Comprehensive Guide to 3000 Ford Tractor Parts Diagram

In the realm of agricultural machinery, comprehending the intricate relationships between various components is essential for effective maintenance and operation. Each element plays a critical role in the overall functionality, contributing to the efficiency and productivity of farming activities. Gaining insights into these relationships enables operators and enthusiasts alike to enhance their knowledge and skills.

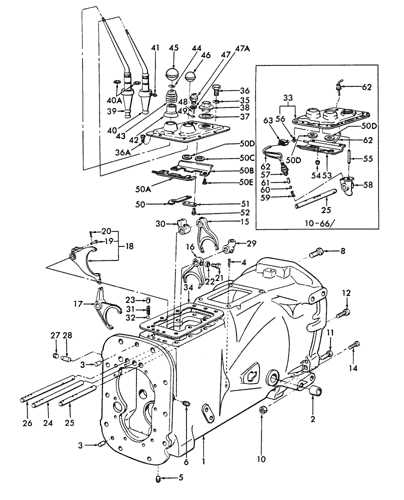

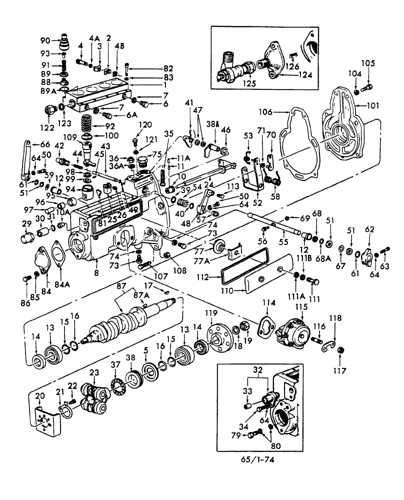

