Understanding the Parts Diagram of the 1920 Ford Tractor

The evolution of farming equipment has significantly transformed agricultural practices, enhancing efficiency and productivity. Understanding the intricate workings of machinery is essential for maintenance and operation. This section delves into the essential elements that constitute classic farming implements, focusing on their structure and functionality.

By examining the specific components and their interconnections, one can gain valuable insights into the mechanics of these robust machines. Each segment plays a crucial role in ensuring optimal performance, and recognizing their arrangement is key for anyone involved in agricultural operations.

Whether you are a seasoned operator or a novice in the field, familiarity with these elements will empower you to troubleshoot issues effectively. Knowledge of how each piece interacts not only aids in repair but also enhances overall machine longevity.

Understanding Ford 1920 Tractors

The compact machines from the early 1990s are known for their reliability and versatility, making them popular choices for a variety of agricultural tasks. With a robust build and an efficient engine, these vehicles have become staples for small farms and landscaping projects. Their design combines functionality with user-friendly features, appealing to both seasoned professionals and new operators.

Key Features

These machines boast a powerful engine that ensures excellent performance across diverse terrains. Their maneuverability allows for easy navigation in tight spaces, making them suitable for both large and small plots of land. Additionally, a range of implements can be attached, enhancing their utility for tasks such as plowing, mowing, and hauling.

Maintenance and Care

To ensure longevity and optimal performance, regular maintenance is essential. This includes checking fluid levels, inspecting belts and hoses, and maintaining the battery. Understanding the maintenance schedule is crucial for keeping the machine in top condition and minimizing downtime during critical work periods.

Key Features of the Ford 1920

This versatile agricultural machine stands out for its remarkable performance and durability. Designed to tackle various tasks, it combines innovative engineering with user-friendly features, making it a favorite among farmers and landowners alike.

Powerful Engine: The robust power unit offers exceptional torque, enabling efficient operation under heavy loads. Its reliability ensures consistent performance in diverse conditions.

Compact Size: The smaller dimensions allow for easy maneuverability in tight spaces, making it ideal for both large fields and smaller plots. This agility enhances productivity during various farming activities.

Hydraulic System: The advanced hydraulic setup provides smooth operation of implements, ensuring that attachments work seamlessly. This feature significantly increases the machine’s versatility for different agricultural tasks.

Operator Comfort: The ergonomic design includes a comfortable seating arrangement and easily accessible controls, minimizing fatigue during long hours of work. This attention to operator comfort enhances overall efficiency.

Durability: Built with high-quality materials, this model is designed to withstand the rigors of daily use. Its sturdy construction ensures a long lifespan, making it a sound investment for any farming operation.

Common Applications for Ford 1920

This versatile machine is widely utilized in various agricultural and landscaping tasks, making it a reliable choice for both professional and personal use. Its design allows for efficient performance in multiple settings, from small farms to large estates. Operators appreciate its ability to handle different attachments, enhancing its functionality and adaptability to specific jobs.

Agricultural Tasks

In the realm of farming, this equipment is commonly employed for plowing, tilling, and planting. With the right implement, it can efficiently prepare soil for crops, ensuring optimal growing conditions. Additionally, its power enables the transportation of materials, such as hay and feed, which is essential for livestock management.

Beyond agricultural applications, this machine is also favored in landscaping and maintenance projects. Its capability to maneuver in tight spaces makes it ideal for tasks like grading, mowing, and clearing debris. Operators find it particularly useful for maintaining lawns and gardens, as well as for performing snow removal during winter months. The combination of versatility and strength ensures that it meets the needs of various outdoor activities.

