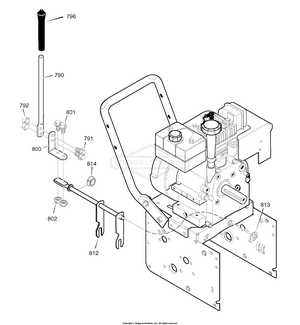

Toro 826 LE Parts Diagram Overview

When maintaining outdoor machinery, having a clear understanding of its individual elements is crucial. Each part plays a significant role in the overall functionality and efficiency of the device. By familiarizing oneself with these components, users can enhance performance and ensure longevity.

Exploring the layout of these elements can provide valuable insights into how they interact and contribute to the machine’s operation. A comprehensive overview not only aids in troubleshooting issues but also facilitates smoother repairs and replacements when necessary.

Whether you are an enthusiast or a professional, grasping the intricate design of your machinery is essential. It empowers you to make informed decisions regarding maintenance and upgrades, ultimately optimizing the performance of your equipment.

Understanding Toro 826 LE Parts

When exploring the components of outdoor machinery, it is essential to comprehend how each element contributes to the overall functionality. A well-structured approach to identifying these elements can enhance maintenance and repair tasks, ensuring optimal performance and longevity.

Key Components Overview

Each segment plays a pivotal role in the efficiency of the equipment. From the engine assembly to the chute control, understanding the interaction between these sections helps in diagnosing issues and streamlining repairs. Attention to detail is crucial for effective upkeep.

Maintenance Tips

Regular inspections and timely replacements can prevent major breakdowns. Familiarizing oneself with the specific functions of each part not only aids in troubleshooting but also empowers users to make informed decisions about repairs and enhancements.

Overview of Toro 826 LE Model

This section provides a comprehensive examination of a specific snow removal machine, highlighting its features, functionality, and user experience. Understanding its design and operation will help users maximize efficiency during winter months.

Key Features

The model is designed for optimal performance in snow clearance. Key attributes include powerful engines, durable construction, and user-friendly controls, making it suitable for residential and commercial use.

Specifications

| Feature | Description |

|---|---|

| Engine Power | Powerful engine for efficient snow removal. |

| Width | Designed to clear wide paths quickly. |

| Weight | Sturdy construction for stability in heavy snow. |

| Control System | User-friendly controls for ease of operation. |

Key Components of the Snowblower

Understanding the essential elements of a snow-clearing machine is crucial for effective operation and maintenance. Each component plays a significant role in ensuring that the equipment functions optimally during harsh winter conditions.

Engine: The power source of the machine, the engine is responsible for generating the necessary force to drive the entire unit. Its performance directly impacts efficiency and snow-clearing capacity.

Auger: This spiral blade mechanism collects and breaks up the snow, allowing it to be effectively propelled towards the discharge chute. A well-functioning auger is vital for tackling heavy, compacted snow.

Chassis: The main frame provides structural integrity and houses all other components. A robust chassis ensures durability and stability while operating on various terrains.

Discharge Chute: This component directs the cleared snow away from the path, allowing for efficient snow management. Its adjustability is essential for directing snow to the desired location.

Controls: The user interface enables operators to adjust speed, direction, and chute angle. Ergonomic and intuitive controls enhance usability, making it easier to navigate challenging conditions.

Wheels or Tracks: These provide mobility and traction, essential for maneuvering through deep snow. Depending on the model, either option may offer distinct advantages in terms of stability and control.

Recognizing the roles of these fundamental parts contributes to better care and performance of the snow-clearing device, ensuring efficient operation throughout the winter season.

Importance of Parts Diagram

Understanding the intricacies of mechanical devices is crucial for effective maintenance and repair. A visual representation of components plays a vital role in facilitating this understanding, allowing users to identify, locate, and manage various elements efficiently.

Benefits of a Visual Representation

- Enhances comprehension of assembly and disassembly processes.

