Toyota Tundra Front End Parts Overview

The intricate structure at the front of a vehicle plays a vital role in both functionality and aesthetics. This section delves into the various elements that constitute this area, highlighting their significance in ensuring optimal performance and safety. Each component is designed to work harmoniously, contributing to the overall integrity of the automobile.

Identifying these components is crucial for anyone involved in maintenance or repairs. A clear visualization aids in understanding how each part interacts within the assembly, making it easier to diagnose issues or plan upgrades. By examining the layout of these elements, one can appreciate the engineering behind a vehicle’s design and the importance of each piece in achieving seamless operation.

In this exploration, we will discuss the various sections of the vehicle’s forward assembly, focusing on their functions and interconnections. Whether for educational purposes or practical application, grasping this knowledge is essential for enthusiasts and professionals alike.

The front section of a vehicle is essential for both aesthetics and functionality. It plays a significant role in the overall performance, safety, and appearance of the automobile. Understanding its vital elements can help in maintenance and enhancement efforts.

- Bumper: This component absorbs impact and protects the underlying structure during collisions.

- Grille: Positioned at the front, it allows airflow to the engine while contributing to the vehicle’s design.

- Fenders: These arch over the wheels, shielding them from debris and enhancing the visual appeal.

- Headlights: Essential for visibility, they illuminate the road ahead, improving safety during nighttime driving.

- Radiator Support: This structure secures the radiator in place, ensuring proper cooling for the engine.

- Hood: This cover protects the engine compartment and provides access for maintenance.

Understanding these components not only aids in identifying potential issues but also empowers vehicle owners to make informed decisions regarding repairs and upgrades.

Importance of Proper Part Identification

Accurate identification of components is crucial in ensuring the optimal functionality and longevity of any vehicle. Knowing the specific elements involved in the assembly allows for effective maintenance, repair, and replacement. This awareness helps prevent errors that could lead to further damage or safety hazards, enhancing overall performance and reliability.

Benefits of Correct Component Recognition

Recognizing the correct components offers numerous advantages, including improved compatibility during replacements and repairs. This accuracy minimizes the risk of fitting issues and contributes to smoother operations. Furthermore, it can lead to cost savings by avoiding unnecessary purchases of incorrect items, thus streamlining the repair process.

Enhancing Safety Through Accurate Identification

Understanding the exact nature of each component is vital for ensuring safety. Components that are not properly identified can lead to malfunctions, jeopardizing the vehicle’s performance and increasing the risk of accidents. By prioritizing accurate identification, owners can maintain their vehicles in a safe and reliable condition.