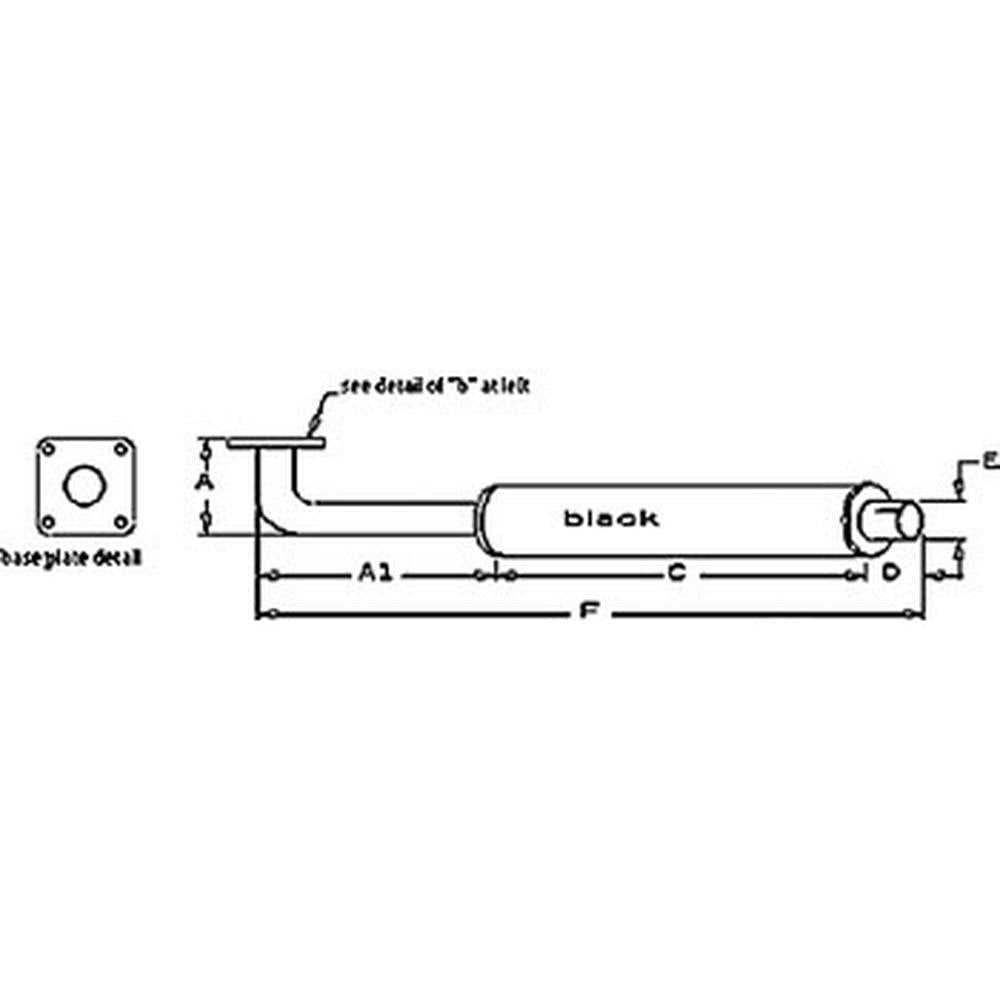

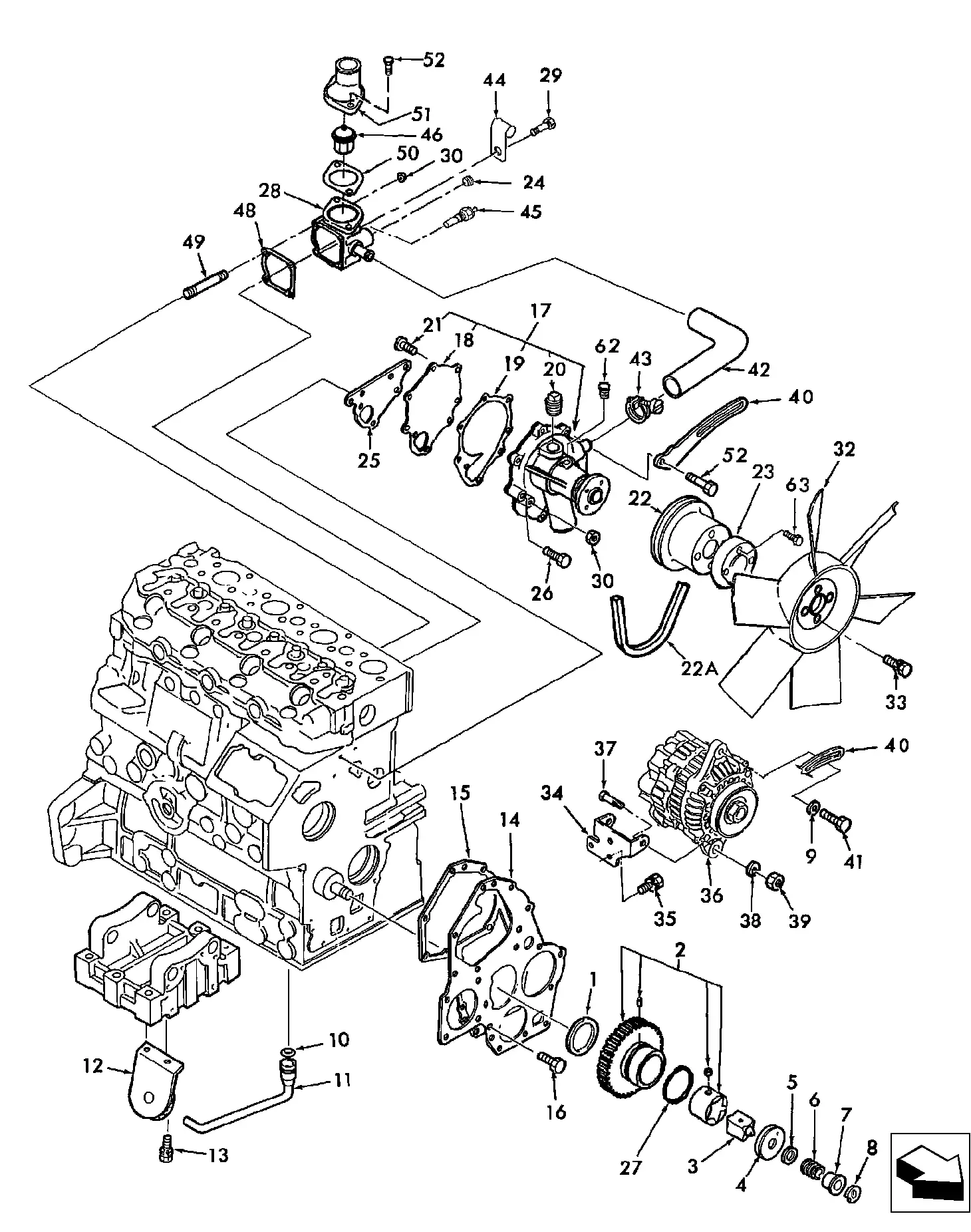

Essential Components of the Tractor

The functionality of agricultural machinery relies heavily on its critical elements. Understanding these components not only aids in maintenance but also enhances overall efficiency during operations. Each part plays a vital role in ensuring optimal performance, contributing to the effectiveness of fieldwork.

Main Elements

- Engine: The powerhouse that drives the entire system, converting fuel into mechanical energy.

- Transmission: This mechanism transfers power from the engine to the wheels, facilitating movement and speed adjustments.

- Hydraulics: Essential for lifting and controlling various implements, allowing for versatile applications.

- Chassis: The structural frame that supports all other components, ensuring stability and durability.

- Wheels: Provide traction and mobility, crucial for navigating different terrains.

Supporting Elements

- Fuel System: Responsible for delivering fuel to the engine, vital for performance.

- Electrical System: Powers lights, ignition, and other electronic components, enhancing functionality.

- Cooling System: Maintains optimal engine temperature, preventing overheating during operation.

- Exhaust System: Manages emissions, ensuring compliance with environmental standards.

Recognizing and understanding these essential elements can significantly improve the performance and longevity of agricultural machinery. Regular inspection and maintenance of each component are crucial for ensuring reliable operation.

Finding Replacement Parts Easily

Locating components for machinery can often be a daunting task. However, with the right approach and resources, the process can become much more manageable. Understanding where to search and how to evaluate options will save both time and effort, ensuring your equipment remains in optimal condition.

Utilizing Online Resources

The internet offers a wealth of information for sourcing components. Here are some effective strategies:

- Search Engines: Use specific keywords related to the component you need to find.

- Manufacturer Websites: Many manufacturers provide detailed catalogs and listings for their products.

- Online Marketplaces: Platforms such as eBay or specialized retailers often have a wide selection available.

- Forums and Communities: Engage with online groups where enthusiasts share resources and tips.

Local Options and Networking

Exploring local resources can also yield valuable results. Consider the following:

- Local Dealers: Visit authorized dealers who may stock original or compatible items.

- Salvage Yards: Check out salvage yards for used components that are still in good condition.

- Networking: Connect with other users or professionals who may have recommendations or leads on where to find what you need.

By leveraging both online and local avenues, you can streamline the process of finding the necessary items for your equipment. Stay proactive and resourceful, and you’ll enhance your chances of a successful search.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components brings a multitude of advantages that enhance both performance and longevity. These meticulously crafted items are designed to meet the exact specifications set forth by the manufacturer, ensuring optimal compatibility and reliability.

