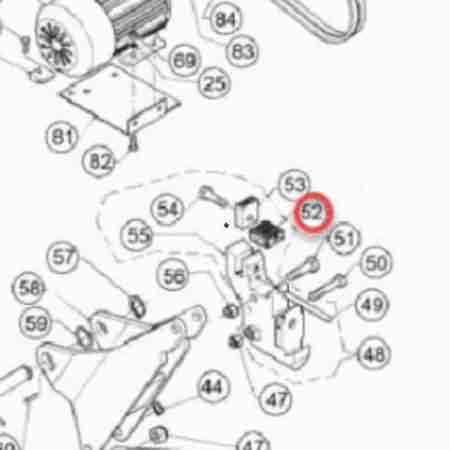

Toro CCR 3650 Parts Diagram Overview

When it comes to ensuring the smooth operation of outdoor equipment, having a clear overview of how the individual elements fit together is essential. Knowing the placement and function of various mechanical components can greatly simplify maintenance and repairs, saving both time and effort.

Each part plays a critical role in the overall performance of a machine. By familiarizing yourself with how these elements are structured and how they interconnect, you can more easily identify potential issues and address them before they lead to bigger problems. This proactive approach not only extends the life of the equipment but also optimizes its efficiency.

In this section, we will explore the arrangement of key components that form the backbone of the system. Gaining a deeper understanding of this layout will enable more effective troubleshooting and upkeep, ensuring long-term reliability.

Component Overview

This machine is built from a variety of essential components that work together to ensure smooth functionality. Understanding the key elements and how they interact can help maintain and extend the life of the device. Each part has a specific role, contributing to efficient operation during winter tasks.

| Component | Function |

|---|---|

| Engine | Powers the entire system, enabling the machine to remove snow efficiently. |

| Auger | Breaks down and directs snow into the chute for discharge. |

| Chute | Controls the direction where the cleared snow is thrown. |

| Drive Belt | Transfers power from the engine to the auger and wheels, ensuring motion and operation. |

| Scraper Bar | Helps remove snow close to the ground while protecting the surface. |

Engine Parts and Specifications

The internal structure of a snow removal machine relies heavily on its core mechanical components. These elements work together to ensure optimal performance and efficiency during operation. Understanding the arrangement and specifications of each part can help maintain and extend the lifespan of the engine.

Key Components include vital elements such as the combustion chamber, piston, crankshaft, and valves. These elements operate in sync to convert fuel into the necessary energy, propelling the machine forward. Each component plays a crucial role in ensuring that the engine functions smoothly and powerfully.

Technical Specifications often vary depending on the design and purpose of the machine. The power output, engine capacity, and fuel type are essential parameters that influence the machine’s efficiency. It’s important to regularly check these specifications to ensure that the equipment continues to meet performance expectations.

Starter Assembly Breakdown

The starter mechanism plays a crucial role in the operation of any machine, ensuring a smooth and reliable start. This section delves into the essential components of the system, outlining how each part interacts to initiate function. Understanding these individual elements is key to maintaining and troubleshooting the starting mechanism effectively.

Key Components of the Starter

The system comprises several critical elements, each contributing to its overall efficiency. Key among these are the ignition switch, starter motor, and connecting gears. These parts work together to create the initial motion needed to activate the device. Below is a detailed look at the individual components and their roles.

| Component | Description |

|---|---|

| Ignition Switch | Responsible for activating the starter motor by completing the electrical circuit. |

| Starter Motor | Converts electrical energy into mechanical movement to initiate the engine. |

| Connecting Gears | Transmit the starter motor’s motion to the engine’s flywheel, initiating the engine’s operation. |

Common Issues and Solutions

Starter systems

Chute Control Mechanism Details

The chute control system is essential for directing snow flow, allowing users to manage the discharge direction with ease. By understanding the design and operation of this mechanism, one can optimize efficiency and ensure proper maintenance.

Key components of the control system include various levers and gears, which work together to adjust the chute’s angle. These elements are engineered for smooth movement, ensuring precise direction control.

