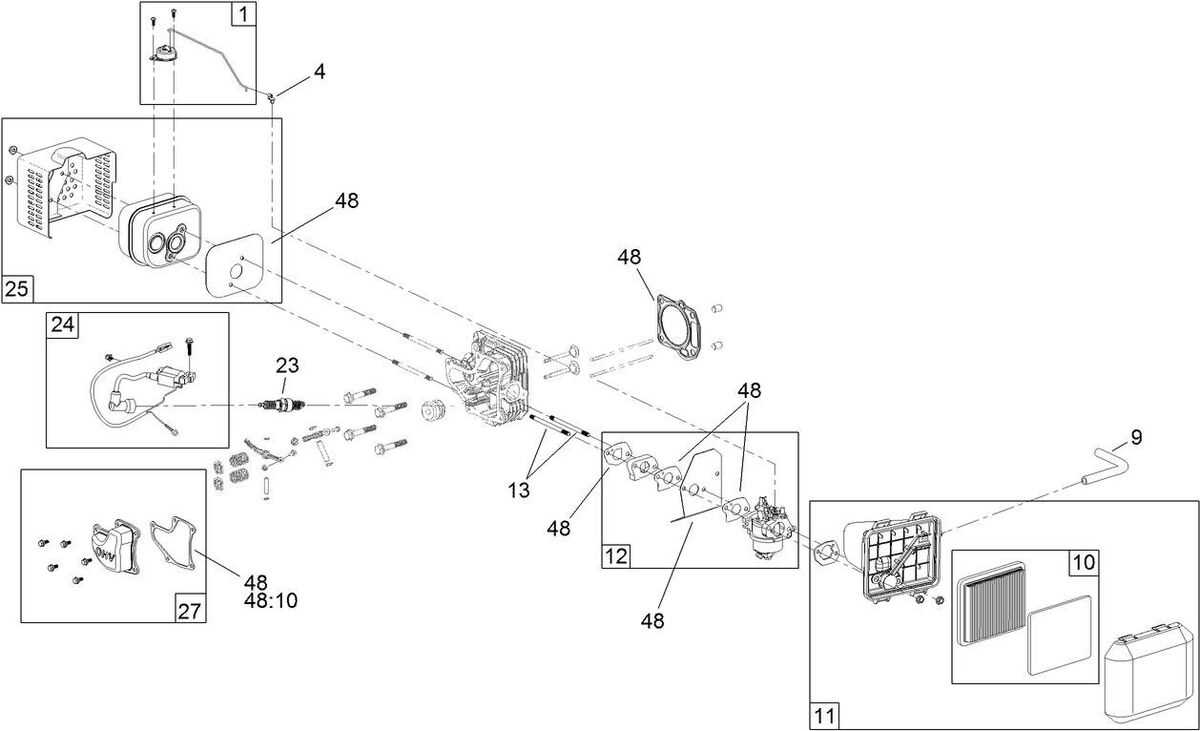

Toro Carburetor Parts Diagram Overview

In the realm of small machinery, a clear visual representation of essential components plays a vital role in maintaining optimal performance. Whether you are troubleshooting issues or performing routine maintenance, comprehending how each element fits together can greatly enhance your efficiency and effectiveness. A well-organized schematic serves as a guide, illuminating the intricate relationships between various mechanical parts.

Delving into these illustrations not only simplifies repairs but also fosters a deeper understanding of how engines operate. Recognizing the function of each component allows for informed decision-making during maintenance tasks. By breaking down complex systems into manageable sections, users can approach their machinery with confidence and clarity.

Exploring these visual aids provides invaluable insights, making it easier to identify potential problems and implement solutions. This knowledge empowers operators to keep their equipment running smoothly, ultimately extending its lifespan and ensuring reliable performance in the long run.

Toro Carburetor Parts Overview

This section provides an insight into the various components that contribute to the efficient functioning of fuel delivery systems in small engines. Understanding these elements is crucial for maintenance and troubleshooting, ensuring optimal performance and longevity of the equipment.

Key Components

The essential elements include a mixture of air and fuel, regulated through specific mechanisms. Each component plays a vital role in achieving the right blend and controlling the flow, which directly impacts the engine’s efficiency and reliability.

Component Functions

| Component | Description |

|---|---|

| Float | Regulates the fuel level in the chamber, ensuring a consistent supply. |

| Needle Valve | Controls the flow of fuel into the chamber based on the float’s position. |

| Jet | Allows a specific amount of fuel to mix with air for combustion. |

| Choke | Restricts airflow to enrich the fuel mixture during starting. |

| Throttle | Regulates the engine speed by adjusting the air-fuel mixture ratio. |

By familiarizing oneself with these critical elements, operators can ensure proper adjustments and maintenance, leading to improved performance and durability of their equipment.