- Facilitates accurate identification of individual components.

- Streamlines troubleshooting by highlighting potential problem areas.

Guidelines for Effective Usage

- Familiarize yourself with the layout to improve efficiency during repairs.

- Refer to the visual aid regularly to ensure correct reassembly.

- Use it as a reference for ordering replacements when necessary.

Ultimately, a well-structured visual guide serves as an indispensable tool for both novice and experienced users, enhancing overall operational effectiveness.

Identifying Major Assemblies

Understanding the key components of any mechanical system is crucial for effective maintenance and repair. By recognizing the principal structures, users can troubleshoot issues more efficiently and ensure longevity.

- Engine Assembly

- Transmission System

- Chassis Framework

- Control Mechanism

- Attachment Tools

Each of these assemblies plays a vital role in the overall functionality. Familiarity with their locations and functions aids in systematic problem-solving.

- Inspect the engine for any signs of wear.

- Check the transmission for fluid levels and leaks.

- Examine the chassis for structural integrity.

- Assess the control mechanism for responsiveness.

- Evaluate attachment tools for compatibility.

By delving into these elements, users can develop a comprehensive understanding, ultimately enhancing their operational expertise.

Common Issues with Toro 826 LE

In the realm of snow removal equipment, certain challenges often arise that can impede performance and efficiency. Identifying these common problems is essential for maintaining optimal functionality and ensuring smooth operation during harsh winter conditions.

| Issue | Description | Solution |

|---|---|---|

| Stalling Engine | Frequent engine shutdowns can occur due to fuel flow problems or ignition issues. | Check fuel lines and replace spark plugs if necessary. |

| Clogged Chute | Snow buildup in the discharge chute can lead to inefficient clearing. | Regularly clear debris and apply non-stick spray. |

| Weak Auger Performance | Poor auger function can result from worn belts or faulty gears. | Inspect and replace worn components as needed. |

| Unresponsive Controls | Control levers may become sticky or unresponsive over time. | Lubricate control mechanisms to restore smooth operation. |

Finding Replacement Parts Easily

Locating components for your machinery can be a straightforward process with the right approach. By understanding where to search and how to navigate resources, you can save time and ensure that you get the necessary items for repairs or upgrades.

- Online Retailers: Numerous websites specialize in offering various components for equipment. Utilizing filters can help narrow down your options efficiently.

- Manufacturer Websites: Directly visiting the official sites can provide you with detailed information on available components and specifications.

- Local Dealers: Checking with nearby distributors can be beneficial. They often have stock or can order specific items for you.

- Community Forums: Engaging in online communities can yield valuable insights. Members often share recommendations for reliable sources.

When searching, consider the following tips:

- Gather all relevant details about the required item, including model numbers and specifications.

- Compare prices from different sources to find the best deals.

- Check customer reviews to ensure the quality of the components you intend to purchase.

With these strategies, acquiring necessary items can become a much simpler task, allowing you to maintain your equipment efficiently.

How to Read Parts Diagrams

Understanding the visual representations of components is essential for effective maintenance and repairs. These illustrations serve as guides, providing insights into how various elements fit together and function within a larger system. By mastering the interpretation of these graphics, you can streamline your repair processes and enhance your technical knowledge.

Identifying Symbols and Labels

Each graphic features specific symbols and labels that denote various elements. Familiarize yourself with these indicators to quickly pinpoint necessary components. Look for a legend or key that explains the symbols, making it easier to navigate through the visual representation.

Understanding Component Relationships

Beyond recognizing individual parts, grasping how these elements interconnect is crucial. Pay attention to lines and arrows, which illustrate relationships and interactions between components. This understanding will ultimately empower you to diagnose issues and perform repairs more effectively.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficient operation of your equipment. Implementing a few simple practices can significantly extend its lifespan and enhance performance.

Routine Checks

- Inspect components regularly for wear and tear.

- Clean filters and air intakes to prevent blockages.