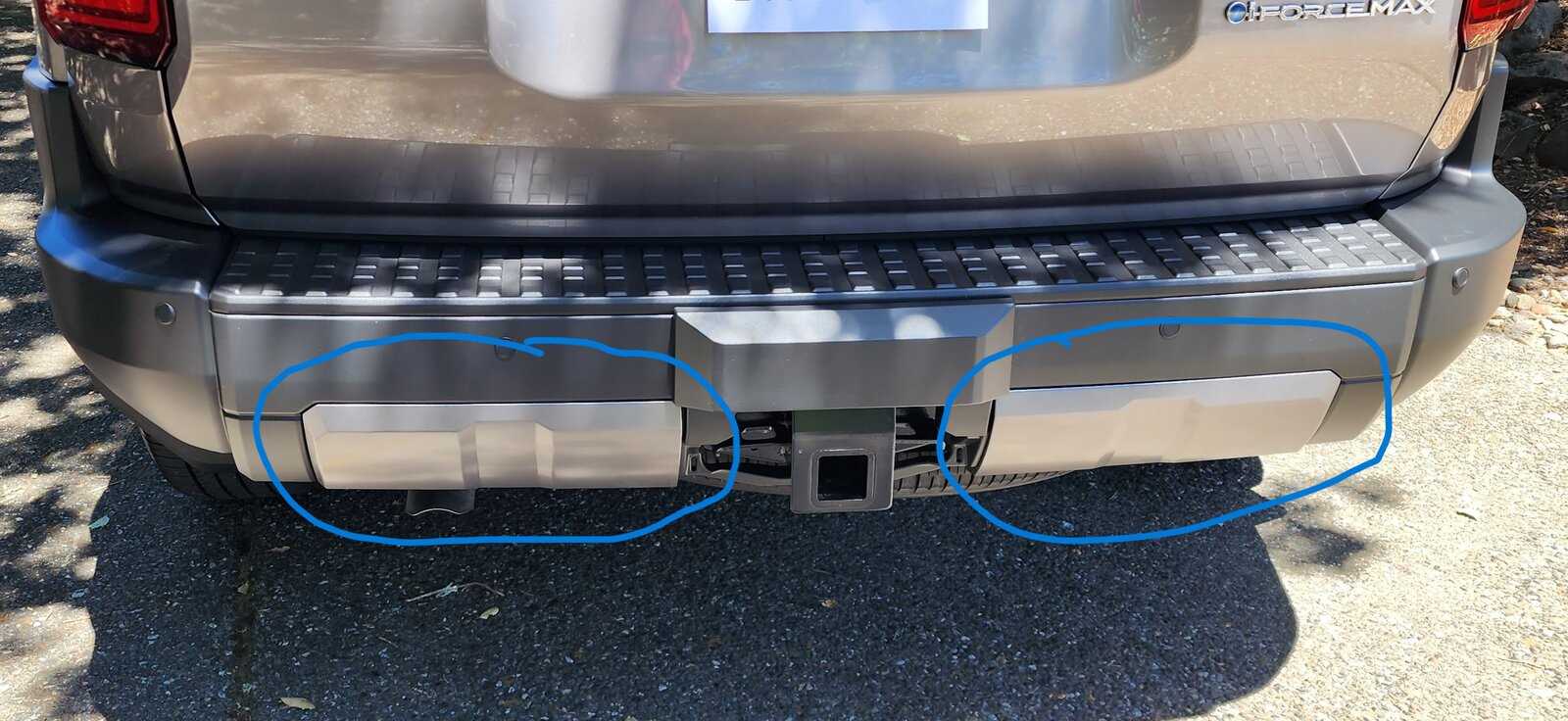

Common Issues with Front End Components

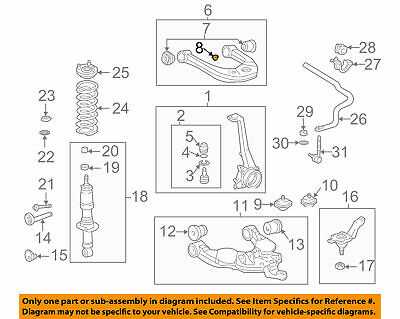

The front section of a vehicle is crucial for its performance and handling. Various components in this area may encounter problems over time due to wear and tear, environmental factors, or improper maintenance. Recognizing these common issues can help vehicle owners address them promptly, ensuring safer and smoother operation.

Signs of Component Wear

As components age, they may exhibit specific symptoms indicating the need for attention. These can include unusual noises, vibrations, or changes in steering response. Identifying these signs early can prevent further damage and costly repairs.

Maintenance and Inspection

Regular maintenance and inspection are essential for ensuring the longevity of various components. A thorough check-up can help detect issues such as misalignment, leaks, or damaged parts before they escalate into more significant problems.

| Issue | Symptoms | Recommended Action |

|---|---|---|

| Worn Bushings | Clunking noises, poor handling | Replace worn bushings |

| Loose Connections | Vibrations, steering instability | Tighten or replace loose connections |

| Damaged Tie Rods | Uneven tire wear, steering misalignment | Inspect and replace damaged tie rods |