Understanding Carburetor Functionality

The essential mechanism responsible for mixing fuel and air plays a crucial role in the operation of combustion engines. This intricate system ensures that the right proportions of these elements are delivered to the engine, optimizing performance and efficiency. A thorough understanding of how this assembly functions can significantly enhance maintenance and troubleshooting practices.

Basic Principles of Operation

At its core, this device relies on the principles of fluid dynamics. It utilizes a venturi effect to create a vacuum, drawing in fuel from the reservoir and mixing it with incoming air. The mixture’s ratio is vital, as it influences the engine’s power output and emissions. A finely-tuned setup will allow for smooth acceleration and efficient combustion.

Common Components and Their Roles

Several key elements contribute to the overall functionality of this assembly. Jet nozzles regulate fuel flow, while throttle plates control the volume of air entering the system. Float chambers maintain a consistent fuel level, ensuring optimal performance under various conditions. Understanding these components helps users identify potential issues and implement effective solutions.

Identifying Common Toro Models

Recognizing various models of lawn equipment is essential for proper maintenance and repair. Different variations may have unique specifications and components that need to be understood for efficient operation. This section provides guidance on how to identify some of the most popular models used in landscaping and gardening.

Key Features to Look For

- Engine Type: Observe whether the engine is electric or gas-powered, as this often indicates the model type.

- Deck Size: Measure the cutting deck width; common sizes can give clues to the model’s intended use.

- Handle Design: Examine the handle configuration; folding handles may suggest a more portable model.

- Wheel Size: Check the diameter of the wheels, which can affect maneuverability and suitability for different terrains.

Popular Models to Recognize

- Model A: Known for its lightweight design and efficient grass cutting, ideal for small yards.

- Model B: Features a powerful engine and larger deck, perfect for extensive lawns and commercial use.

- Model C: Offers electric operation with advanced battery life, suitable for eco-conscious users.

- Model D: A versatile model that combines mulching and bagging capabilities for diverse landscaping needs.

