In addition, familiarizing oneself with these elements can streamline the troubleshooting process. By visualizing how each part fits into the larger assembly, operators can ensure their equipment functions optimally. This knowledge serves not only to facilitate repairs but also to extend the lifespan of the machine.

Furthermore, recognizing the significance of each element allows users to make informed decisions when purchasing replacements or upgrades. Whether you’re a seasoned professional or a novice, understanding the layout and function of these components is invaluable for maintaining efficiency and performance.

Toro 824 Parts Diagram Overview

This section provides a comprehensive insight into the essential components and their arrangement for a specific snow removal machine. Understanding the layout of these elements is crucial for effective maintenance and repair. Each piece plays a significant role in the machine’s overall functionality, and recognizing their positions can facilitate troubleshooting and enhance operational efficiency.

Importance of Understanding Component Layout

Familiarizing oneself with the arrangement of individual elements allows users to identify issues promptly. By having a clear view of where each component fits, operators can perform repairs more efficiently and reduce downtime. This understanding not only aids in immediate fixes but also contributes to the long-term upkeep of the equipment.

Key Elements and Their Functions

The main components of the equipment include various drive mechanisms, blades, and control features. Each of these parts serves a unique function, from power transmission to ensuring user control during operation. Recognizing how these elements interact can significantly improve the user’s ability to manage the machine effectively.

Understanding Toro 824 Components

In any machinery, the various elements play crucial roles in ensuring optimal performance and reliability. A comprehensive understanding of these components allows users to maintain and troubleshoot equipment effectively. This section will explore the essential parts and their functions, contributing to the overall efficiency of the machine.

Every unit consists of multiple components, each designed for specific tasks. These elements work together to facilitate smooth operation, from the power source to the moving parts. Knowing how each component interacts enhances the user’s ability to perform repairs and improvements.

Additionally, familiarizing oneself with the individual parts can aid in identifying potential issues before they escalate. Regular maintenance and inspection of each element not only prolongs the lifespan of the equipment but also ensures safety during operation. Understanding the nuances of these components empowers users to make informed decisions regarding upgrades and replacements.

By delving into the intricacies of the machinery’s design, users can appreciate the engineering that supports its functionality. This knowledge fosters confidence in managing the equipment and ultimately leads to better outcomes in performance and productivity.

Importance of Parts Diagrams

Understanding the various components of machinery is crucial for effective maintenance and repair. Visual representations that illustrate the intricate relationships between these elements can significantly enhance a user’s ability to identify and resolve issues efficiently. Such illustrations serve as essential references for both novices and experienced technicians alike, fostering a deeper comprehension of how each element contributes to the overall functionality of the equipment.

Facilitating Repairs is one of the primary advantages of using visual aids. By clearly displaying the layout and arrangement of different sections, these tools allow users to pinpoint problematic areas quickly. This streamlined approach minimizes downtime and ensures that necessary adjustments or replacements are executed with precision.

Moreover, enhanced communication is another key benefit. When discussing repair or maintenance tasks with colleagues or professionals, having a visual reference can eliminate confusion and ensure everyone is on the same page. This shared understanding is vital in collaborative environments, where teamwork plays a significant role in achieving optimal outcomes.

Lastly, utilizing these visual resources can lead to improved safety during maintenance tasks. By familiarizing oneself with the components and their placements, users can navigate the machinery more confidently, reducing the risk of accidents and ensuring a safer working environment. Overall, visual representations are invaluable for anyone engaged in the upkeep of mechanical systems.