- Check fluid levels and replace them as needed.

Storage Practices

- Store equipment in a dry, sheltered location to avoid rust.

- Use protective covers when not in use.

- Remove fuel if storing for an extended period.

By following these recommendations, you can optimize your machinery’s performance and longevity, ensuring it serves you well for years to come.

Tools Required for Repairs

When tackling maintenance or fixing machinery, having the right tools on hand is crucial for efficiency and effectiveness. A well-equipped toolbox not only simplifies the repair process but also ensures that tasks are completed safely and accurately.

Essential tools include a variety of wrenches, screwdrivers, and pliers, which are fundamental for disassembling and reassembling components. Additionally, a reliable socket set can provide the necessary leverage for stubborn bolts.

For more intricate tasks, specialty tools may be required, such as torque wrenches or alignment tools, which help maintain the integrity of the equipment during reassembly. Don’t forget to include safety gear like gloves and goggles to protect yourself while working.

In summary, preparing a comprehensive set of tools is a vital step that can significantly enhance the repair experience and prolong the lifespan of your equipment.

Safety Precautions When Working

Ensuring a safe working environment is crucial for preventing accidents and injuries. By adhering to certain guidelines and practices, individuals can protect themselves and others while engaging in maintenance or operational tasks. Awareness of potential hazards and preparation are key components of a safe workflow.

General Guidelines

Before commencing any work, it is important to evaluate the workspace and identify potential risks. Proper attire and protective equipment should be utilized to minimize exposure to harmful elements. Regular inspections of tools and machinery are essential to ensure they are functioning correctly and safely.

Emergency Procedures

Having a clear understanding of emergency protocols can greatly reduce the impact of unexpected incidents. Workers should be familiar with the location of first aid kits and emergency exits, and know how to report accidents promptly. Regular drills can enhance readiness and response times in critical situations.

| Precaution | Description |

|---|---|

| Personal Protective Equipment (PPE) | Always wear appropriate gear such as gloves, goggles, and helmets. |

| Tool Inspection | Check tools and machinery for damage or wear before use. |

| Work Area Cleanup | Keep the workspace tidy to prevent tripping hazards. |

| Emergency Contact | Have a list of emergency contacts accessible at all times. |

Upgrades and Accessories Available

Enhancing the performance and versatility of your outdoor equipment can significantly improve its efficiency and effectiveness. Various modifications and additional tools can elevate your experience, making tasks easier and more enjoyable. Below is a selection of popular enhancements and accessories that can be incorporated.

| Accessory Type | Description | Benefits |

|---|---|---|

| Snow Thrower Attachment | Equip your machine with a specialized attachment for efficient snow removal. | Increased clearing capability during winter months. |

| Extra Blades | Replace worn-out blades with high-quality alternatives for optimal cutting. | Enhanced durability and cutting performance. |

| Cab Enclosure | Install a weather-resistant cab for improved operator comfort. | Protection from harsh elements while working. |

| Weight Kits | Add weight to increase traction and stability. | Better control on slippery surfaces. |

| Lights | Install additional lighting for extended work hours. | Enhanced visibility in low-light conditions. |

Customer Reviews and Experiences

This section explores the insights and feedback shared by users regarding their experiences with a popular outdoor equipment model. Customers often highlight the performance, reliability, and ease of use, offering valuable perspectives that can guide potential buyers in their decision-making process.

Many users express satisfaction with the equipment’s ability to handle various tasks, emphasizing its robustness and efficiency. Positive remarks frequently mention its user-friendly features, which enhance the overall experience and make operation straightforward for individuals of all skill levels.

Conversely, some reviews identify areas for improvement, particularly concerning maintenance and availability of replacement components. These critiques serve as constructive feedback, helping manufacturers understand customer needs and expectations.

Overall, the collection of user experiences provides a comprehensive view of the product’s strengths and weaknesses, enabling future purchasers to make informed choices based on real-life applications.