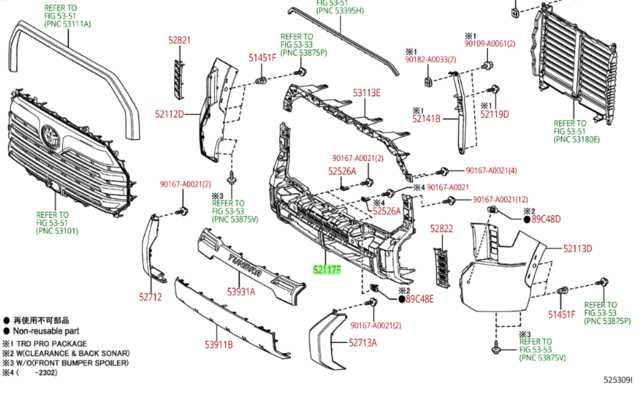

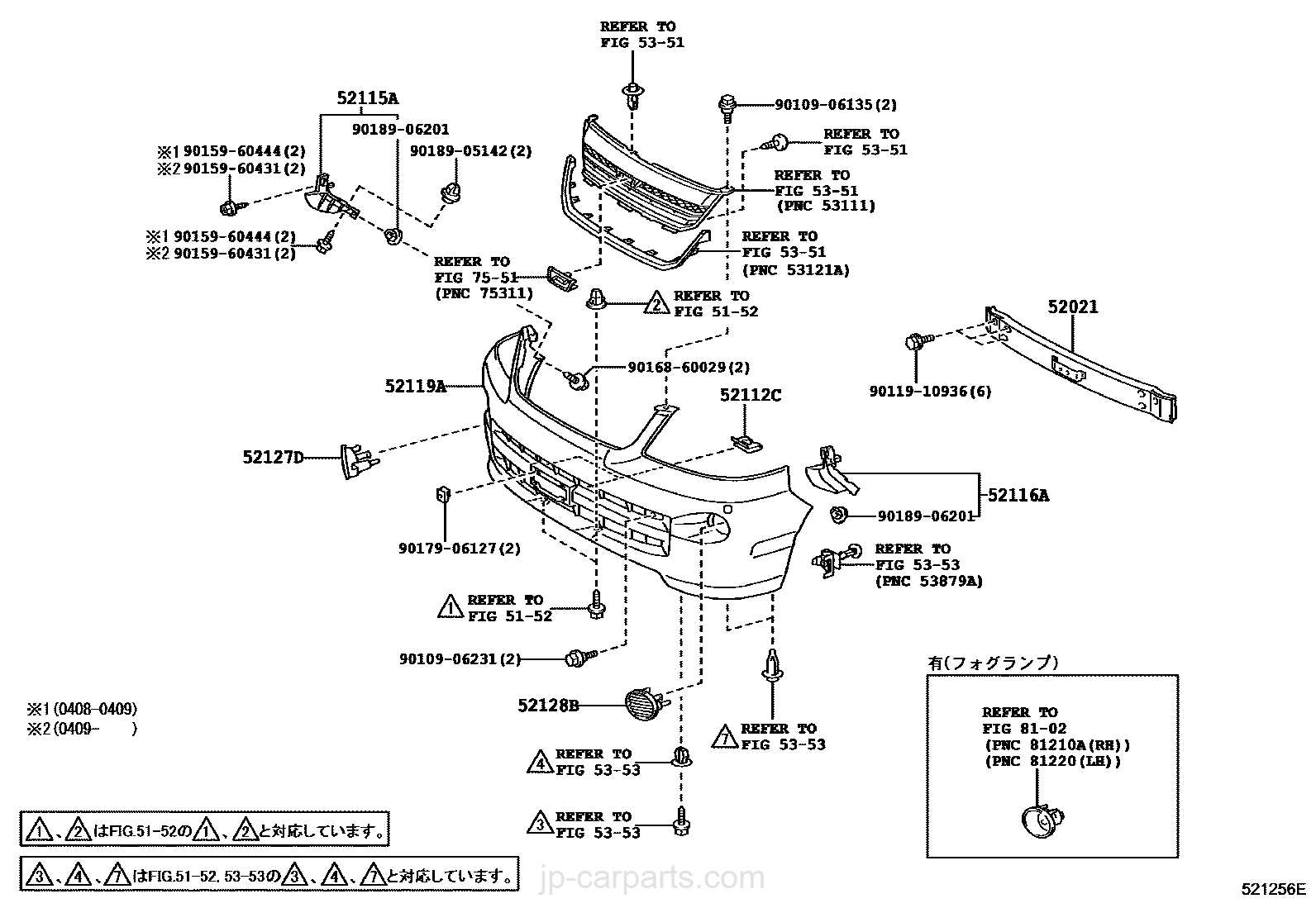

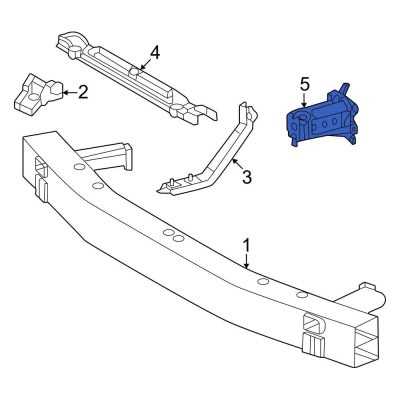

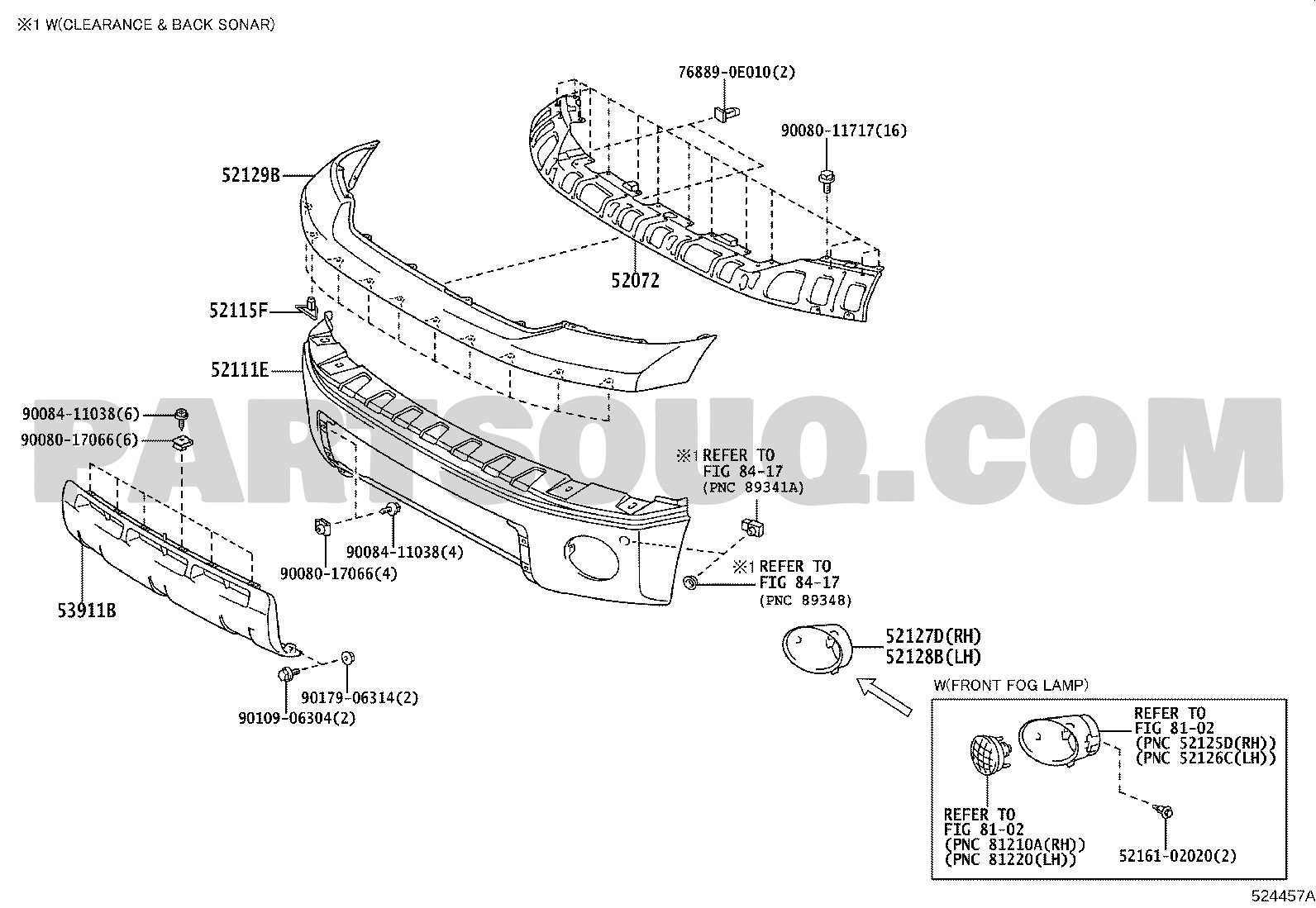

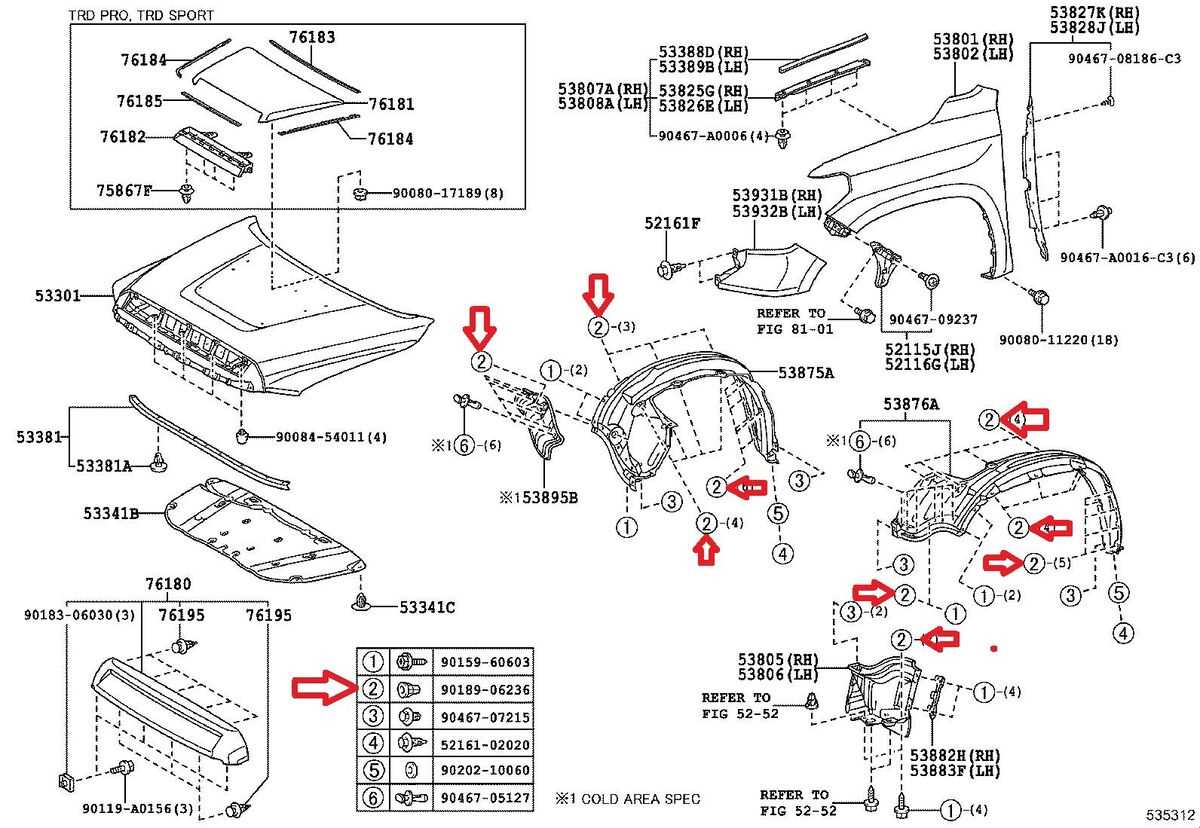

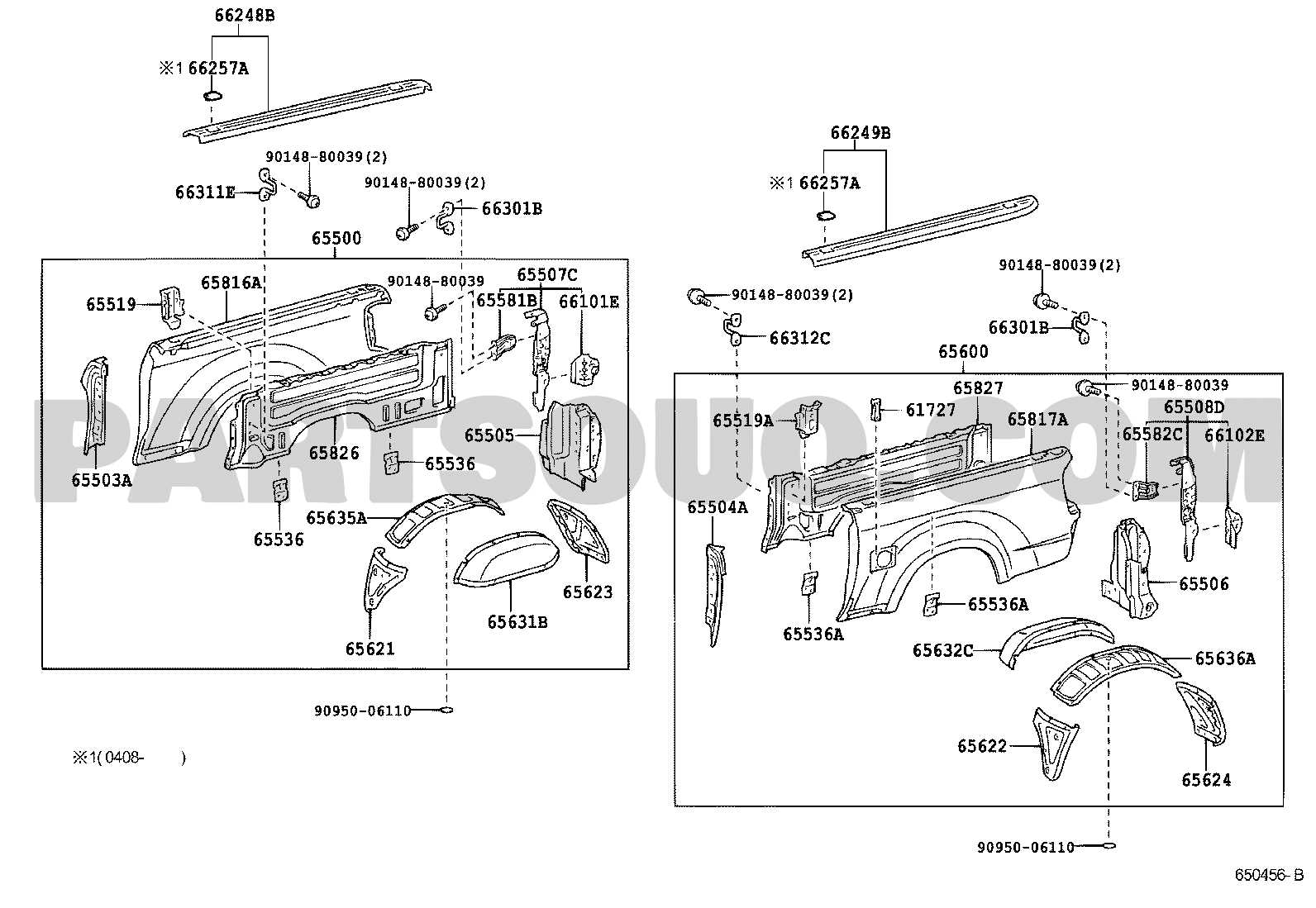

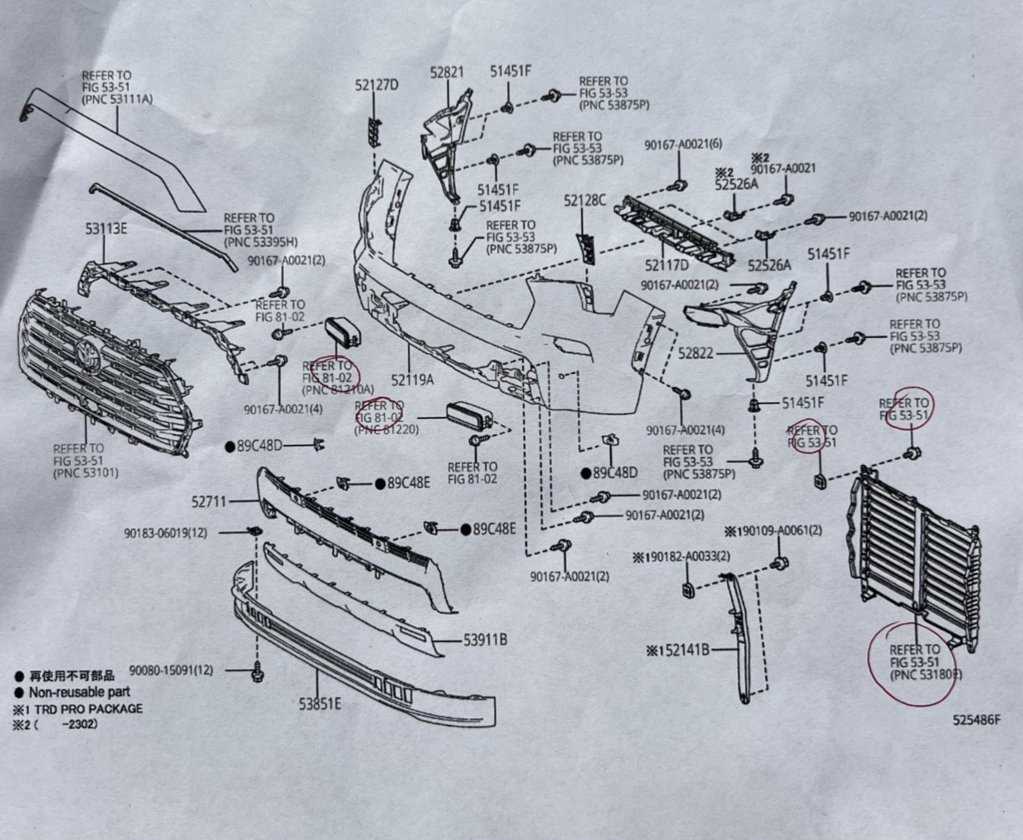

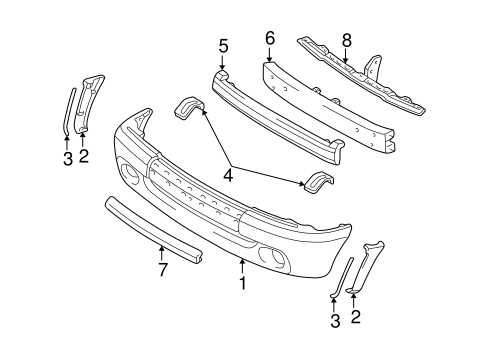

Detailed Parts Diagram Description

This section provides an in-depth overview of the components that make up the front structure of a vehicle. Understanding these elements is essential for maintenance, repair, and upgrades, ensuring optimal performance and safety. The following points outline key features and considerations when examining the arrangement and functionality of these elements.

- Components Overview: Each element plays a significant role in the overall functionality and aesthetics.

