Comprehensive Guide to Ford 1300 Tractor Parts Diagram

In the realm of farming and agricultural practices, the efficiency of machinery plays a pivotal role in productivity. Each piece of equipment is composed of numerous elements, each contributing to the overall functionality and performance. Recognizing how these components interact is essential for maintenance and operational success.

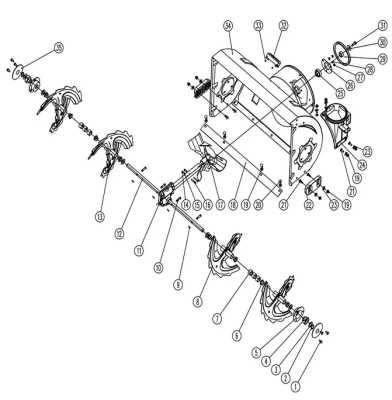

Detailed visual representations of machinery components can significantly enhance one’s understanding of their configuration and function. Such illustrations serve as valuable resources for both seasoned operators and newcomers, providing insights into assembly and troubleshooting. By familiarizing oneself with these schematics, users can ensure their machinery remains in optimal condition.

When delving into the specifics of machinery design, it becomes clear that knowledge of each element can lead to better decision-making and efficiency. This understanding not only aids in repairs but also fosters a deeper appreciation for the engineering that underlies agricultural innovations. As we explore these visual aids, we will uncover the intricacies of machinery and how they contribute to successful farming operations.

Understanding the Ford 1300 Tractor

When exploring the world of compact agricultural machinery, it’s essential to grasp the unique features and capabilities that define a specific model. This model is celebrated for its robustness and versatility, making it a staple among those who require reliable performance in various farming tasks.

Key Features

The design of this machine emphasizes user-friendliness and efficiency. Its compact size allows for maneuverability in tight spaces, while the powerful engine provides the necessary torque for heavy-duty operations. Additionally, operators appreciate the thoughtful arrangement of controls, which enhances the overall experience and productivity.

Maintenance and Care

To ensure longevity and optimal performance, regular maintenance is crucial. Understanding the various components and their functions helps in identifying potential issues before they escalate. Simple tasks, such as checking fluid levels and inspecting belts, contribute significantly to the reliability of this machine. Investing time in upkeep not only enhances performance but also maximizes the lifespan of the equipment.

History of the Ford 1300 Model

The evolution of this compact agricultural machine reflects a significant chapter in the advancement of farming technology. Designed to meet the needs of small-scale farmers, it combines efficiency with versatility, making it a preferred choice for many in the industry. Its introduction marked a turning point, offering enhanced productivity and ease of use.

Originally launched in the late 1970s, this model was part of a broader movement towards more accessible and efficient machinery. It was engineered to tackle a variety of tasks, from tilling to hauling, and quickly gained popularity due to its robust design and reliable performance. The attention to detail in its construction helped it stand out in a competitive market.

Over the years, numerous upgrades were implemented, further improving functionality and user experience. Innovations in engine performance and drivetrain systems contributed to greater fuel efficiency and reduced maintenance needs. As farming practices evolved, this machine adapted, ensuring it remained relevant through changing agricultural demands.

Today, the legacy of this model continues as it holds a place in the hearts of many who value its contribution to modern farming. Its influence can be seen in the design of contemporary machinery, demonstrating the lasting impact of its foundational principles.

Key Features of the Ford 1300

This machine is designed for efficiency and versatility, making it a popular choice among users in various agricultural settings. Its robust construction and reliable performance make it suitable for a range of tasks, from tilling to hauling. Below are some of the standout characteristics that contribute to its reputation.

- Compact Size: Ideal for navigating tight spaces and smaller plots, allowing for increased maneuverability.

- Powerful Engine: Equipped with a strong engine that provides ample horsepower, facilitating efficient operation even under load.

- User-Friendly Controls: Features intuitive controls that simplify operation, making it accessible for both experienced operators and beginners.

- Durability: Built with high-quality materials to withstand harsh conditions and prolonged use, ensuring longevity.

- Versatile Attachments: Compatible with a variety of implements, enhancing its functionality for different tasks.

- Efficient Fuel Consumption: Engineered to maximize fuel efficiency, reducing operational costs over time.

These features collectively enhance its usability and effectiveness in various farming applications, making it a valuable asset for agricultural professionals.

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for efficient maintenance and repair. Visual representations serve as essential tools that enhance comprehension and streamline the troubleshooting process. By providing a clear view of various elements, these illustrations help users identify, locate, and replace components accurately.