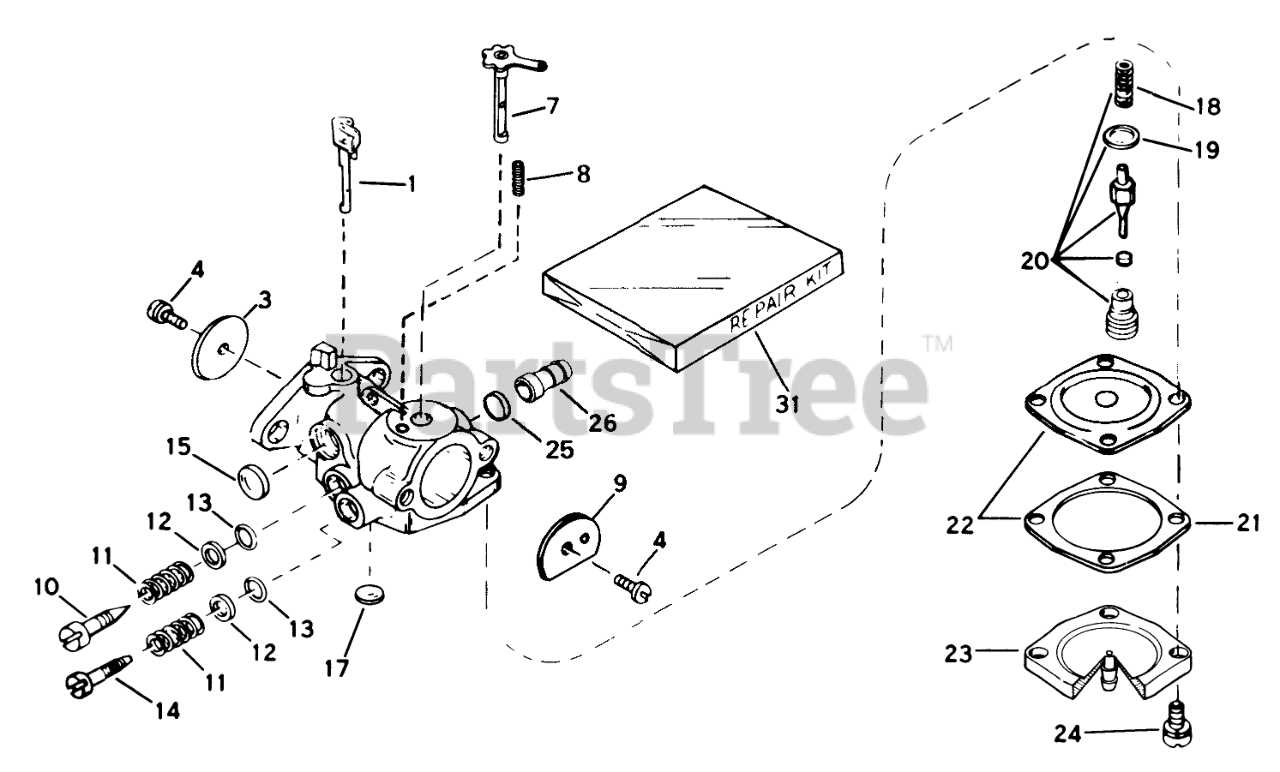

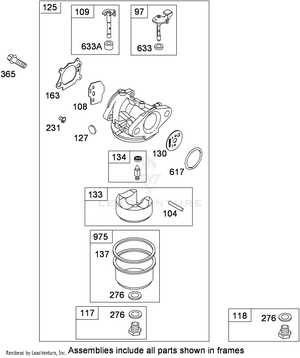

Key Components of Toro Carburetors

The efficiency and performance of small engines greatly depend on the intricate assembly of various crucial elements within their fuel delivery systems. Understanding these key components allows for better maintenance and troubleshooting, ensuring optimal functionality over time.

| Component | Description |

|---|---|

| Fuel Bowl | This reservoir holds a steady supply of fuel, regulating flow to the engine. |

| Float | A buoyant device that controls the fuel level in the bowl, ensuring the correct amount is available for combustion. |

| Needle Valve | Works in conjunction with the float to manage fuel intake, opening and closing as necessary. |

| Venturi | A narrowed section that increases air velocity, creating a vacuum that draws in fuel for mixing. |

| Throttle Plate | This adjustable flap regulates airflow, influencing engine speed and power output. |

| Choke Mechanism | Used to restrict airflow during starting, enriching the fuel mixture for easier ignition. |

By familiarizing oneself with these essential components, users can enhance their understanding of how fuel systems operate, leading to more effective care and improved engine performance.

Importance of a Parts Diagram

Understanding the intricacies of mechanical components is essential for effective maintenance and repair. A visual representation of these elements serves as a valuable tool, guiding users through the complexities of assembly and disassembly. Such illustrations facilitate not only the identification of individual components but also enhance the overall comprehension of their interconnections and functions.

Enhanced Troubleshooting

Utilizing a visual reference significantly aids in diagnosing issues within the system. When users can clearly see how components fit together, it becomes easier to pinpoint malfunctioning parts. This clarity streamlines the troubleshooting process, allowing for quicker identification and resolution of problems.

Improved Efficiency

Having access to a detailed visual guide enhances efficiency during repair tasks. Users can easily locate and verify the components they need, reducing the time spent searching or making assumptions. This efficiency not only saves time but also minimizes the risk of errors, ultimately leading to more successful repairs.

How to Read Carburetor Diagrams

Understanding technical illustrations related to engine components can significantly enhance your ability to maintain and troubleshoot machinery. These visuals serve as a roadmap, providing essential information about the various elements and their interconnections. By familiarizing yourself with these representations, you can gain valuable insights into the operational mechanics of the system.

Identifying Key Components

Start by recognizing the main features depicted in the visual representation. Look for labels that indicate the function of each part, such as fuel inlets, adjustment screws, and airflow passages. Understanding these components will help you grasp how they work together to facilitate the engine’s performance.

Understanding Flow and Functionality

Next, pay attention to the flow lines and arrows that illustrate the movement of fuel and air through the system. These indicators provide clarity on how the mixture is prepared and delivered to the engine. By analyzing these pathways, you can troubleshoot issues related to fuel delivery and performance.

Common Issues with Toro Carburetors

Engine components that regulate fuel and air mixtures often encounter several typical problems that can impact performance. Understanding these common malfunctions can help users maintain optimal functionality and extend the lifespan of their equipment.

One prevalent issue is improper fuel flow, which can result from clogs in the fuel delivery system. This blockage may stem from debris or residue build-up, leading to insufficient fuel reaching the engine. Regular cleaning and maintenance can mitigate this problem.

Another frequent challenge involves air leaks, which disrupt the intended mixture ratio. A faulty gasket or seal can allow excess air to enter the system, causing rough idling or stalling. Inspecting and replacing worn components is essential for preventing this issue.

Additionally, starting difficulties are often linked to inadequate fuel atomization. This can occur when the internal components are dirty or damaged, hindering the efficient mixing process. Routine inspections and cleanings are vital to ensure optimal performance.