- Material Quality: The materials used for construction affect durability and performance.

- Assembly Techniques: Proper assembly methods ensure stability and efficiency.

- Interchangeability: Some components may be interchangeable with those from different models, allowing for flexibility in repairs.

Understanding the positioning and function of each element aids in diagnosing issues and enhancing the overall driving experience. Moreover, familiarity with the assembly can facilitate smoother upgrades and repairs.

- Location: Knowledge of where each component is situated helps in efficient troubleshooting.

- Functionality: Each part serves a specific purpose that contributes to vehicle performance.

- Maintenance Tips: Regular checks and upkeep of these components can prolong their lifespan and enhance safety.

By exploring these facets, vehicle owners and enthusiasts can gain a comprehensive understanding of the structure, leading to informed decisions regarding maintenance and modifications.

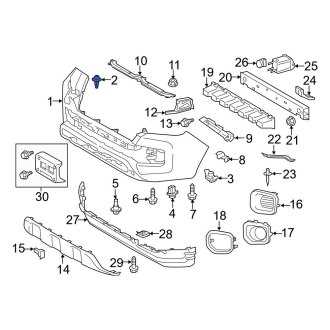

How to Read the Diagram

Understanding technical illustrations is crucial for effective maintenance and repair of vehicles. This section will guide you through the essential elements of a schematic representation, allowing you to interpret the visual information accurately and make informed decisions about repairs or replacements.

Key Components of the Illustration

When analyzing a schematic, it is important to recognize the various symbols and labels used. These elements provide information about the function and location of specific components within the vehicle. Familiarity with these symbols can significantly enhance your ability to navigate the illustration.

Interpreting Relationships and Connections