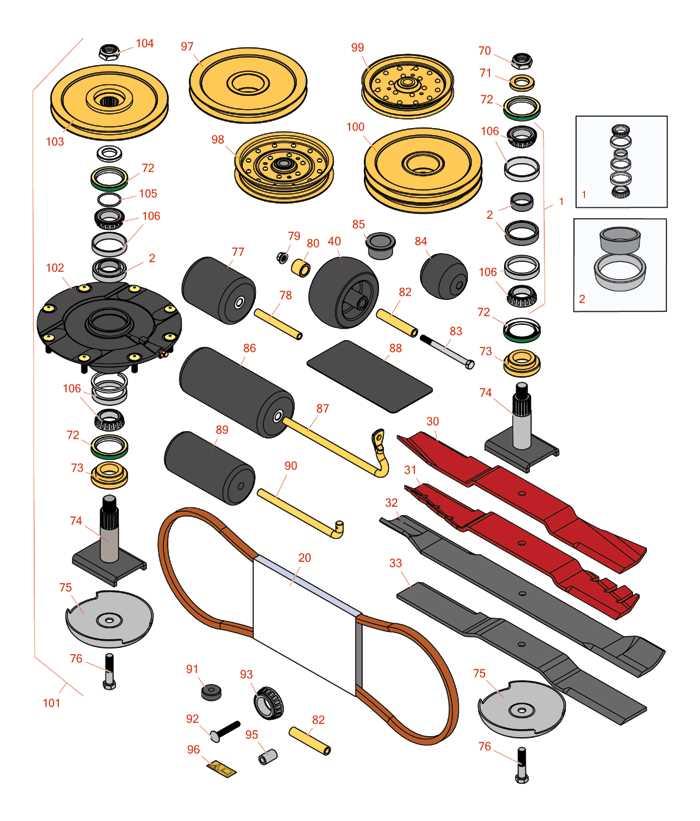

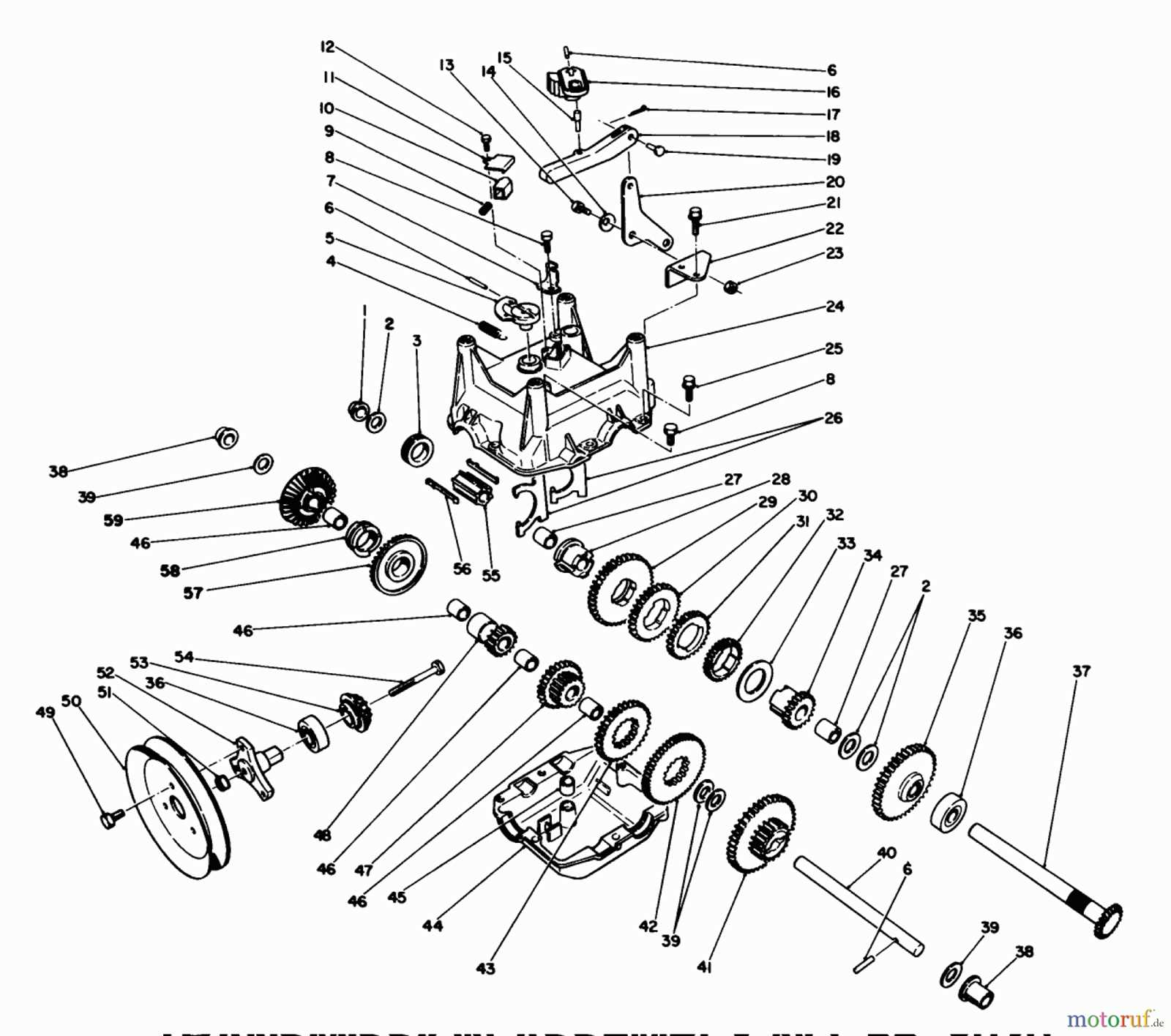

How to Use the Parts Diagram

Utilizing a visual representation of components can significantly enhance your understanding of assembly and maintenance tasks. This resource acts as a valuable guide, allowing users to easily identify and locate each element within the machinery. Familiarity with this illustration can streamline repairs and replacements, ensuring efficient operation.