Enhancing Clarity and Precision

One of the key benefits of using these visual aids is the increased clarity they offer. Complex systems can be daunting, but with well-structured visuals, users can quickly grasp the relationships between different components. This clarity minimizes the risk of errors during assembly or disassembly, ensuring that each element is handled appropriately.

Facilitating Efficient Repairs

Furthermore, these illustrations significantly expedite repair processes. Technicians can refer to detailed visual guides to locate the necessary elements swiftly, reducing downtime. Timely maintenance not only extends the lifespan of the machinery but also enhances overall productivity, making these resources invaluable in any workshop.

Main Components of the Tractor

The essential elements of a farming machine are crucial for its functionality and efficiency. Understanding these components helps in maintenance and enhances operational performance. Below are the key parts that contribute to the overall performance of the vehicle.

- Engine: The powerhouse that drives the entire system, converting fuel into mechanical energy.

- Transmission: This system transmits power from the engine to the wheels, allowing for speed variation and torque adjustment.

- Chassis: The framework that supports the body and components, providing structural integrity.

- Hydraulic System: A vital mechanism that uses fluid power to facilitate lifting and maneuvering implements.

- Steering Mechanism: This allows for directional control, ensuring precision in navigation and operation.

Each component plays a significant role, and their proper functioning is essential for achieving optimal performance in agricultural tasks.

How to Read Parts Diagrams

Understanding schematics is essential for effective maintenance and repair tasks. These illustrations provide a visual representation of components and their relationships, making it easier to identify necessary elements for various jobs. Familiarity with these visuals can save time and reduce errors during assembly or disassembly processes.

Key Elements of Schematic Illustrations

When examining these representations, several key features should be noted:

| Element | Description |

|---|---|

| Symbols | Each component is typically represented by a unique symbol, indicating its function and connection to other parts. |

| Labels | Many visuals include labels with part numbers or names, aiding in quick identification and sourcing of components. |

| Connections | Lines or arrows demonstrate how parts are linked, clarifying their interactions and installation sequence. |

Tips for Efficient Interpretation

To effectively navigate these illustrations, consider the following tips:

- Start by familiarizing yourself with common symbols used in schematics.

- Cross-reference labels with a parts list for accuracy.

- Pay attention to connection lines, as they provide crucial information about assembly order.

Common Replacement Parts for Ford 1300

Maintaining the longevity and efficiency of agricultural machinery often requires replacing certain components. Understanding the most frequently needed items can help owners keep their equipment in optimal working condition. Below are some essential elements that tend to wear out over time and may need attention.

- Filters: Regularly changing air, oil, and fuel filters is crucial for the smooth operation of machinery.

- Belts: Various belts, including those for power take-off and drive systems, can fray and break, necessitating timely replacement.

- Hoses: Hydraulic and coolant hoses are vital for maintaining fluid dynamics and should be inspected regularly for leaks and wear.

- Battery: A reliable energy source is essential; batteries often require replacement due to age or performance issues.

- Tires: The condition of tires directly impacts traction and stability, making them a frequent item for replacement.

Regular maintenance and timely replacement of these components can significantly enhance performance and prolong the life of your machinery.

Finding Genuine Ford Parts

When it comes to maintaining heavy machinery, sourcing authentic components is crucial for ensuring optimal performance and longevity. Quality materials not only enhance functionality but also provide peace of mind, knowing that the equipment operates as intended. Here are some essential tips for locating reliable supplies.

| Tip | Description |

|---|---|

| Research Authorized Dealers | Seek out distributors that are officially recognized to guarantee the authenticity of the items. |

| Check Serial Numbers | Verify the serial numbers on components to ensure they match the manufacturer’s specifications. |

| Read Reviews | Look for customer feedback to gauge the reliability of the supplier and the quality of the items offered. |

| Ask for Documentation | Request proof of authenticity or certificates that verify the origin of the components. |

| Utilize Online Forums | Engage with communities that focus on machinery to share experiences and recommendations regarding suppliers. |

Aftermarket Parts: Pros and Cons

When considering alternatives for machinery components, it’s essential to weigh the benefits and drawbacks of opting for aftermarket solutions. These options often provide a viable path for users looking to save costs or find specific enhancements not available through original manufacturers.

Advantages of aftermarket components typically include lower prices and a wider variety of choices. Many users appreciate the ability to source items that may offer improved performance or compatibility with specific needs. Additionally, some aftermarket suppliers provide enhanced warranties or guarantees, which can offer peace of mind.

However, there are also disadvantages to consider. Quality can vary significantly among different manufacturers, leading to potential reliability issues. Using non-original parts might also affect the warranty of the equipment, and compatibility concerns may arise, resulting in further complications or additional costs down the line. Users should conduct thorough research to ensure that they make informed decisions.