Additionally, the linkage mechanism plays a crucial role in connecting the control handle to the chute itself, allowing for seamless operation even in demanding conditions.

Understanding the Auger System

The auger mechanism plays a vital role in ensuring efficient snow removal by moving accumulated snow away from surfaces. This system consists of rotating blades designed to gather and discharge snow quickly. Understanding how these components work together is key to maintaining smooth operation, especially during challenging conditions.

- The rotating blades are responsible for collecting snow from the ground and directing it into the chute.

- The system’s power relies on proper alignment and tension, which guarantees that snow is efficiently gathered and moved.

- Regular maintenance of the blades ensures optimal performance and reduces the chance of clogging.

Overall, the auger system ensures that large amounts of snow can be efficiently managed, even during heavy snowfall. Keeping the system clean and well-lubricated will prolong its lifespan and enhance its functionality.

Belt and Pulley Arrangement

The configuration of belts and pulleys plays a crucial role in the effective operation of machinery. This system is designed to transfer power from one component to another, ensuring smooth functionality and efficiency. Understanding the layout and mechanics involved is essential for maintenance and troubleshooting.

Components of the System

- Belts: Flexible loops that transmit motion between pulleys.

- Pulleys: Grooved wheels that guide and support the belts.

- Tensioners: Devices that maintain the proper tension in the belt, ensuring optimal performance.

- Idlers: Pulleys that change the direction of the belt and provide additional support.

Importance of Proper Alignment

Ensuring that the belts and pulleys are correctly aligned is vital for preventing wear and tear. Misalignment can lead to:

- Increased friction, causing overheating.

- Accelerated wear of both belts and pulleys.

- Reduced efficiency in power transfer.

Regular inspection and adjustment of the belt and pulley arrangement can significantly enhance the lifespan of the components and improve overall performance.

Skid Plates and Scraper Bar Guide

The skid plates and scraper bar play a crucial role in enhancing the efficiency of snow removal equipment. These components are designed to protect the underlying surfaces while ensuring optimal performance during operation. Their design and placement are critical for achieving the desired results, especially in challenging conditions.

Understanding the Functionality

The primary function of the skid plates is to provide a smooth glide over various surfaces, reducing friction and preventing damage. Meanwhile, the scraper bar is essential for effectively clearing away accumulated snow or debris. Together, they contribute to the overall effectiveness and longevity of the machinery.

Maintenance and Replacement

Regular inspection of these components is vital for maintaining peak performance. Signs of wear or damage should be addressed promptly to avoid further complications. Replacing worn parts with high-quality substitutes ensures that the equipment operates efficiently and prolongs its lifespan.

Installation Tips

When installing new skid plates or scraper bars, ensure that they are properly aligned and securely fastened. This not only guarantees optimal functionality but also enhances safety during use. Consulting the manufacturer’s guidelines can provide additional insights into the installation process.

Ignition System Parts

The ignition system is a crucial component in ensuring the efficient operation of small engines. This system is responsible for generating the spark necessary to ignite the fuel-air mixture in the combustion chamber. Understanding the various components that comprise the ignition system is essential for effective maintenance and troubleshooting.

Key Components

Several vital elements contribute to the overall functionality of the ignition system. Each part plays a specific role in the process of generating and delivering the spark needed for combustion.

Component Overview

| Component | Function |

|---|---|

| Spark Plug | Creates a spark to ignite the fuel-air mixture. |

| Ignition Coil | Transforms low voltage from the battery into high voltage for the spark plug. |

| Ignition Module | Controls the timing of the spark generation based on engine position. |

| Flywheel | Generates magnetic field to trigger the ignition coil. |

| Trigger Coil | Detects the position of the flywheel and sends signals to the ignition module. |