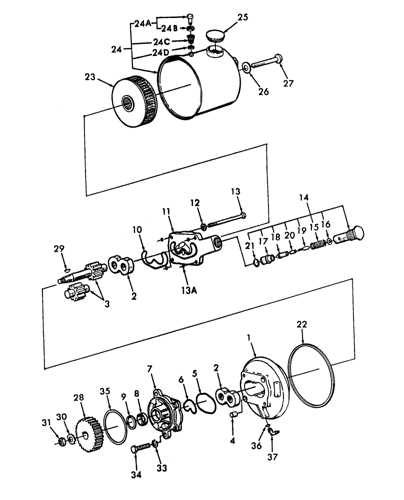

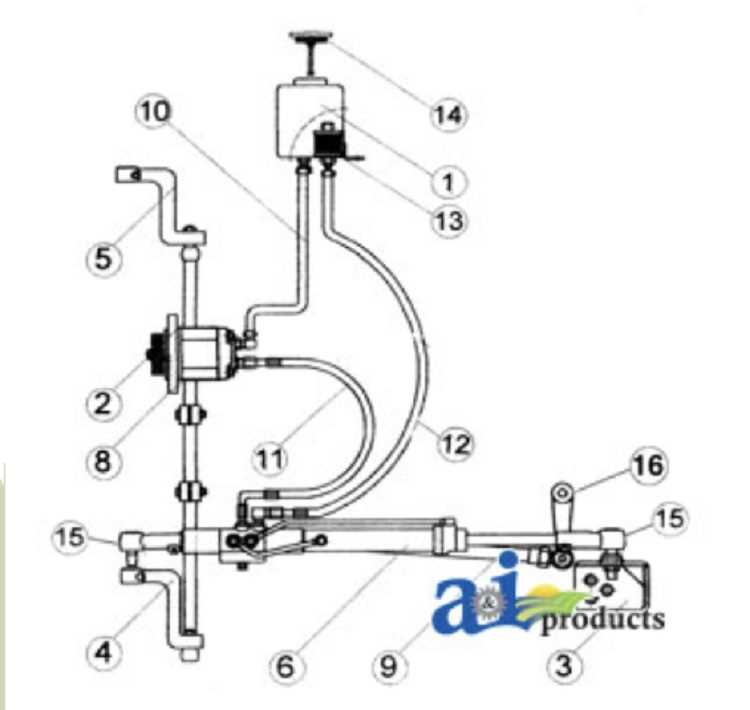

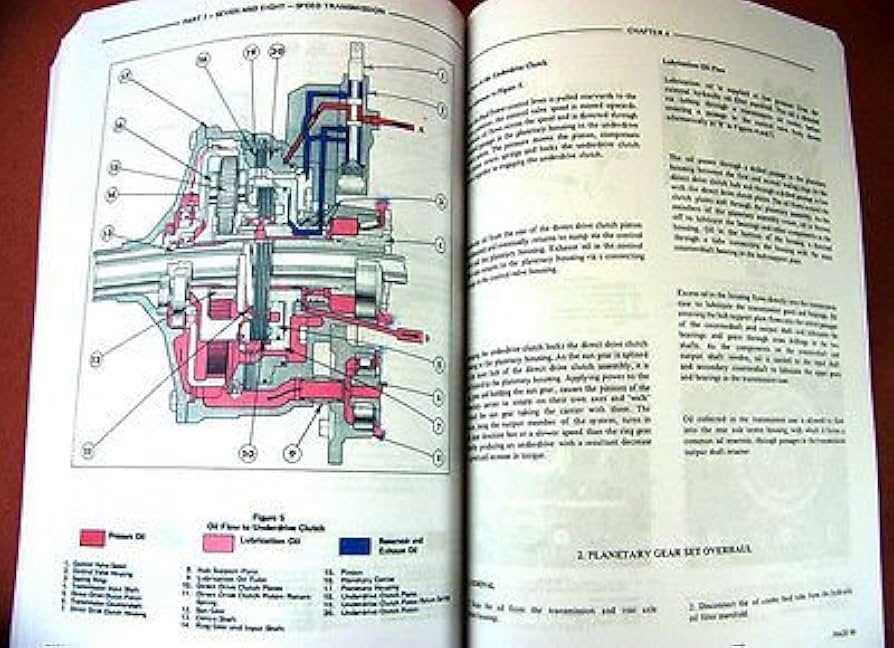

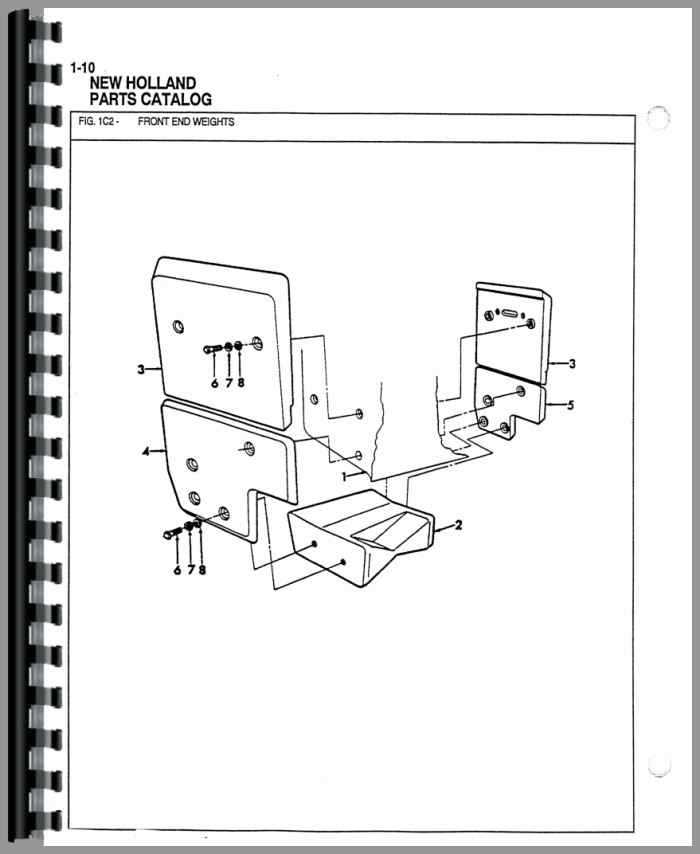

Visual representations serve as invaluable tools for identifying and understanding the myriad elements that comprise these machines. By exploring these illustrations, one can pinpoint specific components and their connections, allowing for a more systematic approach to troubleshooting and repairs. This knowledge is crucial for anyone looking to optimize the performance of their equipment.