Ultimately, the choice between original and aftermarket options depends on individual requirements and circumstances. Balancing cost, quality, and performance is crucial for achieving the best outcome for maintenance and repairs.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your machinery requires a proactive approach to upkeep and care. Regular maintenance not only enhances performance but also prevents unexpected breakdowns and costly repairs. By implementing a few essential practices, you can significantly improve the durability and reliability of your equipment.

1. Regular Inspections: Conduct routine checks to identify any signs of wear or damage. This includes examining belts, hoses, and connections to ensure everything is in optimal condition.

2. Fluid Levels: Keep an eye on essential fluids such as oil, coolant, and hydraulic fluid. Maintaining proper levels helps prevent overheating and reduces friction, thereby extending the life of components.

3. Cleanliness: Ensure that the machine is kept clean from dirt and debris. Regular washing and cleaning of air filters can improve efficiency and prevent dust accumulation that may affect performance.

4. Lubrication: Proper lubrication of moving parts is critical. Regularly apply grease to joints and bearings as specified in the manufacturer’s guidelines to minimize wear.

5. Storage: If the equipment is not in use for extended periods, store it in a dry and sheltered location. This helps protect it from environmental factors that could lead to deterioration.

6. Follow Manufacturer Guidelines: Always refer to the maintenance schedule and recommendations provided by the manufacturer. Adhering to these guidelines ensures that all necessary tasks are performed timely.

By following these maintenance tips, you can significantly enhance the longevity of your machinery, ensuring it remains reliable for years to come.

Repair Guides for Common Issues

Maintaining machinery can often lead to unexpected challenges. This section aims to provide clear guidance on tackling frequent problems encountered during operation. With the right knowledge and tools, many issues can be resolved efficiently, minimizing downtime and ensuring optimal performance.

Engine Overheating

One of the most common complications is engine overheating. This can stem from a variety of causes, including low coolant levels, a malfunctioning thermostat, or a blocked radiator. To address this issue, first check the coolant level and top it up if necessary. If the coolant is adequate, inspect the thermostat for proper function and ensure the radiator is free of debris.

Transmission Troubles

Transmission issues can manifest as difficulty shifting gears or unusual noises. Begin troubleshooting by examining the fluid level; insufficient fluid can lead to poor performance. If the fluid is contaminated or burnt, a change is necessary. Additionally, inspect the linkage for any signs of wear or misalignment.

Regular maintenance and prompt attention to these problems can prolong the life of your equipment. Always consult the manual for specific instructions and safety guidelines.

Where to Buy Ford 1300 Parts

Finding quality components for your agricultural machinery is crucial for maintaining optimal performance. There are various avenues available for sourcing these essential items, ensuring you can keep your equipment running smoothly. This guide will help you navigate the best options for acquiring the necessary supplies.

Online Retailers

Many online platforms specialize in offering a wide range of equipment supplies. These websites often provide detailed descriptions and specifications, making it easier to find the right items for your needs. Look for retailers that offer customer reviews and ratings to gauge the quality of their offerings.

Local Dealers and Salvage Yards

Visiting local dealers or salvage yards can be a cost-effective way to find what you’re looking for. These establishments often have a selection of both new and used components, allowing you to compare prices and conditions. Building relationships with local suppliers may also lead to personalized recommendations.

| Source Type | Advantages | Considerations |

|---|---|---|

| Online Retailers | Convenience, variety, competitive pricing | Shipping times, potential return issues |

| Local Dealers | Immediate availability, local support | Limited selection, higher prices |

| Salvage Yards | Cost savings, unique finds | Quality variability, may require more effort |

Resources for Ford Tractor Enthusiasts

For those passionate about vintage machinery, finding reliable information and support is essential. This section aims to provide a collection of valuable resources that cater to enthusiasts seeking guidance, parts, and community engagement related to their beloved equipment.

Online Communities

Joining forums and social media groups can greatly enhance your experience. These platforms allow you to connect with fellow enthusiasts, share knowledge, and exchange tips on maintenance and restoration. Websites dedicated to enthusiasts often host discussion boards where members can ask questions and receive advice from experienced individuals.

Reference Materials

Books, manuals, and instructional videos serve as excellent resources for understanding the intricacies of machinery. Look for comprehensive guides that cover various models, maintenance routines, and troubleshooting techniques. Websites specializing in historical equipment often provide downloadable manuals, ensuring you have the right information at your fingertips. Additionally, video tutorials can visually guide you through repairs and upgrades, making the learning process more accessible.