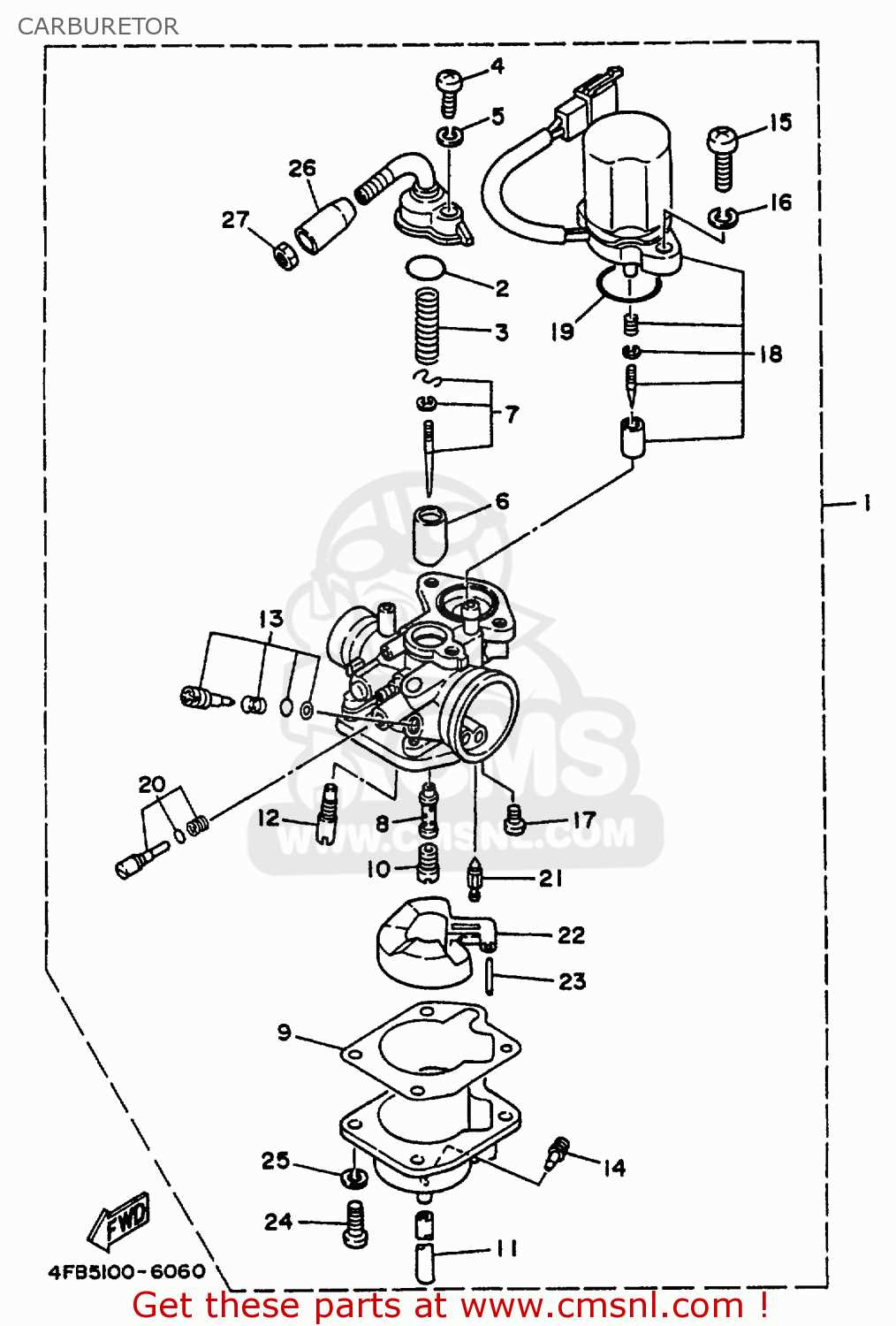

Fuel System Components

The fuel system is a critical aspect of any machinery, responsible for delivering the energy needed for operation. Understanding the various elements that comprise this system is essential for maintenance and performance optimization. Below are the key components that make up the fuel delivery mechanism.

- Fuel Tank: The reservoir where fuel is stored, ensuring an adequate supply for the engine’s demands.

- Fuel Pump: This component is vital for transferring fuel from the tank to the engine, often equipped with filters to remove impurities.