Quality Assurance: One of the primary benefits of OEM components is the assurance of quality. These items undergo rigorous testing and adhere to strict standards, providing peace of mind that you are using the best possible options for your machinery.

Precision Fit: OEM components are engineered to fit seamlessly, minimizing the risk of malfunction due to improper installation or mismatched specifications. This precision helps maintain the overall efficiency and functionality of your equipment.

Longevity: Investing in OEM items often translates to increased durability. These components are built with high-grade materials that resist wear and tear, ultimately extending the lifespan of your machinery.

Warranty Protection: Many manufacturers offer warranties on their original equipment components. This protection not only covers the part itself but also can safeguard your entire system, reducing long-term repair costs.

Performance Reliability: Using OEM components ensures that your equipment operates at peak performance. With the right parts in place, you can expect consistent and dependable operation, reducing the likelihood of unexpected breakdowns.

In summary, choosing original equipment manufacturer components over alternatives guarantees superior quality, a perfect fit, enhanced longevity, warranty coverage, and reliable performance. These benefits collectively contribute to the overall efficiency and effectiveness of your machinery.

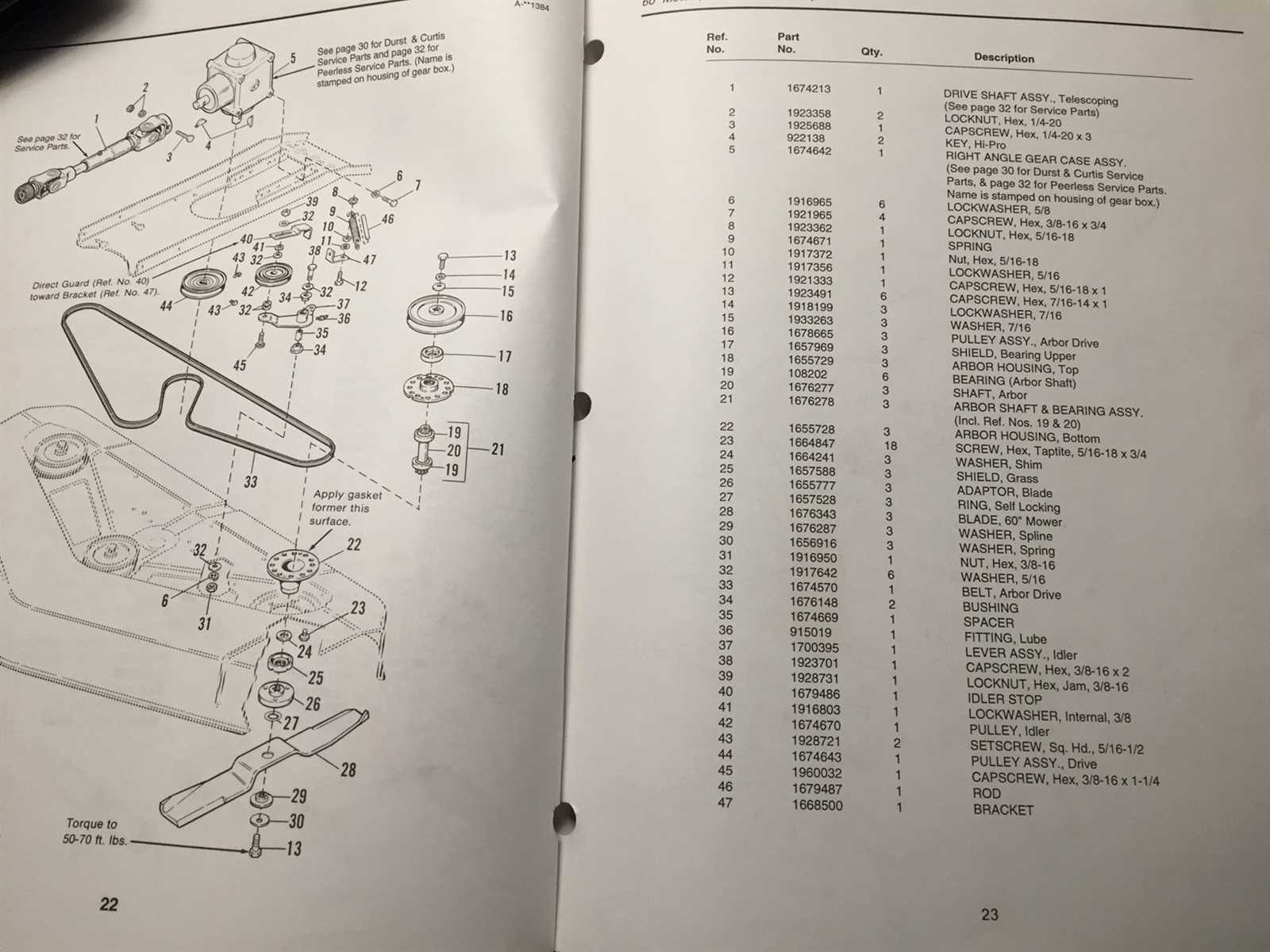

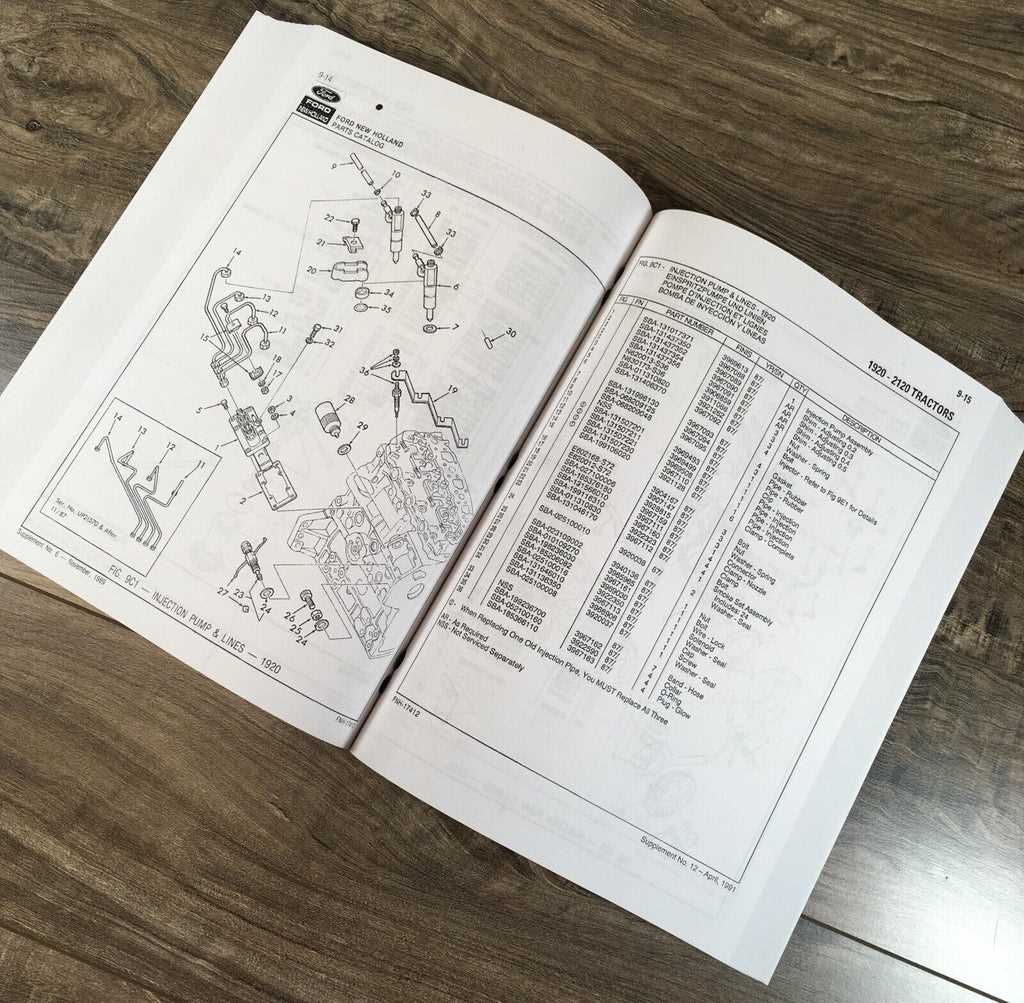

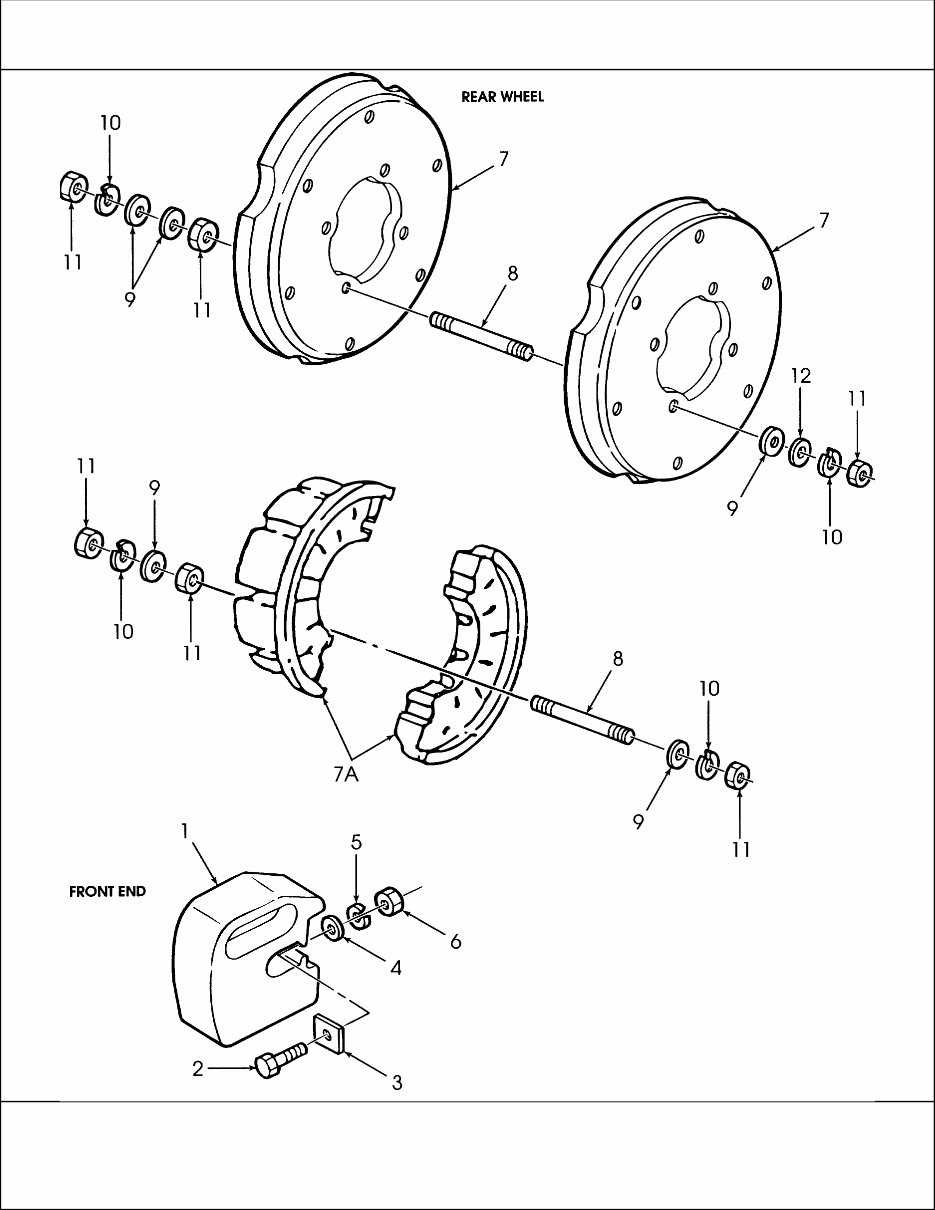

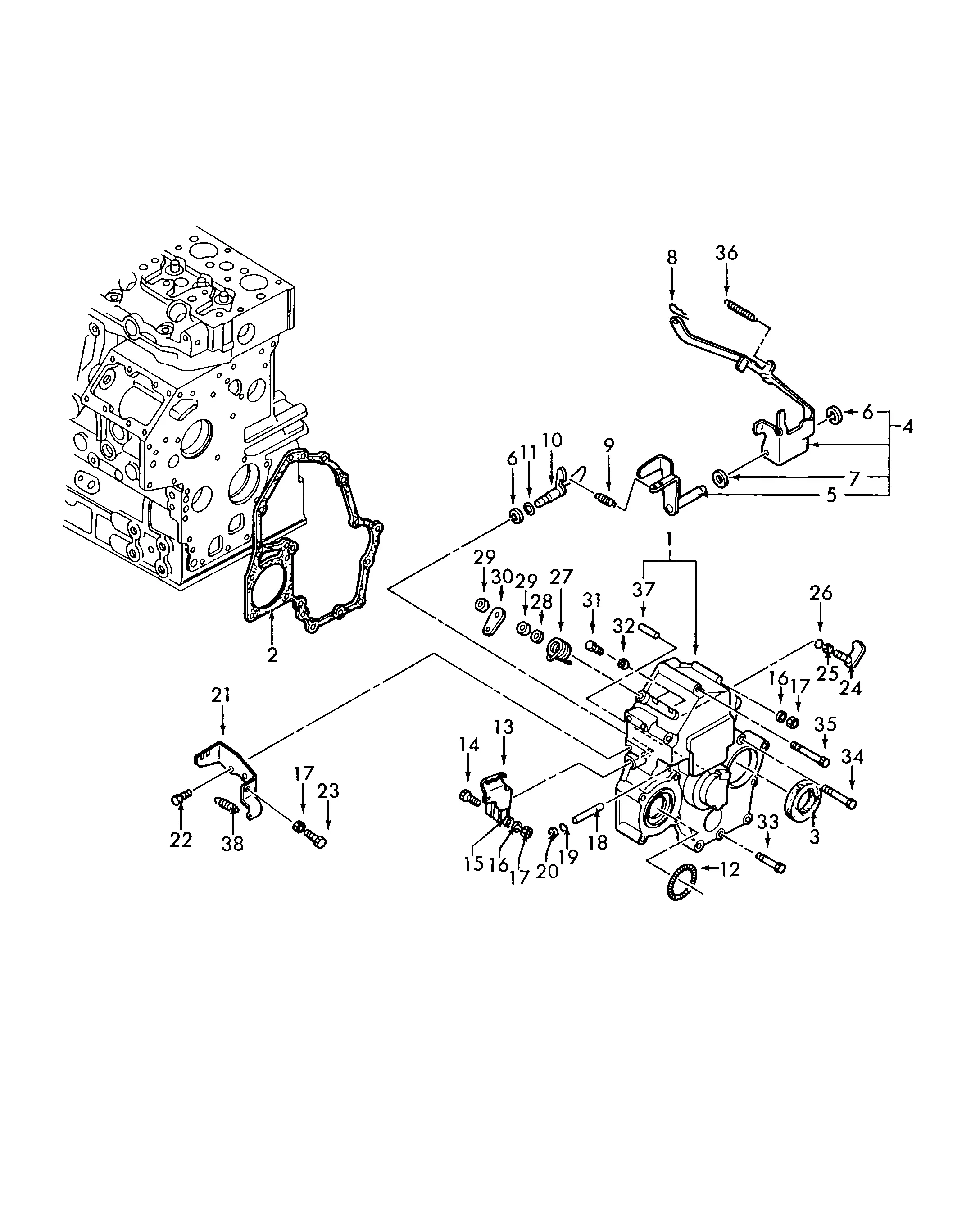

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repair tasks. These illustrations serve as valuable resources, allowing users to identify various elements and their relationships within a complex system.

Key Components of the Illustration

- Labels: Each part is typically labeled with a reference number or name, which corresponds to a list or legend.

- Connections: Arrows or lines may indicate how different components interact or connect with one another.

- Views: The image may show different angles, providing a comprehensive understanding of how parts fit together.

Steps to Effectively Interpret the Illustration

- Start by reviewing the legend to understand the meaning of each label.

- Identify key components that are critical for your task.

- Examine the connections to see how components work together.

- Take notes or highlight crucial parts for quick reference during repairs.

Common Repairs for Ford 1920

Maintenance and repairs are essential for ensuring the longevity and efficiency of your equipment. Regular inspections can help identify common issues that may arise, allowing for timely interventions and minimizing downtime. This section highlights frequent repairs that owners often encounter, providing insight into typical problems and their solutions.