Furthermore, familiarity with these schematics not only aids in repairs but also fosters a deeper appreciation for the engineering that underpins modern agricultural technology. Recognizing how each piece interacts with others enhances the ability to anticipate potential issues before they arise, ultimately leading to increased longevity and functionality of the machinery.

Understanding 3000 Ford Tractor Parts

Every machinery enthusiast knows that comprehending the various components of agricultural equipment is essential for effective maintenance and operation. This knowledge not only enhances performance but also extends the lifespan of the equipment. By familiarizing oneself with the intricate system of elements, one can ensure smooth functionality and efficient troubleshooting when issues arise.

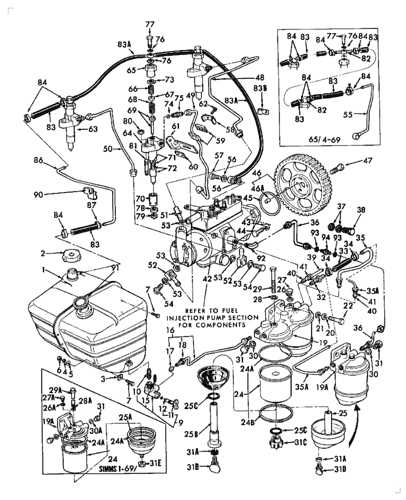

Identification of individual components plays a crucial role in understanding how they work together to drive the overall mechanism. Each element, from the engine to the hydraulic systems, contributes to the seamless operation of the entire setup. Recognizing these components helps operators make informed decisions regarding repairs and upgrades.

Moreover, maintaining a clear grasp of how different parts interact allows for better problem-solving skills. When a malfunction occurs, knowing which part is responsible can save time and resources. Thus, investing time in learning about the various elements is invaluable for both novices and seasoned users alike.

Importance of a Parts Diagram

Understanding the intricacies of machinery is essential for effective maintenance and repair. A visual representation of components can significantly enhance one’s ability to identify and address issues efficiently. Such illustrations serve as a crucial reference, allowing users to locate specific elements and comprehend their functions within the overall system.

Benefits of Visual References

Visual references offer several advantages, including:

| Advantage | Description |

|---|---|

| Enhanced Clarity | Illustrations simplify complex structures, making it easier to understand layouts and connections. |

| Quick Identification | Users can swiftly locate components, reducing downtime during repairs. |

| Improved Communication | Visual aids facilitate discussions among technicians and enthusiasts, fostering better collaboration. |

Supporting Efficient Maintenance

Access to a well-structured visual guide is invaluable for routine upkeep. It ensures that essential elements are not overlooked and aids in planning maintenance schedules effectively. Ultimately, these references promote longevity and optimal performance of machinery.

Common Issues with Ford 3000 Tractors

While these machines are renowned for their durability and reliability, they can still encounter a range of challenges over time. Understanding these common problems can help owners maintain performance and prolong the lifespan of their equipment.