- Fuel Filter: A crucial element that prevents contaminants from entering the engine, prolonging its life and enhancing efficiency.

- Fuel Lines: These conduits transport fuel between various components, designed to withstand pressure and prevent leaks.

- Carburetor: In systems that utilize carburetion, this part mixes air and fuel in the correct ratio for combustion.

- Injectors: In fuel-injected systems, these devices spray fuel directly into the combustion chamber for precise delivery.

Each of these components plays a vital role in ensuring the effective and efficient operation of the equipment. Regular inspection and maintenance of the fuel system are essential to prevent issues and enhance overall performance.

Transmission and Drive Mechanism

The transmission and drive mechanism plays a crucial role in the overall performance and functionality of outdoor power equipment. It facilitates the transfer of power from the engine to the working components, ensuring efficient operation and optimal maneuverability. Understanding this system is essential for maintenance and troubleshooting.

Components of the Drive System

- Gearbox: Converts engine speed into usable power.

- Drive Belt: Transfers power between the engine and gearbox.

- Clutch: Engages and disengages the drive mechanism as needed.

- Sprockets: Help in transferring motion effectively through chains.

Functionality and Maintenance

Regular maintenance of the drive system is vital for ensuring longevity and reliability. Key maintenance practices include:

- Inspecting the drive belt for wear and replacing it if necessary.

- Checking the gearbox for proper lubrication.

- Ensuring the clutch operates smoothly without sticking.

- Cleaning any debris from the sprockets and chains.

Handlebar and Control Setup

Setting up the handlebar and controls is crucial for achieving optimal performance and comfort while operating your snow removal machine. Proper alignment and adjustment ensure that the user can navigate and manage the equipment efficiently.

First, ensure that the handlebar is securely attached and at a comfortable height for the operator. This adjustment allows for better maneuverability and reduces strain during use. It is essential to tighten all connections to prevent any movement while in operation.

Next, familiarize yourself with the control mechanisms. Each function should be easily accessible, allowing for quick responses to changing conditions. Regularly inspect the controls for any signs of wear or malfunction to maintain reliability.

Lastly, personal preferences play a significant role in control setup. Some users may prefer a certain grip style or control configuration that enhances their experience. Experimenting with different setups can lead to improved handling and efficiency.

Shear Pins and Their Purpose

Shear pins are critical components designed to protect machinery from damage during operation. They play a vital role in ensuring that the equipment functions safely and efficiently. By breaking under excessive stress, these pins help to prevent more significant mechanical failures and costly repairs.

Functionality of Shear Pins

The primary function of shear pins is to act as a safety mechanism. When a machine encounters a blockage or excessive load, the shear pin will fail, effectively disconnecting the power source from the driven components. This mechanism serves several purposes:

- Prevents damage to gears and motors.

- Avoids safety hazards for operators.

- Facilitates easy replacement after failure.

Replacement and Maintenance Considerations

Regular inspection and timely replacement of shear pins are essential for maintaining optimal performance. Here are some tips for ensuring their effectiveness:

- Check for wear and tear periodically.

- Use the correct size and material for replacements.

- Follow the manufacturer’s guidelines for installation.

Key Maintenance Points for Longevity

Ensuring the durability and optimal performance of your equipment requires regular attention to specific maintenance practices. These practices not only enhance functionality but also extend the lifespan of the machinery. By implementing a structured maintenance routine, users can prevent wear and tear, leading to a more efficient operation.

Regular inspections are essential to identify any signs of wear before they escalate into significant issues. Checking components for any signs of damage or malfunction can help in addressing problems early on. Additionally, keeping the equipment clean is crucial; dirt and debris can interfere with performance and cause unnecessary strain on parts.

Lubrication is another critical factor in maintenance. Properly lubricating moving parts reduces friction, which in turn minimizes wear. It’s advisable to follow the manufacturer’s guidelines on the frequency and type of lubricant to use. Finally, seasonal maintenance checks, especially before heavy usage periods, can help ensure everything is functioning as it should and ready for optimal performance.