Besides recognizing individual components, understanding how they are interconnected is vital. Lines and arrows often indicate relationships between elements, showing how they interact within the system. Paying attention to these connections helps in troubleshooting issues effectively.

| Symbol | Description |

|---|---|

| Circle | Indicates a connection point |

| Arrow | Shows flow direction or movement |

| Square | Represents a component or assembly |

Tools Needed for Front End Repairs

When performing maintenance on the forward assembly of a vehicle, having the right tools is essential for ensuring a successful repair process. A well-equipped workshop allows for efficient handling of various tasks, from minor adjustments to significant overhauls. Below is a list of essential instruments that will facilitate these repairs.

| Tool | Description |

|---|---|

| Socket Set | A collection of sockets and ratchets to loosen and tighten fasteners. |

| Torque Wrench | An adjustable tool used to apply a specific torque to bolts and nuts. |

| Jack and Jack Stands | Equipment for lifting the vehicle securely to access the underside. |

| Screwdriver Set | A variety of screwdrivers to handle different types of screws. |

| Pliers | Tools for gripping, twisting, and cutting wires or small components. |

| Hammer | A tool for driving or removing components and adjusting alignments. |

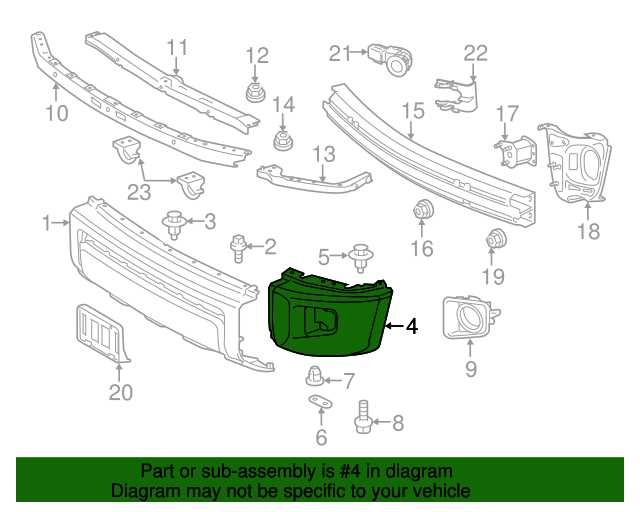

Step-by-Step Repair Process

This section outlines a comprehensive guide for conducting repairs on the front assembly of your vehicle. Following a systematic approach will help ensure that all components are addressed effectively and safely, promoting longevity and performance.