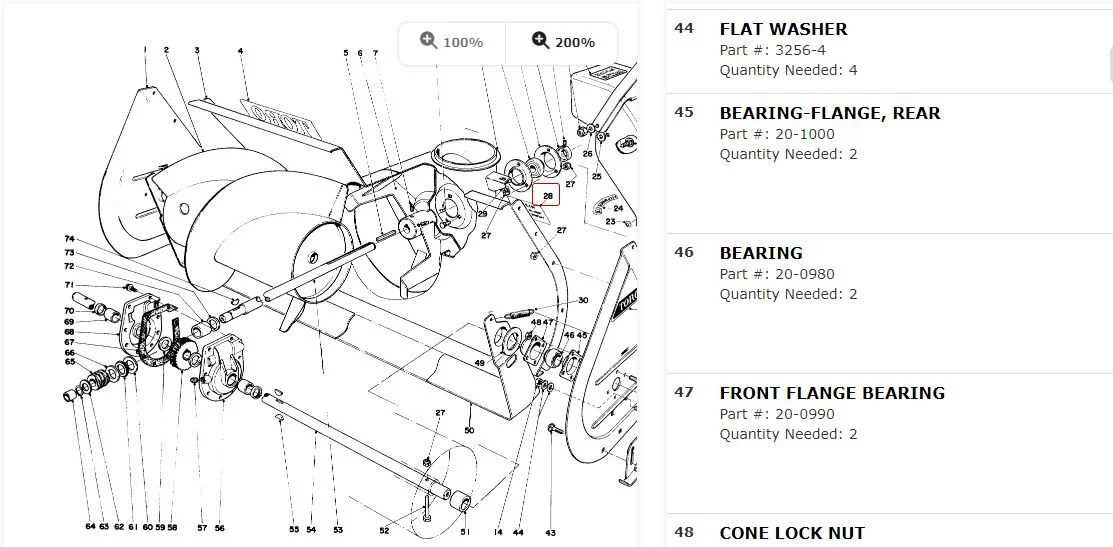

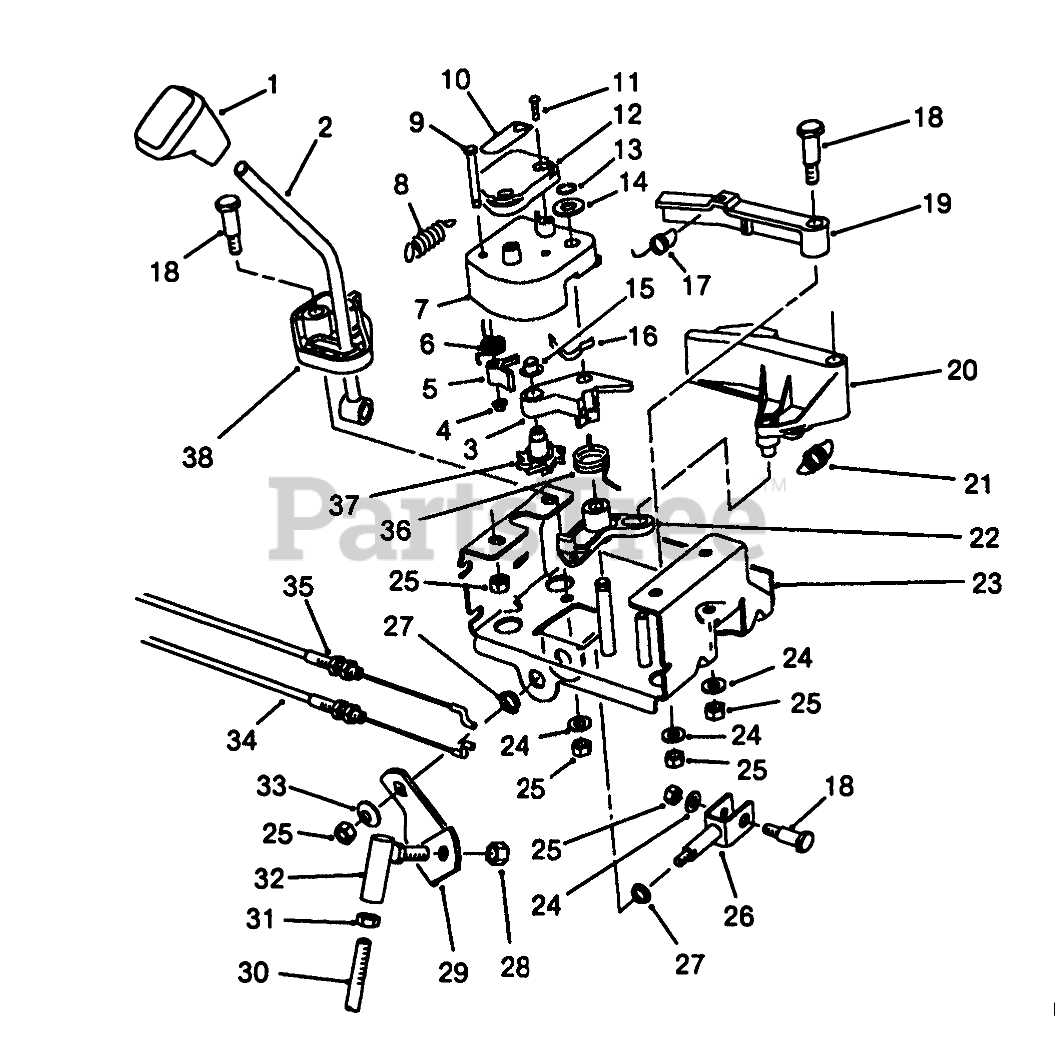

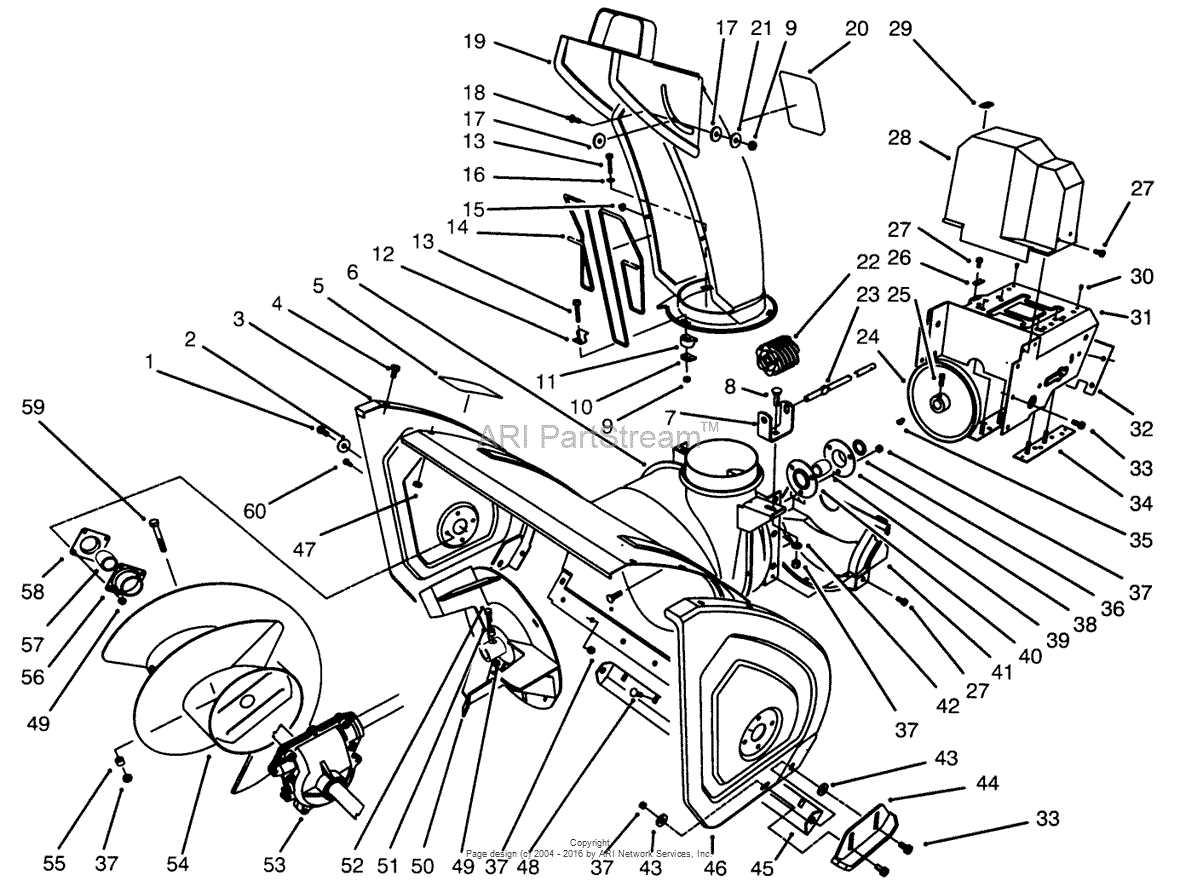

To effectively navigate the visual guide, begin by examining the overall layout. Look for numbered sections or highlighted areas that correspond to individual components. Each section typically provides details about the specific parts, such as their names and functions. This approach aids in recognizing essential elements and their roles in the overall functionality of the equipment.

Once you have identified the necessary components, refer to the accompanying documentation or manual for further details on installation or maintenance procedures. Taking notes on key observations from the visual representation can also assist in creating a checklist for your repair or assembly tasks, enhancing your efficiency and accuracy.

Common Toro 824 Parts Explained

This section provides an overview of essential components found in a popular snow clearing machine, highlighting their roles and functions. Understanding these elements is crucial for maintaining and repairing the equipment efficiently.