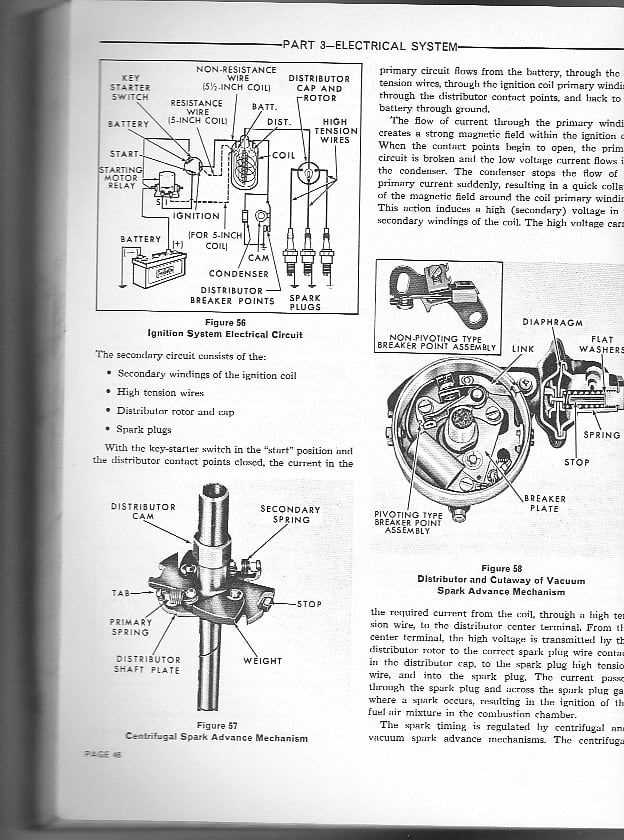

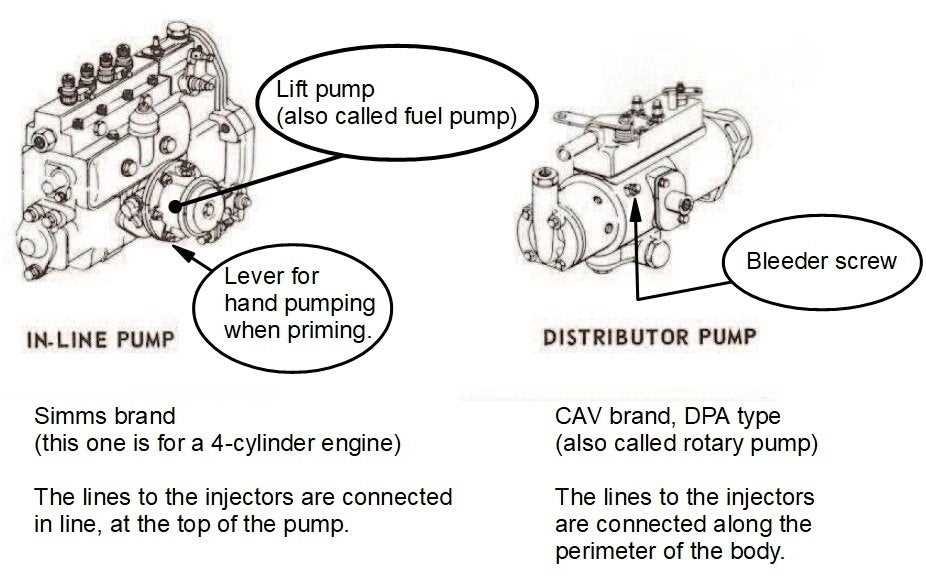

- Starting Difficulties: Many users report issues with ignition and starting, often linked to the battery, starter motor, or fuel system.

- Overheating: Overheating can occur due to insufficient coolant, a malfunctioning thermostat, or issues with the radiator.

- Poor Hydraulics: Hydraulic system failures can stem from low fluid levels, leaks, or worn components.

- Transmission Problems: Gear shifting difficulties might arise from worn gears, low transmission fluid, or linkage issues.

- Electrical Failures: Electrical system issues may manifest as faulty wiring, blown fuses, or issues with the alternator.

By recognizing these potential pitfalls, operators can take proactive measures to address them, ensuring efficient operation and minimizing downtime.

Key Components Explained

This section aims to provide an overview of essential elements that contribute to the functionality and performance of agricultural machinery. Understanding these components is vital for effective maintenance and operation, ensuring that the equipment remains reliable and efficient over time.

| Component | Description |

|---|---|

| Engine | The powerhouse that drives the entire system, converting fuel into mechanical energy. |

| Transmission | Facilitates the transfer of power from the engine to the wheels, allowing for speed adjustments. |

| Hydraulic System | Enables the operation of various attachments and implements through fluid power. |

| Chassis | The framework that supports all other components and provides stability during operation. |