1. Gather Necessary Tools and Materials

Before starting the repair, collect all essential tools and replacement materials. Having everything at hand will streamline the process and reduce unnecessary delays.

2. Secure the Vehicle

Park your vehicle on a level surface and engage the parking brake. Use wheel chocks to prevent any movement while working on the assembly.

3. Remove Existing Components

Carefully detach the damaged parts. Begin with any fasteners or clips, using appropriate tools to avoid damaging surrounding components.

4. Inspect and Clean

After removing the old components, inspect the area for any signs of wear or damage. Clean the surfaces to prepare for the installation of new parts.

5. Install New Components

Position the new parts in place, ensuring they align correctly with the assembly. Secure them using the original fasteners or new ones as needed.

6. Test Functionality

Once installation is complete, conduct a thorough test to verify that everything operates smoothly. Check for any unusual noises or misalignments during operation.

7. Finalize the Repair

After confirming proper functionality, tidy up the work area. Dispose of any old parts responsibly and ensure all tools are stored properly.

Maintenance Tips for Longevity

Ensuring the long-term performance of your vehicle requires consistent care and attention. Regular maintenance not only enhances functionality but also extends the lifespan of essential components. By following a few simple practices, you can keep your automobile operating efficiently for years to come.

Regular Inspections: Conducting routine checks on vital systems, such as brakes, suspension, and fluid levels, can help identify potential issues before they escalate. Early detection often results in less costly repairs.

Fluid Maintenance: Regularly changing engine oil and other fluids is crucial for optimal performance. Clean fluids reduce wear and tear on moving parts, ensuring smoother operation and better fuel efficiency.

Tire Care: Maintaining proper tire pressure and regularly rotating tires can significantly enhance handling and prolong tire life. Additionally, keeping an eye on tread wear will help prevent unexpected blowouts.

Cleaning: Keeping the exterior and undercarriage clean from dirt and grime helps prevent corrosion and rust. Regular washes, especially in harsh climates, can protect vital components from damage.

Professional Servicing: Seeking professional assistance for major repairs or scheduled maintenance can ensure that all aspects of your vehicle are functioning correctly. Qualified technicians can provide insights and services that may not be apparent during casual inspections.

Upgrading Front End Components

Enhancing the front assembly of your vehicle can significantly improve its performance, aesthetics, and overall driving experience. By carefully selecting and replacing various components, you can achieve a more responsive and dynamic ride, tailored to your specific needs. This section will explore key aspects of upgrading these vital elements.

Key Benefits of Upgrading

- Improved Handling: Enhanced components can lead to better steering response and stability.

- Increased Durability: Upgraded materials often provide greater strength and resistance to wear.

- Enhanced Aesthetics: New components can refresh the appearance of your vehicle.

- Better Performance: Optimized parts can improve acceleration and braking efficiency.

Considerations Before Upgrading

- Compatibility: Ensure new components are compatible with your vehicle’s specifications.

- Installation: Decide whether you will install parts yourself or hire a professional.

- Budget: Plan your expenses to accommodate both parts and labor costs.

- Purpose: Define what improvements you want, whether for off-road capability, daily driving, or aesthetics.

Choosing Quality Replacement Parts

When it comes to vehicle maintenance and repairs, selecting high-quality components is essential for ensuring optimal performance and longevity. Quality replacements not only enhance the vehicle’s functionality but also contribute to safety on the road. Understanding how to identify reliable options can make a significant difference in your overall driving experience.

Here are some key considerations when choosing superior components:

- Brand Reputation: Researching manufacturers with a history of producing durable and reliable components can guide your selection.

- Material Quality: Look for replacements made from robust materials that can withstand wear and tear over time.

- Warranty and Support: A solid warranty indicates the manufacturer’s confidence in their products, providing peace of mind for consumers.

- Compatibility: Ensure that the components are compatible with your vehicle’s specifications to avoid performance issues.

- Customer Reviews: Reading feedback from other consumers can provide valuable insights into the reliability and performance of the replacements.

By focusing on these aspects, you can make informed decisions that will enhance the reliability and efficiency of your vehicle.