-

Engine Issues:

- Overheating due to coolant leaks

- Hard starting caused by fuel delivery problems

- Excessive smoke indicating worn piston rings

-

Transmission Problems:

- Difficulty shifting gears often related to low fluid levels

- Unusual noises indicating worn bearings

- Slipping gears requiring adjustment or replacement

-

Electrical Failures:

- Dead battery or charging system issues

- Faulty wiring causing intermittent power loss

- Malfunctioning starter motor preventing ignition

-

Hydraulic System Repairs:

- Leaking hoses leading to pressure loss

- Slow or unresponsive hydraulic controls

- Contaminated fluid requiring complete system flush

Addressing these common repairs promptly can enhance performance and extend the life of your equipment. Regular maintenance checks and understanding these issues can prevent larger problems in the future.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your machinery requires consistent care and attention. Regular maintenance not only prevents unexpected breakdowns but also enhances performance and efficiency. Below are key practices to follow for optimal upkeep.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Check Fluid Levels | Weekly | Monitor oil, coolant, and fuel levels to ensure proper functioning. |

| Inspect Belts and Hoses | Monthly | Look for signs of wear or damage and replace as needed. |

| Clean Air Filters | Every 100 hours | Keep filters clean to promote efficient air intake and engine performance. |

| Tighten Fasteners | Quarterly | Check and tighten bolts and screws to prevent loose components. |

| Inspect Tires | Monthly | Ensure proper tire pressure and tread condition for safe operation. |

Implementing these practices will help maintain efficiency and reliability over time. Always consult the manufacturer’s guidelines for specific recommendations tailored to your equipment.

Where to Buy Quality Parts

When seeking high-quality components for agricultural machinery, it’s essential to explore reliable sources that ensure durability and performance. Various avenues exist, ranging from specialized retailers to online platforms, each offering unique advantages.

Consider the following options to find premium components:

| Source Type | Advantages | Considerations |

|---|---|---|

| Authorized Dealers | Genuine products, expert advice | Higher prices, limited selection |

| Online Marketplaces | Wide variety, competitive pricing | Quality varies, check reviews |

| Local Salvage Yards | Affordable options, hard-to-find items | Used condition, potential wear |

| Specialized Retailers | Expert knowledge, tailored services | May be pricier, limited stock |

Exploring these options can help you make informed choices and ensure your machinery operates at its best.

Aftermarket vs. Original Parts

When it comes to maintaining machinery, the choice between factory components and third-party alternatives is crucial. Each option offers distinct advantages and considerations that can significantly impact performance and longevity. Understanding these differences helps in making informed decisions for optimal functionality.

Original components are designed specifically for the equipment, ensuring perfect compatibility and adherence to manufacturer standards. These items typically provide enhanced reliability and may come with warranties that offer peace of mind. However, they can often be more expensive, reflecting their premium quality and brand assurance.

On the other hand, aftermarket alternatives frequently present a cost-effective solution, appealing to those seeking to minimize expenses. These products may vary widely in quality; while some can match or even exceed the performance of original items, others might fall short. It’s essential to conduct thorough research and select reputable suppliers to ensure satisfactory results.

Ultimately, the choice between original and aftermarket components depends on specific needs, budget constraints, and desired outcomes. Weighing the benefits of each can lead to a more tailored approach in maintaining machinery efficiently.

Tractor Parts Maintenance Checklist

Regular upkeep of machinery components is essential for ensuring optimal performance and longevity. A comprehensive checklist can help operators systematically inspect and maintain various elements, preventing costly repairs and downtime. This guide outlines critical areas to focus on during routine evaluations.

Essential Components Inspection

Begin by examining the engine assembly for any signs of wear or leaks. Check fluid levels, ensuring that oil and coolant are at appropriate levels. Next, inspect the transmission system; look for smooth shifting and any unusual noises that may indicate internal issues. Pay attention to the electrical system as well, testing the battery and wiring for integrity.

Wear and Tear Assessment

Inspect belts and hoses for fraying or cracking, as these can lead to significant operational failures. Evaluate the undercarriage components, including tires and tracks, checking for proper inflation and tread wear. Finally, review the hydraulic systems for leaks and functionality, ensuring that all connections are secure and that fluids are clean and at the right levels.

Resources for Ford Tractor Owners

Maintaining and optimizing your machinery requires access to reliable information and quality materials. This section provides valuable resources that can assist owners in ensuring their equipment runs smoothly and efficiently.

- Online Forums: Engage with fellow enthusiasts and professionals to share tips, ask questions, and find solutions. Popular platforms include:

- TractorByNet

- Reddit’s r/Tractors

- YesterdaysTractors

lessCopy code

- Service manuals available through online retailers

- Digital downloads from manufacturer websites

- Library resources or archives

- Local dealerships

- Specialty shops that focus on vintage machinery

- Online marketplaces like eBay and Amazon

- Regional clubs

- State associations

- Meetup groups for enthusiasts

Utilizing these resources can significantly enhance the experience of ownership and ensure that your machinery remains in peak condition for years to come.