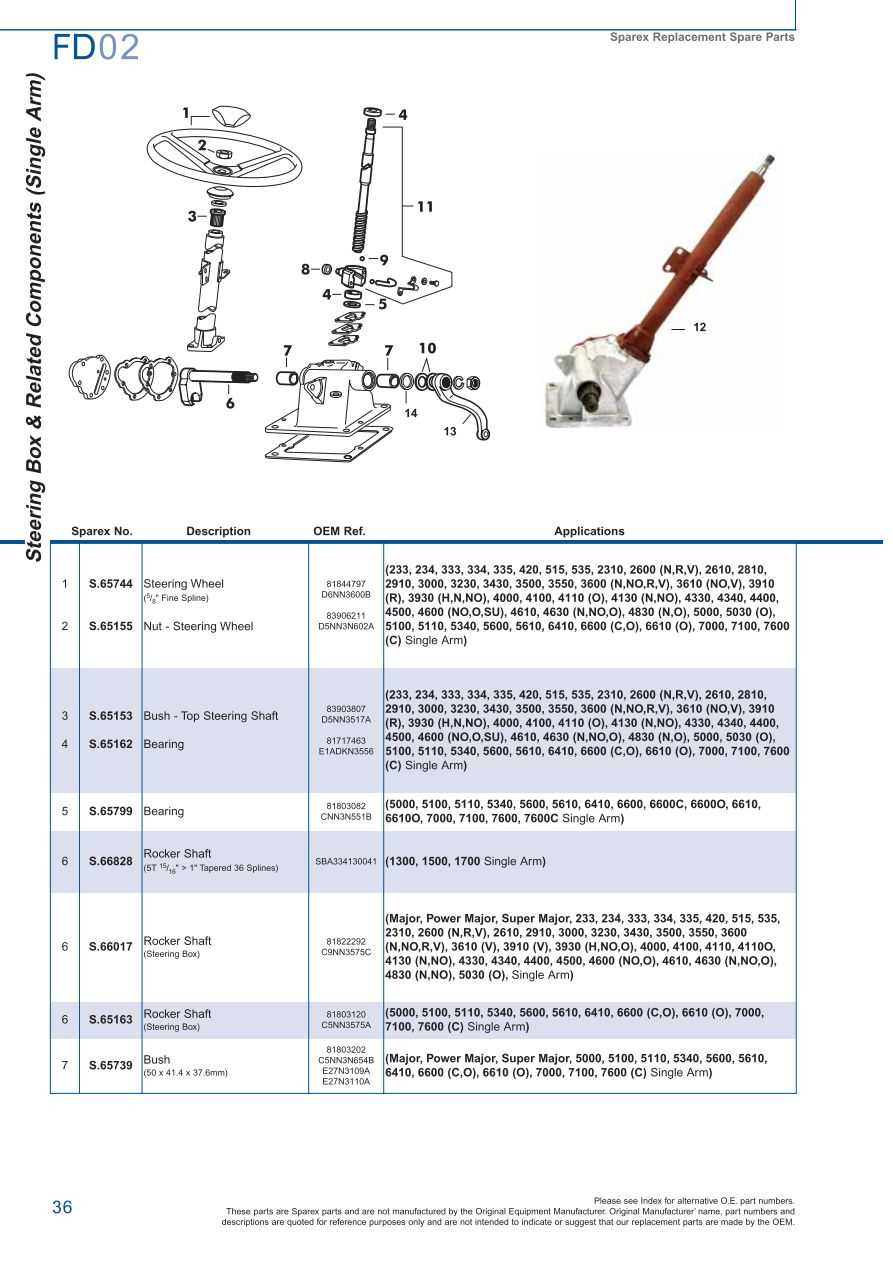

| Steering Mechanism | Allows for directional control, ensuring precise navigation in various terrains. |

How to Read the Diagram

Understanding a schematic representation of machinery can greatly enhance your repair and maintenance skills. Familiarizing yourself with the symbols and layout will allow for a more effective troubleshooting process.

To effectively interpret the illustration, consider the following steps:

- Identify the key: Look for a legend that explains the symbols used.

- Follow the flow: Trace the connections and pathways to see how components interact.