Key Components

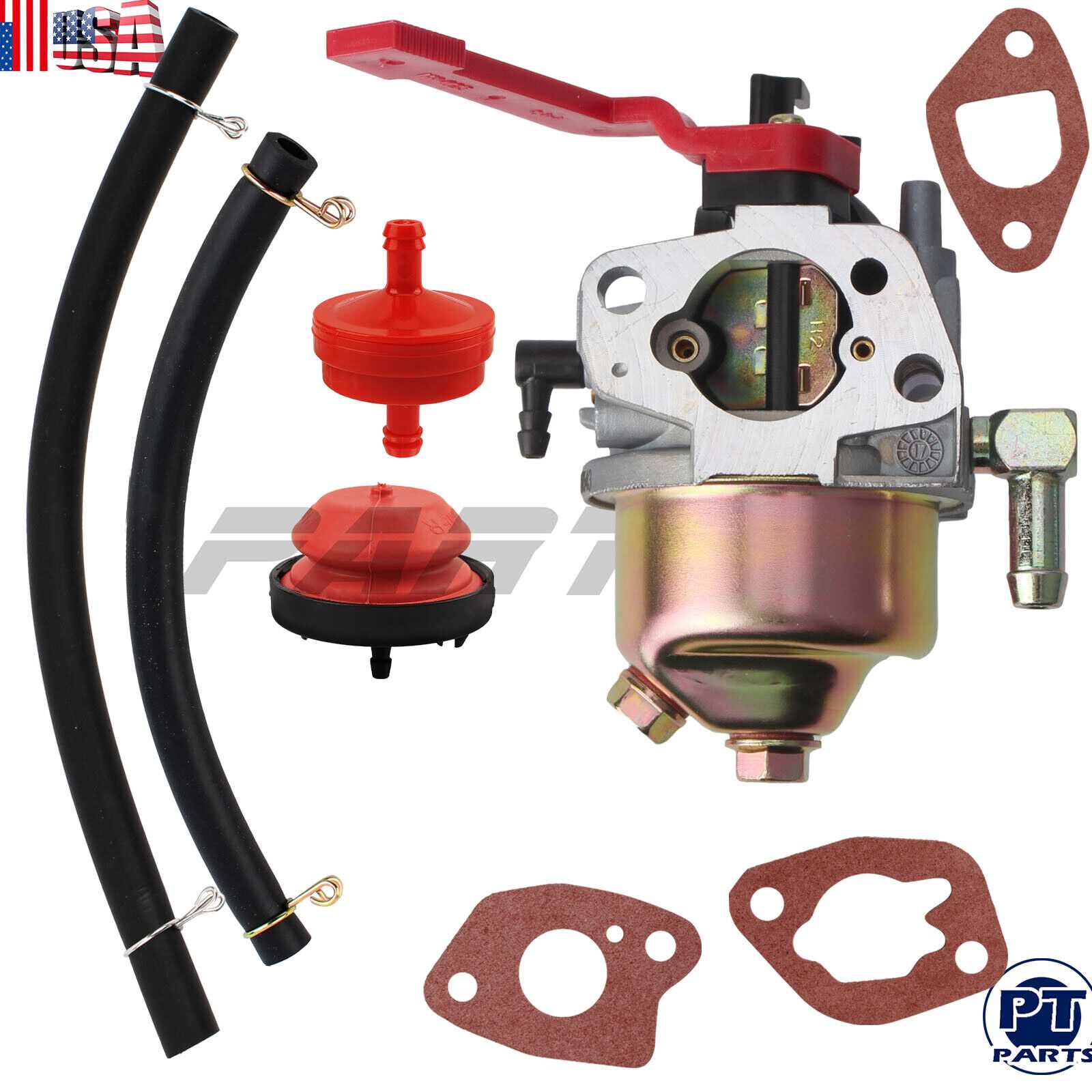

The primary elements of the snow blower include the engine, which powers the entire machine, and the auger, responsible for gathering and breaking up snow. The impeller then directs the snow out of the chute, ensuring effective snow removal.

Maintenance Essentials

Regular upkeep of the fuel system is vital for optimal performance. Additionally, inspecting the drive belts helps prevent unexpected breakdowns during use. Ensuring these components are in good condition can significantly enhance the lifespan of the equipment.

Finding Replacement Parts Easily

Locating suitable components for your machinery can often seem challenging. However, with the right strategies and resources, you can simplify the process and ensure that your equipment remains in optimal condition.

One of the most effective methods to find necessary replacements is to utilize comprehensive online resources. Numerous websites specialize in providing detailed information about various components, including specifications and compatibility.

- Start by visiting manufacturer websites that offer catalogs of available items.

- Consider joining forums or communities where enthusiasts and professionals share their experiences and advice.

- Utilize online marketplaces that focus on machinery, as they frequently have a vast selection of components.

In addition, obtaining a detailed reference can prove invaluable. Manuals often contain useful information about specifications and part numbers, aiding in accurate identification. If these documents are unavailable, reaching out to customer service can provide further assistance.

- Make a list of the specific components you need.

- Cross-reference this list with available online resources.

- Contact local dealers to check for availability.

By following these steps, you can enhance your chances of successfully finding the necessary components for your equipment without unnecessary delays.

Maintenance Tips for Toro 824

Regular upkeep of your equipment is crucial for ensuring optimal performance and longevity. By following a few essential practices, you can enhance the efficiency and reliability of your machine, minimizing potential issues down the line.

1. Clean the Equipment: After each use, make sure to remove any debris or dirt from the exterior and components. This prevents buildup that could affect functionality.