Lastly, improper adjustments can lead to engine performance issues, such as poor acceleration or excessive emissions. Ensuring that settings are calibrated according to manufacturer specifications can alleviate these problems and enhance overall efficiency.

Steps for Carburetor Maintenance

Regular upkeep of the fuel delivery mechanism is essential for optimal engine performance. Following a systematic approach ensures longevity and efficiency. Here are key actions to consider for effective maintenance.

| Step | Description |

|---|---|

| 1. Disassemble | Carefully remove the assembly from the engine, ensuring to keep track of all components. |

| 2. Clean | Use a suitable cleaner to eliminate dirt and debris from all surfaces, especially the fuel channels. |

| 3. Inspect | Examine all elements for wear or damage. Replace any faulty components as necessary. |

| 4. Reassemble | Carefully put all parts back together, following the correct sequence to avoid misalignment. |

| 5. Test | Reconnect the assembly to the engine and conduct a performance check to ensure everything is functioning smoothly. |

Finding Replacement Parts Easily

Locating the necessary components for your equipment can often feel overwhelming. However, understanding where to look and how to navigate the available resources can simplify the process significantly. This section aims to guide you in your quest for suitable replacements, ensuring that your machinery remains operational without undue stress.

Online Resources: The internet is a treasure trove of information. Numerous websites specialize in providing detailed catalogs of components, complete with images and specifications. Utilizing these platforms allows you to compare options and find exactly what you need with just a few clicks.

Local Suppliers: Visiting local retailers can be advantageous as well. Establishments that focus on tools and machinery often carry a selection of components or can order them for you. Speaking directly with knowledgeable staff can lead to helpful recommendations tailored to your specific requirements.

Community Forums: Engaging with online communities can provide insights that standard resources might not cover. Enthusiasts and experts often share their experiences, suggesting reliable sources and sharing tips for successful installations. These discussions can be invaluable when searching for hard-to-find items.

Maintenance Manuals: Always consult maintenance documentation associated with your machinery. These manuals not only offer crucial information regarding assembly but often include lists of compatible components. This ensures that you select the right items that will function seamlessly within your equipment.

By leveraging these strategies, you can streamline your search for replacements, ultimately saving time and effort while ensuring your tools operate at their best.

Tools Needed for Carburetor Repair

When undertaking the task of overhauling the fuel delivery system, having the right tools at your disposal is essential for a successful outcome. The appropriate equipment not only streamlines the process but also ensures precision in every step, reducing the likelihood of errors and damage to components.

Essential tools typically include a set of wrenches and screwdrivers, which are crucial for disassembling and reassembling various elements. A cleaning solution is also vital for removing accumulated deposits and ensuring optimal functionality. Additionally, a gasket scraper helps in the removal of old seals, preventing leaks during reassembly.

For more intricate adjustments, having a caliper on hand is advisable to measure components accurately. Finally, a good workbench with adequate lighting provides the necessary workspace to conduct repairs safely and efficiently.

Troubleshooting Carburetor Problems

Identifying and resolving issues with fuel delivery systems is essential for maintaining optimal engine performance. Many factors can lead to inefficiencies, including blockages, improper adjustments, or wear and tear on components. By understanding common symptoms and their potential causes, you can effectively restore functionality and improve overall operation.

Common Symptoms and Causes

Several signs may indicate a malfunctioning fuel system. Engine stalling, difficulty starting, or irregular idling can suggest fuel flow problems. These issues often stem from clogged passages, incorrect air-fuel mixtures, or malfunctioning components. Conducting a systematic examination can help pinpoint the source of the trouble.

Steps for Effective Diagnosis

Begin troubleshooting by inspecting the fuel lines and filters for blockages. Ensure that all connections are secure and that there are no leaks. Next, check the internal mechanisms for wear or damage, as this can significantly impact performance. Adjustments to the air-fuel ratio may also be necessary to achieve the correct balance for efficient operation. Regular maintenance and cleaning can prevent many common issues and extend the lifespan of the system.

Resources for Toro Carburetor Information

Understanding the components and functionality of small engine fuel systems is crucial for maintenance and troubleshooting. A variety of resources are available for those looking to gain insights into these essential mechanisms.

Online Resources

- Manufacturer Websites: Official sites often provide manuals, guides, and specifications for their products.

- Forums and Community Groups: Engaging with fellow enthusiasts can yield valuable tips and shared experiences.

- Video Tutorials: Platforms like YouTube offer visual guides that can assist in both understanding and repairs.

Printed Materials

- Repair Manuals: Comprehensive books are available for in-depth knowledge and troubleshooting techniques.

- Industry Magazines: Publications focused on small engine maintenance often include articles and tips.

- Parts Catalogs: These provide detailed listings and illustrations that can aid in identifying necessary components.