- Segment the information: Break down the diagram into smaller sections for easier comprehension.

Keep in mind the importance of scale and measurements, as these can impact your understanding of how parts fit together.

By practicing these techniques, you’ll gain confidence in navigating complex representations and applying that knowledge to practical tasks.

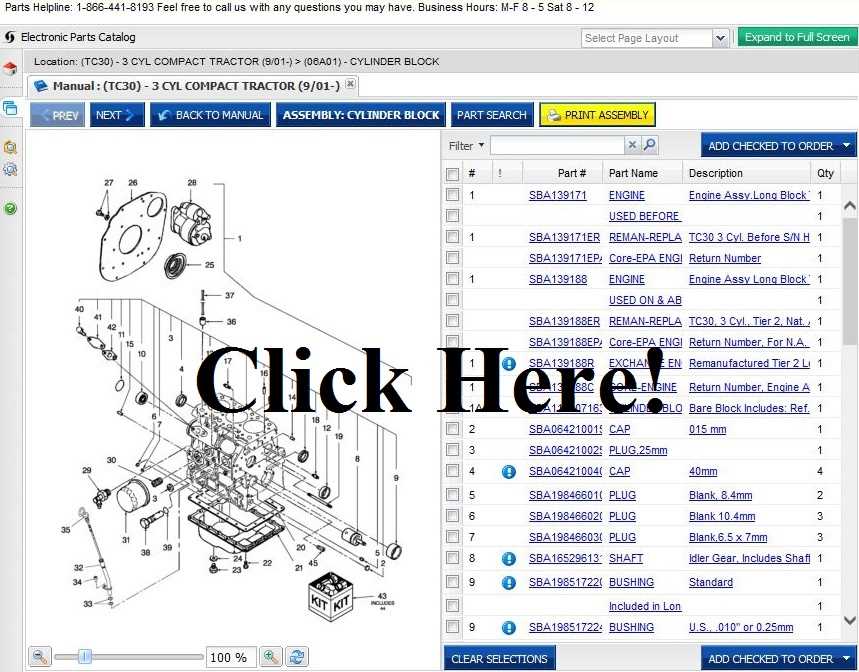

Finding Replacement Parts Easily

Locating the right components for your machinery can often feel overwhelming. However, with the right strategies, this process can become straightforward and efficient. Understanding where to look and how to organize your search is key to successful maintenance and repair.

Online Resources: Utilize various websites dedicated to equipment repair, where you can browse catalogs and diagrams. These platforms often provide filters to narrow down your search by specifications or type, making it easier to find exactly what you need.

Local Dealers: Building a relationship with local suppliers can be invaluable. They often have extensive knowledge about the equipment and can assist in identifying compatible components that might not be readily available online.

Community Forums: Engaging in online communities or forums can yield helpful insights. Experienced users frequently share their recommendations for reliable sources and potential substitutes for hard-to-find items.

Maintenance Tips for Longevity

Ensuring the durability of your machinery requires consistent care and attention. Regular maintenance not only extends the lifespan of your equipment but also enhances performance and efficiency. Adopting a proactive approach to upkeep can prevent costly repairs and downtime, ultimately safeguarding your investment.

Regular Inspections

Conducting routine inspections is crucial for identifying potential issues before they escalate. Pay attention to signs of wear and tear, and make it a habit to check essential components frequently. This diligence will help you catch problems early and keep your machinery in optimal condition.

Scheduled Servicing

Establishing a maintenance schedule can significantly improve the longevity of your equipment. Adhere to the manufacturer’s recommendations regarding servicing intervals, and ensure that all necessary tasks are performed. This includes fluid changes, filter replacements, and any specific maintenance tasks tailored to your model.

| Maintenance Task | Frequency |

|---|---|

| Fluid Checks | Weekly |

| Filter Replacements | Every 100 hours |

| General Inspection | Monthly |

| Professional Servicing | Annually |

Upgrades for Enhanced Performance

Improving the functionality of your agricultural machinery can significantly boost its efficiency and longevity. Whether you’re looking to increase power output, enhance fuel efficiency, or improve handling, several modifications can help you achieve these goals. Investing in high-quality components can lead to noticeable improvements in overall performance.