2. Inspect Belts and Cables: Regularly check for signs of wear or damage on belts and cables. Replacing these parts when necessary will help avoid unexpected breakdowns.

3. Change Oil and Filters: Keep your engine running smoothly by changing the oil and filters as recommended in the manufacturer’s guidelines. This promotes better performance and extends the life of the engine.

4. Check Tires: Ensure that the tires are properly inflated and in good condition. Proper tire maintenance not only improves traction but also enhances overall safety during operation.

5. Store Properly: When not in use, store your equipment in a dry, sheltered area. This protects it from harsh weather conditions that can lead to corrosion and other forms of damage.

By implementing these straightforward maintenance tips, you can ensure that your machine remains in excellent condition, ready to tackle any task effectively.

Assembly Instructions

Assembling your equipment requires careful attention to detail and a systematic approach. This section provides essential guidelines to ensure a smooth and efficient process, enabling you to achieve optimal functionality and performance.

Begin by organizing all components and tools, ensuring that everything is readily accessible. Familiarize yourself with the various elements involved in the assembly. Next, follow the step-by-step instructions, paying close attention to any specific orientation or alignment needed for proper installation. It is crucial to secure each piece firmly to prevent any operational issues.

During assembly, consider consulting the accompanying manual for detailed illustrations and explanations. This will aid in clarifying any uncertainties and enhance your understanding of the assembly process. After completing the assembly, conduct a thorough inspection to confirm that all components are correctly positioned and secured.

Note: If you encounter any difficulties or have questions during the assembly, do not hesitate to reach out to customer support or consult with a professional for assistance.

Repairing Your Toro 824 Unit

Maintaining your snow removal equipment is crucial for optimal performance during the winter months. Regular inspections and timely repairs can prevent costly issues and ensure that your machine operates smoothly. Understanding the components and how they interact will aid in identifying problems and executing effective fixes.

Start by familiarizing yourself with the key components of the machine. Knowing the function of each part will make troubleshooting easier. Below is a table outlining common components and their purposes:

| Component | Function |

|---|---|

| Auger | Collects and directs snow into the chute. |

| Chassis | Supports the entire structure and houses internal components. |

| Engine | Provides the power necessary for operation. |

| Drive Belt | Transfers power from the engine to the auger and wheels. |

| Skid Shoes | Adjust the height of the unit above the ground. |

When addressing any issues, always refer to the manufacturer’s manual for guidance on the repair process. This resource will provide detailed instructions tailored to your specific model, enhancing your repair efficiency.

Identifying Faulty Components Quickly

Recognizing malfunctioning elements in machinery is crucial for maintaining efficiency and preventing costly repairs. By utilizing systematic approaches and visual aids, users can swiftly pinpoint issues, ensuring timely interventions. This process not only enhances performance but also extends the lifespan of the equipment.

One effective method involves comparing the current state of components with standard specifications. Observing discrepancies can lead to early detection of wear or damage. Additionally, employing visual resources can simplify the identification process, allowing for quick reference during troubleshooting.

| Common Symptoms | Potential Issues | Recommended Actions |

|---|---|---|

| Unusual noises | Loose or worn parts | Tighten or replace components |

| Overheating | Blocked airflow or lubrication problems | Clean vents and check fluid levels |

| Decreased performance | Clogged filters or damaged belts | Replace filters and inspect belts |

Resources for Toro 824 Owners

Owning a high-performance snow removal machine comes with the responsibility of proper maintenance and understanding its components. Accessing reliable information and support is crucial for ensuring the longevity and efficiency of your equipment. This section provides valuable resources that can help users find the necessary guidance and tools for optimal operation.

Online Forums and Communities

Engaging with fellow enthusiasts through online forums can be an excellent way to gather insights and share experiences. These platforms often have sections dedicated to troubleshooting and best practices, allowing users to learn from one another. Joining a community can also provide access to valuable tips for maintenance and repairs.

Manufacturer’s Manuals and Documentation

Consulting the official manuals is essential for understanding the specifications and care procedures of your machine. These documents typically contain detailed instructions on maintenance schedules and troubleshooting tips. Additionally, many manufacturers offer online access to their documentation, making it easy to find the necessary information at your fingertips.