One effective upgrade is the installation of a high-flow air intake system. This modification allows for better airflow to the engine, resulting in improved combustion and increased horsepower. Additionally, upgrading the exhaust system can reduce back pressure, further enhancing engine efficiency.

Consider also enhancing the hydraulic system with upgraded pumps and valves. These improvements can lead to faster response times and increased lifting capacity, making your equipment more versatile and effective in various tasks.

Finally, implementing advanced electronic controls can optimize performance by providing real-time data and diagnostics. This technology allows for precise adjustments, ensuring that your machinery operates at peak efficiency under varying conditions.

Where to Source Genuine Parts

Finding authentic components for your machinery is essential for maintaining optimal performance and longevity. Several reliable avenues exist to help you acquire these original replacements, ensuring that your equipment continues to operate smoothly.

Authorized Dealers

One of the most dependable sources for genuine replacements is through authorized dealers. They offer a wide range of products and often provide:

- Expert advice on compatibility and installation

- Warranty options for peace of mind

- Access to the latest inventory and models

Online Retailers

The internet has transformed the way we shop for components. Many reputable online retailers specialize in genuine items, providing convenience and competitive pricing. Consider the following:

- Check customer reviews and ratings for credibility.

- Look for websites that offer a secure purchasing process.

- Ensure the retailer provides detailed descriptions and specifications.

By utilizing these resources, you can ensure you are investing in quality items that will enhance the efficiency and reliability of your equipment.

Tools Needed for Repairs

When undertaking maintenance or repair tasks, having the right equipment at your disposal is essential for achieving optimal results. Proper tools not only facilitate efficiency but also ensure safety during the process. Understanding which instruments are necessary can make a significant difference in the outcome of your work.

Basic hand tools such as wrenches, screwdrivers, and pliers are fundamental for various adjustments and repairs. Additionally, specialized tools like socket sets and torque wrenches provide the precision needed for specific tasks. Power tools, including drills and impact wrenches, can expedite processes and enhance performance, especially in more demanding jobs.

Beyond hand and power tools, having access to diagnostic equipment can greatly assist in identifying issues. Instruments such as multimeters and pressure gauges are invaluable for troubleshooting and ensuring all systems function correctly. Always keep your workspace organized and ensure your tools are in good condition to streamline your repair efforts.

Frequently Asked Questions

This section aims to address common inquiries related to equipment maintenance and component identification. Here, you will find valuable insights that help in understanding various aspects of your machinery.

- What are the benefits of having a visual reference?

A visual reference aids in quickly locating components, ensuring efficient repairs and maintenance.

- How can I identify the correct components?

Referencing a comprehensive guide can help in distinguishing parts based on model specifications.

- Where can I find replacement components?

Replacement items can be sourced from authorized dealers, online marketplaces, or specialty stores.

- Is it necessary to follow a guide during repairs?

While not mandatory, following a guide can significantly reduce the chances of errors during maintenance.

- What should I do if I can’t find a specific component?

Consider reaching out to support forums or contacting specialists who may offer assistance.

Resources for Further Learning

Expanding your knowledge in machinery maintenance and repair can significantly enhance your skills and confidence. There are numerous resources available that can provide valuable insights and detailed information on various components and their functionalities. This section highlights some essential materials and platforms to help you deepen your understanding.

Books and Manuals

- Service Manuals: Comprehensive guides that cover specifications, assembly instructions, and troubleshooting techniques.

- Repair Guides: Step-by-step instructions for common repairs and maintenance tasks.

- Technical Books: In-depth discussions on machinery theory and operational practices.

Online Resources

- Forums: Engaging with communities can provide practical advice and firsthand experiences from other enthusiasts and professionals.

- Video Tutorials: Visual aids can help clarify complex processes and techniques.

- Manufacturer Websites: Official sites often provide downloadable resources and specifications directly related to your equipment.

Utilizing these resources will not only improve your technical abilities but also connect you with a network of like-minded individuals dedicated to the craft.